Vapor-assisted metal micro-droplet manufacturing device and method

A gas-phase assisted and manufacturing device technology, which is applied in the direction of additive processing, can solve the problems of high melting point of metal materials, high surface tension, and difficulty in uniformly reducing the diameter of micro-droplets, and achieve good mechanical properties and uniform metal lattice structure , Improve the effect of precision and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

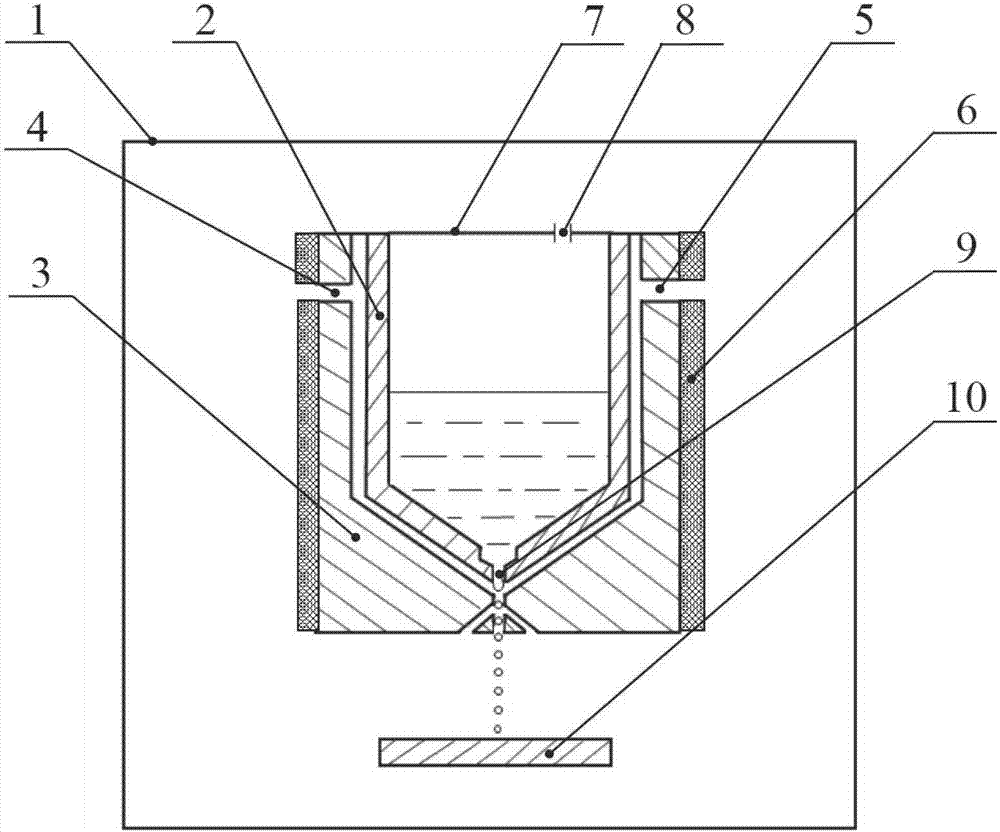

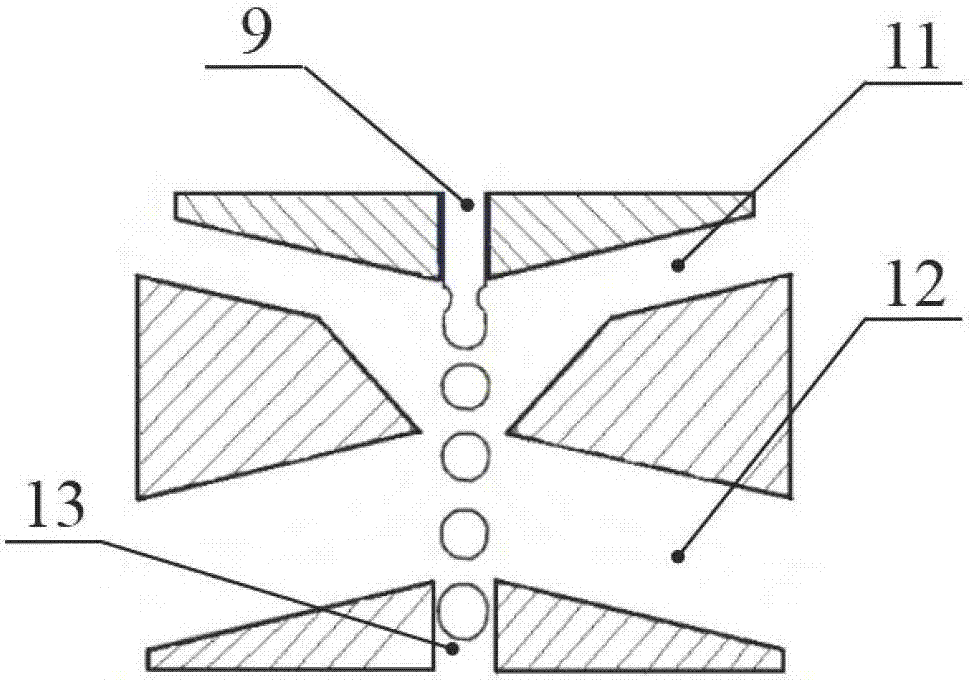

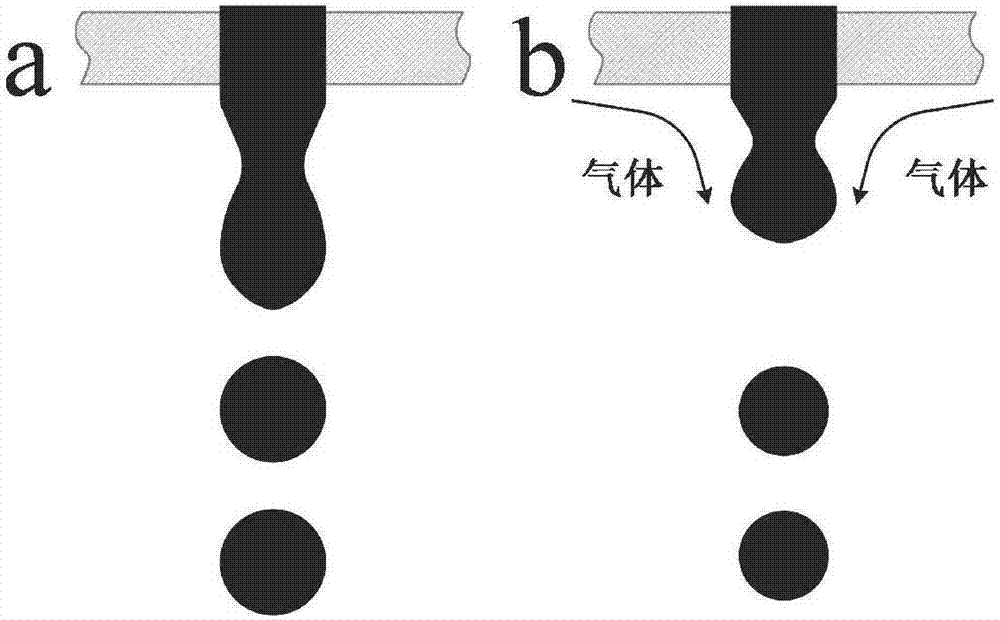

[0012] The working process and effect of a gas-phase assisted metal micro-droplet manufacturing method of the present invention will be described in detail below in conjunction with the structural drawings.

[0013] like figure 1 , figure 2 As shown, the whole device includes a sealed box 1, an inner crucible 2, an outer crucible 3, a first constant pressure gas inlet 4, a second constant pressure gas inlet 5, a heater 6, a sealing plate 7, a pulsating pressure gas inlet 8, and a liquid Outlet 9, droplet deposition platform 10, air inlet channel 11, air leakage channel 12, droplet outlet 13.

[0014] The specific working process of the device is as follows: keep the inside of the sealed box 1 in a closed environment to keep the internal temperature constant, and at the same time be an oxygen-free environment, all filled with inert gas to prevent metal oxidation; the inner crucible 2 stores liquid metal, The top of the inner crucible 2 is sealed by a sealing plate 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com