Preparation method of low-silicon SAPO-34 molecular sieve

A technology of molecular sieve and silicon source, which is applied in the field of preparation of SAPO-34 molecular sieve, can solve the problems of shortening the induction period, poor repeatability, and difficulty in synthesis, and achieve the effect of shortening the induction period, simplifying the preparation process, and good amplification repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the low-silicon SAPO-34 molecular sieve provided by the present invention is characterized in that it comprises the following steps: (1) according to (0.7~2)P 2 o 5 :(0.01~0.2)SiO2 2 :Al 2 o 3 :(20~100)H 2 The molar ratio of O, mix the silicon source, phosphorus source and aluminum source evenly, and dry to obtain a silicon-phosphor-aluminum dry glue with a solid content of not less than 60%; (2) contact and mix the silicon-phosphorus-aluminum dry glue with a template agent to obtain a mixture , wherein, 1 mole of Al in silicon phosphorus aluminum dry glue 2 o 3 In other words, the amount of template added is 1 to 2.5 moles; (3) the mixture B is placed in a closed reactor to crystallize under autogenous pressure and the product is recovered, wherein the crystallization is from low to high The temperature range is divided into three sections sequentially. The crystallization temperature of the adjacent two sections is different and the cry...

Embodiment 1

[0039] The same proportion and steps as Comparative Example 3, the difference is that the crystallization of the mixture is crystallized in stages, after aging at room temperature for 10 hours, crystallization at 150°C for 10 hours, and crystallization at 200°C for 40 hours, take out the crystallization when the temperature of the reactor drops to room temperature The product, the sample is filtered or centrifuged and washed with deionized water until neutral, the sample is dried in a constant temperature drying oven at 80-120°C, and finally placed in a roasting furnace at a constant temperature of 550°C for 5 hours.

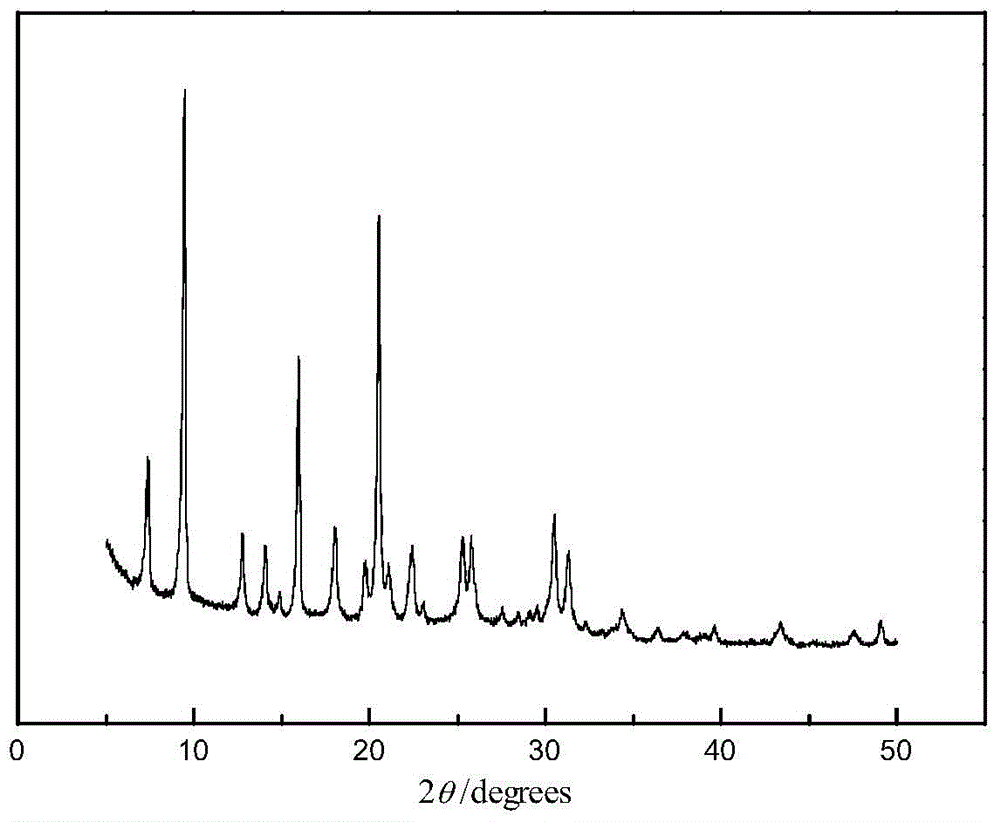

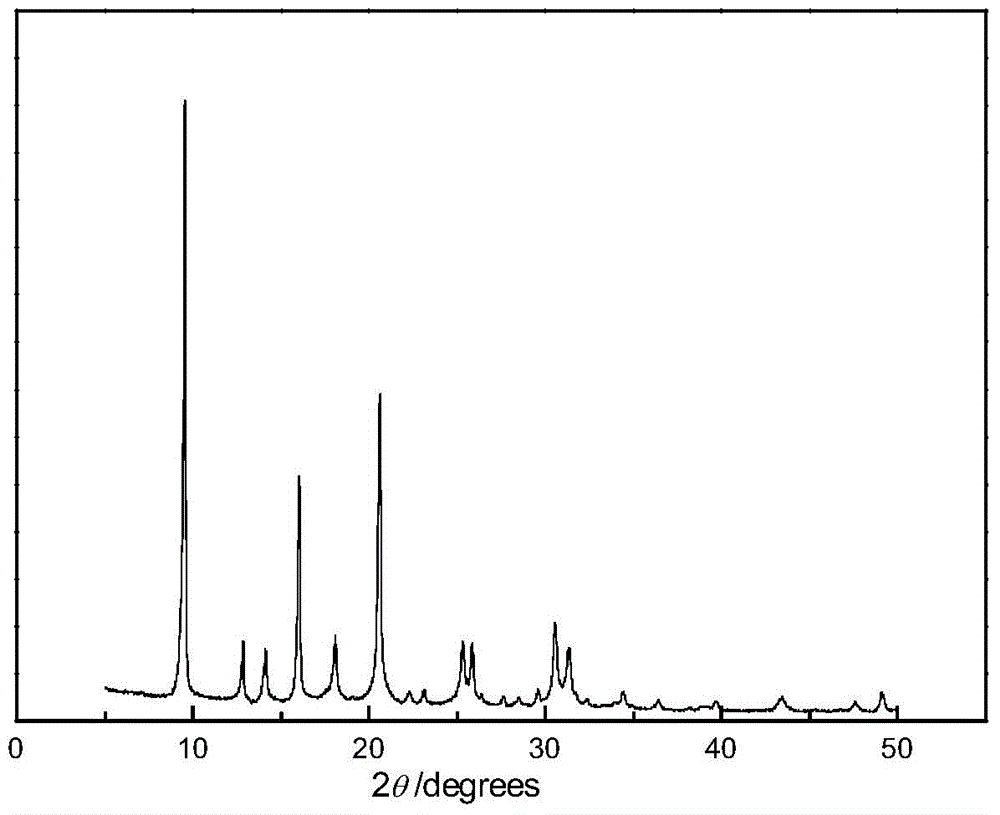

[0040] Gained sample is measured through XRD diffraction and scanning electron microscope, and its XRD diffraction pattern is shown in image 3 , SEM photo see Figure 4 . The XRD spectrum shows that it is a pure-phase SAPO-34 molecular sieve; the SEM photo shows that the grains are regular, the grains are cubic, and the average grain size is 500nm.

Embodiment 2

[0042] Weigh 7g of SB powder and dissolve it in 25g of deionized water, stir rapidly for 1 hour, mix with the solution formed by adding 9.2g of 85% orthophosphoric acid into 30g of deionized water and stir evenly, then add 1g of 30% acidic silica sol, and stir rapidly to obtain a mixture , stirred in a constant temperature water bath at 70°C for 12h, and dried the mixture at 100°C for 24h to obtain a silicon-phosphoraluminum glue with a solid content of 85%.

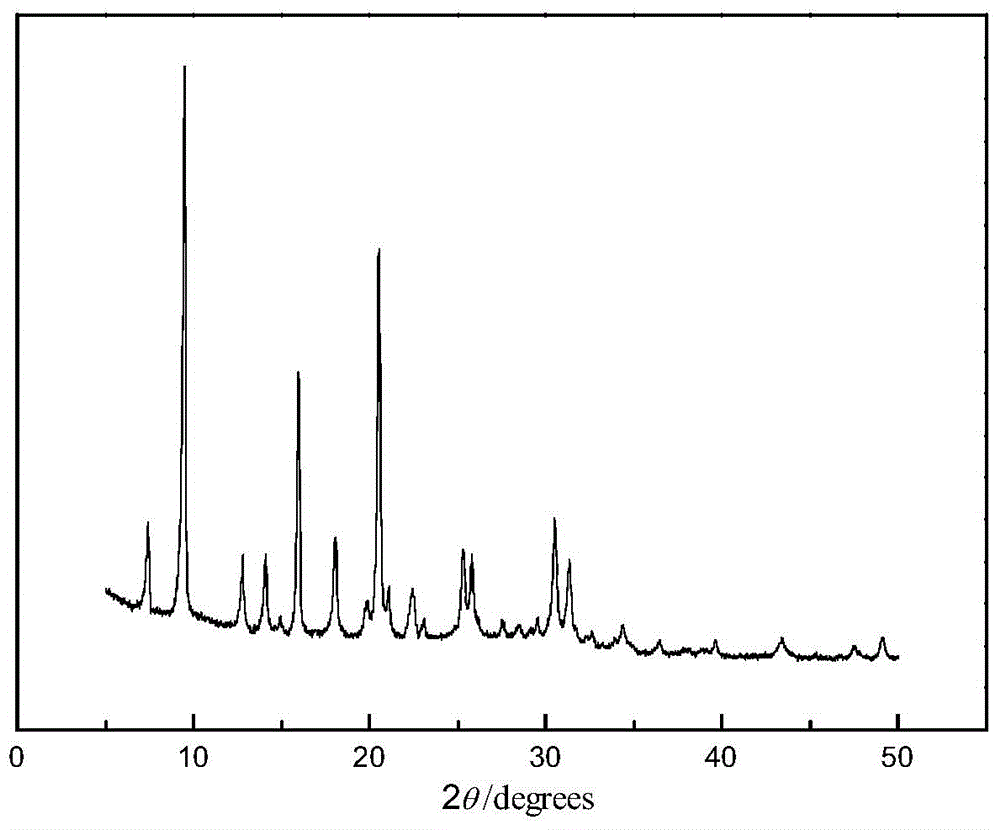

[0043] Transfer the silica-phosphoraluminum glue to a 100 mL stainless steel autoclave, add 27 g of tetraethylammonium hydroxide and 2 g of triethylamine, and stir for 2 h to obtain a mixture. Segmented crystallization: aging at room temperature for 10 hours, crystallization at 150°C for 10 hours, and crystallization at 200°C for 40 hours. When the temperature of the autoclave dropped to room temperature, the crystallized product was taken out, filtered or centrifuged and washed with deionized water until neutral, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com