Preparation method of polyether modified siloxane

A technology of polyether modification and siloxane, applied in chemical instruments and methods, silicon organic compounds, dissolution, etc., can solve problems such as high risk, pollute the environment, affect workers' health, etc., reduce side reactions, and be easy to operate and the effect of controlling and shortening the induction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

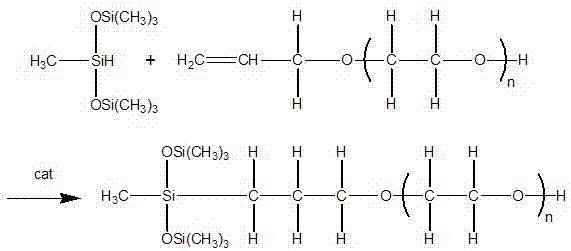

Method used

Image

Examples

Embodiment 1

[0022] Put 550g of allyl-terminated polyoxyethylene ether and 5ml of speier catalyst into a 1000ml four-necked flask equipped with a stirrer and a thermometer. 2 Start stirring under protection, slowly increase the temperature to 90°C, activate at this temperature for 1 hour, and then continuously add 220g heptamethyltrisiloxane dropwise to the system, control the reaction temperature between 100-110°C, and add dropwise After the completion of the reaction for 3-4 hours, continuous sampling is performed for infrared analysis. After the reaction is completed, the catalyst is first adsorbed with activated carbon, and then the by-products are removed by vacuum distillation. Compared with the conventional reaction, the reaction time is shortened by nearly 1 hour. After testing, the result shows that the product content is more than 95%, and the side reactions are greatly reduced, which effectively improves the reaction efficiency.

Embodiment 2

[0024] Add 575g of allyl-terminated polyoxyethylene ether and 5ml of speier catalyst into a 1000ml four-necked flask equipped with a stirrer and a thermometer. 2 Start stirring under protection, slowly increase the temperature to 90°C, activate at this temperature for 1 hour, and then continuously add 220g heptamethyltrisiloxane dropwise to the system, control the reaction temperature between 100-110°C, and add dropwise After the completion of the reaction for 3-4 hours, continuous sampling is performed for infrared analysis. After the reaction is completed, the catalyst is first adsorbed with activated carbon, and then the by-products are removed by vacuum distillation. Compared with the conventional reaction, the reaction time is shortened by nearly 1 hour. After testing, the result shows that the product content is above 96%, and the side reactions are greatly reduced, which effectively improves the reaction efficiency.

Embodiment 3

[0026] Put 620g of allyl-terminated polyoxyethylene ether and 5ml speier catalyst into a 1000ml four-necked flask equipped with a stirrer and a thermometer. 2 Start stirring under protection, slowly increase the temperature to 90°C, activate at this temperature for 1 hour, and then continuously add 220g heptamethyltrisiloxane dropwise to the system, control the reaction temperature between 100-110°C, and add dropwise After the completion of the reaction for 3-4 hours, continuous sampling is performed for infrared analysis. After the reaction is completed, the catalyst is first adsorbed with activated carbon, and then the by-products are removed by vacuum distillation. Compared with the conventional reaction, the reaction time is shortened by nearly 1 hour. After testing, the result shows that the product content is more than 95%, and the side reactions are greatly reduced, which effectively improves the reaction efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com