Green alkali-free liquid concrete setting accelerator and preparation method thereof

A technology of concrete and quick-setting agent, applied in the field of concrete processing, can solve the problems of affecting the health of operators, insufficient concrete strength, and high energy consumption in the production process, and achieve the effects of shortening the setting time, shortening the induction period, and small pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

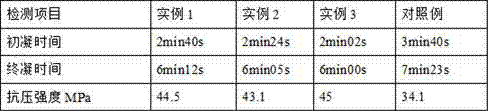

Examples

example 1

[0023] Take 50g of aluminum sulfate, 10g of calcium hydroxide, 3g of organic acid, and 25g of deionized water, put them into a three-neck flask, stir at 300r / min for 1h in a constant temperature water bath at 80°C, and obtain the mother liquor of the quick-setting agent, take 4g of aluminum hexafluoride Add 10g of deionized water, heat to 50°C, stir at 300r / min for 20min, then add 1g of organic alcohol amine, continue stirring for 15min, then drop the accelerator mother liquor at 1mL / min, add 3g of ethyl alcohol after the addition is complete Disodium diamine tetraacetate, heat preservation and stirring at 50°C for 30 minutes, add 0.5 g of stabilizer after cooling to room temperature, and then stir at 200 r / min for 10 minutes to obtain a green alkali-free liquid concrete accelerator.

example 2

[0025] Take 55g of aluminum sulfate, 12g of calcium hydroxide, 4g of organic acid, and 28g of deionized water, put them into a three-neck flask, stir at 350r / min for 1h in a constant temperature water bath at 85°C, and obtain the mother liquor of the quick-setting agent. Take 4g of aluminum hexafluoride Add 11g of deionized water, heat to 55°C, stir at 350r / min for 25min, then add 2g of organic alcohol amine, continue stirring for 18min, then drop the accelerator mother liquor at 1mL / min, add 4g of ethyl alcohol after the dropwise addition Disodium diamine tetraacetate, heat preservation and stirring at 65°C for 35 minutes, add 0.6 g of stabilizer after cooling to room temperature, and then stir at 250 r / min for 15 minutes to obtain a green alkali-free liquid concrete accelerator.

example 3

[0027] Take 60g of aluminum sulfate, 15g of calcium hydroxide, 5g of organic acid, and 30g of deionized water, put them into a three-necked flask, and stir at 400r / min for 2 hours in a constant temperature water bath at 90°C to obtain the mother liquor of the quick-setting agent. Take 5g of aluminum hexafluoride Add 12g of deionized water, heat to 60°C, stir at 400r / min for 30min, then add 3g of organic alcohol amine, continue to stir for 20min, then drop the accelerator mother liquor at 2mL / min, add 5g of ethyl alcohol after the dropwise addition Disodium diamine tetraacetate, heat preservation and stirring at 80°C for 40 minutes, add 0.8 g of stabilizer after cooling to room temperature, and then stir at 300 r / min for 20 minutes to obtain a green alkali-free liquid concrete accelerator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com