Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

179results about How to "Generate uniform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

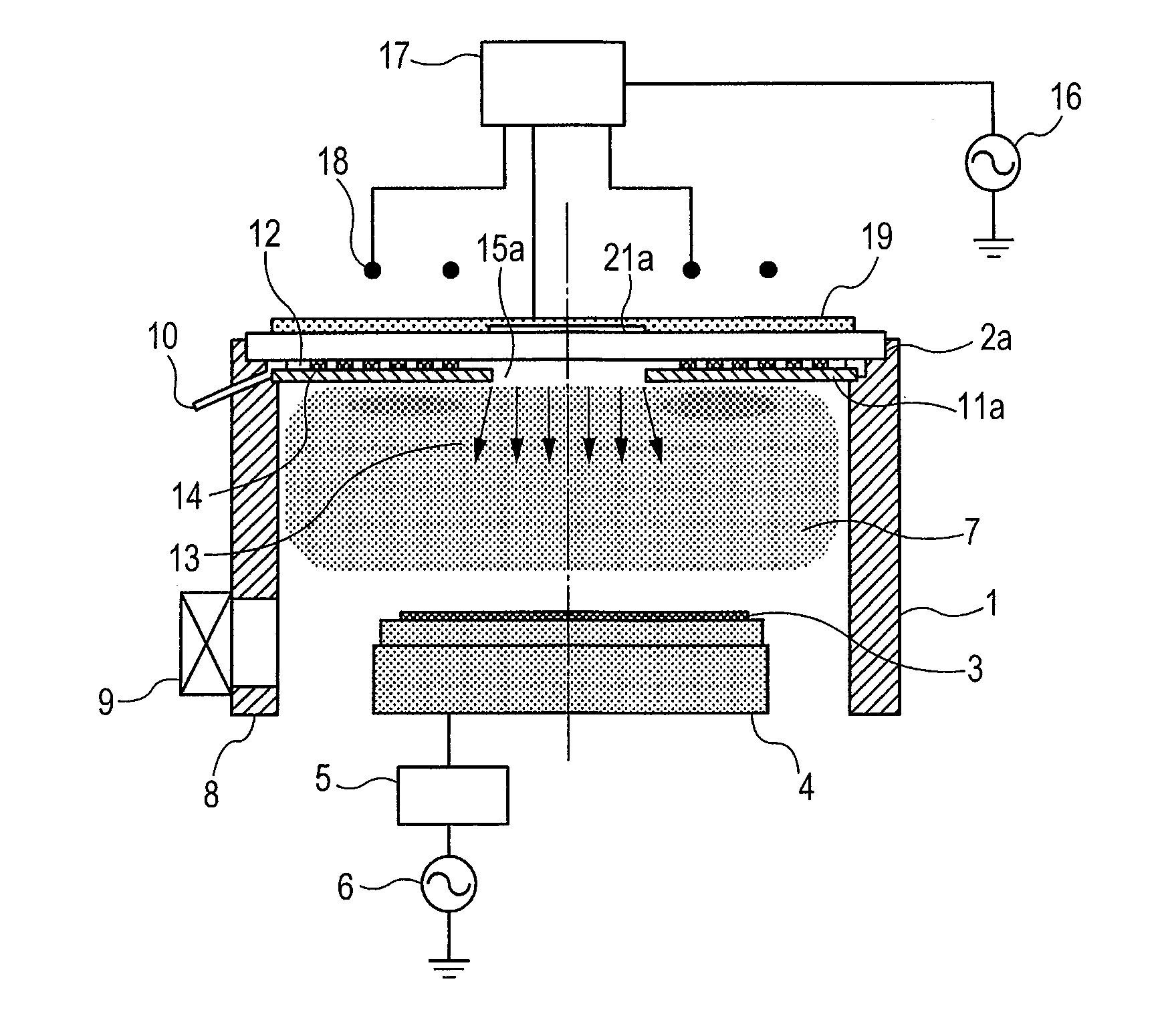

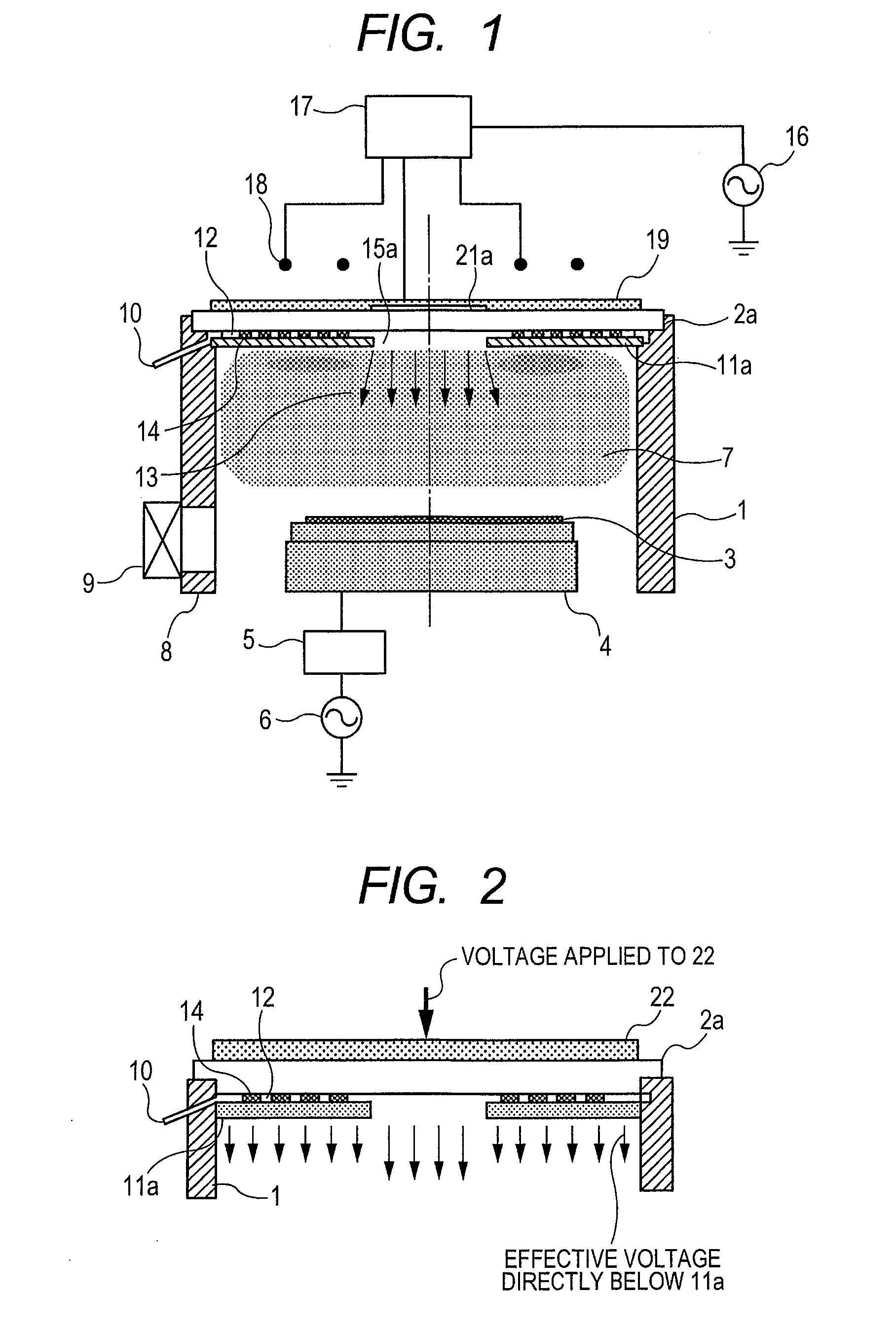

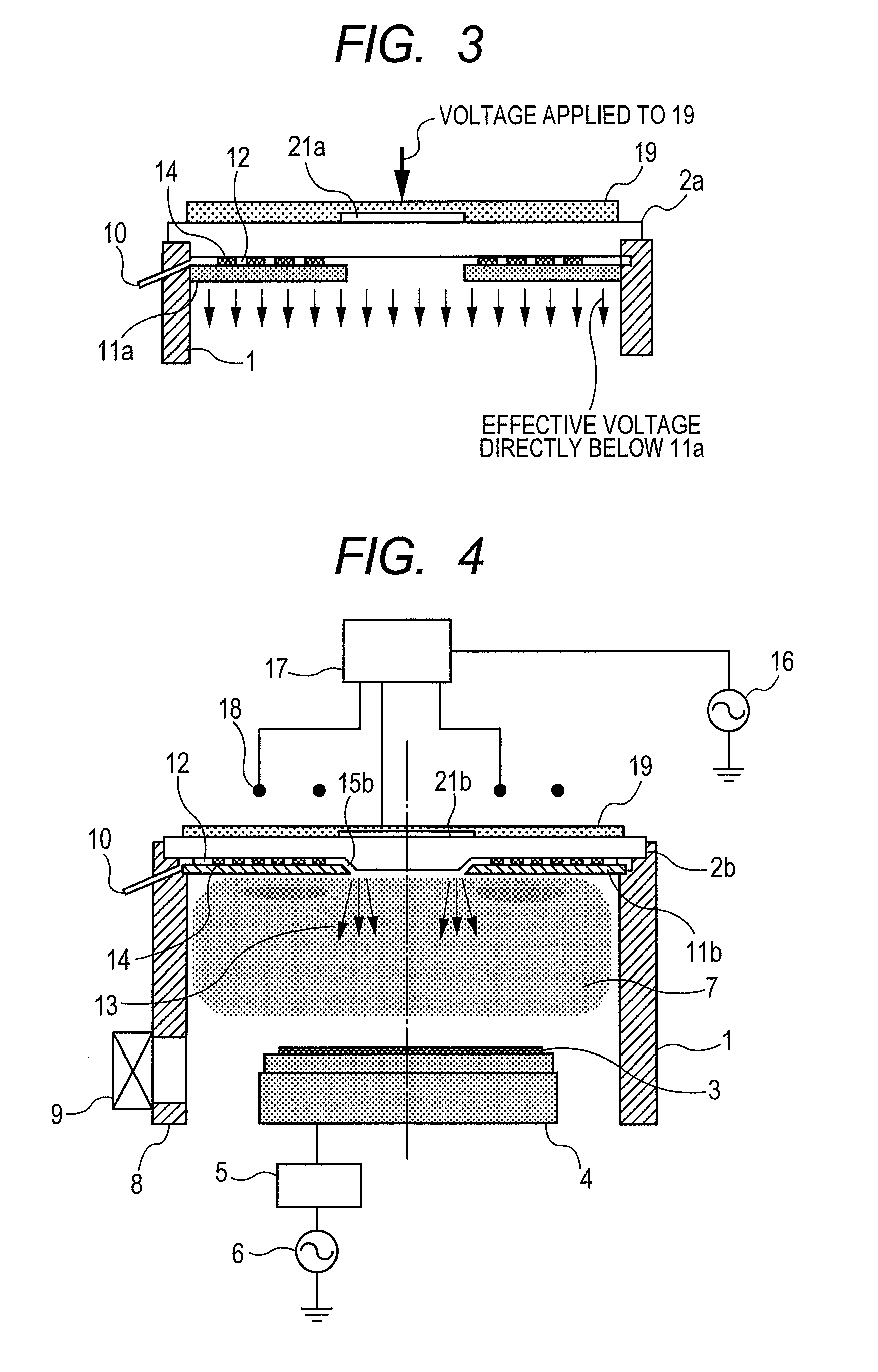

Plasma processing apparatus and method

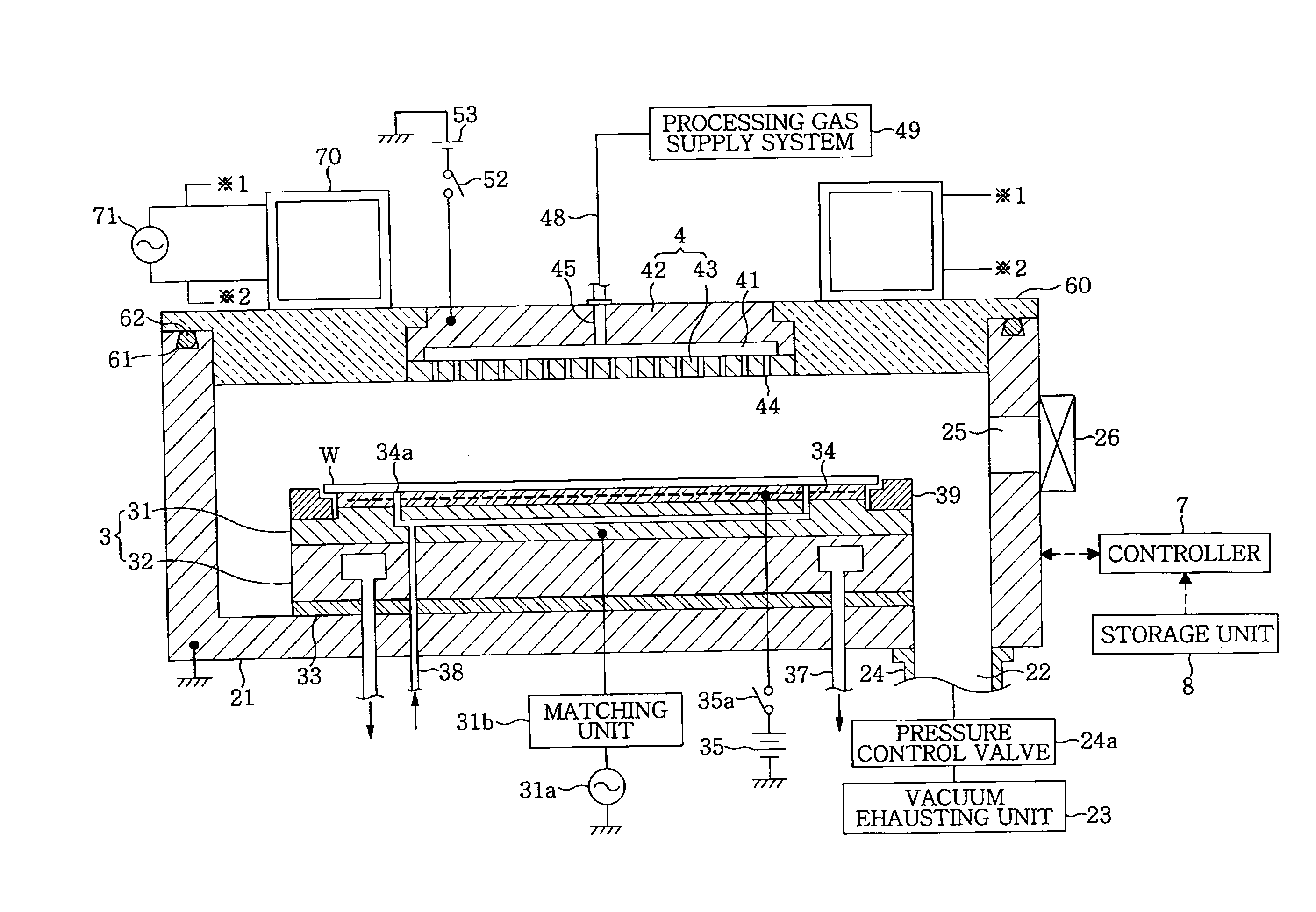

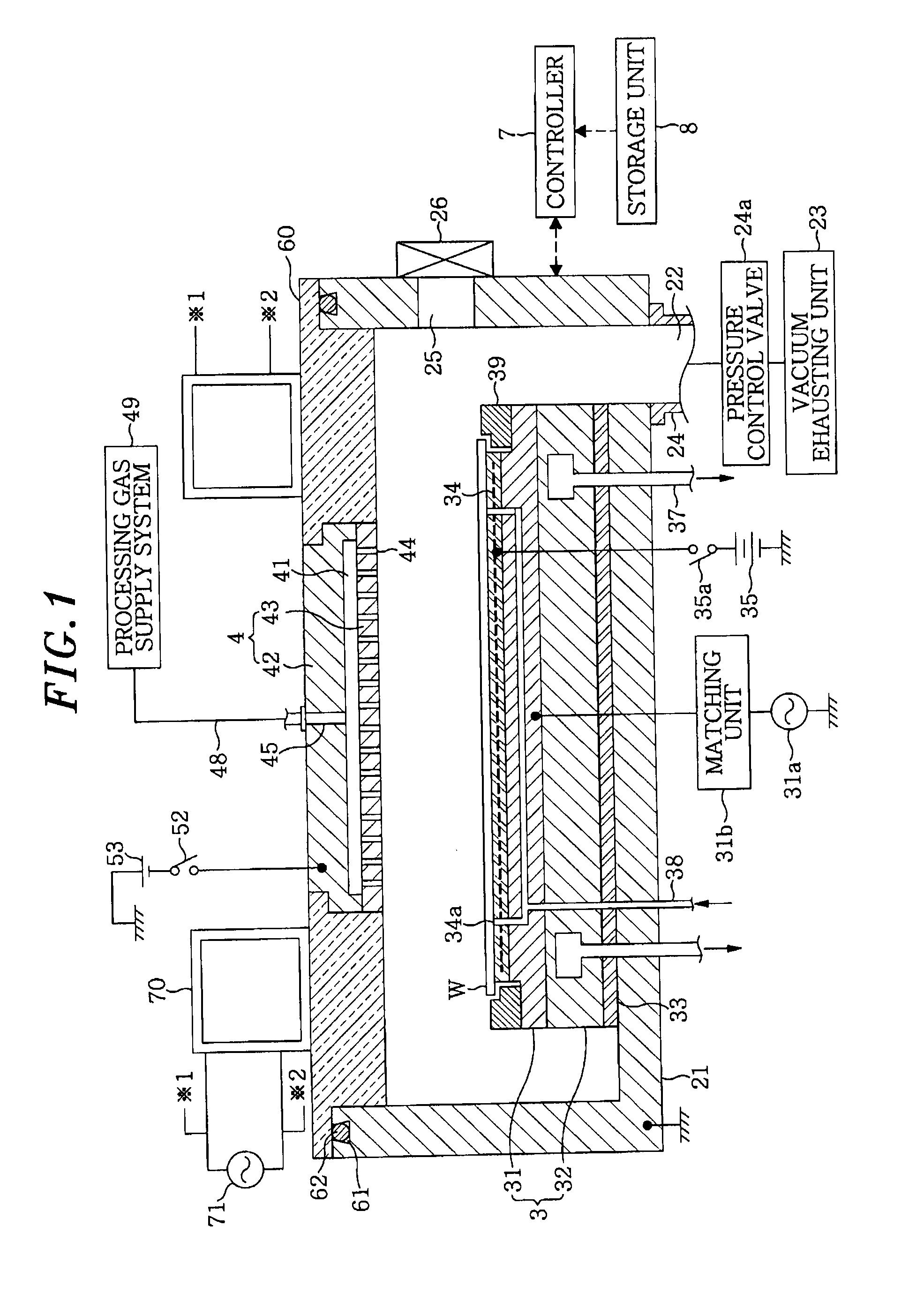

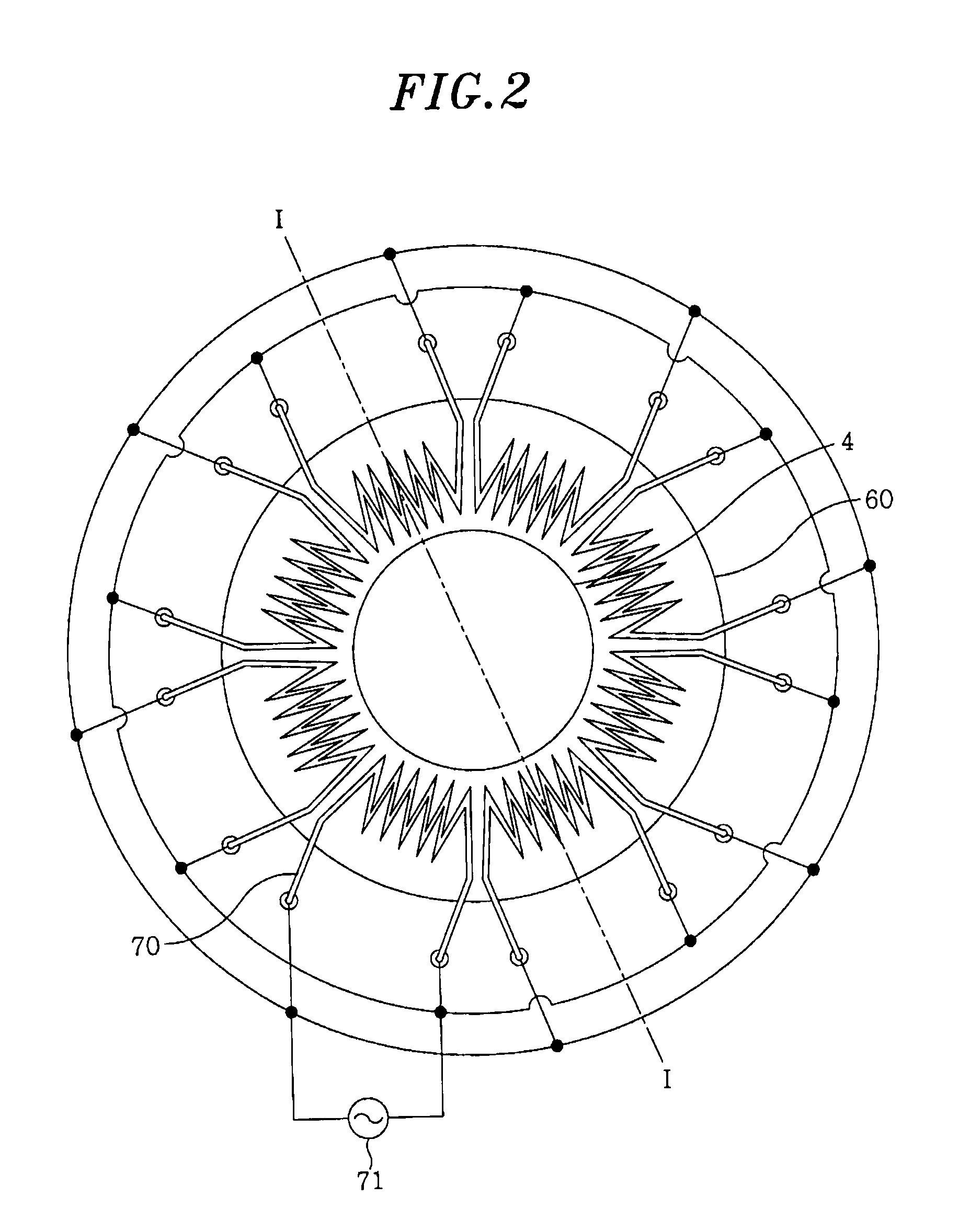

ActiveUS20110174778A1High in-plane uniformityImprove uniformityLiquid surface applicatorsElectric discharge tubesPower flowConductive materials

A plasma processing apparatus performs a process on a substrate by using plasma. The plasma processing apparatus includes a processing chamber; a mounting table which is located in the processing chamber and on which a substrate is mounted; a gas shower head formed of a conductive material provided to face the mounting table and having at the bottom surface thereof a plurality of gas injection openings for supplying a processing gas into the processing chamber; an induction coil to which a high frequency current is supplied to generate an inductively coupled plasma in a region surrounding a space below the gas shower head; a negative voltage supplying unit for applying a negative DC voltage to the gas shower head to allow an electrical field, which is induced by the induction coil, to be drawn to a central portion of the processing region; and a unit for evacuating the processing chamber.

Owner:TOKYO ELECTRON LTD

Battery charging apparatus with planar inductive charging platform

ActiveUS8040103B2Generating magnetic flux substantially uniformlyGenerate uniformBatteries circuit arrangementsTransformersBattery chargeElectrical battery

A battery charging apparatus comprises an inductive charging platform including a charging surface on which an electrical device to be charged is to be placed, and a first winding for generating lines of magnetic flux generally perpendicular to the charging surface. To compensate for voltage sag caused by a reduction in the flux generated by the first winding, a second winding is located within an area defined by the first winding for generating an auxiliary magnetic flux generally perpendicular to the charging surface.

Owner:CITY UNIVERSITY OF HONG KONG

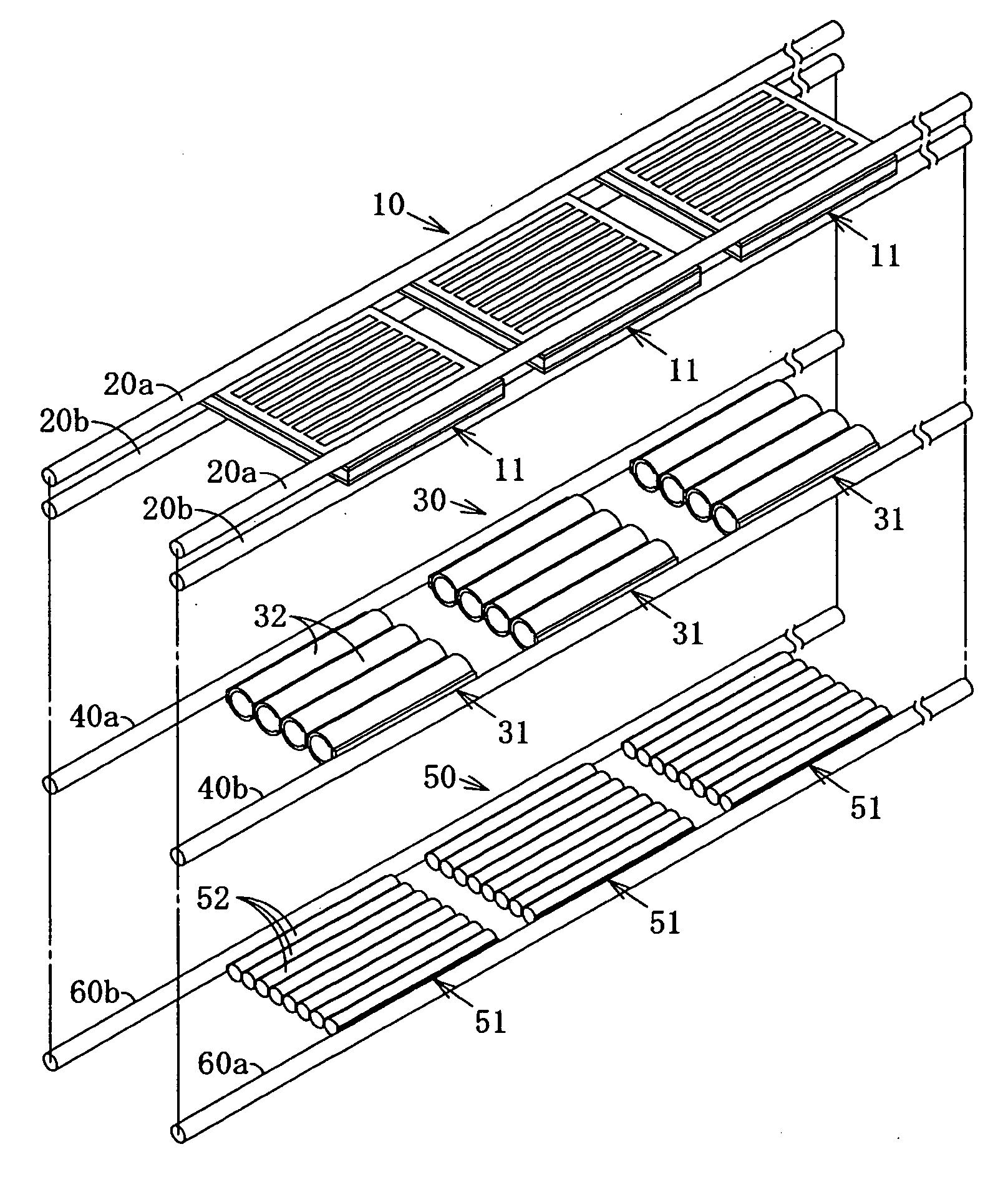

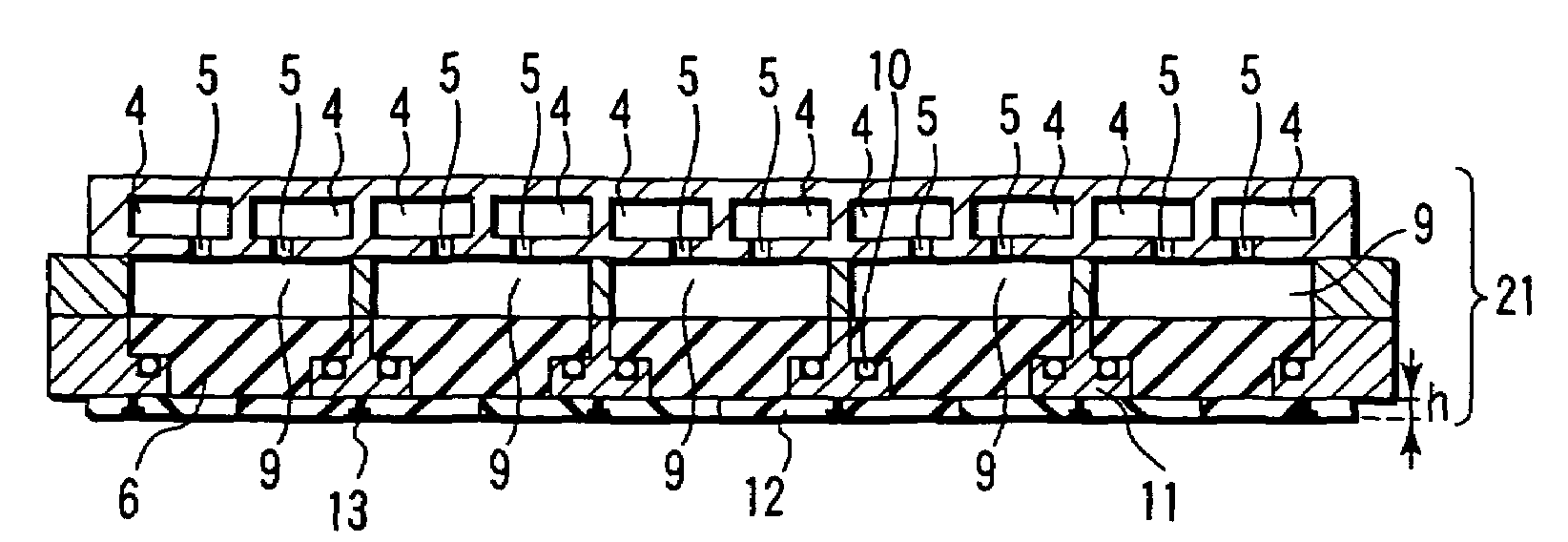

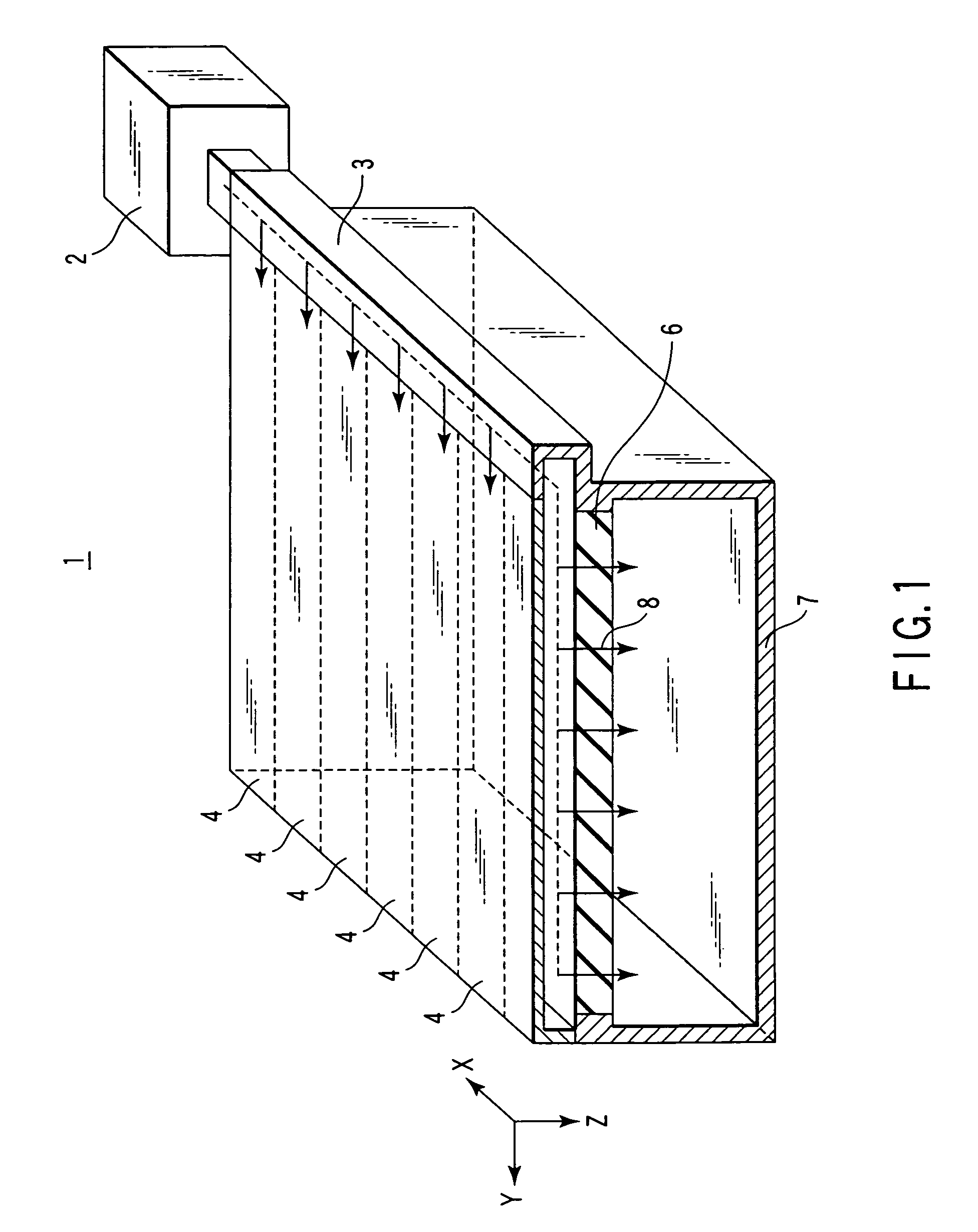

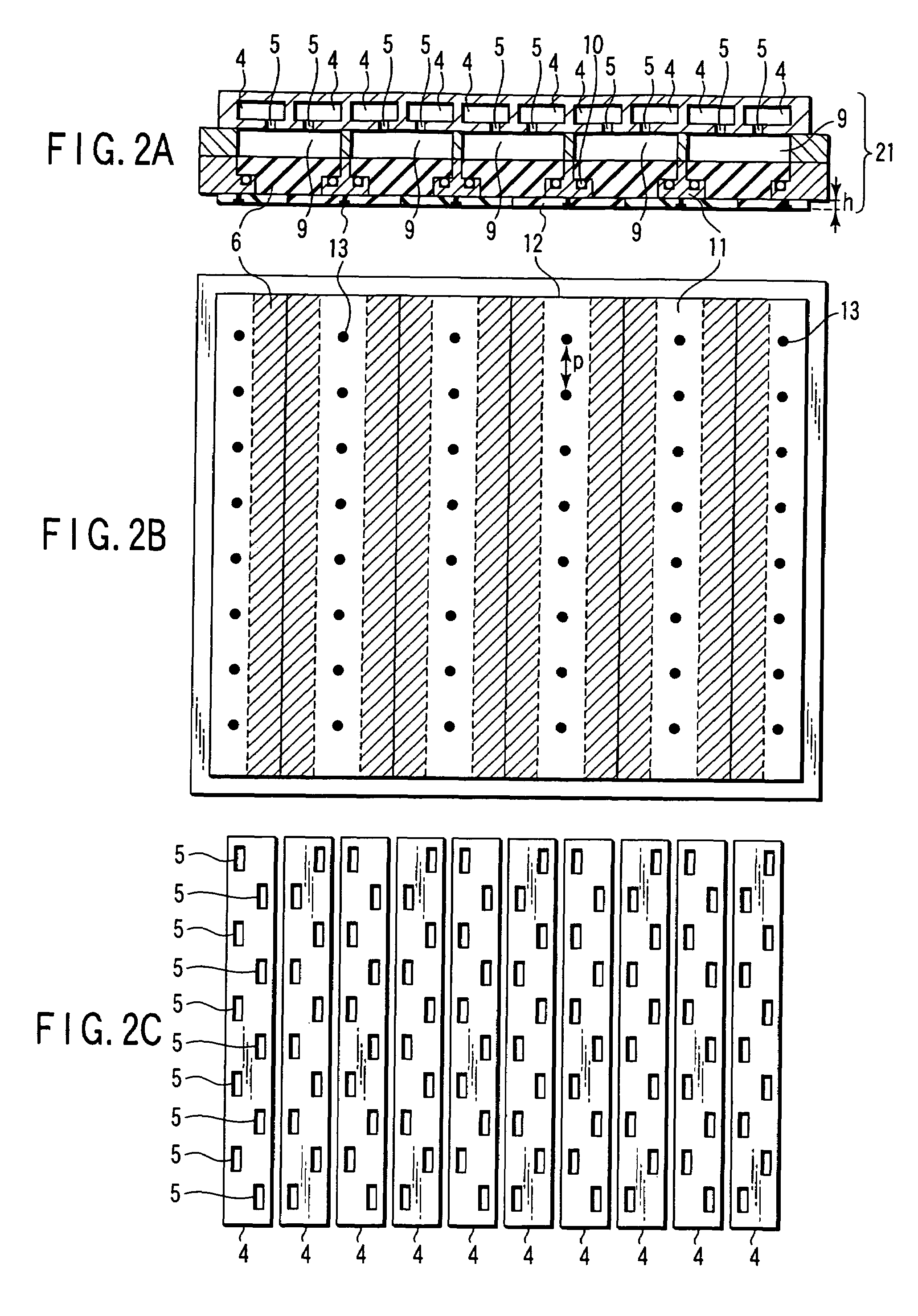

Stacked solar cell device

InactiveUS20100018568A1Improve photoelectric conversion efficiencyGenerate uniformPhotovoltaic supportsPV power plantsEngineeringSolar cell

This stacked solar battery device includes a plurality of solar battery units 4, an enclosure case made of a metal plate to house these solar battery units 4 therein, a cover glass having a partial cylindrical lens formed. The plurality of solar battery units 4 are housed in a plurality of recesses of the enclosure case, and are sealed with a sealing material of synthetic resin. The solar battery unit 4 has a planar light receiving solar battery module 10, and rod light receiving solar battery modules 30 and 50 stacked so that the module having a shorter center wavelength of the sensitivity wavelength band is positioned closer to the incident side of the sunlight. The solar battery module 10 is configured so that five planar light receiving solar-battery cells 11 are connected in parallel with four connection rods 20a and 20b, and the sunlight modules 30 and 50 are configured so that five sub modules 31 and 51 are connected in parallel respectively with the connection rods 40a, 40b, 60a and 60b. The sub modules 31 and 51 are configured so that a plurality of rod-shaped solar battery cells 32 and 52 respectively are connected in series.

Owner:SPHELAR POWER

Surface-finishing agent and finished material and method of surface finishing

InactiveUS20060266258A1Developing surfaceHigh water slipping propertyOther chemical processesFibre treatmentSoil propertiesSlurry

The present invention provides a surface-treating agent to form fine roughness on the surface of a material and more specifically a surface treating-agent which forms fine roughness on the surface of a material and is easy to process, thereby being useful for materials for highly water-repellent glass, lenses and fabric, materials with an excellent anti-soiling property, panels having an excellent light scattering property, illumination of optical fiber and the like, materials and coatings to prevent accumulation and adhesion of snow or icicle formation on antennas, wires and steel towers, and roughness formation on the surface of semiconductor substrates; the treated materials; and a method of surface treatment to develop the roughness. The surface-treating agent of the present invention has an average primary particle diameter in the range of 1-50 nm, contains fine particles in the range of 5-60% by mass of the total amount of the surface-treating agent in a slurry of nanoparticles which are treated for water repellency and mechanically dispersed in a solvent containing a volatile solvent, and forms a roughness structure with upward protrusions having a spatial periodicity of 0.1-50 μm on the surface of a material by volatilizing the solvent or dipping repeatedly in water upon treating the surface of the material.

Owner:KEIO UNIV

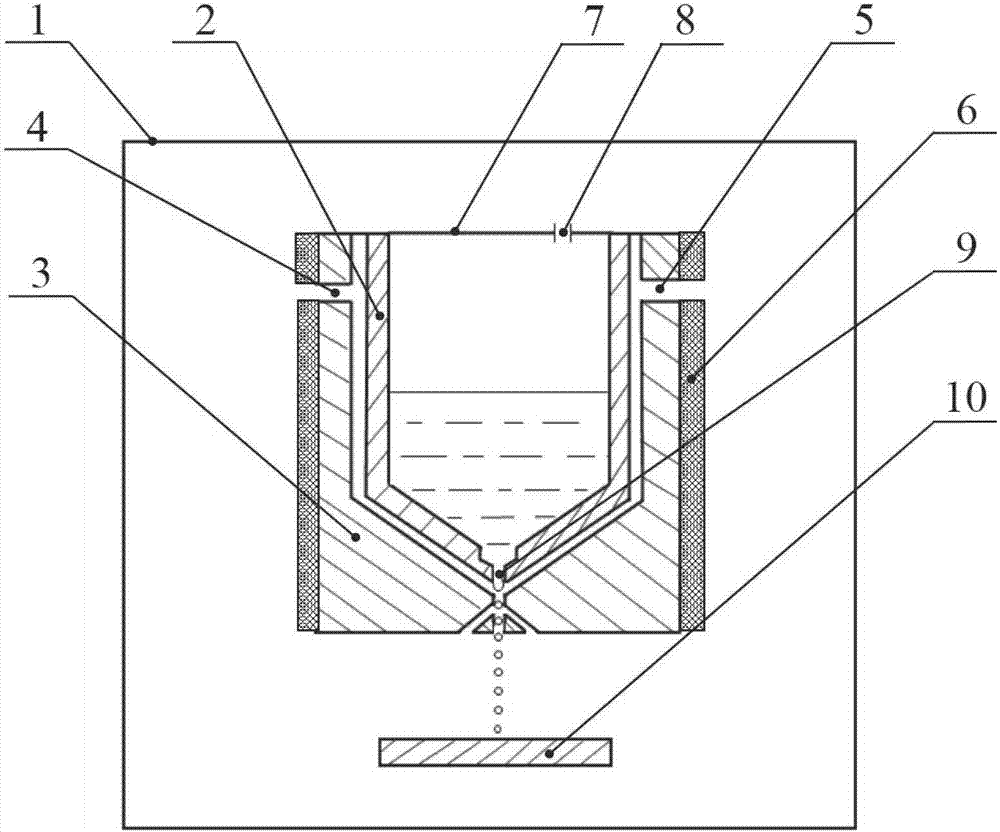

Plasma processing apparatus, method for producing reaction vessel for plasma generation, and plasma processing method

InactiveCN1700953AHigh degree of freedom designSimple designMolten spray coatingSemiconductor/solid-state device manufacturingComputer sciencePlasma processing

PROBLEM TO BE SOLVED: To provide a plasma processing apparatus capable of expanding a processing area and of carrying out uniform processing, and allowing design to be easily changed in response to an object of processing.

Owner:MATSUSHITA ELECTRIC WORKS LTD

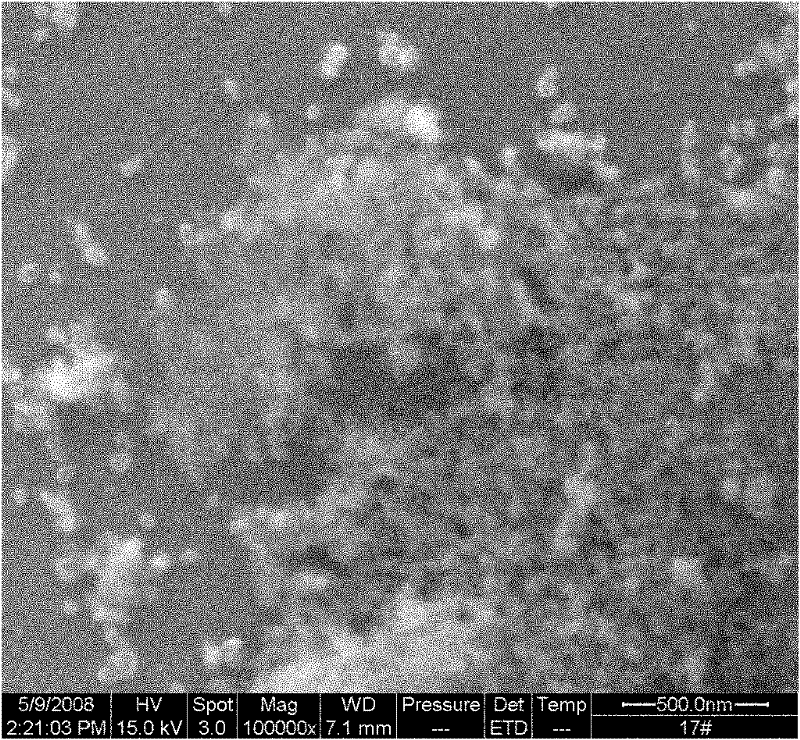

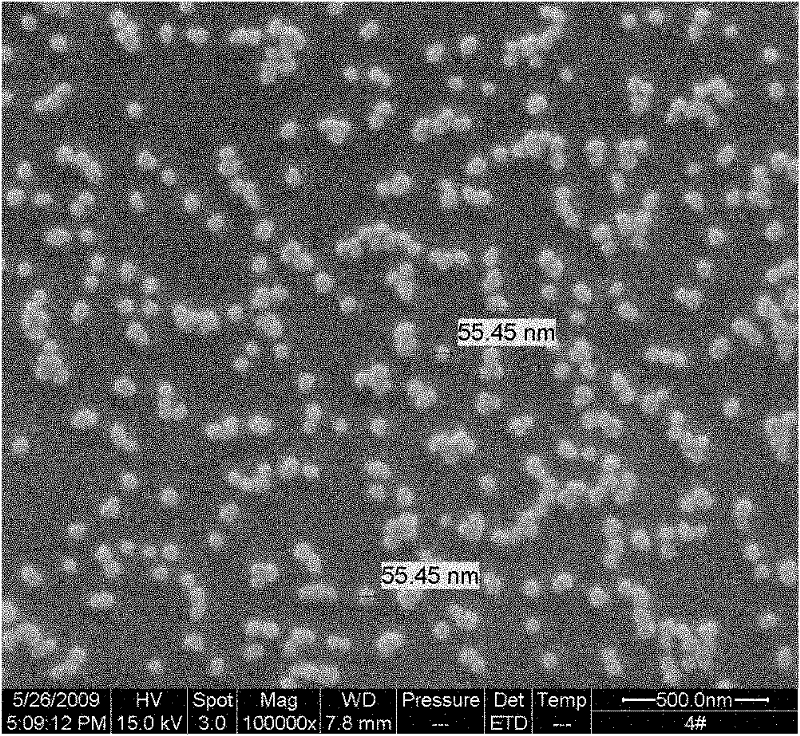

Preparation method for SiO2 sol with high evenness degree

The invention discloses a preparation method for the silica sol with a high evenness degree, belonging to the technical field of electronic manufacturing and SiO2 sol preparation. Under an ultrasonic influence, a silica sol seed solution is prepared and a reaction material is added to the silica sol solution in batches; aqueous solution and metallic silicon powder that serve as basic catalysts are chosen as the reaction material for each batch, and the basic catalyst in each batch is 2-40% of the basic catalyst previously added into the silica sol seed solution, and the metallic silicon powder in each batch is 2-40% of the metallic silicon powder previously added in the silica sol seed solution. After the reaction finishes, the unreacted metallic silicon powder is removed, and the SiO2 sol is produced. The ultrasonic sound adopted for the invention ranges from 20 to 50 kHz. By adopting the invention, production costs can be reduced and product purity is improved. In addition, the method disclosed by the invention has the advantages of safe technical process, simple equipment, and is easy to operate as well as is economic and has high efficiency.

Owner:TSINGHUA UNIV +2

Polysulfonamide nanofiltration or reverse-osmosis composite membrane, and preparation method thereof

InactiveCN107126850AHigh desalination rateImprove desalination propertiesMembranesGeneral water supply conservationSulfonyl chlorideReverse osmosis

The invention discloses a polysulfonamide nanofiltration or reverse-osmosis composite membrane, and a preparation method thereof. the preparation method for the polysulfonamide nanofiltration or reverse-osmosis composite membrane comprises the following steps: pretreatment of a porous supporting membrane; alternate layer-upon-layer assembling of a sulfonyl chloride organic-phase solution and a polyamine water-phase solution on the surface of the porous supporting membrane via reaction; heat treatment; etc.; wherein heat treatment can be carried out during or after layer-upon-layer assembling. Nanoparticles, a surfactant, a catalytic acid absorbent or catalyst, a pore forming agent and other additives are added into the sulfonyl chloride organic-phase solution and the polyamine water-phase solution. The polysulfonamide nanofiltration or reverse-osmosis composite membrane prepared by using the method has improved desalination performance and acid resistance, smoother surface and lower roughness compared with composite membranes prepared through traditional interfacial polymerization, and has good application prospects in the fields of nanofiltration and reverse osmosis.

Owner:青岛致用新材料科技有限公司

Electronic device, manufacturing method of electronic device, and sputtering target

InactiveUS20120049183A1Easy to evaporateHigh heating temperatureCellsSolid-state devicesProduction rateSputtering

A film formation is performed using a target in which a material which is volatilized more easily than gallium when heated at 400° C. to 700° C., such as zinc, is added to gallium oxide by a sputtering method with high mass-productivity which can be applied to a large-area substrate, such as a DC sputtering method or a pulsed DC sputtering method. This film is heated at 400° C. to 700° C., whereby the added material is segregated in the vicinity of a surface of the film. Another portion of the film has a decreased concentration of the added material and a sufficiently high insulating property; therefore, it can be used for a gate insulator of a semiconductor device, or the like.

Owner:SEMICON ENERGY LAB CO LTD

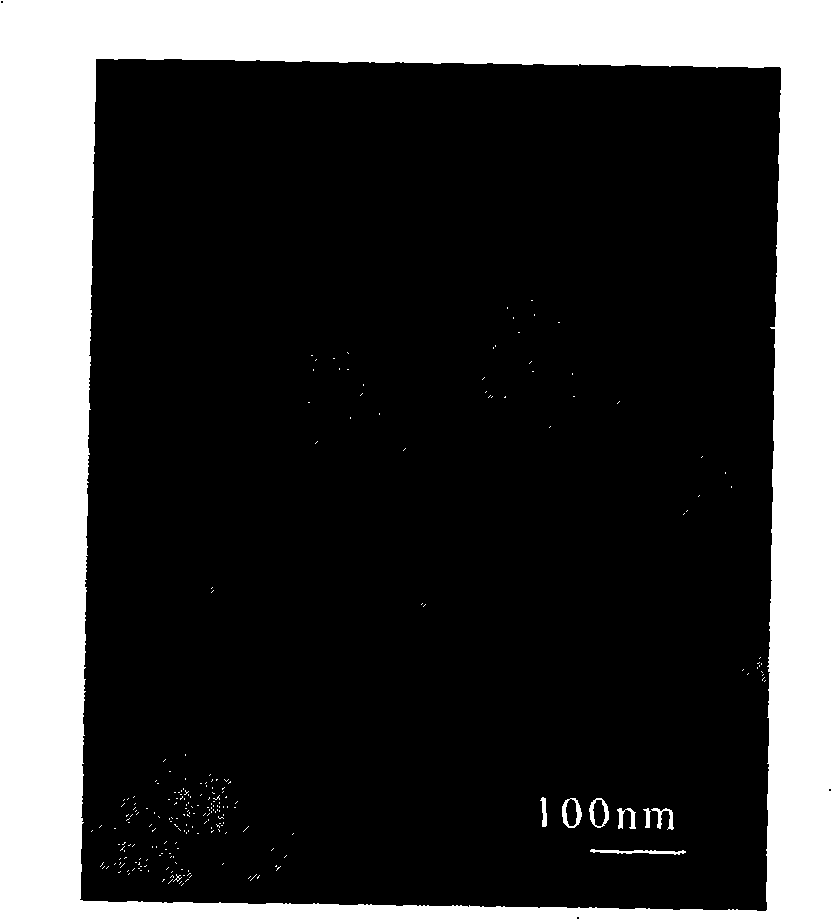

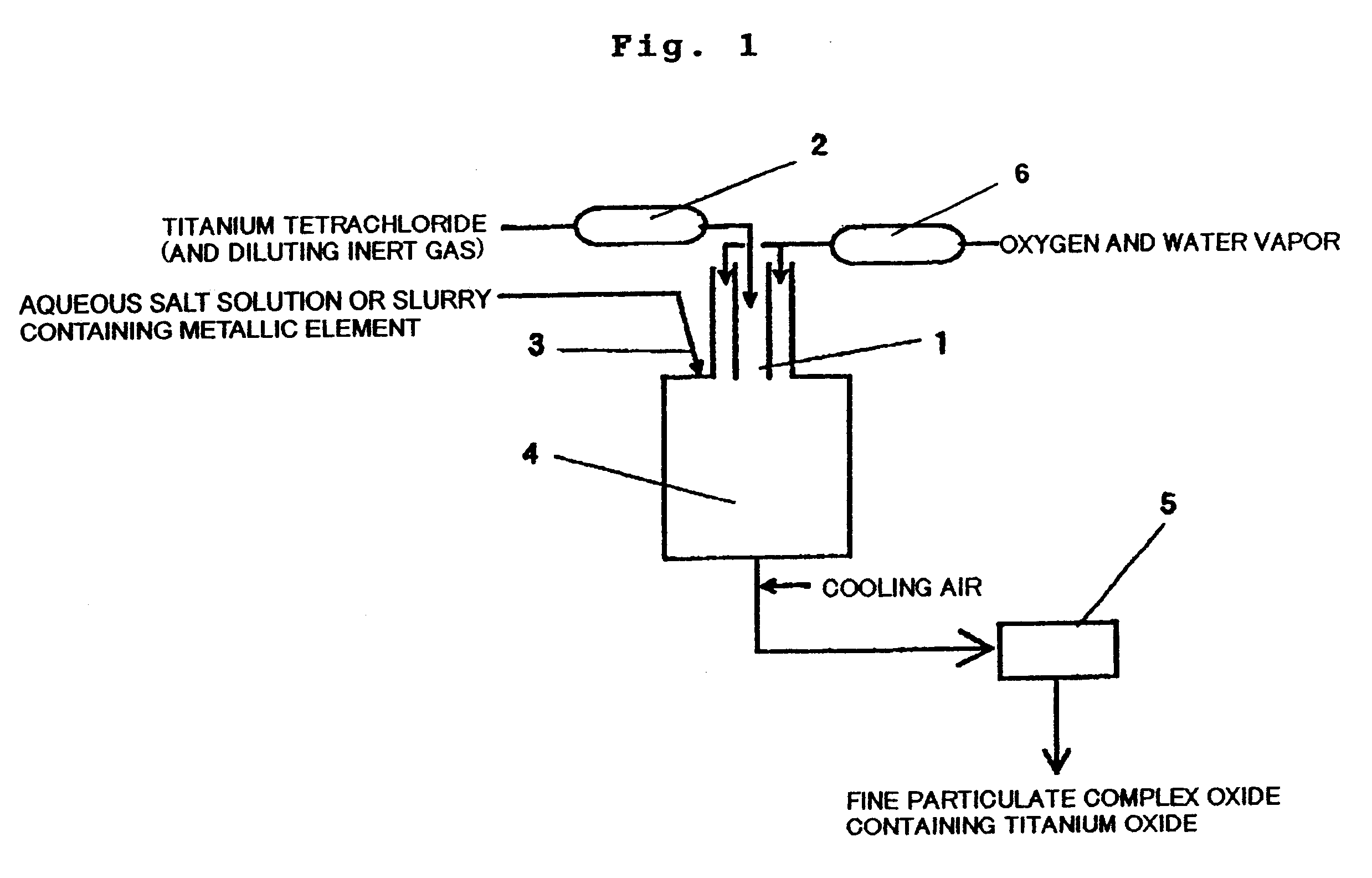

Production process for ultrafine particulate complex oxide containing titanium oxide

InactiveUS20010043904A1Suppress growth of oxideReduce timeMaterial nanotechnologyPigmenting treatmentTitanium tetrachlorideVapor phase

The present invention provides a process for producing ultrafine particulate complex oxide containing titanium oxide, including vapor-phase producing a complex oxide containing titanium oxide having a BET specific surface area of about 5 to about 200 m2 / g, where a starting material gas containing titanium tetrachloride and an oxidizing gas are preheated to about 700° C. or more, and are reacted with a solution or a slurry of a salt containing a metallic element The present invention also provides an ultrafine particulate complex oxide containing titanium oxide obtained by the process, and use of the oxide.

Owner:SHOWA DENKO KK

Multiple stage combustion process to maintain a controllable reformation temperature profile

InactiveUS20050048333A1Uniform exchangeGenerate uniformFuel cells groupingFuel cell auxillariesFuel cellsWorking fluid

A reaction vessel that integrates and balances an endothermic process with at least one exothermic process of the fuel cell system. Preferably the exothermic process is conducted in stages to provide more uniform and / or controllable heat generation and exchange, and to produce a uniform and / or controllable temperature profile in the endothermic reaction process. The invention allows for the elimination of the working fluid loop of prior art systems that had unsatisfactory response times at startup, and during transient conditions, and also added to the overall mass and volume of the fuel cell system.

Owner:GM GLOBAL TECH OPERATIONS LLC

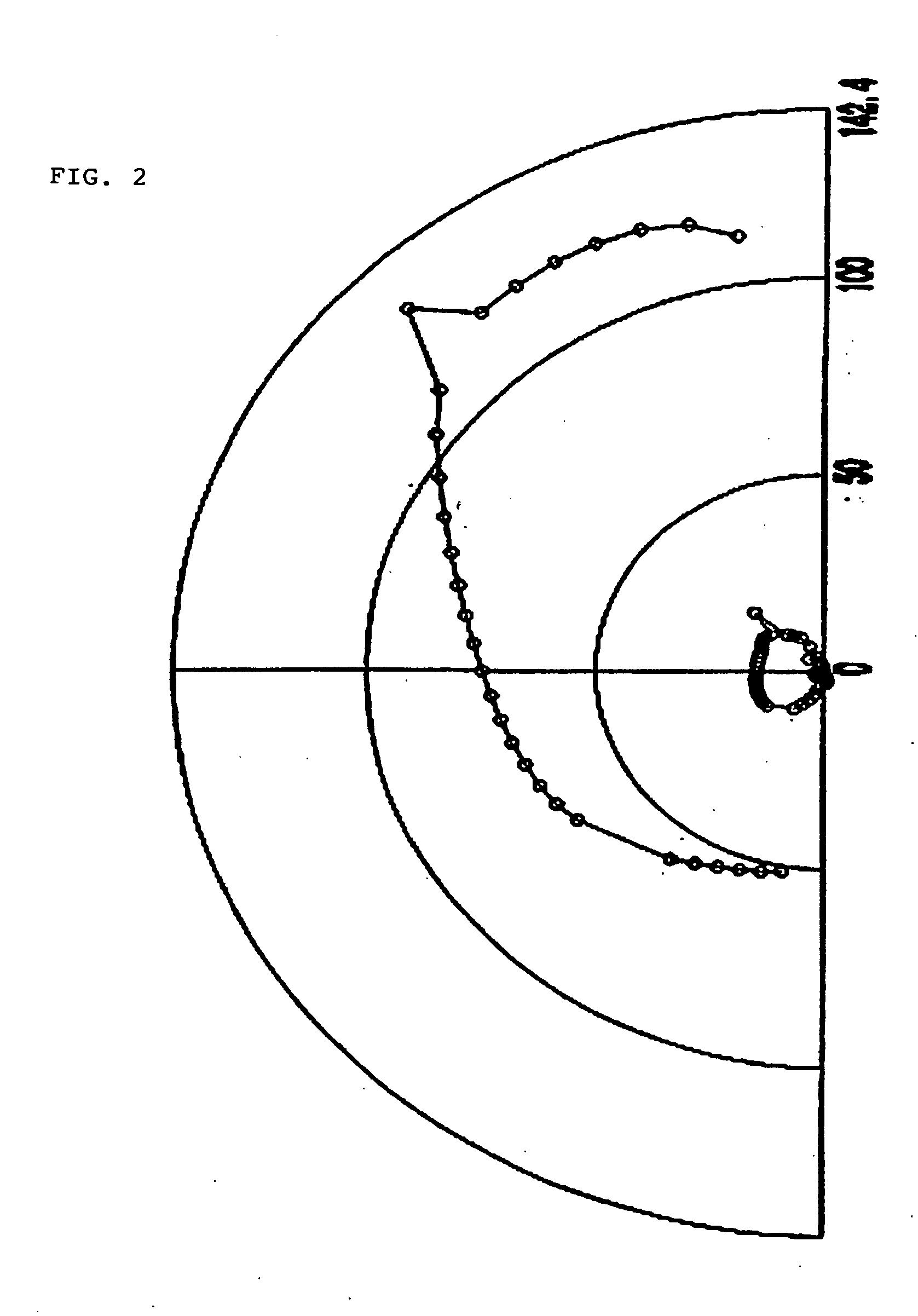

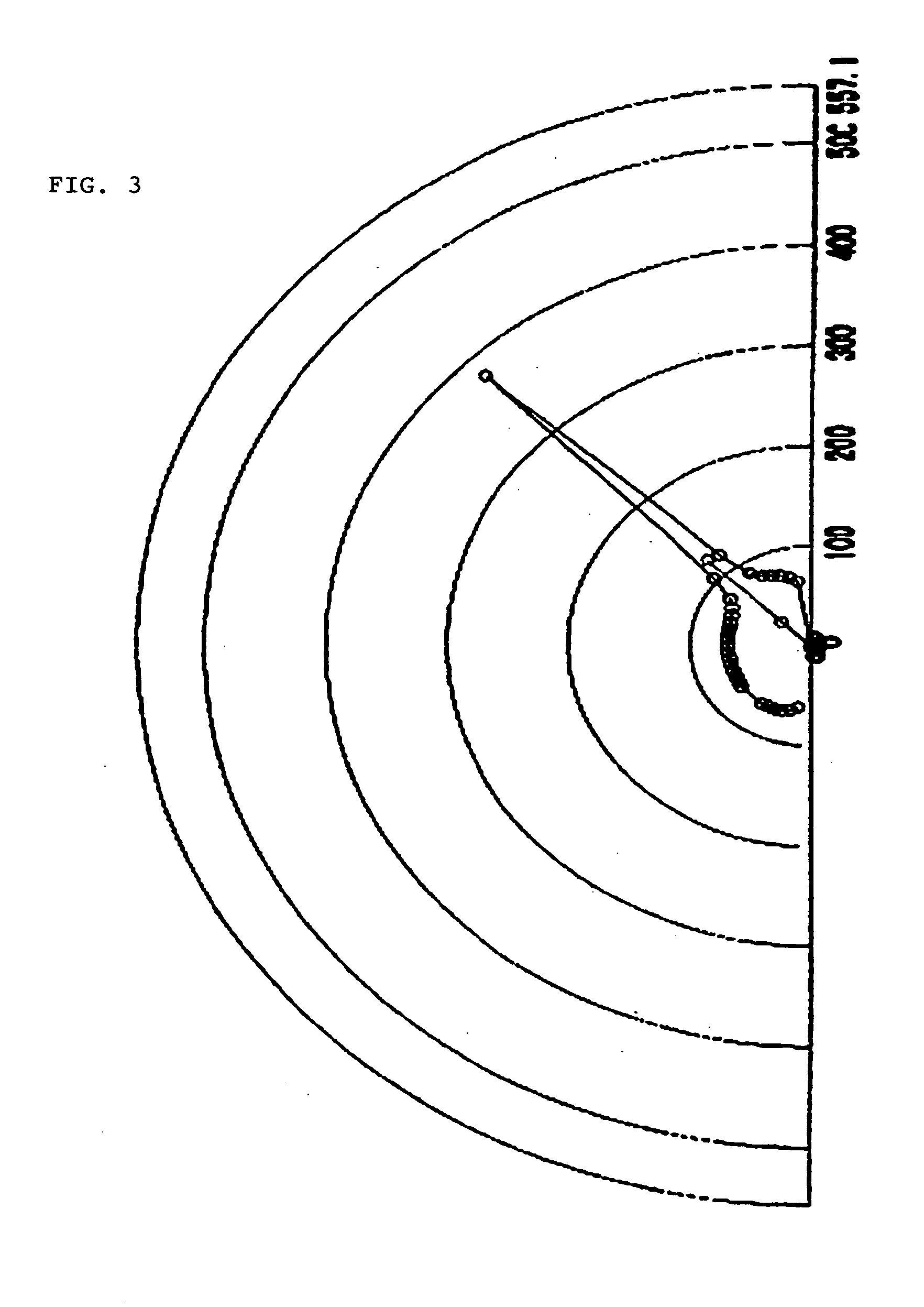

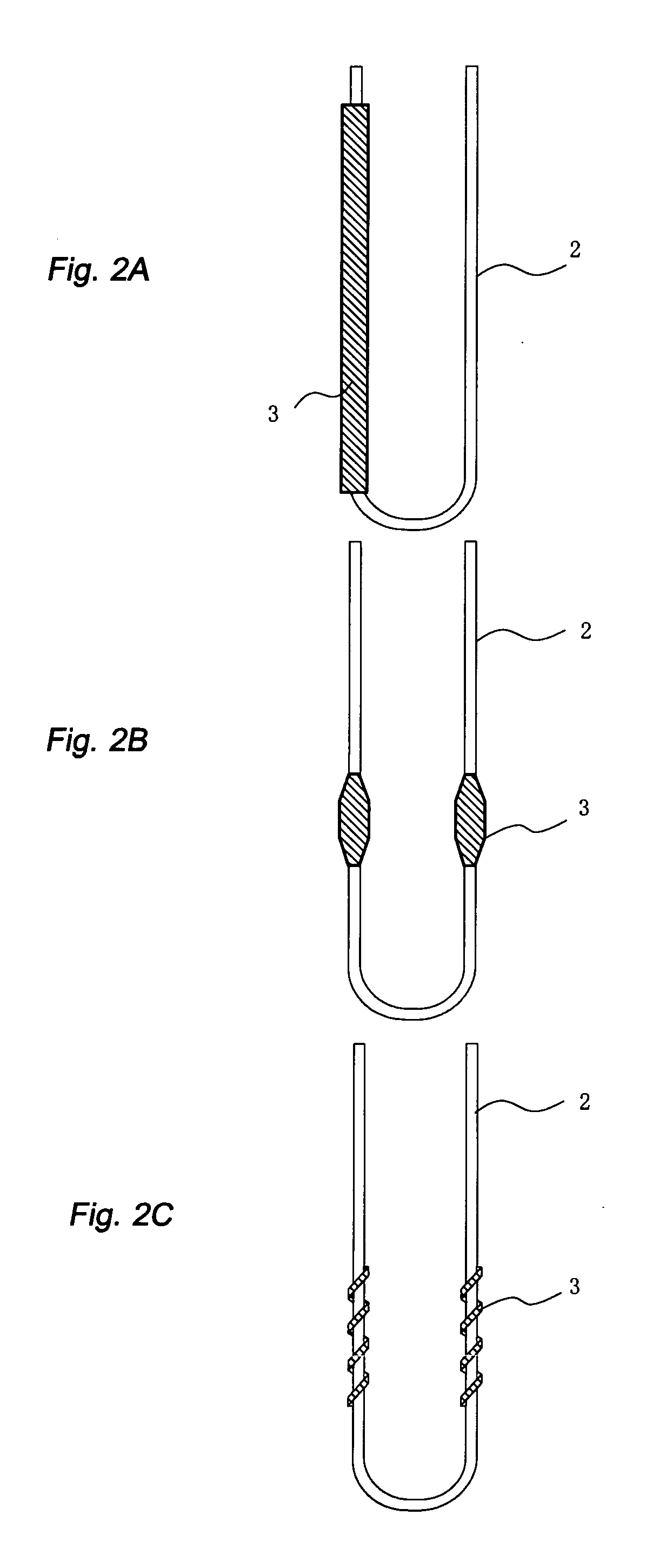

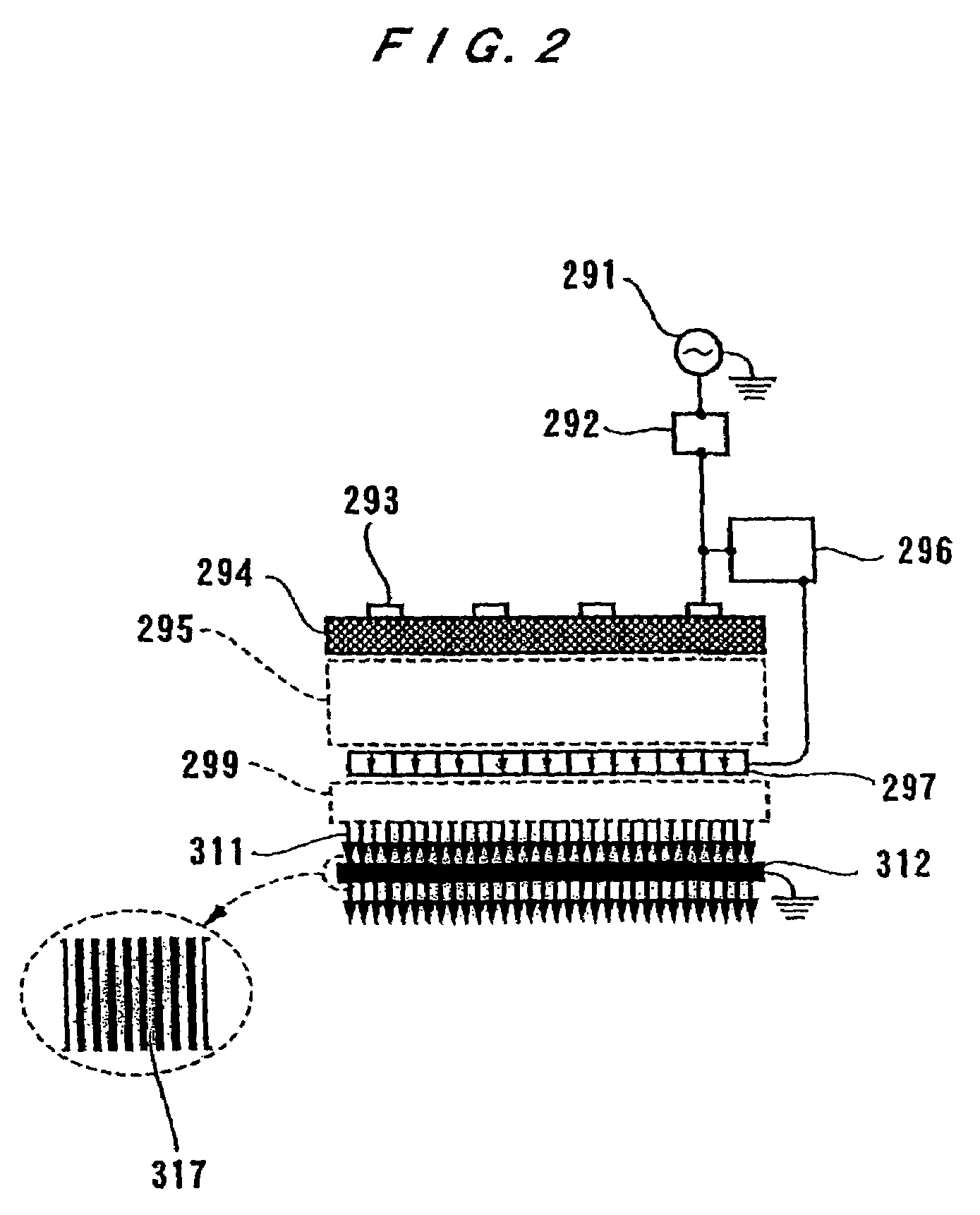

Discharge apparatus, plasma processing method and solar cell

InactiveUS20050067934A1Generate uniformImprove productivityFinal product manufactureSolid cathode detailsElectrical conductorReflected waves

The object of this invention is to realize the new configuration of antenna and the electric power feeding method which substantially suppress the generation of standing wave and consequently to provide a discharge apparatus to generate plasma having an excellent uniformity, a plasma processing method for large-area substrate, and a solar cell manufactured with a high productivity. The present invention is composed of a plurality of U-shaped antenna elements having a power feeding end and a grounded end which are arranged to form an array antenna in such a way that the grounded end and the power feeding end are alternately placed in parallel at regular intervals on a plane, wherein the alternating current electric powers with the same excitation frequency are simultaneously fed to the power feeding ends with the phase shift of 180 degrees between adjacent power feeding ends, the excitation frequency of the alternating current power is 10 MHz-2 GHz, and the length of the conductor is set so that the measured ratio of reflected wave to incident wave is 0.1 or less at the power feeding end. It is also possible to determine the length La of straight conductor to hold the inequality: 0.5(1 / α)<La<10(1 / α). Here, α(1 / m) is a attenuation coefficient.

Owner:IHI CORP

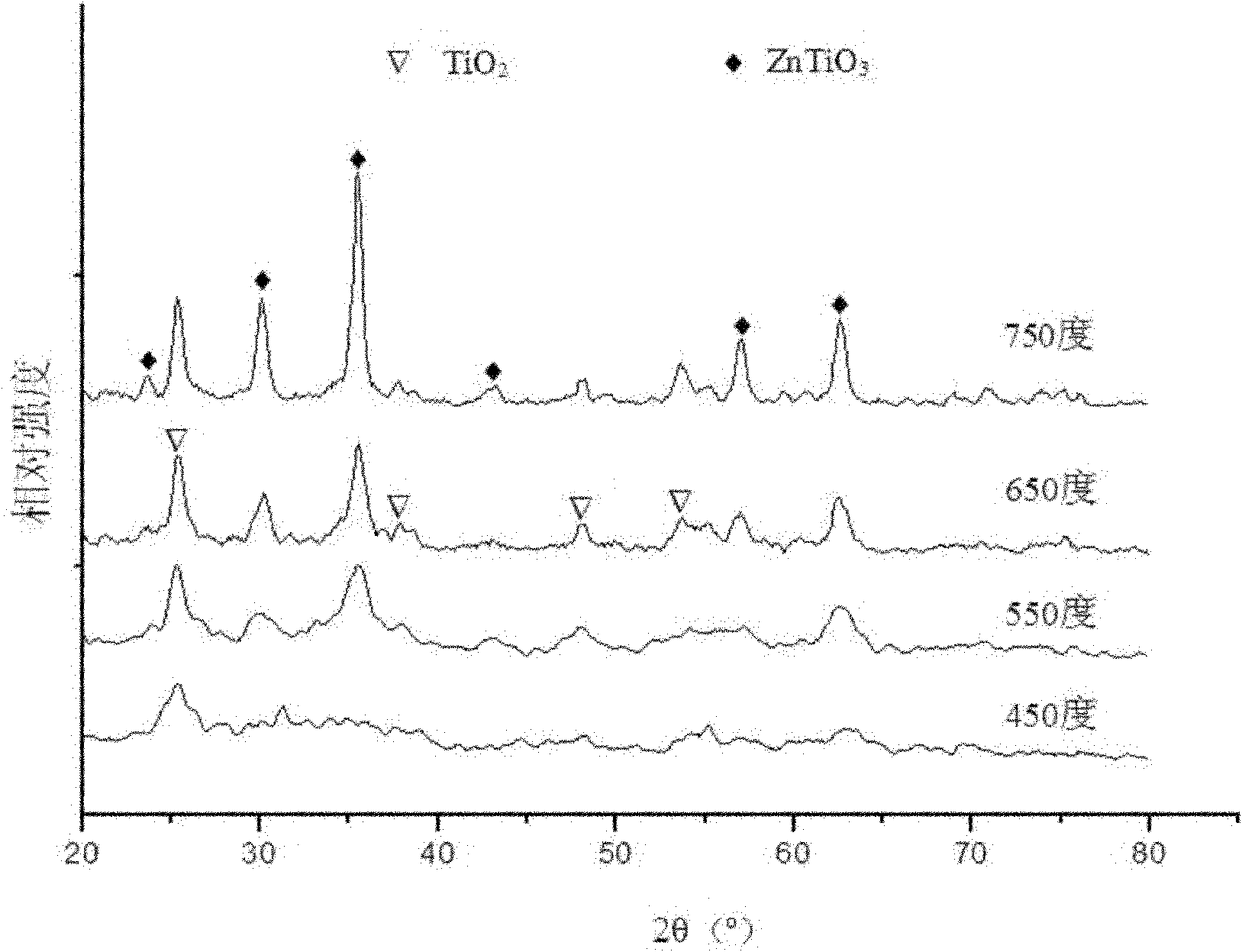

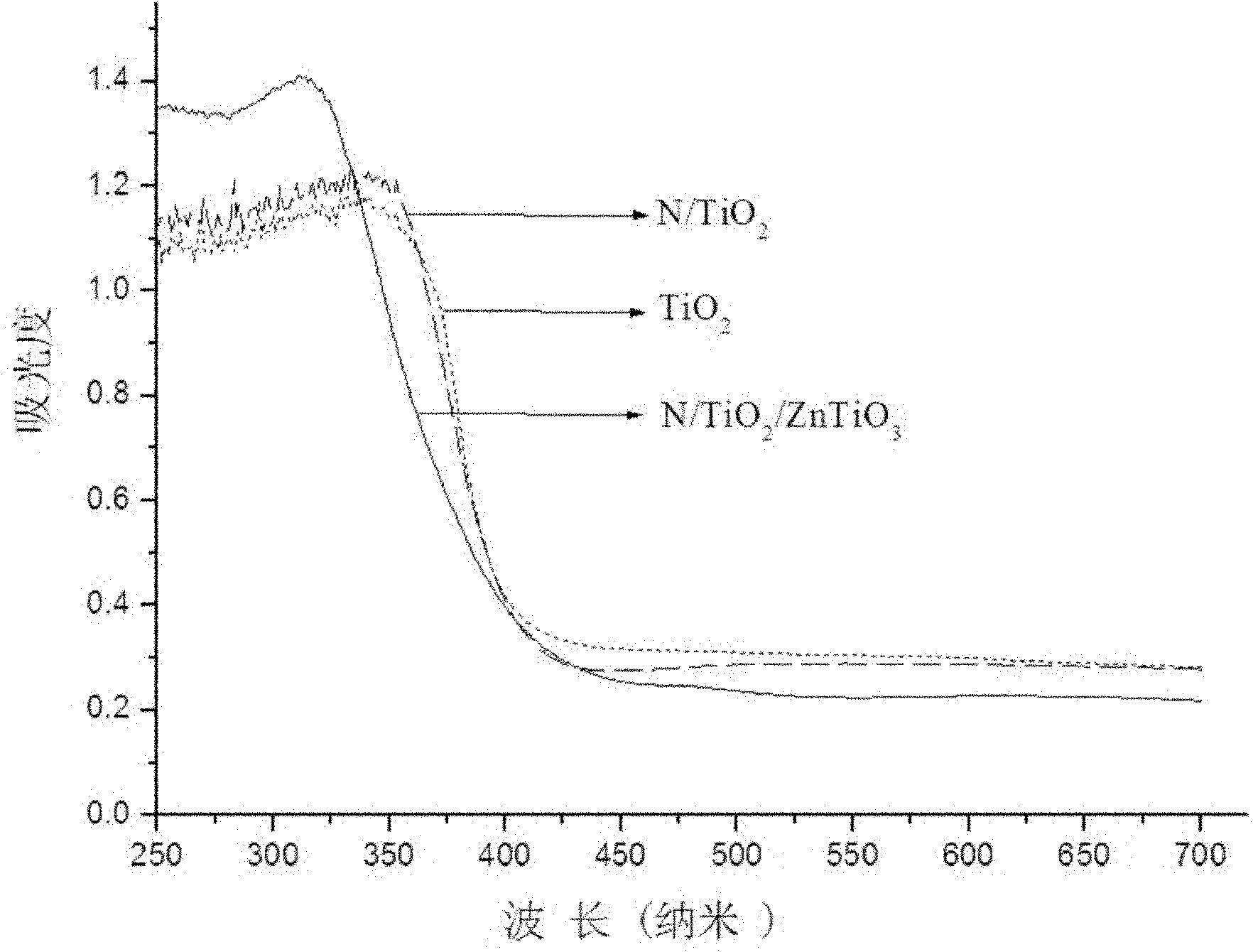

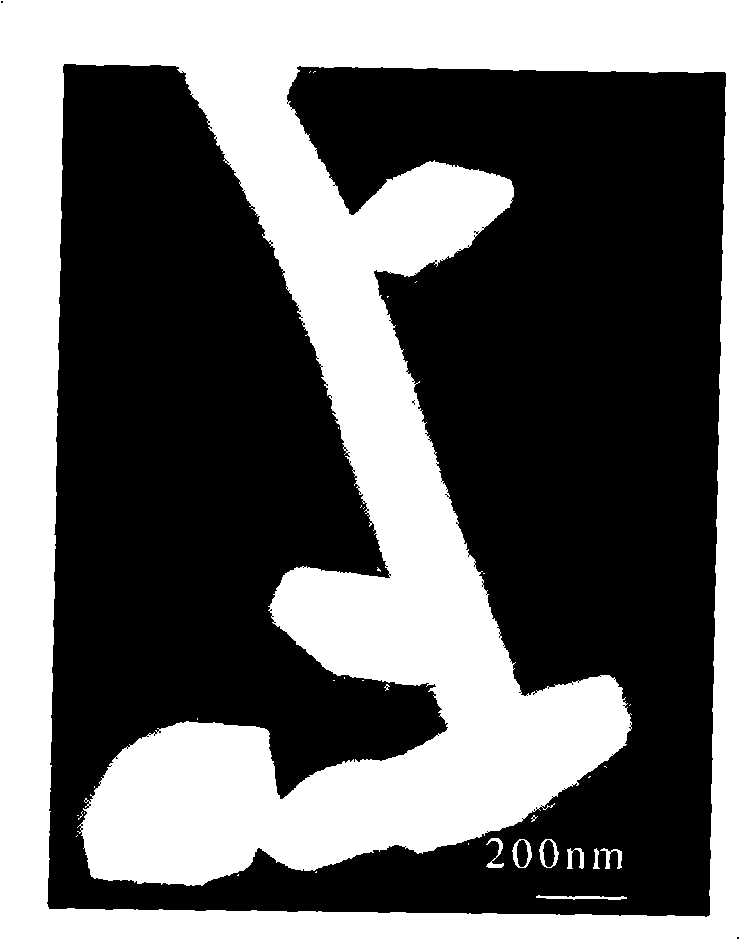

Preparation method of composite photocatalyst containing nitrogen-doped titanium dioxide and zinc titanate

InactiveCN102139206AImprove surface propertiesMild reaction conditionsBiocideWater/sewage treatment by irradiationWater bathsSpectral response

The invention relates to a preparation method of semiconductor composite antibacterial photocatalyst containing nitrogen-doped titanium dioxide and zinc titanate, and belongs to the technical field of the treatment of environmental pollution. The semiconductor composite antibacterial photocatalyst is prepared a uniform coprecipitation method which comprises the following steps of: preparing a mixed solution in the amount-of-substance ratio of titanium sulfate to urea to zinc ions of 1:10:0; continuously mixing the mixed solution; raising the temperature of a water bath to 60 DEG C; adding a surfactant (sodium dodecyl benzene sulfonate) into the mixed solution based on the concentration of 20mg / 150ml; keeping a constant temperature for 0.5h; raising the temperature to 90-100 DEG C again; keeping the temperature for 3-6h; adding ammonia water into the solution to regulate to pH (potential of hydrogen) to be 6-8; washing and drying the obtained product; and forging the product at the temperature of 400-800 DEG C. The preparation method has the advantages of short process flow, simple equipment, simple and convenient operation, and low price of raw materials. The prepared semiconductor composite has the advantages of having good dispersibility, visible spectral response and low energy consumption, and is an environment-friendly antibacterial purification material.

Owner:WUHAN UNIV OF TECH

Abrasive grain CeO2 for chemical and mechanical buffing and method for preparing same

ActiveCN101284952AReduce surface roughnessImprove flatnessPigmenting treatmentSemiconductor/solid-state device manufacturingCrystal systemInorganic salts

The invention relates to a chemical mechanical polishing abrasive particle CeO2 and a method for preparing the same, belonging to the rare earth powder material chemical preparation technical field. The invention is to prepare the CMP abrasive particle by utilization of cerous inorganic salt solution and homogeneous precipitation agent. The method comprises the following steps that: the cerous inorganic salt and the precipitation agent are prepared into solution with certain proportion; the solution is uniformly mixed through ultrasonic vibration; deposits are generated after the solution is heated to a certain temperature; serum is kept stand, aged, filtered and calcined, and then the CeO2 abrasive particle is prepared. The method also accelerates the nucleation rate through addition of surface active agent so as to reduce the reaction temperature, and simultaneously the nodulizing degree of the abrasive particle obtained is also good. The method prepares the CMP abrasive particle, wherein, the CMP abrasive particle belongs to the single-phase cubic crystal system; the space group is O<5>H-FM3M; the dispersibility is good; the grain fineness distribution is uniform; the shape is similar to a sphere; and the specific surface area BET is more than 0 and less than 50m<2> / g.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Preparation method of high-yield high-activity alkynol-coated vinyl platinum complex

ActiveCN105255192AHigh yieldHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsSodium bicarbonatePlatinum complex

The invention discloses a preparation method of a high-yield high-activity alkynol-coated vinyl platinum complex. The preparation method is characterized by comprising the following steps that 1, 100 parts by weight of 1,3-divinyltetramethyldisiloxane is taken to be poured into a reaction kettle; 2, 1-8 parts by weight of chloroplatinic acid is dissolved with solvent to obtain a chloroplatinic acid solution, the chloroplatinic acid solution is poured into the reaction kettle to be stirred, the temperature is increased to 50-60 DEG C, and the reaction time is set for 0.5-2 h; 3, 5-30 parts by weight of sodium bicarbonate is added into the reaction kettle, then the temperature is increased to 60-80 DEG C, and stirring is continuously performed to enable a reaction to be performed for 1-3; 4, 1-10 parts by weight of alkynol is dissolved with 10-100 parts by weight of solvent to obtain an alkynol solution, the alkynol solution is dropwise added into the reaction kettle, and dropwise adding is completed in 0.5-2 h; 5, filtering is performed to obtain filtrate and sodium bicarbonate residues; 6, reduced-pressure solvent removing is performed on the filtrate at 60 DEG C to obtain liquid; 7, vinyl silicone oil is added into the liquid to obtain the high-yield high-activity alkynol-coated vinyl platinum complex. The preparation method is simple and easy to achieve, and the yield of the prepared product can be more than 98 percent.

Owner:ANHUI ZHENGJIE HIGH TECH MATERIALS CO LTD BY SHARE

Micro-arc oxidation treatment method of magnesium alloy

InactiveCN101942689AReduce porosityImprove corrosion resistanceAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a micro-arc oxidation treatment method of a magnesium alloy, and the micro-arc oxidation treatment method comprises pretreatment, micro-arc oxidation, cleaning and post-treatment. The concentration of treatment fluid in the micro-arc oxidation process step in the micro-arc oxidation treatment method of the magnesium alloy is as follows: Na2SiO3 is 4-8g / L, KF is 5-10g / L, and KOH is 8-14g / L. The micro-arc oxidation treatment method comprises the steps of utilizing the principle of metal micro-arc oxidation, carrying out micro-arc oxidation treatment on the surface of the magnesium alloy, leading the surface of the magnesium alloy to grow out a ceramic structural film layer which is combined with a matrix in the micro-immersion gold way, isolating the contact between the surface of the magnesium alloy and atmosphere, carrying out micro-arc oxidation treatment, cleaning, post-treatment and drying on the magnesium alloy product within the stipulated range of parameters after the pre-treatment, generating an oxide film with the thickness of 5-10 mu m on the surface of the product, further spraying with an organic silicon coating and obtaining the film with the thickness of 35-50 mu m, and the micro-arc oxidation treatment method can improve the corrosion resistance of the magnesium alloy product to above 1000 hours and far exceed the requirements of national technical standard.

Owner:DONGGUAN EONTEC CO LTD

Electric heating system, in particular for a hybrid vehicle or electric vehicle

ActiveCN102668691AGenerate uniformHeater elementsPropulsion using engine-driven generatorsElectric heatingHybrid vehicle

The electric heating system, in particular for a hybrid vehicle or electric vehicle, is provided with a heating module (10). The heating module (10) is provided with an electrically insulating, heat-conducting ceramic substrate (14) which has a heating zone (16) and an actuation zone (18), which are spaced apart from one another. The heating module (10) has an electrical resistance heating element (22) which is arranged on the ceramic substrate (14), in the heating zone (16) thereof, and which is embodied as a resistance heating element (24) which is mounted on the ceramic substrate (14). In addition, the heating module (10) has a transistor (26) for controlling the current through the resistance heating conductor (24), wherein the transistor (26) and other optionally present electrical components (28) and conductor tracks (30) are arranged in the actuation zone (18) on the ceramic substrate (14). The heating module (10) is provided with a first cooling element (42) which is thermally coupled to the heating zone (16) of the ceramic substrate (14).

Owner:贝洱海拉温控系统有限公司

Plasma sterilization device for flexible discharge electrode structure

ActiveCN105848397AGenerate uniformMeet the practical applicationLavatory sanitoryDisinfectionSmeltingHigh voltage electrode

The invention discloses a plasma sterilization device for a flexible discharge electrode structure. The plasma sterilization device comprises a power system with a high voltage output circuit, a high voltage electrode connected with a high voltage end of the high voltage output circuit and a grounding electrode, wherein the high voltage electrode and the grounding electrode are in direct contact by mutually twisting spirally, at least one of the high voltage electrode and the grounding electrode is of a flexible structure, and at least one of the high voltage electrode and the grounding electrode comprises an insulating medium; the grounding electrode having the flexible structure is made of a carbon fiber material which has a high smelting point and relatively good conductive property; after the power system is power on, surface discharge is generated in a contact area of the two electrodes to generate a lot of low temperature plasma; and the high voltage electrode and the grounding electrode which are mutually twisted and are in direct contact can sterilize a treated object in a direct contact mode.

Owner:BEIJING RUIYUDA TECH

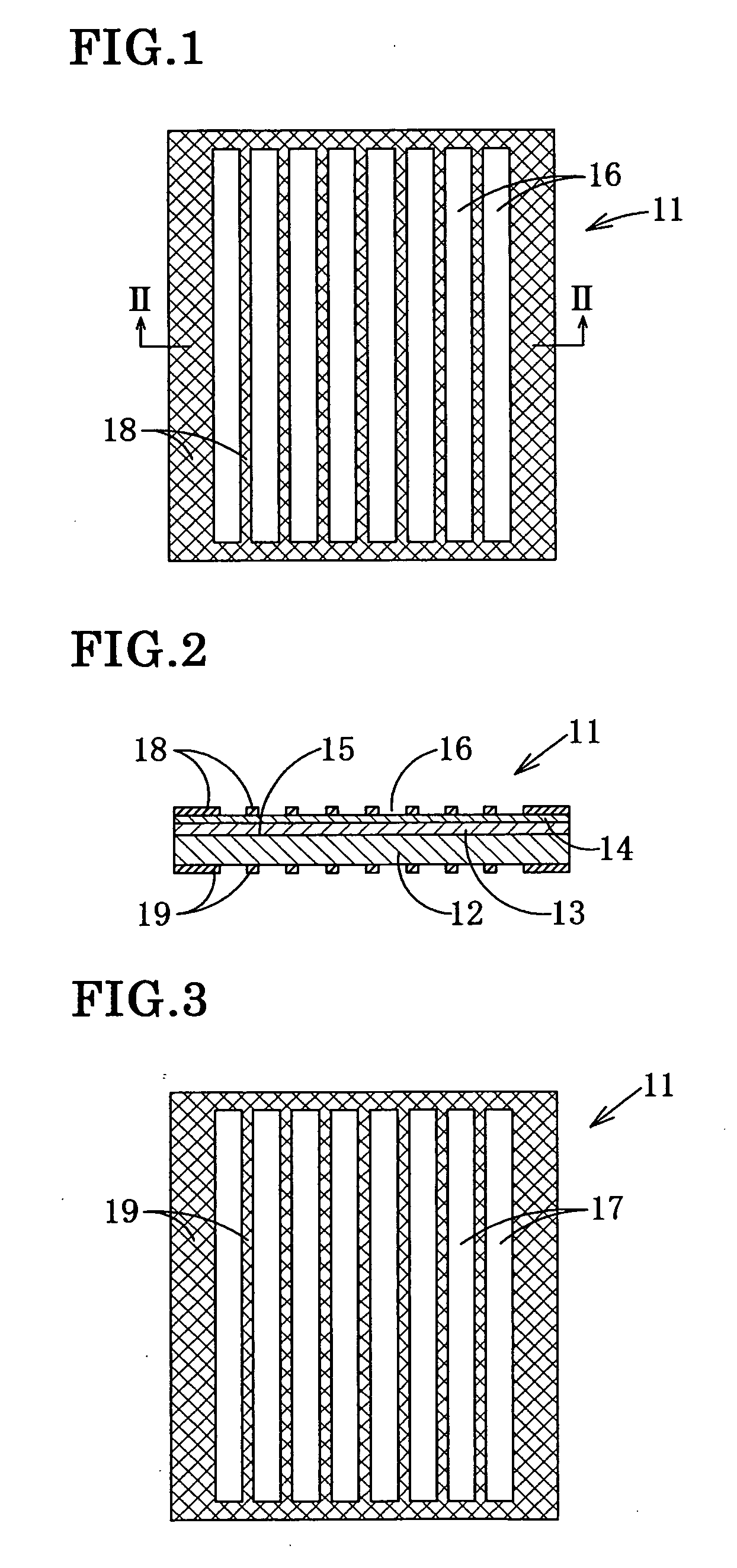

Plasma processing apparatus

ActiveCN101543141AImprove uniformityEnsure axisymmetricElectric discharge tubesSemiconductor/solid-state device manufacturingProjection planePlasma processing

Above an object to be processed, n coil elements (n is two or more integer) having the same shape are arranged axial-symmetrically with respect to an axis which is normal of the surface of the object, and the coil elements are electrically connected parallel to one another to form an induction coil. Each coil element is a circle whose center is the above axis, has a ground end and a feed end justabove the ground end in the same point when the coil is projected onto the projection plane of the object. The coil element comprises a lower surface part having the ground end at one end, a predetermined width, and an arc shape the center angle of which is 360 DEG / n and a feed part having the feed end at one end, a predetermined width, and an arc shape, and is disposed at a level higher than that of the lower surface part, and electrically connected to the lower surface part. Such coil elements can be so combined that the feed end of one coil element is just above the ground end of another coil element.

Owner:SAMCO INC

Production process for ultrafine particulate complex oxide containing titanium oxide

InactiveUS6548169B2Suppressing growth of oxideShorten the timePigmenting treatmentMaterial nanotechnologyParticulatesGas phase

The present invention provides a process for producing ultrafine particulate complex oxide containing titanium oxide, including vapor-phase producing a complex oxide containing titanium oxide having a BET specific surface area of about 5 to about 200 m2 / g, where a starting material gas containing titanium tetrachloride and an oxidizing gas are preheated to about 700° C. or more, and are reacted with a solution or a slurry of a salt containing a metallic element. The present invention also provides an ultrafine particulate complex oxide containing titanium oxide obtained by the process, and use of the oxide.

Owner:SHOWA DENKO KK

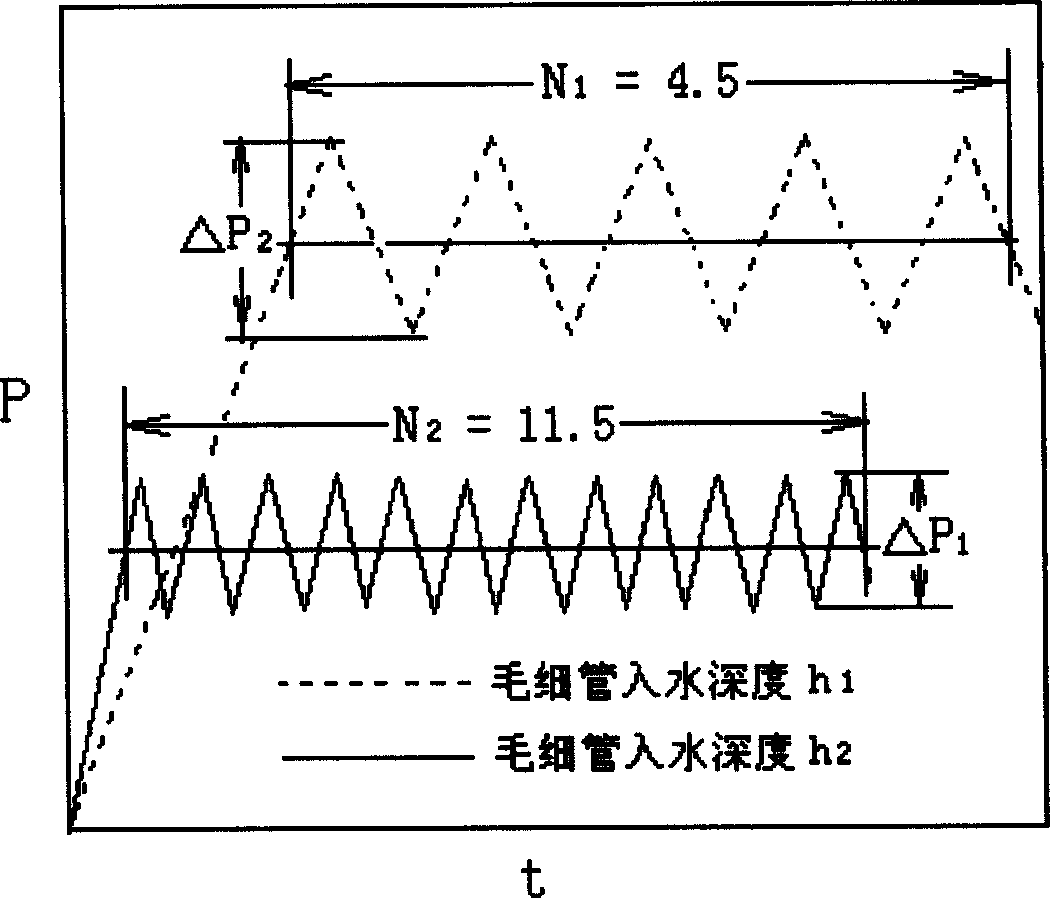

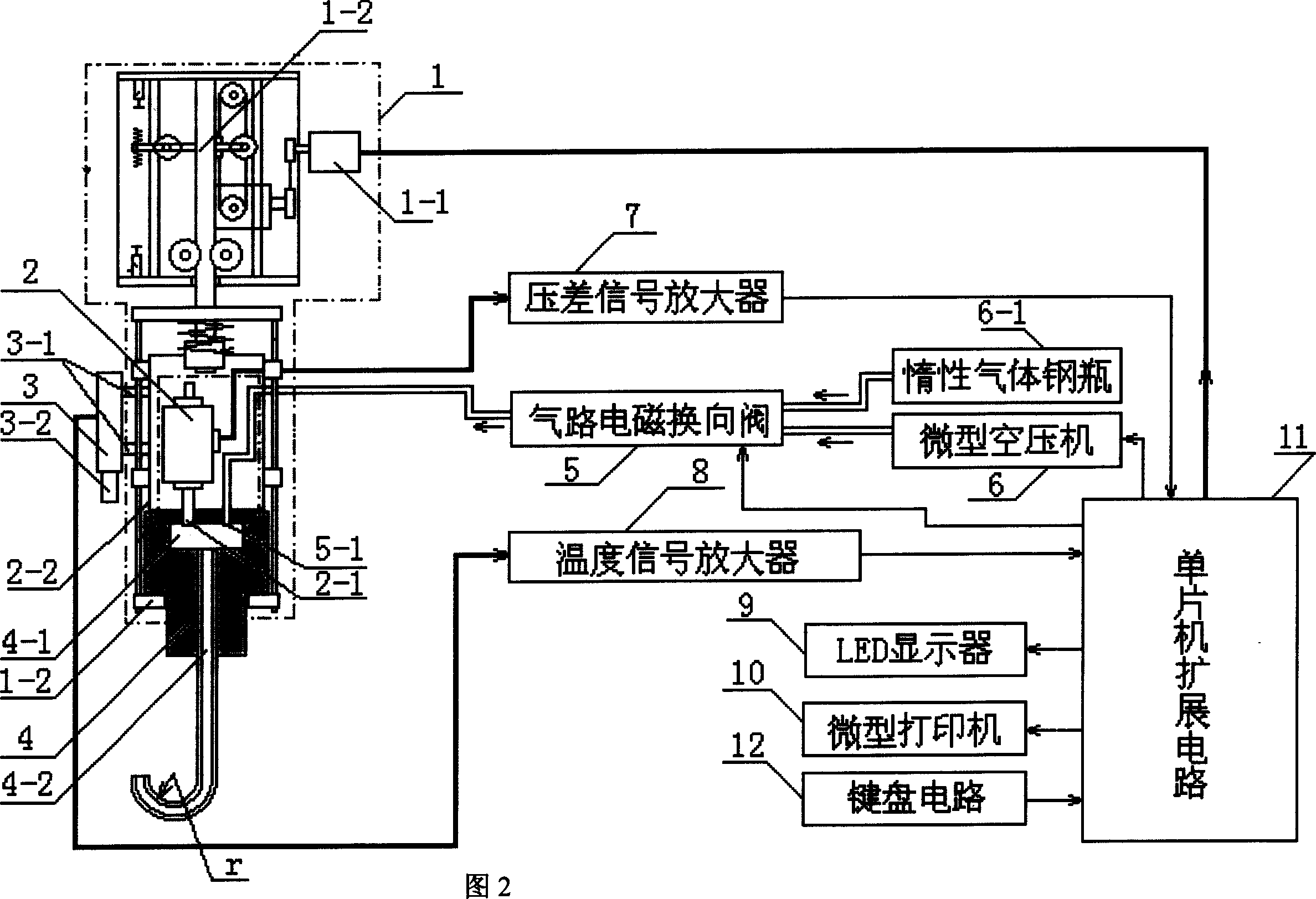

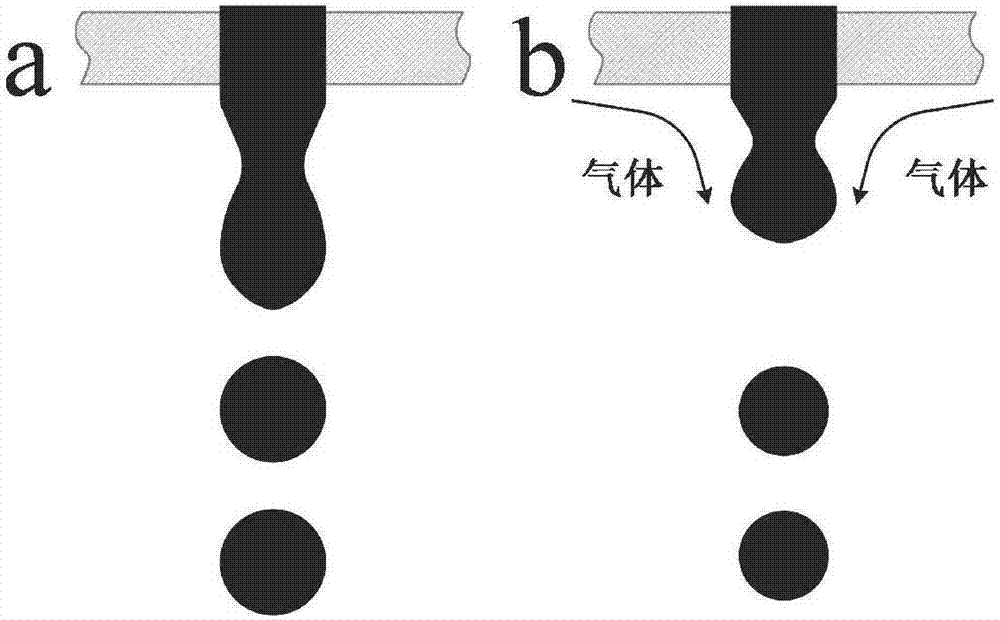

Quick determination device for surface tension of liquid metal and liquid alloy

It is a rapid measurement apparatus for liquid metal and liquid alloy surface tension and it relates to metallurgy and foundry field. The power input end (1-1) is connected with output end of (11) power; the down end of (1-2) is connected with (4) and the upper end of (4-2) is connected with (4-1); the two gas-in end of (5) is separately connected with vent of (6)(6-1); the controlled end of (6) is connected with output end of (11); the controlled end of (5) is connected with output end of (11); the output end of (2) is connected with input end of (11) through (7); the output end of (3) is connected with input end of (11) through (11); the output end of (11)is connected with input end of (9); the output end of (12)is connected with input end of (11).

Owner:HARBIN UNIV OF SCI & TECH

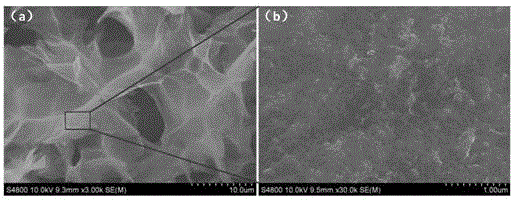

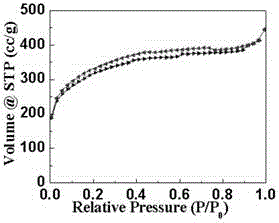

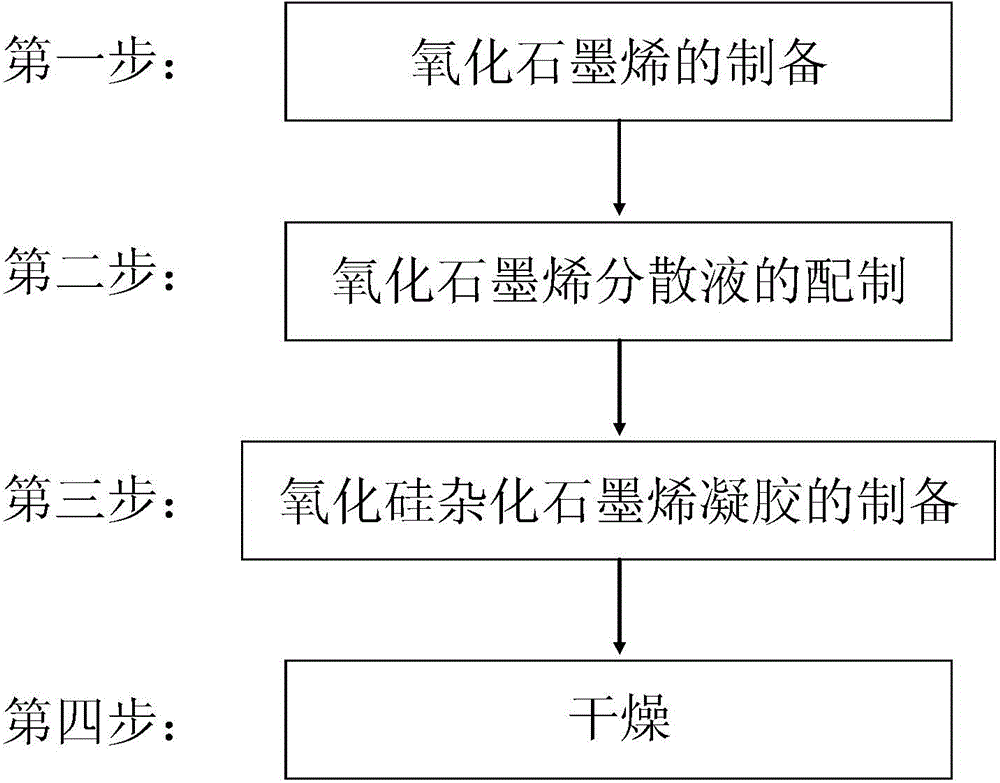

High specific surface area of silicon oxide hybridized graphene aerogel and production method thereof

The invention discloses high specific surface area of silicon oxide hybridized graphene aerogel and a production method thereof. The high specific surface area of silicon oxide hybridized graphene aerogel and the production method aim at solving the problem that the specific surface area is reduced when hybridization is performed on graphene aerogel. The high specific surface area of silicon oxide hybridized graphene aerogel is formed by grapheme through building, wherein a large quantity of silicon oxide particles are distributed on the surface of the grapheme; the high specific surface area of silicon oxide hybridized graphene aerogel comprises a porous structure, wherein the pore diameter of the porous structure is concentrated to be 1 to 500 nm; the porous structure comprises a microporous structure and a macroporous structure. The production method comprises serving graphite powder, siloxane and the like as main raw materials, producing graphene oxide, preparing a graphene oxide dispersing agent and producing silicon oxide hybridized graphene gel and obtaining the high specific surface area of silicon oxide hybridized graphene aerogel after drying. According to the high specific surface area of silicon oxide hybridized graphene aerogel and the production method thereof, tiny particle size of silicon oxide nanoparticles are produced through liquid mixing of the raw materials and a reaction, the introduction on the silicon oxide particles is implemented, meanwhile the partition effect on the grapheme is achieved, and accordingly the high specific surface area of silicon oxide hybridized graphene aerogel is large in specific surface area, small in silicon oxide particle and uniform in distribution.

Owner:NAT UNIV OF DEFENSE TECH

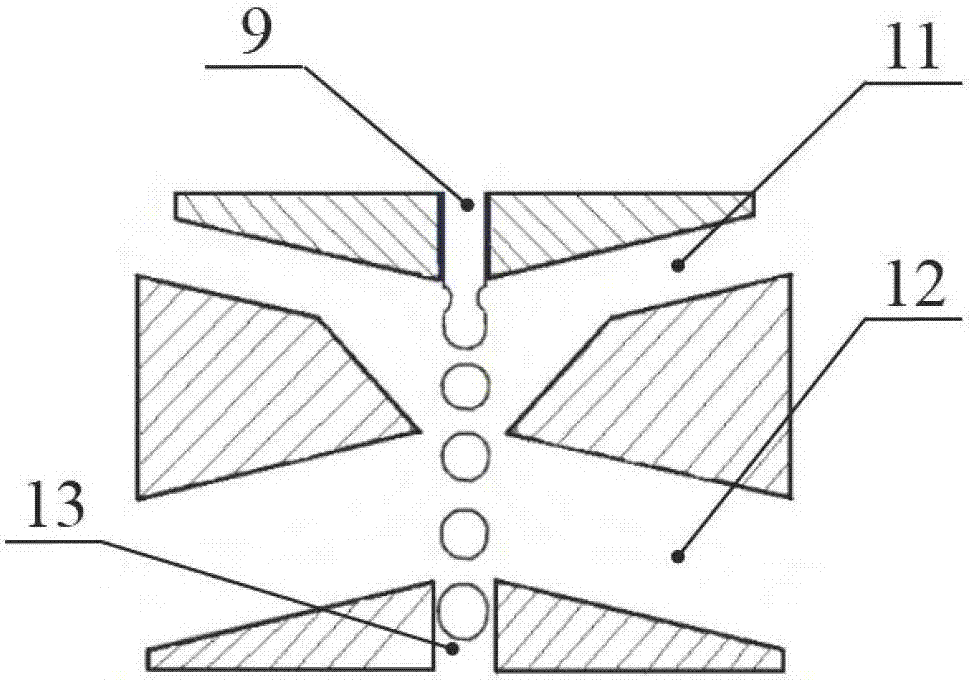

Beam source and beam processing apparatus

InactiveUS7078862B2Generate uniformReduce manufacturing costSemiconductor/solid-state device manufacturingElectric arc lampsBeam sourceIon beam

A beam source has a plasma generating chamber, an antenna for generating plasma in the plasma generating chamber, a first electrode disposed in the plasma generating chamber, and a second electrode disposed in the plasma generating chamber. Both of the antenna and the second electrode face the first electrode. The beam source also includes a power supply for applying a voltage between the first electrode and the second electrode to extract particles from the plasma generated by the antenna. The beam source applies various kinds of beams having a large diameter, such as a positive ion beam, a negative ion beam, and a neutral particle beam, uniformly to a workpiece.

Owner:TOHOKU TECHNO ARCH CO LTD

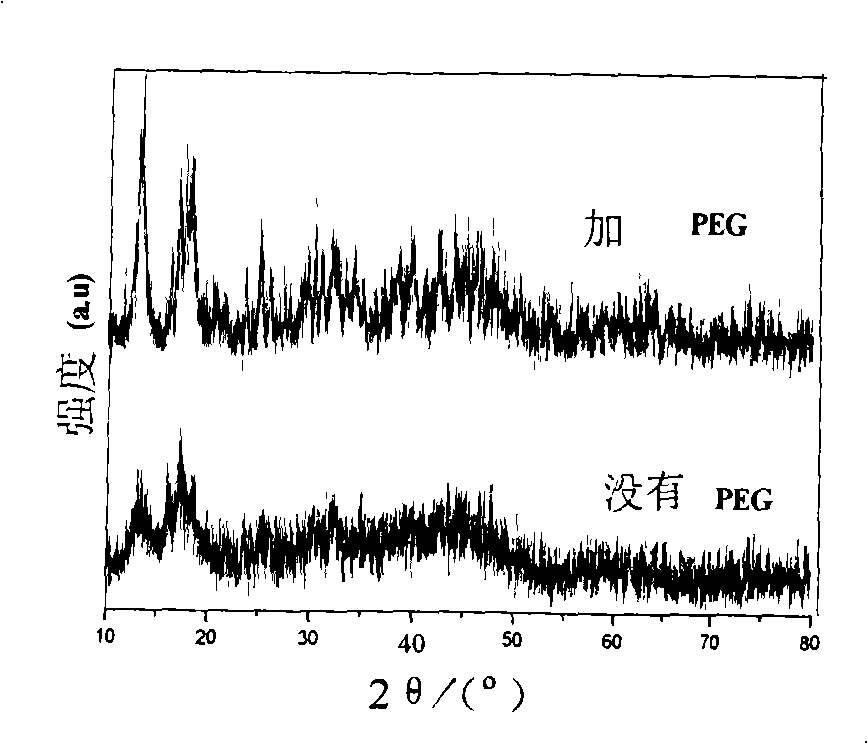

Method for preparing nano zinc oxide in monodisperse, with no agglomeration and strong ultraviolet absorption

InactiveCN1562762AUniform particle size distributionNo reunionZinc oxides/hydroxidesZno nanoparticlesUltraviolet absorption

At first, mixing zinc salt hexahydrated zinc nitrate and ammonia source hexamethylene tetramine according to mole density ratio 1:1.5 and dissolving them in carbinol solutio, then adding polytene pyrrolidone in certainly ratio, stirring till that solution is clear to produce grow reaction liquid of zinc oxide nanometre crystal, putting said reaction liquid into tetrafluoroethylene reactor, closing and increasing temp. to 95-100 deg.C to do reaction, then natural cooling, centrifuging washing, airing to obtain zinc oxide crystal that particle size is 15 nm.

Owner:SHANGHAI JIAO TONG UNIV

High-intensity and super-sulphur ardealite slag cement concrete and preparation method thereof

The invention relates to high-intensity and super-sulphur ardealite slag cement concrete and a preparation method thereof. The high-intensity and super-sulphur ardealite slag cement concrete is prepared by the following method with the steps of (1) ardealite ball milling pretreatment: putting ardealite, fly ash, cement, water reducing agents and water into a ball milling tank to perform wet milling; then performing sieving and aging treatment to obtain ardealite slurry; (2) high-intensity and super-sulphur ardealite slag cement concrete preparation: adding sand, stone coarse aggregates and water into a concrete stirring machine for stirring; after the uniform mixing, adding fine aggregate cement and mineral powder into the concrete stirring machine for continuous stirring; after the uniform stirring, slowly adding the ardealite slurry; finally adding water and water reducing agents; after the sufficient stirring, performing concrete shaping and maintenance, thus obtaining the high-intensity and super-sulphur ardealite slag cement concrete. The high-intensity and super-sulphur ardealite slag cement concrete provided by the invention has the advantages of high intensity, short setting time, good volume stability and difficult cracking.

Owner:WUHAN UNIV OF TECH

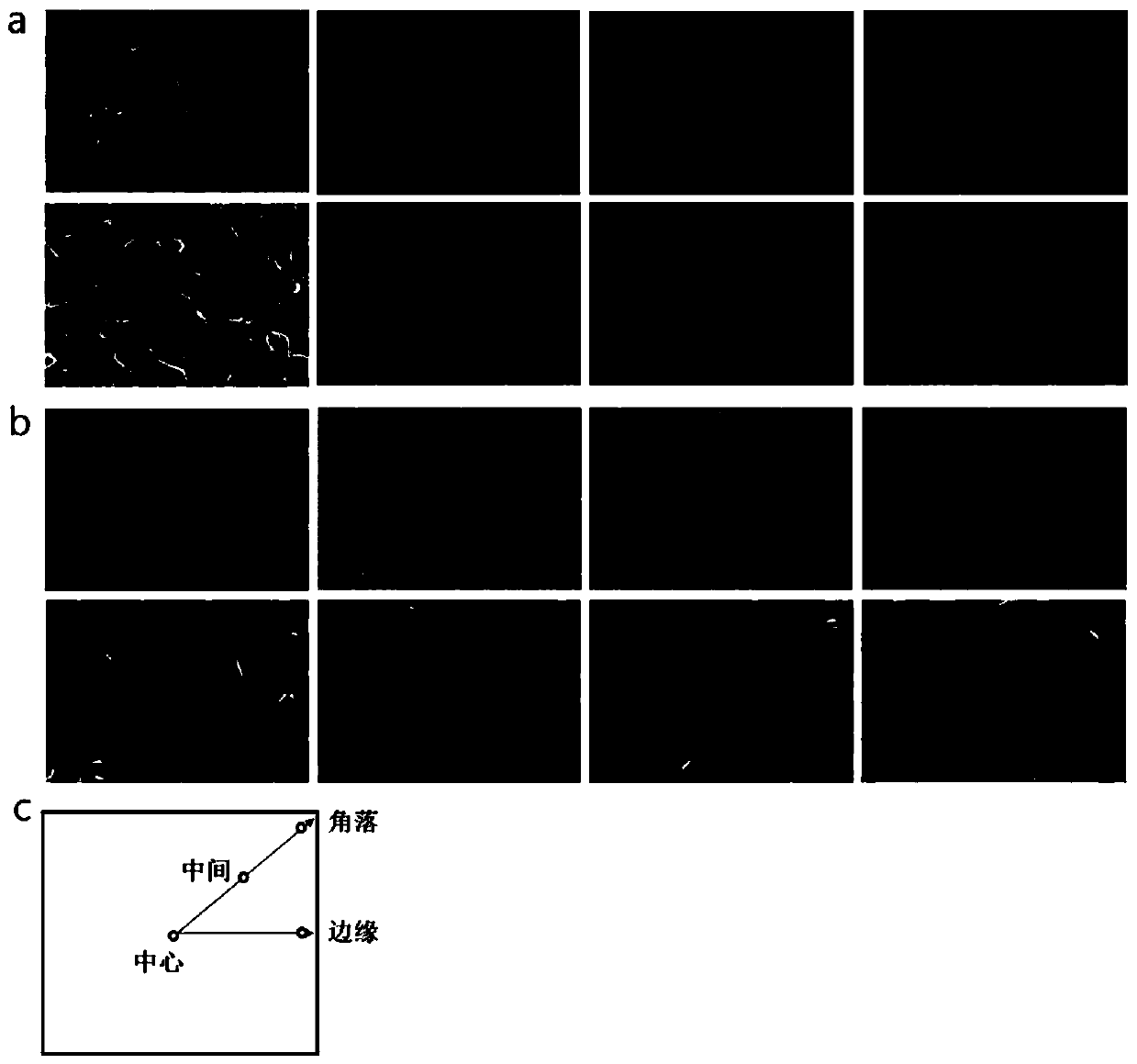

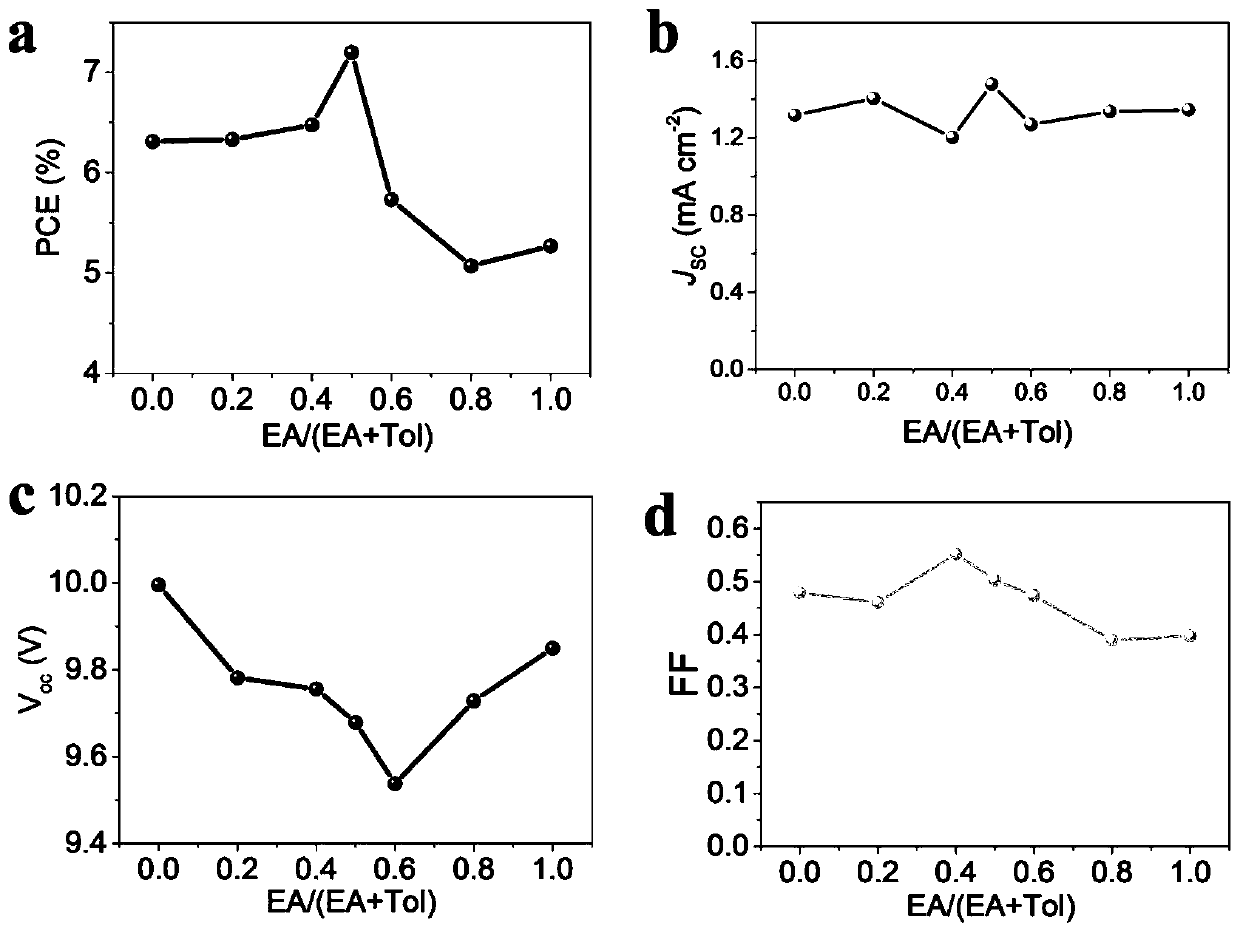

Method for preparing large-area perovskite layer and perovskite solar cell

PendingCN110718632ARefine the grain sizeReduce supersaturationSolid-state devicesSemiconductor/solid-state device manufacturingChlorobenzenePerovskite solar cell

The invention discloses a method for preparing a large-area perovskite layer and a perovskite solar cell. The method comprises the following steps of coating a perovskite precursor solution on a substrate to form a perovskite precursor layer; adding a mixed anti-solvent, and carrying out annealing treatment to obtain the perovskite layer, wherein the mixed anti-solvent is a mixed solvent formed bymixing a solvent A and a solvent B; the solvent A is selected from any one of methylbenzene, chlorobenzene, dichloromethane, ethyl acetate, anisole and diethyl ether, the solvent B is selected from any one of methylbenzene, chlorobenzene, dichloromethane, ethyl acetate, anisole and monohydric alcohol with 3-6 carbon atoms, the solvent A and the solvent B are different, and a volume ratio of the solvent A to the mixed anti-solvent is 10%-90%. In the invention, a supersaturation degree of the perovskite precursor solution in a crystallization process is reduced by using the mixed anti-solvent so that crystallization nucleation sites are uniformly generated, the perovskite thin film with uniform film formation and a large grain size is finally obtained, and a good application prospect is possessed in the field of preparation of large-area perovskite devices.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

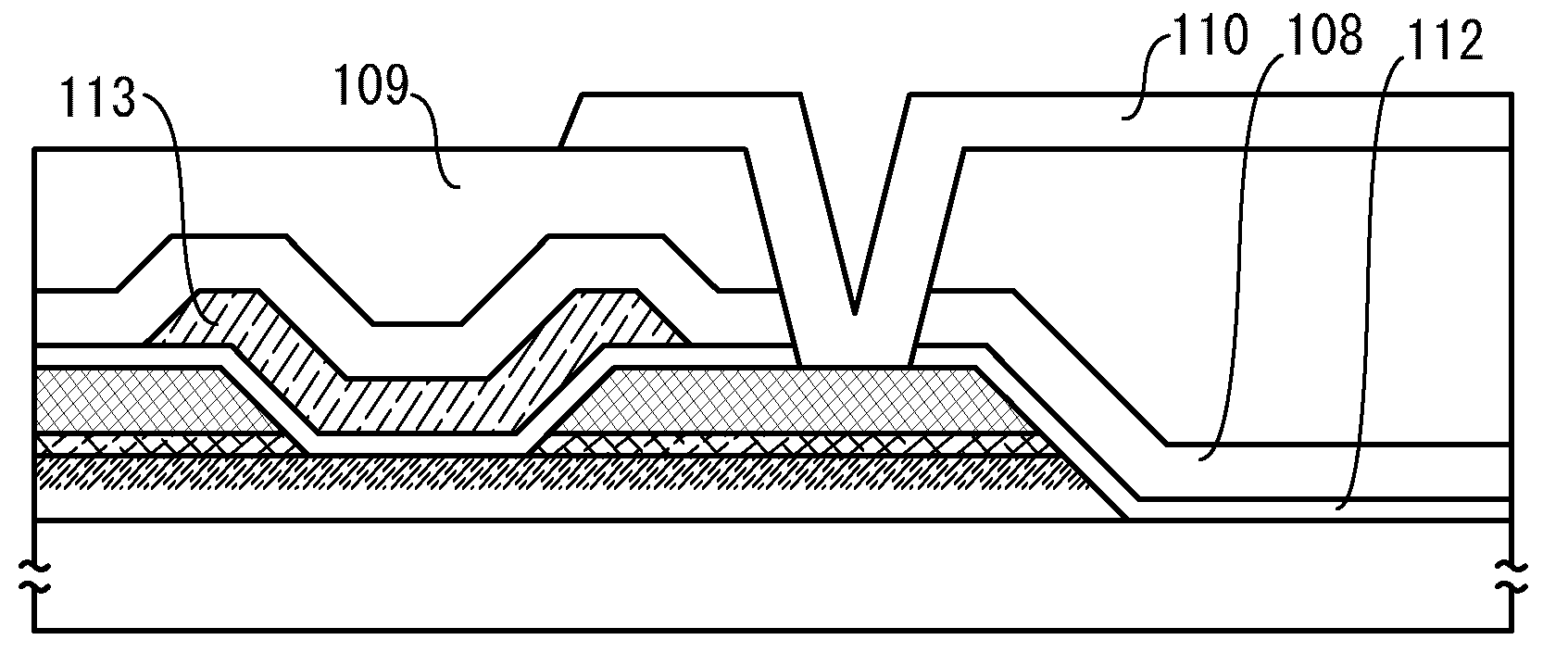

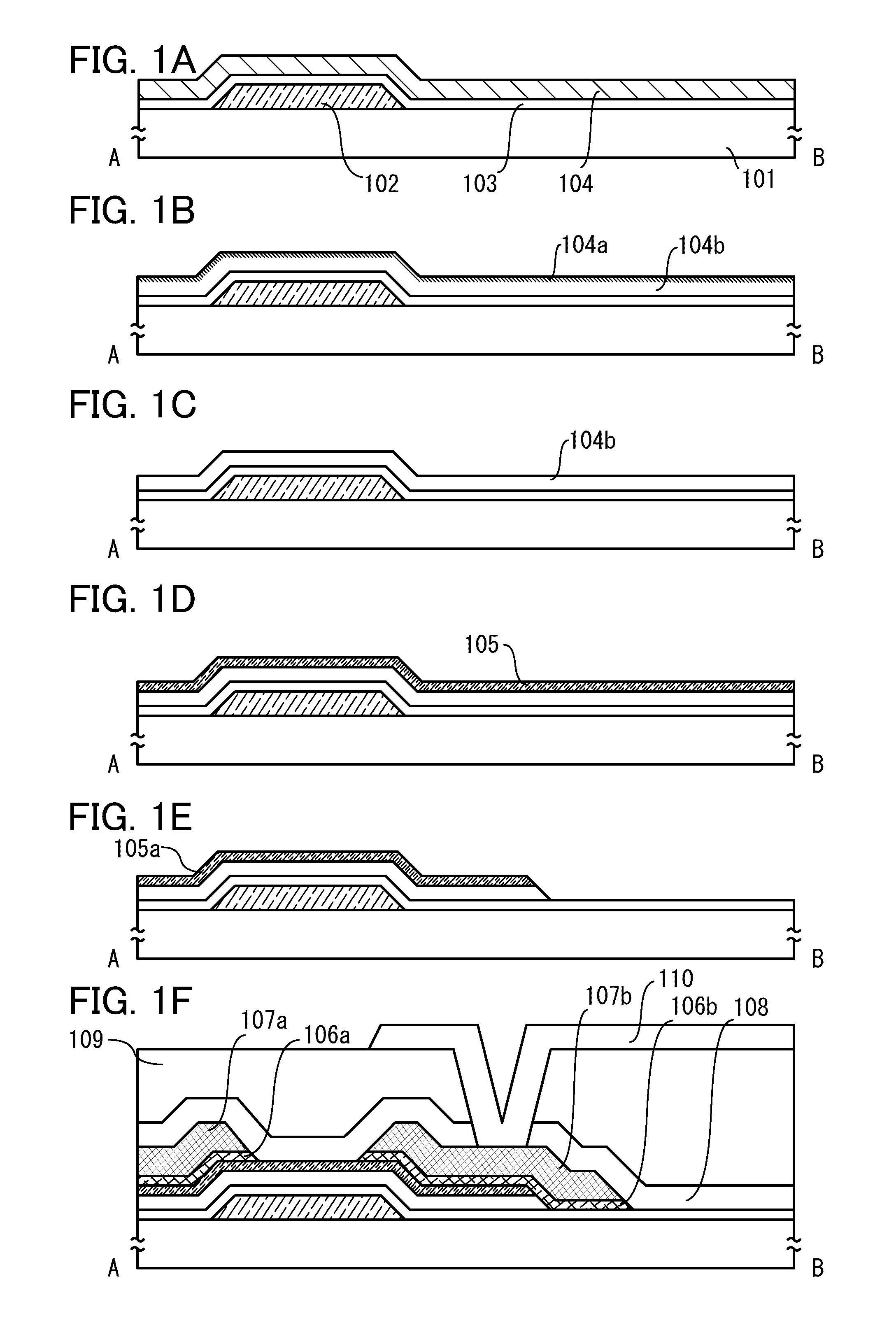

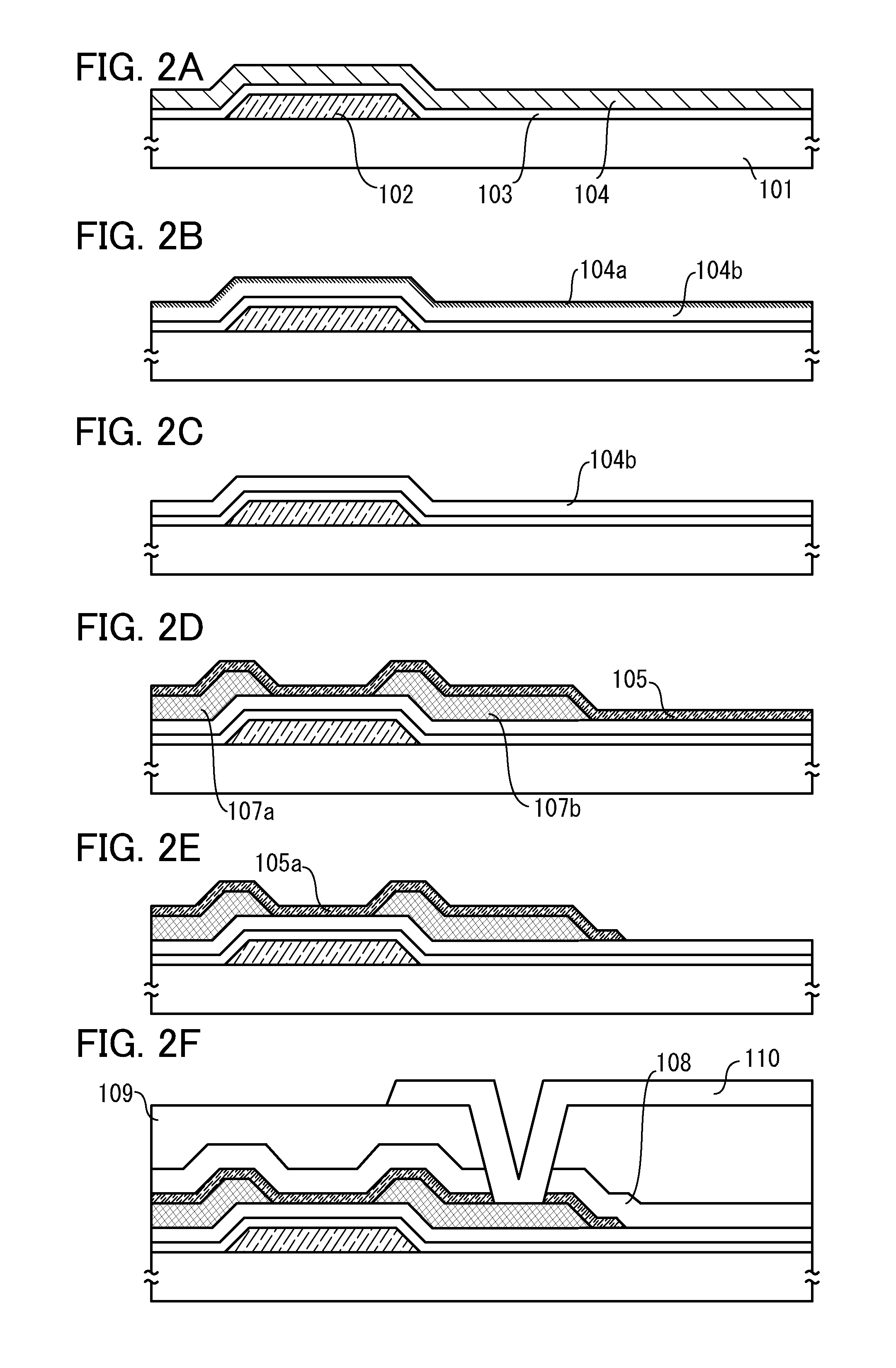

Plasma processing apparatus

InactiveUS20130299091A1Suppress generationImprove etch performanceElectric discharge tubesSemiconductor/solid-state device manufacturingElectricityDielectric

A plasma processing apparatus includes a processing chamber, a flat-plate-like dielectric window, an induction coil, a flat electrode, a RF power source, a gas supply unit, and a sample stage on which a sample is mounted. A process gas supply plate is provided opposite the dielectric window on an inner side of the processing chamber, and a recess portion is formed in the flat electrode on a side opposite the induction coil corresponding to a gas supply position of the process gas supply plate.

Owner:HITACHI HIGH-TECH CORP

Vapor-assisted metal micro-droplet manufacturing device and method

ActiveCN107127345AUniform structureHigh precisionAdditive manufacturing apparatusManufacturing technologyGas phase

The invention discloses a vapor-assisted metal micro-droplet manufacturing device and method and belongs to a micro-droplet jetting additive manufacturing technology. The inside of a seal box body is kept in a closed environment to keep an internal temperature invariable; a liquid metal is stored in an inner crucible, an inert gas with pulsating pressure is introduced from a pulsating pressure gas inlet, and the liquid metal is extruded to flow outside from a liquid outlet; a certain distance is kept between an outer crucible and the inner crucible; a heater wraps the outside of the outer crucible to keep the temperature of an internal environment constant; a high-pressure gas flows from an air inlet passage and a flowing metal liquid is extruded and sheared at a liquid outlet; the high-pressure gas flows outside from an air leakage passage and generated micro-droplets flow outside from a droplet outlet and fall to a deposition platform. Through the viscous shearing action of the gas around the liquid outlet, advanced shear fracture of the liquid is achieved at a droplet formation stage, smaller uniform micro-droplets are generated, improvement of the accuracy and the compactness of a formed part is facilitated, a metal lattice structure is more uniform and the mechanical property is better.

Owner:BEIJING UNIV OF TECH

Plasma processing apparatus with dielectric plates and fixing member wavelength dependent spacing

In a plasma processing apparatus, electromagnetic waves are radiated from slots of waveguides into a processing chamber via dielectric windows that are supported on beams, thereby generating a plasma. A substrate, which is an object of processing, is processed by the generated plasma. Dielectric plates are attached to those surfaces of the beams, which are opposed to the processing chamber. The thickness of each dielectric plate is set at ½ or more of the intra-dielectric wavelength of the electromagnetic waves. Using the plasma processing apparatus, a large-area processing can uniformly be performed.

Owner:SHARP KK

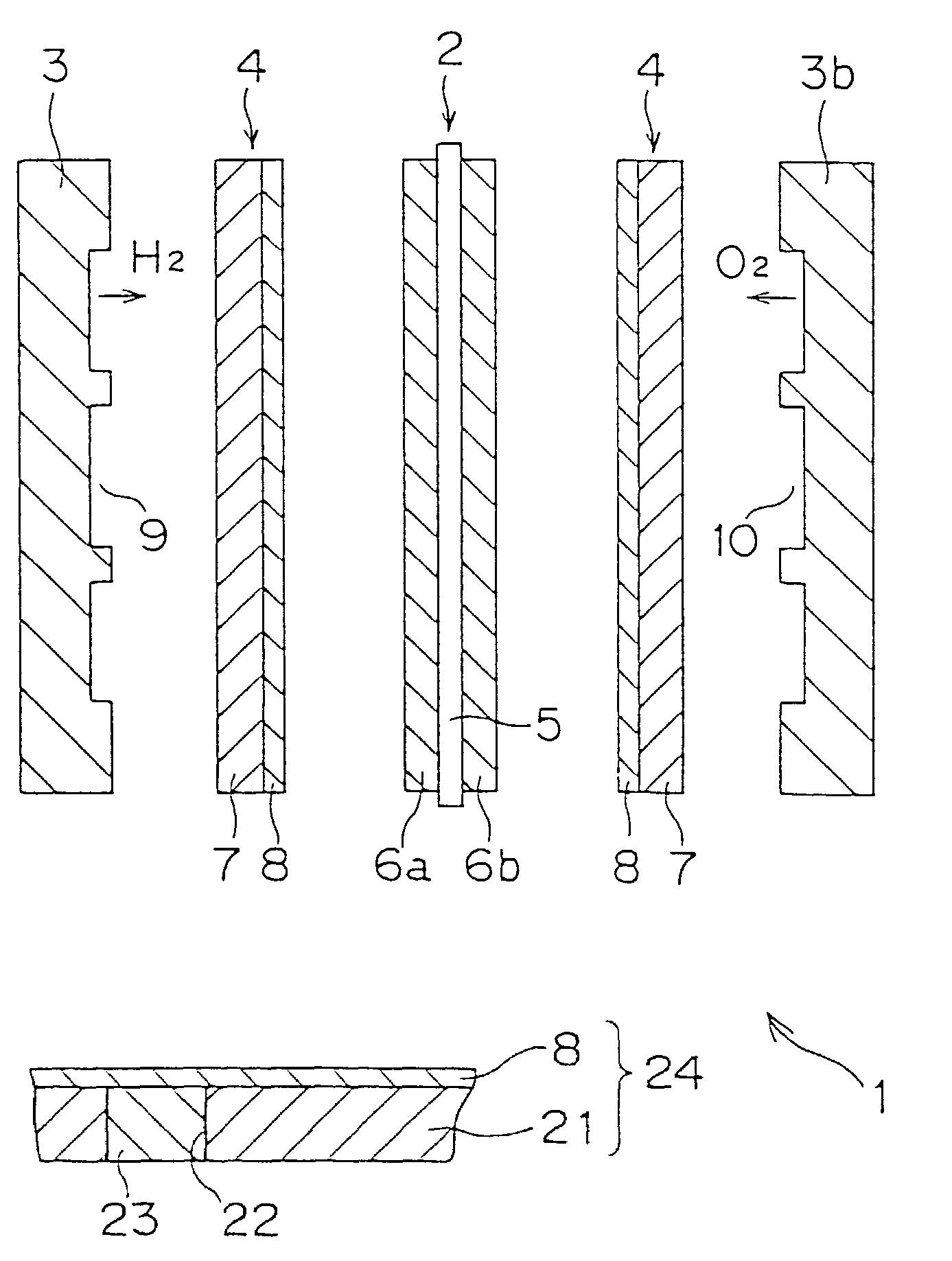

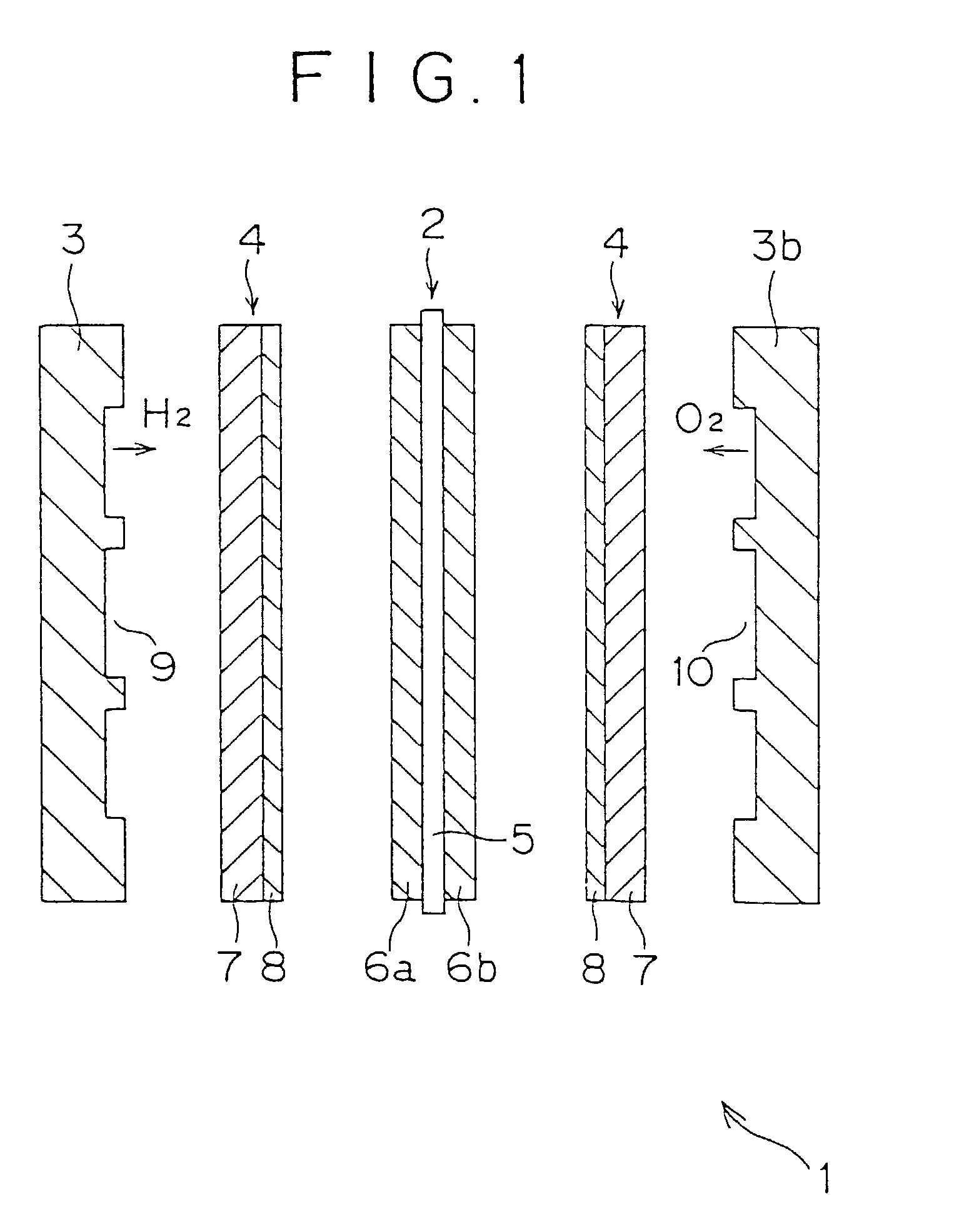

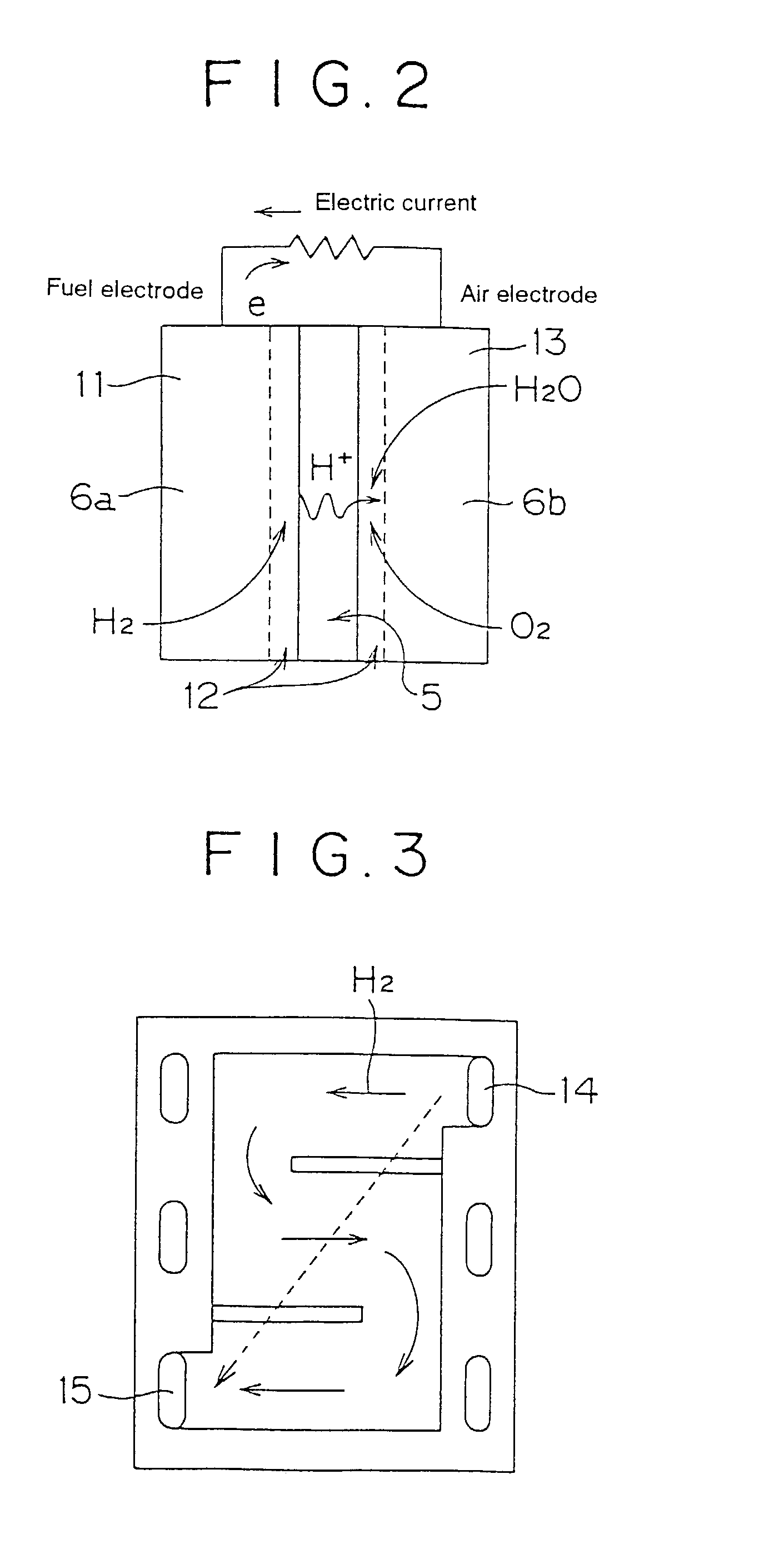

Solid polymer type fuel battery

InactiveUS7001688B2Efficient removalInhibition retentionCell electrodesCell component detailsFuel cellsPhysical chemistry

A polymer electrolyte fuel cell comprising a cell having a solid polymer film, separators disposed on both sides of the cell so as to interpose the cell therebetween, and diffusion layers disposed between the cell and the separators and each having a substrate comprising an electrically conductive porous material and a slurry layer disposed on the substrate, wherein at least a part of each diffusion layer is provided with a gas barrier for preventing the permeation of gas in a direction parallel to the major surface of the diffusion layer.

Owner:MITSUBISHI HEAVY IND LTD

Continuous-casting mold flux for decreasing sticking steel breakouts and preparation method thereof

The invention discloses a continuous-casting mold flux for decreasing sticking steel breakouts and a preparation method thereof. The continuous-casting mold flux for decreasing the sticking steel breakouts comprises the following chemical components of, by weight, 32.5-35.5 percent of SiO2, 29.5-31.5 percent of CaO, 1.5-3.0 percent of MgO, 2.2- 3.0 percent of Al2O3, 0.5-1.5 percent of Fe2O3, 11.0-13.0 percent of Na2O, 10.0-12.0 percent of F-, 3.0-4.0 percent of C solid and the balance unavoidable impurity, wherein the binary basicity is 0.87 to 0.93; a melting point is 1050 to 1070 DEG C; and the viscosity below 1300 DEG C is 0.115Pa*S to 0.135Pa*S. In the practical application of the mold flux, a flame in a crystallizer is uniform; the spreadability is better; caking and agglomerating phenomena do not exist; a melt cinder is stable; the lubrication is sufficient; and the rate of the sticking steel breakouts can be decreased to below 5 percent from original 10 to 20 percent.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com