Preparation method of SAPO-34 molecular sieve

A technology of SAPO-34 and molecular sieve, which is applied in the field of preparation of SAPO-34 molecular sieve, can solve the problems of low single-pot yield and poor repeatability, and achieve the effect of shortening the induction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

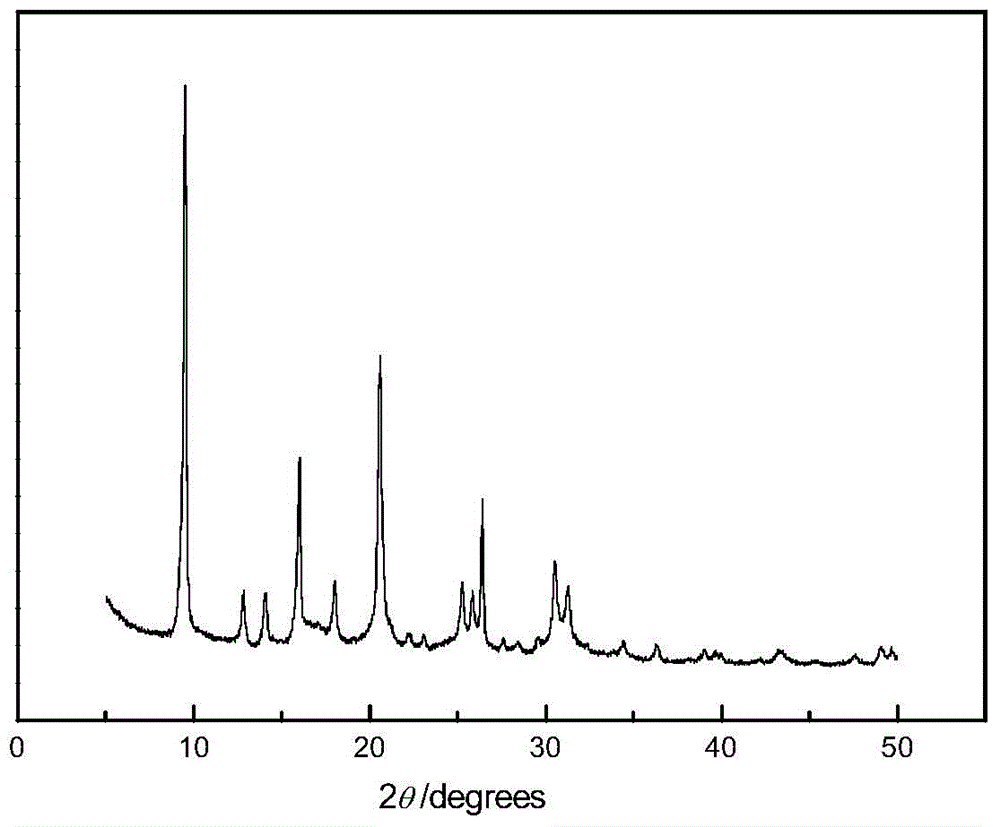

[0020] The preparation method of SAPO-34 molecular sieve provided by the invention is characterized in that comprising the steps:

[0021] (1) The phosphorus source and the aluminum source are adjusted according to (0.6~1.2)P 2 o 5 :Al 2 o 3 :(20~60)H 2 The molar ratio of O is mixed evenly, and dried to obtain phosphor-aluminum dry glue A with a solid content of not less than 60%;

[0022] (2) Contact and mix the aluminum phosphate dry glue A with the template agent and the silicon source to obtain the mixture B, in which, 1 mole of Al in the aluminum phosphate dry glue A 2 o 3 Calculated, the added amount of the template agent is (1-2.5) moles, and the added amount of the silicon source is expressed as SiO 2 Calculated as 0.1 to 1 mole;

[0023] (3) Put the mixture B in a closed reaction kettle to crystallize under autogenous pressure and recover the product, wherein, the crystallization is carried out in three stages in sequence from low to high temperature range, and...

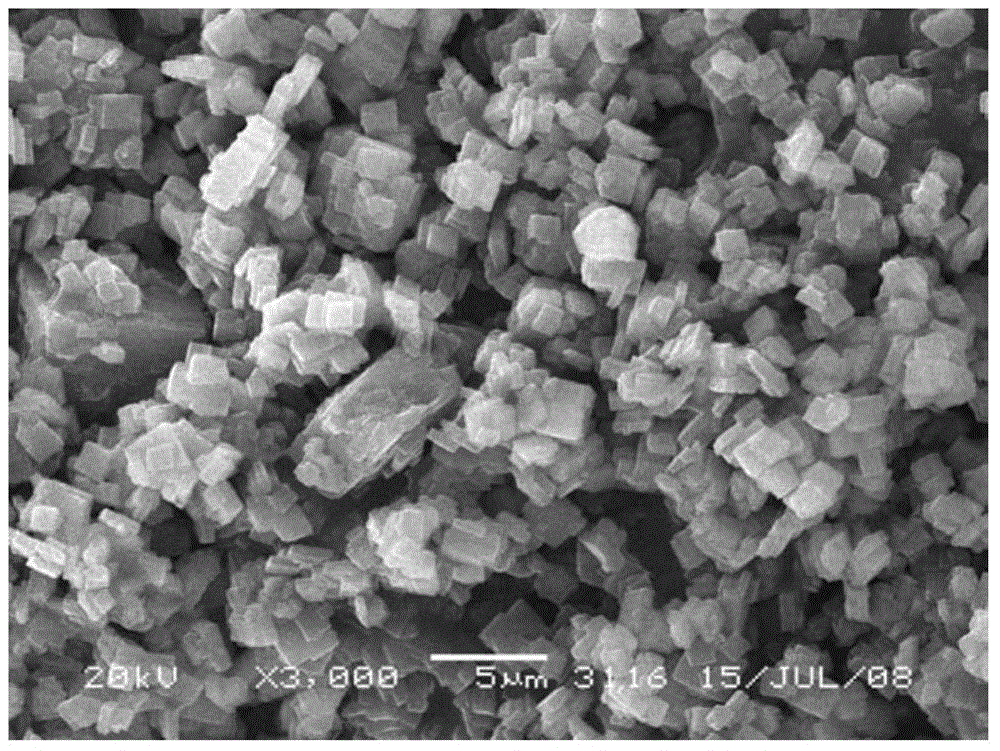

Embodiment 1

[0046] Weigh 7g of dry rubber powder and dissolve it in 10g of deionized water, stir evenly, mix with the solution obtained by adding 11g of 85% analytical pure orthophosphoric acid into 10g of deionized water and stir evenly, and dry at 80°C to obtain phosphate aluminum with 85% solid content glue.

[0047] Move the phosphoraluminum glue to a 100ml crystallization kettle, add 30g tetraethylammonium hydroxide, 5.2g triethylamine, 3g acidic silica sol with a mass fraction of 30% and 17g water, stir evenly, seal the reaction kettle, and crystallize The conditions are divided into steps of aging at room temperature for 10 hours, crystallization at 150°C for 10 hours, and crystallization at 200°C for 40 hours. After the temperature of the kettle drops to room temperature, take out the crystallized product, filter or centrifuge, wash with deionized water until neutral, and place it at 100-110 ℃ in a constant temperature drying oven, and finally placed in a muffle furnace and heated...

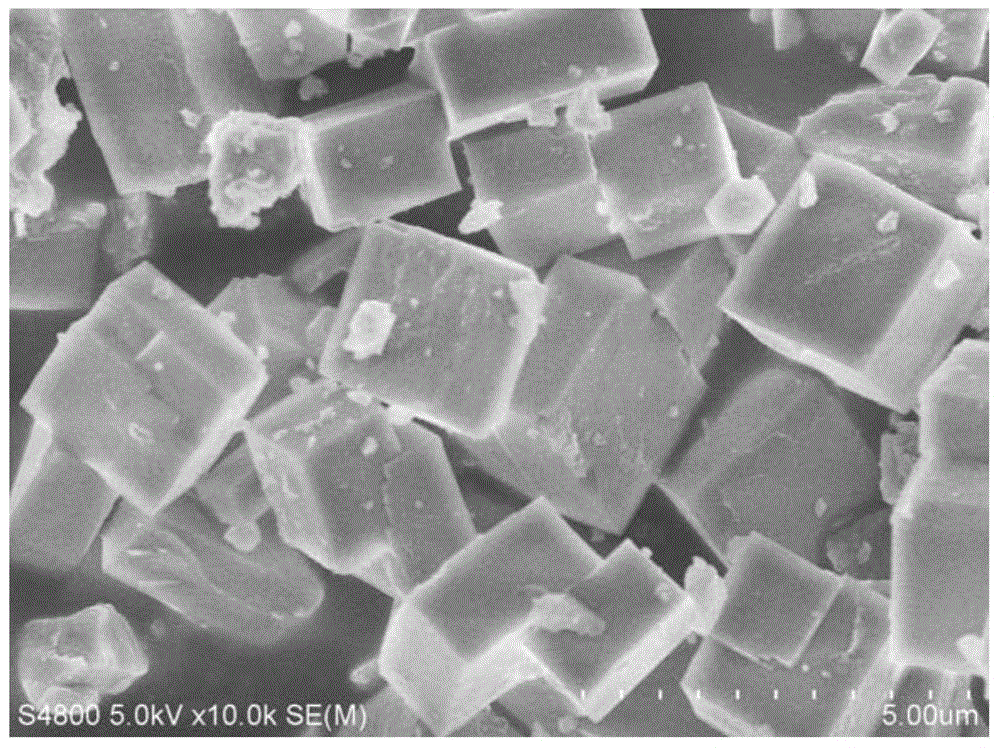

Embodiment 2

[0050] Weigh 7g of SB powder and dissolve it in 25g of deionized water, stir rapidly for 1 hour, mix with the solution obtained by adding 9.2g of 85% analytical pure orthophosphoric acid into 30g of deionized water and stir evenly, dry in a constant temperature dryer at 120°C to obtain a solid content of 85% Phosphor aluminum glue.

[0051] Move the phosphoraluminum glue to a 100ml crystallization kettle, add 30g tetraethylammonium hydroxide and 3g acidic silica sol with a mass fraction of 30%, stir evenly, seal the reaction kettle, and crystallize according to room temperature aging for 10h, 140°C Crystallization for 10h and 170°C crystallization for 70h in stages. After the kettle temperature drops to room temperature, take out the crystallized product, filter or centrifuge and wash it with deionized water until it becomes neutral. The product is dried in a constant temperature drying oven at 100-110°C, and finally put into a muffle furnace and heated to 550°C for constant t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com