Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146results about "Alkali metal sulfite/sulfate dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

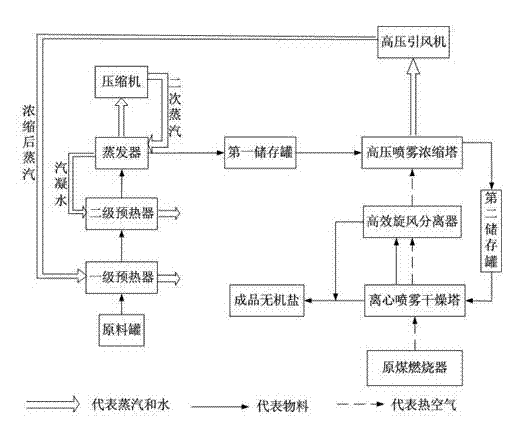

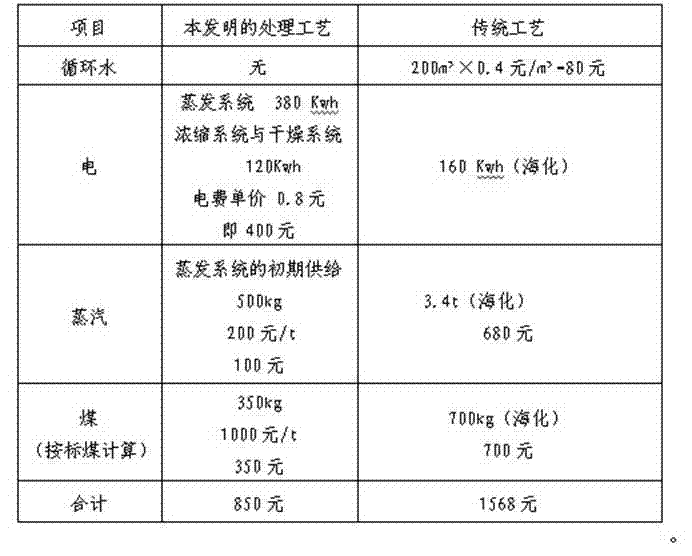

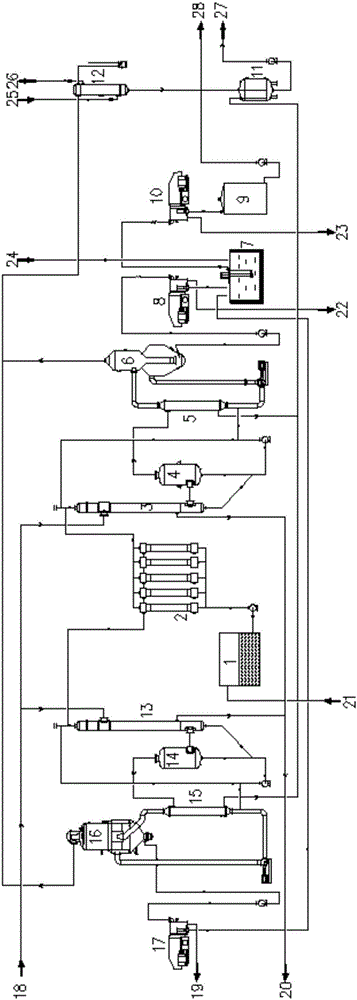

Energy-saving evaporation treatment process of high-salinity wastewater

ActiveCN102964019AStrong adsorption and removal abilityHigh purityCalcium/strontium/barium chloridesMultistage water/sewage treatmentInorganic saltsIndustrial effluent

The invention provides an energy-saving evaporation treatment process of high-salinity wastewater. The energy-saving evaporation treatment process comprises an evaporating system, a concentrating system, a drying system and a heat circulating system. Grading preheating, heating evaporation, adsorption purification, concentration, adsorption purification and high-temperature drying are successively carried out on the high-salinity wastewater treated by a wastewater treatment system to obtain the finished product of inorganic salt, heat exhausted in the evaporation, concentration and drying processes is recycled, and wastewater is discharged. By adopting the technical scheme, wastewater discharged finally meets the national industrial wastewater discharge standard, the purity of the obtained inorganic salt is as high as 99.3%, and the energy-saving effect is remarkable.

Owner:山东大明消毒科技有限公司

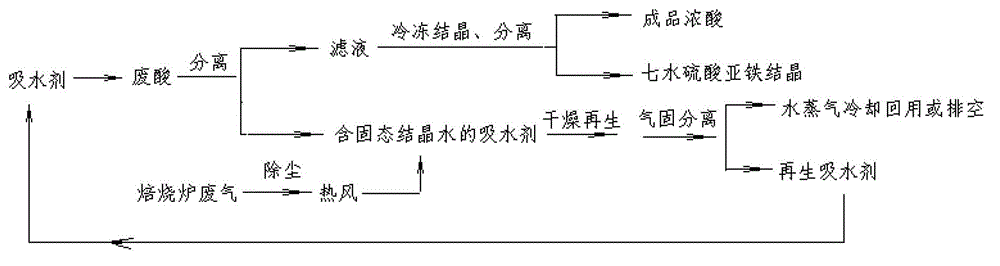

Method for concentrating waste sulfuric acid by utilizing waste heat of titanium dioxide calcinator

InactiveCN102910594ASolve manySolve process problemsSulfur compoundsEnergy inputLiquid waterOperability

The invention discloses a method for concentrating waste sulfuric acid by utilizing waste heat of a titanium dioxide calcinator, comprising the following steps: at normal temperature and pressure, proper amount of water absorbent is added to titanium dioxide waste acid, liquid water is dissolved out in the form of solid crystal water through the water absorbent, filtrate after solid-liquid separation is cooled, iron vitriol in the solution is crystallized and dissolved out, and the acid liquid is further concentrated; the two steps are repeatedly carried out until the concentration of sulfuric acid in the final filtrate reaches more than 60%, and then the final filtrate is utilized in the acid hydrolysis procedure; and the water absorbent is dehydrated and dried to be regenerated by taking dustproof tail gas of the calcinator, and the steam generated in the drying and regeneration is cooled and flows back to technological process as washing water in titanic acid rinsing or is drained. The method provided by the invention solves the problems of more equipment, long flow and easy blockage in the existing technology, and the equipment investment and operating cost are reduced; and the water absorbent is recycled after being regenerated, so that the energy is saved, the consumption is reduced, and the efficiency is obvious; no wastewater, waste gases and residues are generated in the whole technology, the operability is strong, the productivity of equipment is high, the flow is simple, the investment is less, the cost is low, energy is saved, emission is reduced, and the benefit is obvious.

Owner:黄正源

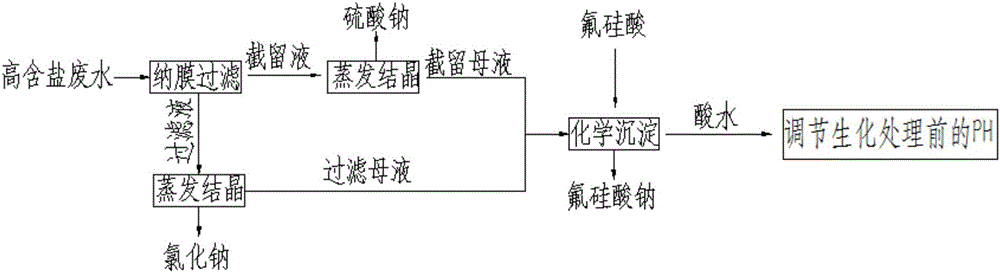

Recycling method for high-salinity wastewater containing sodium chloride and sodium sulfate

InactiveCN105110536AReduce processing costsRealize resource utilizationWater/sewage treatment by centrifugal separationWater contaminantsAcid waterWastewater

The invention discloses a recycling method for high-salinity wastewater containing sodium chloride and sodium sulfate and belongs to the field of wastewater treatment. The method comprises: filtering wastewater through a nanofiltration membrane; performing evaporative crystallization on filtrate through the nanofiltration membrane to obtain sodium chloride and filtered mother liquor; performing evaporative crystallization on retained liquor which does not pass through the nanofiltration membrane to obtain sodium sulfate and retained mother liquor; mixing the filtered mother liquor with the retained mother liquor to obtain a mixture and adding fluosilicic acid into the mixture; and stirring sufficiently the mixture to obtain sodium fluosilicate by filtering. Filtered acid water is used in pH value adjustment of a system before biochemical treatment.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

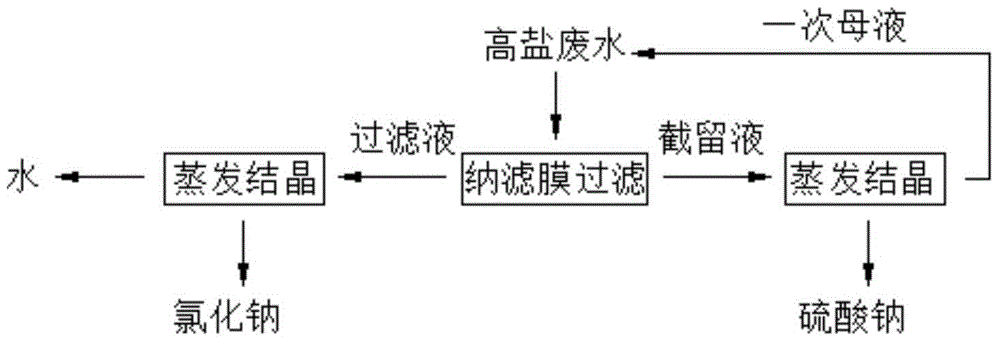

Method for recycling high-salt waste water containing sodium chloride and sodium sulfate

InactiveCN104961285AHigh purityMeet quality requirementsAlkali metal sulfite/sulfate purificationEnergy based wastewater treatmentIndustrial waste waterNanofiltration

The invention discloses a method for recycling high-salt waste water containing sodium chloride and sodium sulfate, and belongs to the field of industrial waste water treatment. The method comprises the steps of filtering by a nanofiltration membrane, evaporating and crystallizing filtrate penetrating through the nanofiltration membrane to obtain sodium chloride, evaporating and crystallizing trapped fluid which cannot penetrate through the nanofiltration membrane to obtain sodium sulfate, returning a primary mother solution to the system, and mixing the primary mother solution with raw materials to be continuously recycled. By adopting the method, sodium sulfate and sodium chloride in the high-salt waste water can be effectively recycled, a purpose of treating the high-salt waste water can be realized, and the current environmental-protection demand can be satisfied, waste can be converted into treasure, the recycling of salts can be realized, and the benefit of factories can be increased.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

Technology for realizing zero discharge of waste water caused by white carbon black production

InactiveCN103482809ALow running costRealize cleaner productionMultistage water/sewage treatmentAlkali metal sulfite/sulfate dehydrationReverse osmosisEvaporation

The invention discloses a technology for realizing zero discharge of waste water caused by white carbon black production. The technology is characterized by comprising the steps: 1, firstly, filtering the waste water caused by white carbon black production by a ceramic membrane to obtain ceramic membrane dialyzate and ceramic membrane concentrated liquid; 2, carrying out plate-frame pressure filtration on the ceramic membrane concentrated liquid to obtain filter residue which is silicon dioxide, recycling the silicon dioxide, enabling filter press water to enter a collecting tank and carrying out circulating treatment on the filter press water; 3, carrying out primary nanofiltration on the ceramic membrane dialyzate, collecting primary nanofiltration concentrated liquid to obtain sodium sulfate concentrated liquid, and carrying out evaporation and concentration to obtain sodium sulfate; and 4, carrying out primary reverse osmosis on primary nanofiltration dialyzate to obtain primary reverse osmosis dialyzate and primary reverse osmosis concentrated liquid, and carrying out evaporation and concentration on the primary reverse osmosis concentrated liquid to obtain sodium sulfate, wherein the primary reverse osmosis dialyzate is produced water and is recycled for white carbon black production. The technology has the beneficial effects that the operation cost is low; inorganic salts and water resources can be recycled, and zero discharge and a win-win situation of environmental protection benefit and economic benefit can be realized.

Owner:XIAMEN STARMEM TECH

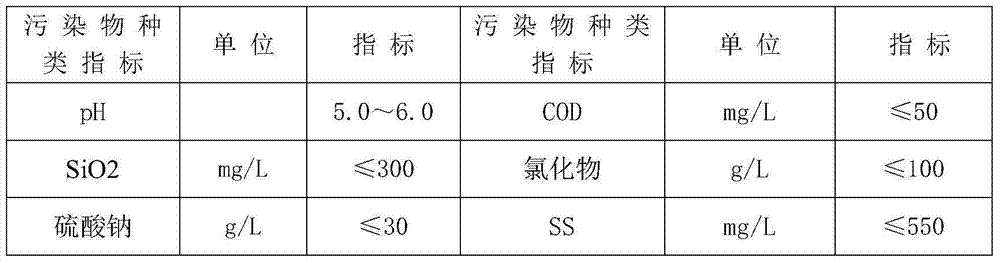

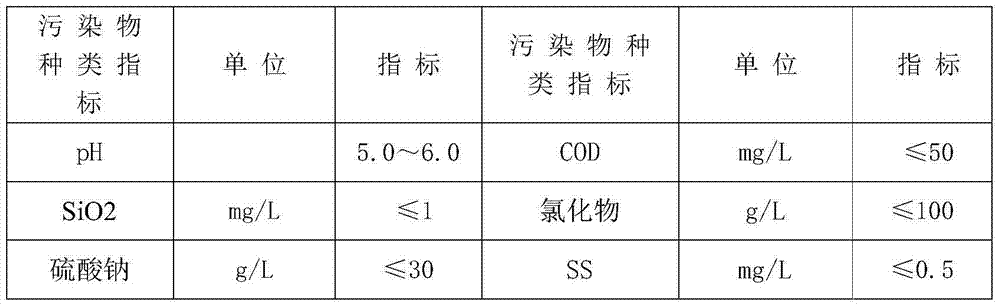

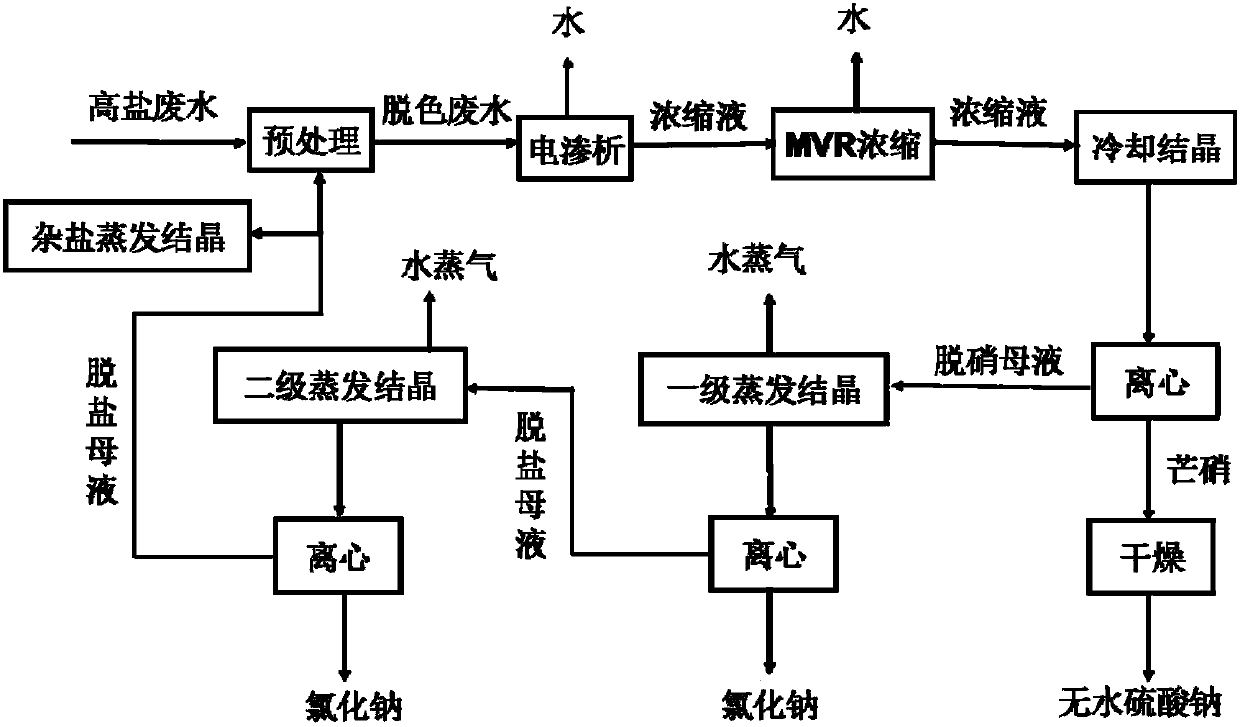

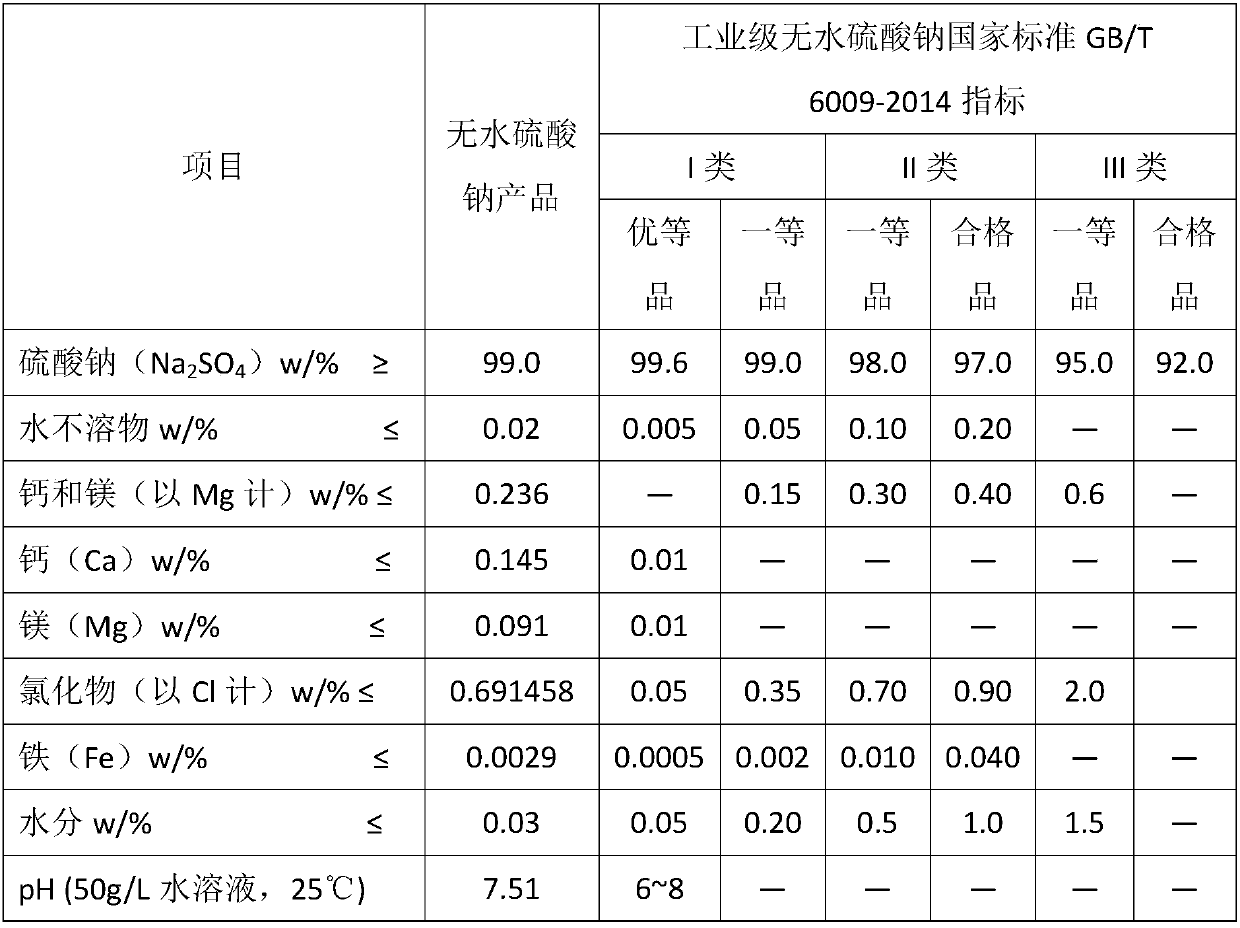

Separate crystallization method for extracting recyclable high-purity sodium sulfate and sodium chloride from high-salinity wastewater

ActiveCN107867707AAchieve zero discharge treatmentReduce processing costsWater contaminantsMultistage water/sewage treatmentActivated carbonEvaporation

The invention relates to a separate crystallization method for extracting recyclable high-purity sodium sulfate and sodium chloride from high-salinity wastewater. Activated carbon is adopted for decolorization pretreatment, the COD can be significantly reduced, and insoluble impurities and soluble substances such as Ca<2+>, Mg<2+>, silicate and the like can be removed simultaneously; after pretreatment, the wastewater is sent to electrodialysis and mechanical steam recompression devices sequentially for concentration, and sodium sulfate and sodium chloride are approximately saturated through concentration according to the initial composition of sodium sulfate and sodium chloride in the wastewater; the concentrated wastewater is sent to a crystallizer, sodium sulfate is obtained cooling crystallization, directly extracted, washed and dried, and an anhydrous sodium sulfate product is obtained; a concentrated solution of denitration mother liquor is subjected to two-stage evaporative crystallization, and the sodium chloride product is directly extracted, washed and dried; part of mother liquor obtained after two-stage evaporation salt removal returns to the system and is mixed with fed wastewater to be recycled, the rest mother liquor is sent to a mixed salt evaporative crystallizer. The sodium sulfate and sodium chloride products reaching the national standard are obtained.

Owner:TIANJIN UNIV

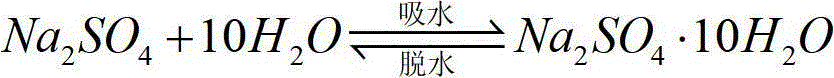

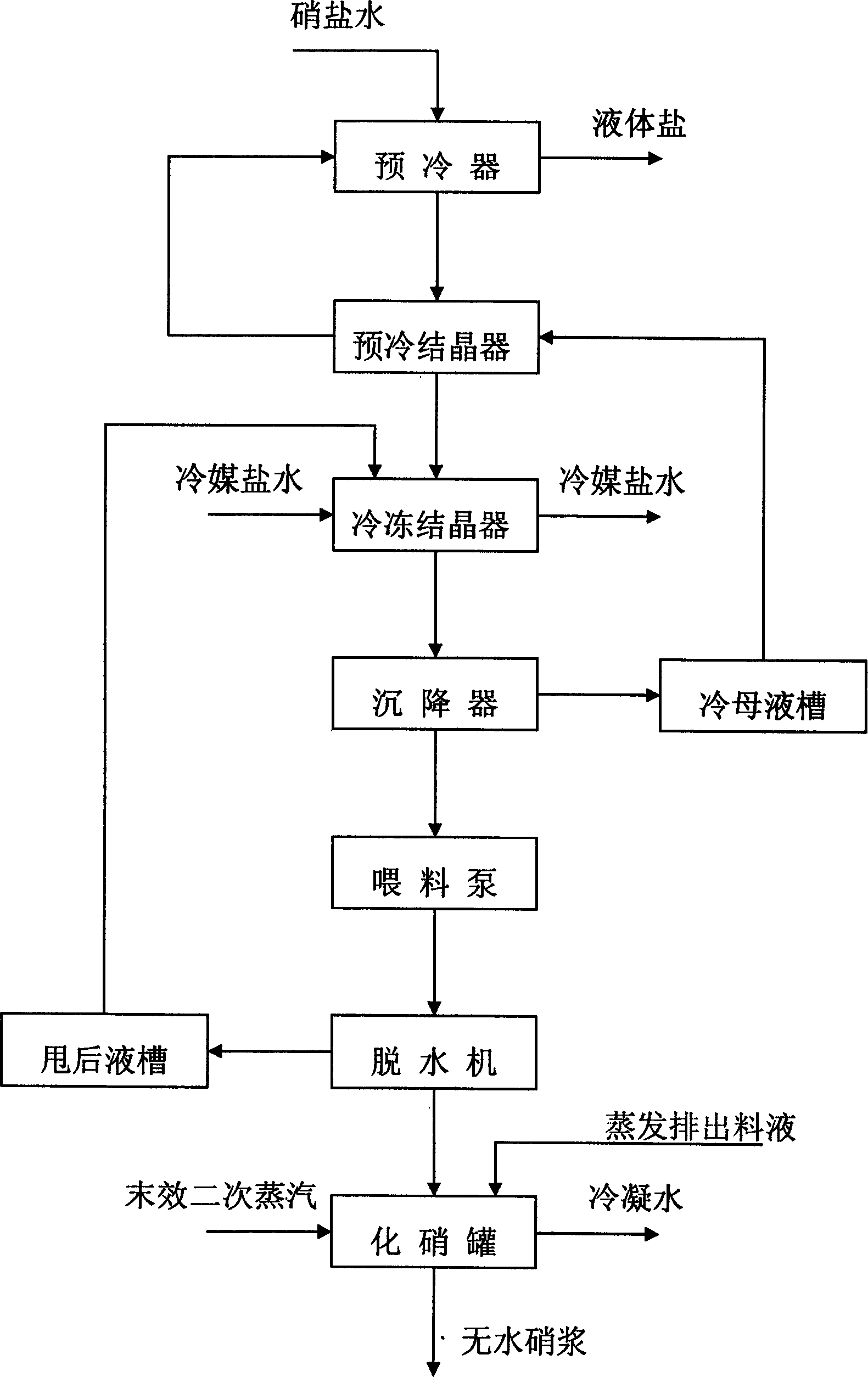

Process for preparing anhydrous mirabilite by freezing method

ActiveCN1837050AEasy to operateReasonable heat transfer temperature differenceChemical industryAlkali metal sulfite/sulfate dehydrationMirabiliteSodium sulfate

The invention discloses a new technics about the production of freezing method absolute nitrate, containing steps as follows: getting the solution contains saltpeter across precooler to doing coolant elementary cooling by cold mother liquor; switching the feed liquid from precooler to precooler crystallizer; adding the feed liquid from precooler crystallizer in cooler crystallizer to freeze the feed liquid to -5-7Deg C for the saltpeter separating of second phase refrigeration; Adding the feed liquid from cooler crystallizer in depressor for solid-liquid separation; passing the discharged sodium sulfate from precooler through screw pump to feed the dewatering machine; putting the dewatered sodium sulfate in saltpeter melting tank, mixing with the swinged liquid of evaporate discharged feed liquid or absolute nitrate plasm, making sodium sulfate autolyze by end effect quadratic steam heating. In the saltpeter melting procedure of this method, adopting hot material and sodium sulfate mixing melt saltpeter, at the same time, using low-grade second steam heat energy heat up the feed liquid, compared to the former pervaporation, this method is more reasonable, energy saving and ensure the quality of product.

Owner:ENG TECH INST CO LTD OF CNSIC

Method for recovering sulfate radicals from dechlorinated light salt brine to prepare anhydrous sodium sulfate

InactiveCN102515207ASolve the large consumptionSolve equipment corrosionAlkali metal sulfite/sulfate dehydrationSulfate radicalsCentrifugation

Owner:YIBIN TIANYUAN GRP CO LTD

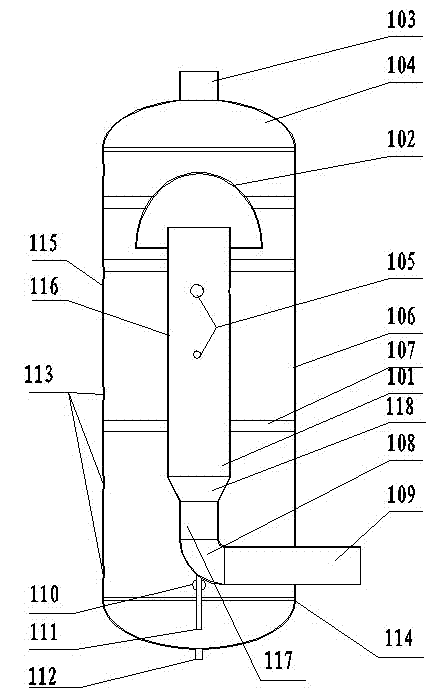

Process and device for producing pyrotechnite from sodium sulfate decahydrate

ActiveCN101966997AReduce evaporation energy consumptionShort processAlkali metal sulfite/sulfate dehydrationMelting tankEvaporation

The invention relates to a process and a device for producing pyrotechnite from sodium sulfate decahydrate. The process comprises the following steps of: (1) putting the sodium sulfate decahydrate into a hot melting tank for hot melting to form solution of sodium sulfate; (2) heating the solution of sodium sulfate, conveying the solution of sodium sulfate to an evaporator, concentrating and evaporating the solution of sodium sulfate, and crystallizing and precipitating part of anhydrous sodium sulfate; (3) compressing secondary steam of the evaporator, conveying the compressed steam to a heating chamber of the evaporator; and (4) performing solid-liquid separation on the dissolved solution of sodium sulfate to obtain solid anhydrous sodium sulfate, and drying, weighing and packaging. The device comprises the heat melting tank, a liquor storage tank, a feed delivery pump, a heat exchanger and the evaporator which are connected sequentially, wherein the evaporator is sequentially connected with a centrifugal machine, a mother liquor tank, a mother liquor pump and a feed inlet of the evaporator; and the evaporator is provided with a vacuum pump, and a steam outlet of the evaporator is connected with a separator, a compressor and the heating chamber of the evaporator. In the process and the device, the sodium sulfate decahydrate is subjected to melting evaporation through the technology of steam compression, so the evaporating energy consumption can be reduced, and the purity of products can reach over 99 percent; and the process and the device require investments, are high in economic benefits and save energy greatly.

Owner:江苏瑞能防腐设备有限公司

Battery-grade lithium hydroxide monohydrate production process applying novel combined calcium removal

PendingCN110950363AReduce contentSulfate/bisulfate preparationAlkali metal sulfite/sulfate dehydrationPhysical chemistryProcess engineering

The invention discloses a battery-grade lithium hydroxide monohydrate production process applying novel combined calcium removal. The battery-grade lithium hydroxide monohydrate production process comprises the following steps: (1) sequentially calcining, cooling, and finely grinding spodumene, adding an acid for reaction, and then, carrying out size mixing; 2) adding a calcium salt into an obtained slurry, stirring and leaching; 3) filtering an obtained filtered clear liquid again, and purifying the filtered clear liquid by using an alkaline solution; 4, filtering a solution obtained throughcausticization in the former step; 5) freezing a filtered causticized solution in a refrigeration workshop to separate out sodium sulfate decahydrate and a lithium hydroxide solution; and 6) evaporating, concentrating and purifying sodium sulfate decahydrate. The production process can reduce calcium using amount effectively, is excellent in calcium removing effect, and can reduce product calciumcontent.

Owner:广西雅保锂业有限公司

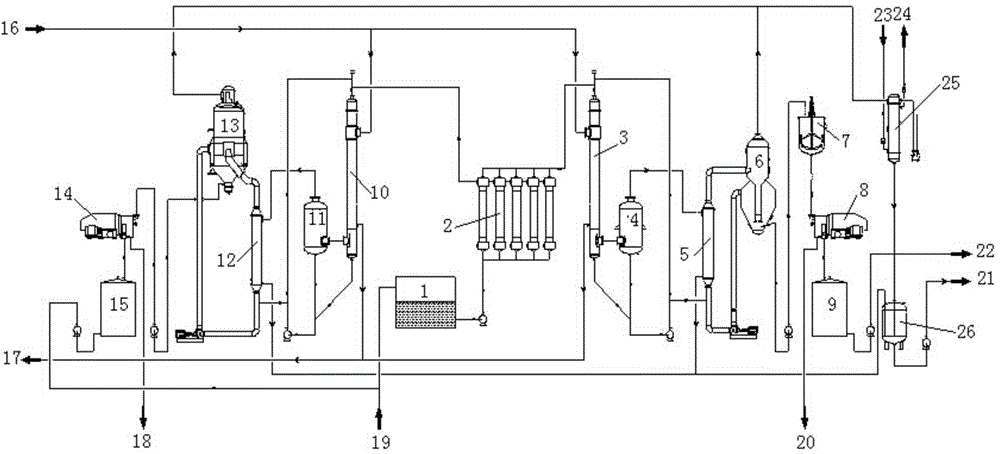

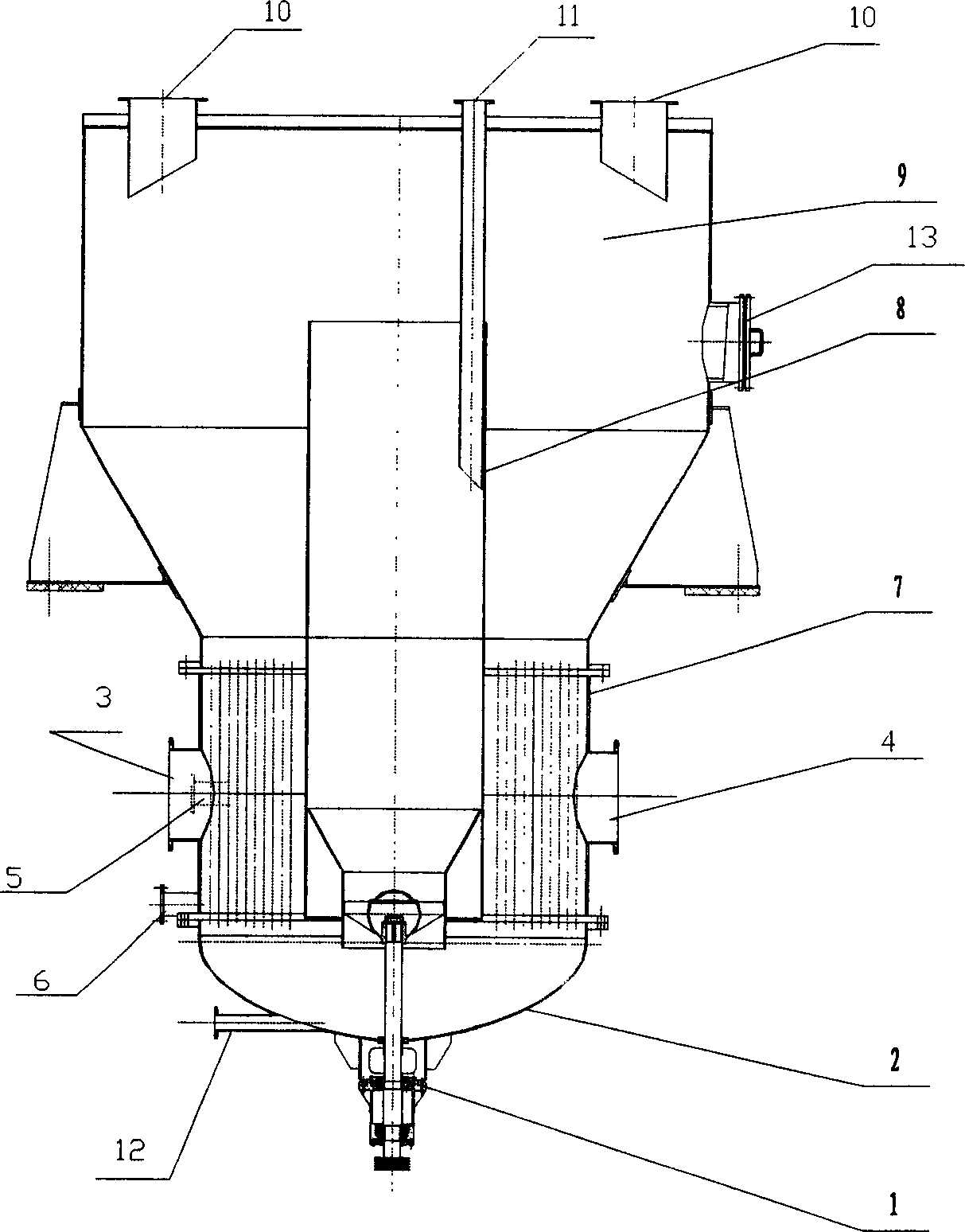

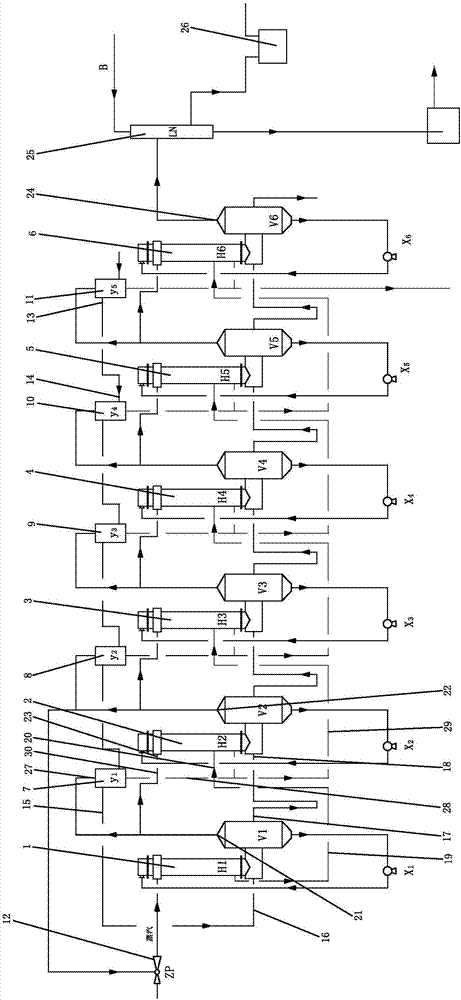

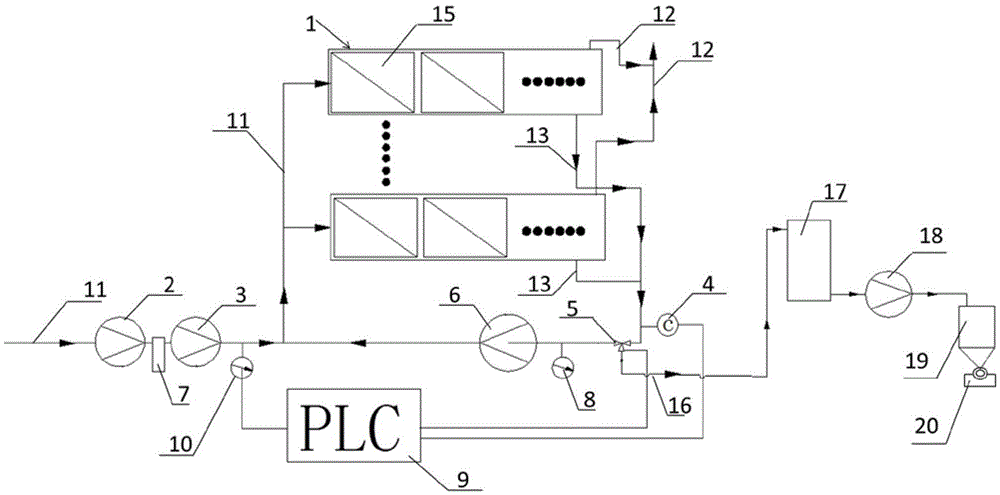

Multi-effect evaporation concentration technology, multi-effect evaporation crystallization technology and multi-effect evaporation concentration device of solution containing sulfuric acid and sulfate

The invention discloses a multi-effect evaporation concentration technology, a multi-effect evaporation crystallization technology and a multi-effect evaporation concentration device of a solution containing sulfuric acid and sulfate. The technologies and the device are characterized in that low-temperature-difference heat transfer flow evaporation is adopted; step-by-step secondary steam series preheating is adopted; an acid bath is led as an evaporation crystallization carrier; and last-effect or last-two-effect evaporation crystallization is adopted. The evaporation concentration and crystallization device mainly comprises (1-n)-effect evaporation crystallizers, (1-n)-effect circulating pumps, 1-(n-1)- or 1-(n-2)-stage preheaters, condensers and vacuum devices. According to the technologies and the device, a steam-water ratio of acid bath 5-7-effect evaporation crystallization reaches an advanced level of 0.17-0.19; a steam-water ratio of acid water and two-bath 6-8-effect evaporation crystallization reaches an advanced level of 0.13-0.15; a steam-water ratio of a low-concentration acid water 7-9-effect evaporation concentration device can further reach an advanced level of 0.09-0.11, but the state-of-the-art steam-water ratio of 16-stage flash evaporation crystallization is 0.255 in the current industry.

Owner:许达人 +1

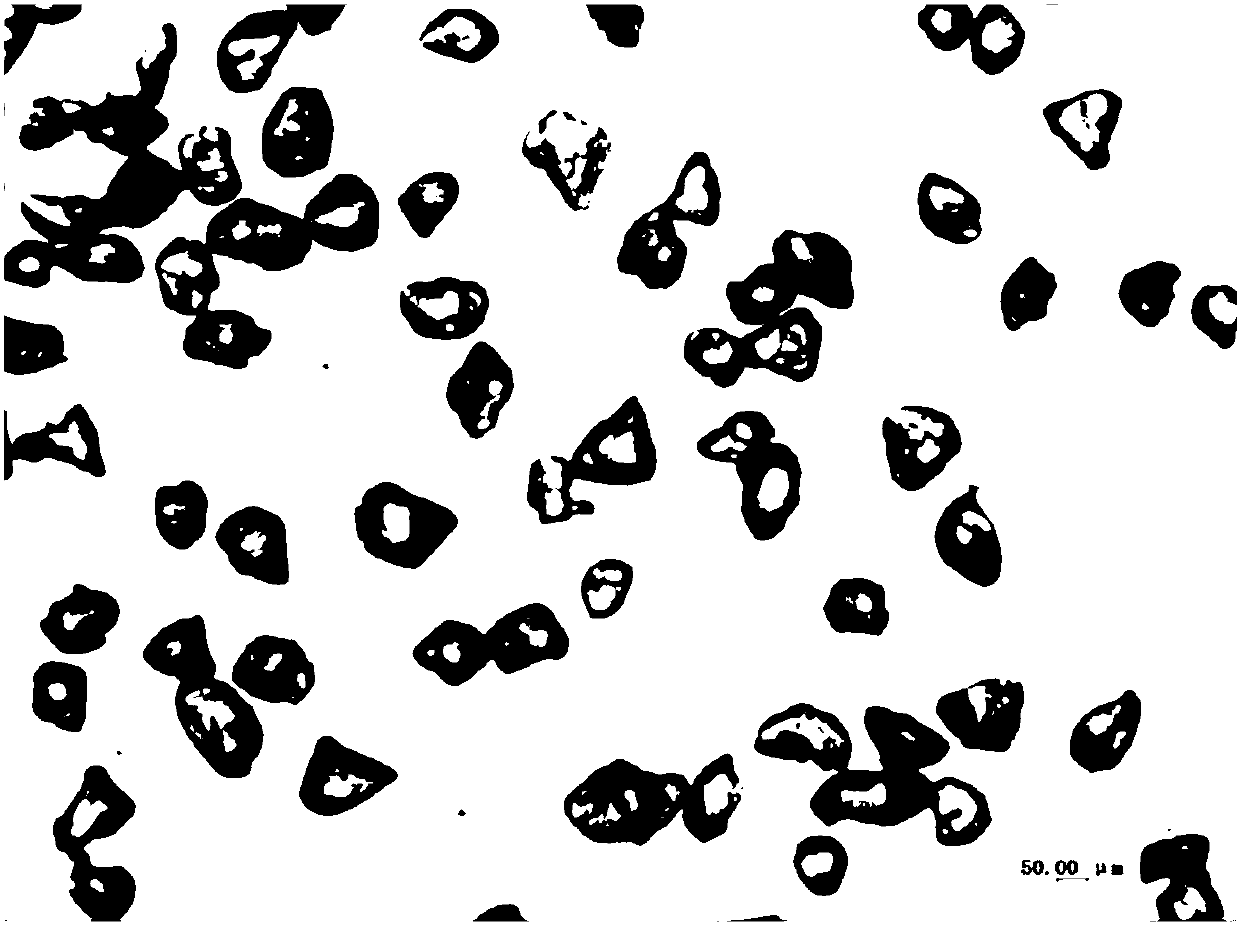

Production method of anhydrous sodium sulfate and production equipment thereof

The invention provides a production method of purely-natural anhydrous sodium sulfate with a pH value being 6 to 8 and production equipment thereof. The production method of the anhydrous sodium sulfate disclosed by the invention comprises the following steps of: (1) purifying a sodium-sulfate aqueous solution; (2) preparing sodium sulfate decahydrate through the saturated crystallization of the sodium-sulfate aqueous solution at the temperature of 32.4 DEG C; (3) melting the sodium sulfate decahydrate in a melting tank; and (4) washing anhydrous sodium-sulfate crystals, concentrating the anhydrous sodium-sulfate crystals in a concentrator, and then dewatering and drying through a centrifugal machine to obtain the anhydrous sodium sulfate. Because two-time crystallization is adopted and no other chemical reagent is added in the production method of the anhydrous sodium sulfate and the production equipment of the production method, the produced industrial anhydrous sodium sulfate is natural, the content of Na2SO4 in a product is larger than 99.80wt%, the pH value is 6 to 8, and the product with the granularity D50 being 70-1200mu m can be produced.

Owner:HUNAN HENGYANG XINLI CHEM

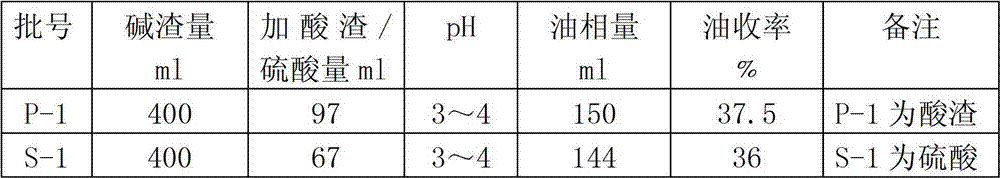

Comprehensive utilization method of catalytic cracking gasoline sludge

ActiveCN102786176AReduce the possibility of oxidative deteriorationLess investmentOrganic chemistryOrganic compound preparationSludgeOil phase

The invention discloses a comprehensive utilization method of catalytic cracking gasoline sludge. The invention relates to the comprehensive utilization method of a gasoline sludge resource. The main contents are as follows: firstly neutralizing gasoline sludge by sulfuric acid alkylation acid sludge, carrying out oil-water separation on a neutralized product to form an oil phase and a water phase; respectively carrying out constant-pressure or moderate vacuum distillation on black brown oil phase with malodor to obtain bright light oil without malodor and crude phenol; naturally evaporating the water phase to separate out sodium persulfate crystal, and carrying out processes such as recrystallization on crystal sodium sulfate, and finally obtaining fine powder feed-level sodium sulfate by forcibly airing and baking the crystal sodium sulfate.

Owner:LANZHOU KANGSHUN PETROCHEM

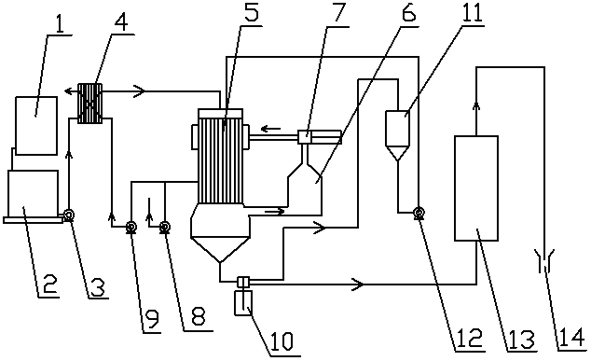

Anhydrous sodium sulfate production system and production method

ActiveCN103241749AReduce manufacturing costImprove economyAlkali metal sulfite/sulfate purificationSolution crystallizationFluidized bedEvaporation

The invention discloses an anhydrous sodium sulfate production system and a production method and aims to solve the problems that the conventional anhydrous sodium sulfate is high in production cost and low in production quality. The anhydrous sodium sulfate production system comprises a multistage reduction tower, a neutralization reaction kettle, a flocculent precipitate tank, a crystallizing tank and a vapor compressor, wherein evaporation and crystallization are finished in one unit; the chromium salt denitration liquid is subjected to reduction, neutralization reaction, flocculent precipitate and multistage filtering and is pumped into the evaporation and crystallization system, the crystal product is discharged and is pumped into a centrifugal machine through a crystal slurry pump, the centrifuged crystal product is fed into a fluidized bed dryer through a spiral conveyer, and the dried finished product enters a storage bin and is packaged. The anhydrous sodium sulfate granules can be effectively and freely controlled, and the technical problems that the anhydrous sodium sulfate is high in production cost, the evaporator is short in operation cycle and bad in heat exchange effect are solved.

Owner:GANSU LANPEC TECH +3

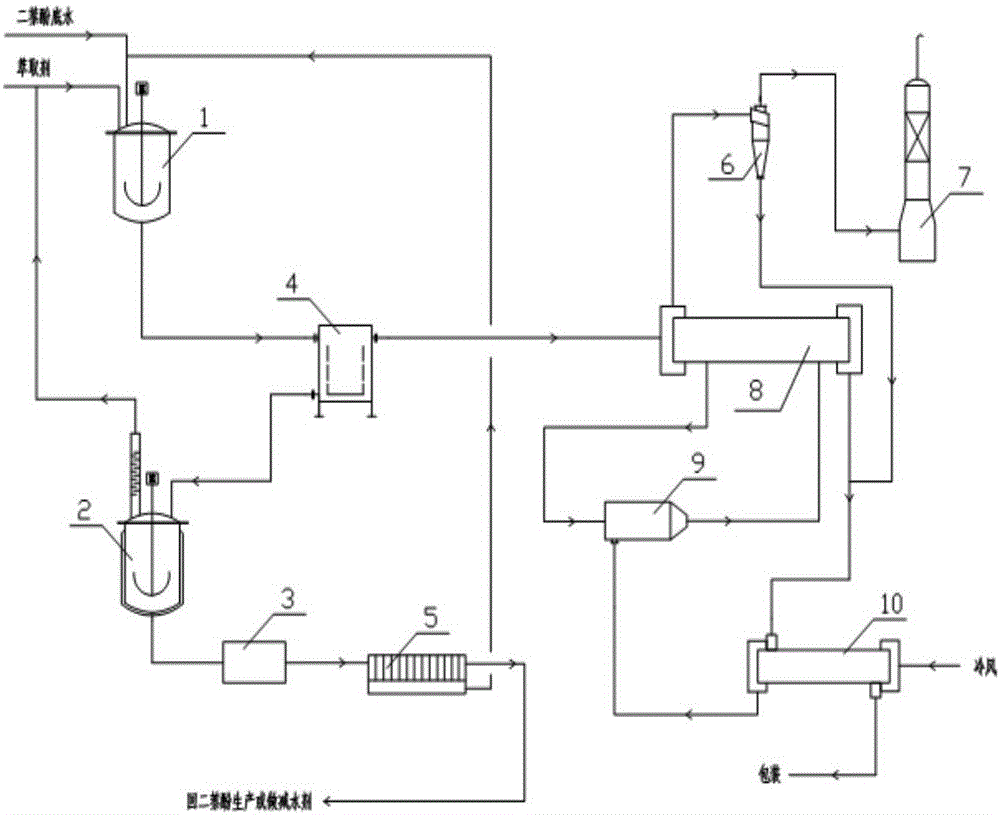

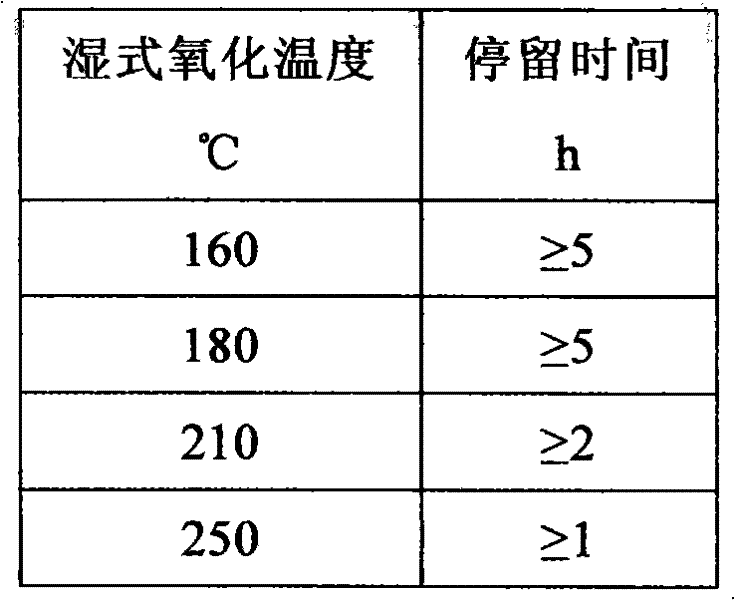

2-naphthol high-salt and high-concentration organic matter wastewater recycling process and system

ActiveCN105967415AEase of industrial implementationGood technical and economic effectOrganic chemistryOrganic compound preparationHigh concentrationSulfite salt

The invention discloses a 2-naphthol high-salt and high-concentration organic matter wastewater recycling process and system; an extraction crystallization process is designed for recovery naphthalenesulfonate for reuse production; organic compounds are oxidized at high temperature for producing anhydrous sodium sulfate for sale, tail gas is absorbed for producing sodium sulfite for circular use in 2-naphthol production; all components of 2-naphthol wastewater are recycled with low cost, zero emission of pollutants is realized, and the method is a currently reasonable recycling process for the 2-naphthol high-salt and high-concentration organic wastewater, and at the same time, the system for realizing the process is designed. The process and the system have popularization value for recycling disposal of the high-organic-matter wastewater, and have great economic and social effects.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +2

Method for preparing industrial anhydrous sodium sulfate

InactiveCN102001690ASave energyReduce manufacturing costAlkali metal sulfite/sulfate purificationAlkali metal sulfite/sulfate dehydrationHigh sodiumChemical industry

The invention relates to a method for preparing industrial anhydrous sodium sulfate in the technical field of the chemical industry, in particular to a method for preparing industrial anhydrous sodium sulfate from sodium sulfate containing waste liquor which is from the preparation of white carbon black by utilizing a sulfate precipitation method. By adopting the process of distilling and concentrating the waste liquor in one step, the invention uses suitable organic small-molecule alcohol to prepare the industrial anhydrous sodium sulfate through the supersaturated precipitation of the sodium sulfate contained in the waste liquor which is from the preparation of the white carbon black by using the sulfate precipitation method, not only has simple process steps, but also has high sodium sulfate recovery. The invention opens up an effective path for obtaining a sodium sulfate product with less impurity content, high quality, small water content, and the like. Raw material adopted by the method of the invention is the waste liquor which is rich in the sodium sulfate and is from the preparation of the white carbon black by using the sulfate precipitation method so that the production cost is decreased, the problem of environmental pollution caused by the emission of the waste liquor is lessened, and the production process has characteristics of energy saving and environment protection.

Owner:陈君华

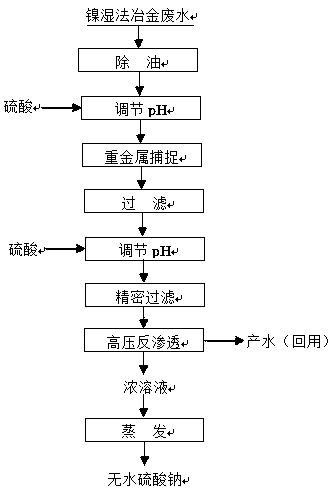

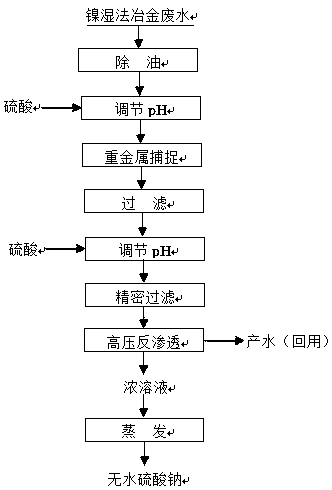

Zero-emission process of nickel hydrometallurgy wastewater containing heavy metals, oil and high-concentration mixed salts

ActiveCN109987742AAchieve separationHigh separation precisionFatty/oily/floating substances removal devicesWater contaminantsHigh concentrationEvaporation

The invention discloses a zero-emission process of nickel hydrometallurgy wastewater containing heavy metals, oil and high-concentration mixed salts. The wastewater contains the heavy metals, the high-concentration mixed salts (carbonates and sulfates) and a small amount of oil substances (solvent oil and an extracting agent). The method comprises the following steps: firstly, removing oil by carrying out adsorption by special resin, then preliminarily adjusting the pH value of the wastewater, removing heavy metal ions which are mainly nickel ions in the wastewater through a heavy metal capturing agent, removing precipitations, adjusting the pH value of the wastewater to be acidic to completely convert the carbonates in the wastewater into sulfates, then carrying out precise filtering to remove insoluble fine particles in the wastewater to obtain a relatively pure sodium sulfate solution, finally, concentrating the wastewater by high-pressure reverse osmosis, reusing the water producedby a membrane for production, and recovering anhydrous sodium sulfate from the obtained concentrated brine by mechanical vapor recompression (MVR) or multi-effect evaporation. According to the invention, the treatment problem of the nickel hydrometallurgy wastewater which has a complex system and contains heavy metals, high-concentration composite salts and a small amount of oil is effectively solved, and meanwhile, recycling and zero emission of the salts in the wastewater are realized.

Owner:HOHAI UNIV

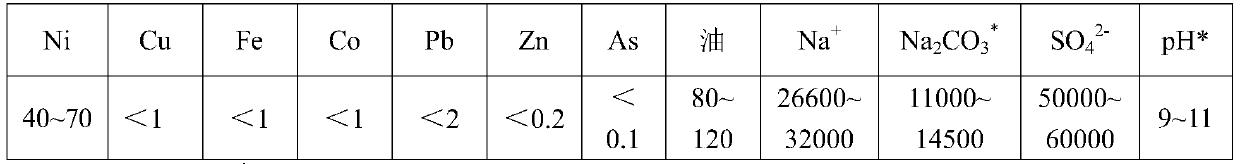

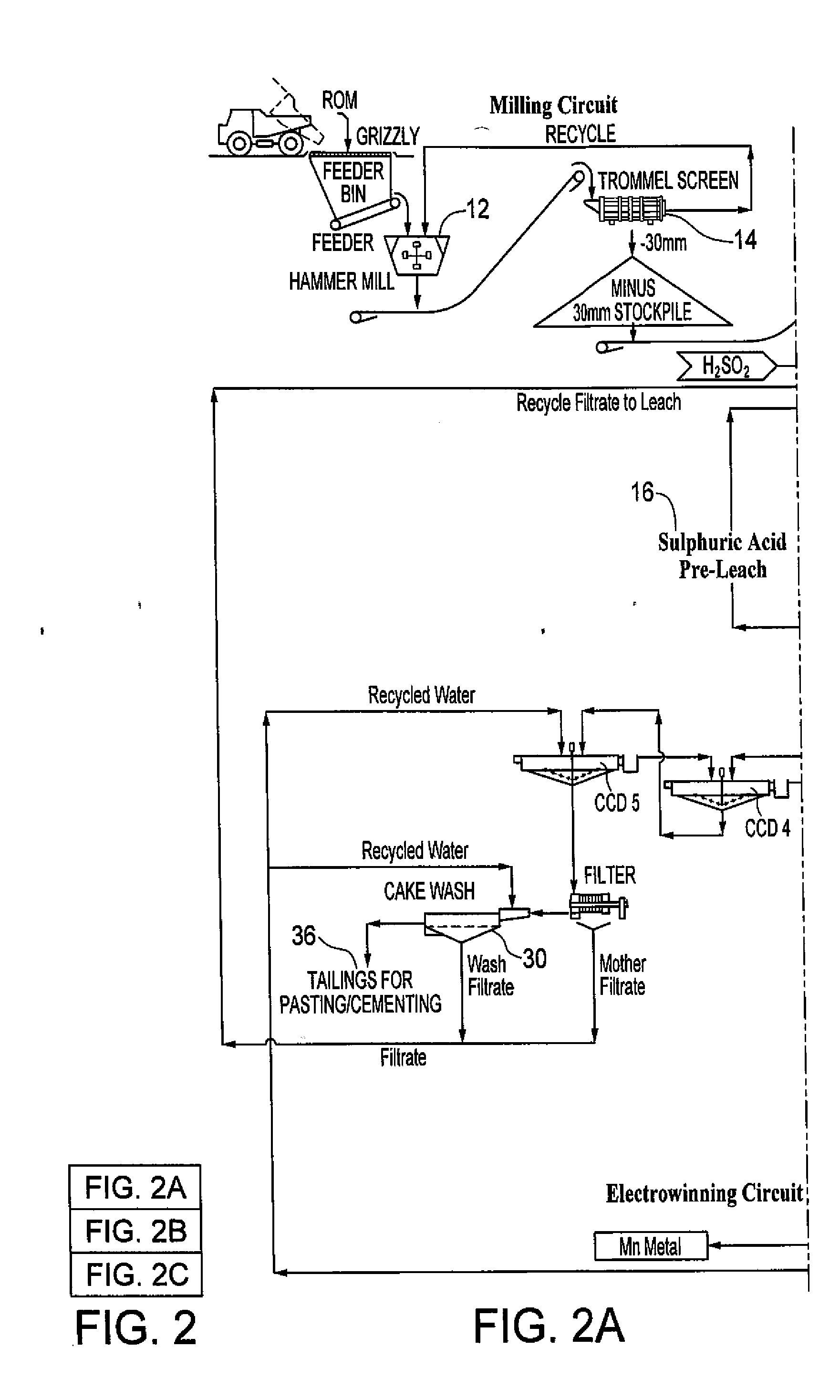

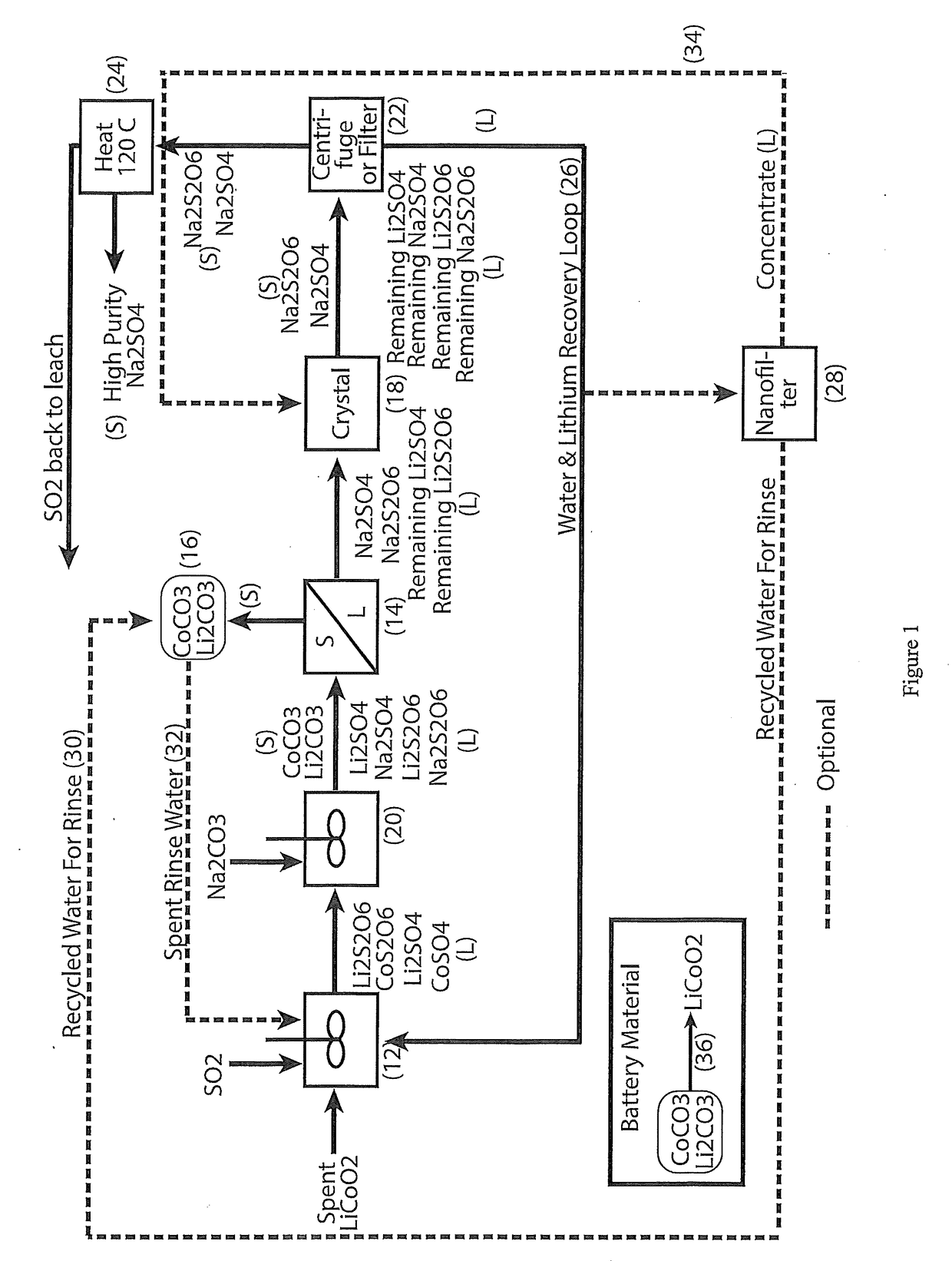

Processing of manganous sulphate/dithionate liquors derived from manganese resource material

ActiveUS20120207666A1Rubidium/caesium/francium compoundsAlkali metal sulfite/sulfate dehydrationManganese sulphateDithionate

The process concerns hydrometallurgical processing of manganese sulphate and manganese dithionate containing liquors and recovery of water therefrom. Sodium sulphate and / or sodium dithionate containing liquors are derived from manganese sulphate and manganese dithionate containing liquids, which are then cooled to produce crystals of sodium sulphate decahydrate and sodium dithionate dehydrate. The sodium sulphate decahydrate and sodium dithionate dehydrate crystals are then heated to a temperature sufficient to decompose the sodium sulphate decahydrate crystals to form anhydrous sodium sulphate crystals, sodium dithionate hydrate crystals and water, after which water is removed from the sodium sulphate and sodium dithionate hydrate crystal. The sodium sulphate and sodium dithionate dehydrate crystals are then heated to form anhydrous sodium sulphate, sulfur dioxide and water or steam. The anhydrous sodium sulphate is then separated from the sulfur dioxide and water.

Owner:AMERICAN MANGANESE

Treatment system and method for recycling and zero emission of binary high-salt complex-system nickel hydrometallurgy wastewater

ActiveCN110015795AClear ingredientsRecycling process is simpleWater contaminantsTreatment involving filtrationHigh concentrationFiltration

The invention discloses a treatment system and method for recycling and zero emission of binary high-salt complex-system nickel hydrometallurgy wastewater. Firstly, organic matter is removed by electro-catalytic oxidation and activated carbon adsorption; then the pH value of the wastewater is adjusted, so that carbonates are completely converted into sulfates; precision filtration is carried out,and then heavy metals which are mainly nickel is recycled through ion exchange and enrichment, so that a sodium sulfate water solution subjected to organic matter removal and heavy metal removal is obtained; finally, anhydrous sodium sulfate in salt water is recycled through spray drying; and meanwhile, dried water vapor is condensed and recycled and is returned to a production system. The invention effectively solves the treatment problem of the complex-system nickel hydrometallurgy wastewater containing heavy metals, high-concentration composite salts and a small amount of macromolecular organic matter, recycling of heavy metal nickel and salt in the wastewater is realized at the same time, and meanwhile, the condensed water can be recycled to the production system, so that comprehensiveutilization and zero emission of resources in the wastewater are truly realized.

Owner:HOHAI UNIV

Method for recovering reagent level anhydrous sodium sulfate from raffinate obtained in process of extracting nickel from nickel sulfate solution

InactiveCN102887534AReduce manufacturing costEfficient removalAlkali metal sulfite/sulfate purificationAlkali metal sulfite/sulfate dehydrationPhosphate ionPhosphoric acid

The invention provides a method for recovering reagent level anhydrous sodium sulfate from raffinate obtained in a process of extracting nickel from a nickel sulfate solution by adopting bi(2-ethylhexyl)phosphate (P204) as an extracting agent. The method comprises the following steps of: firstly adding a certain amount of hydrogen peroxide in raffinate for gently heating and insulating, and adding active carbon for absorbing and filtering to remove a small amount of organic matters; then adding excessive sodium sulphide in filtrate to remove heavy metal ions such as nickel and the like, adding sodium persulfate to remove excessive sulphur ions and chloride ions in a system, adding excessive calcium hydroxide in the filtrate to remove phosphate radical ions, and removing excessive calcium hydroxide by using sodium carbonate; and finally, after regulating the pH value of the filtrate by using concentrated sulfuric acid to 5-6, concentrating and crystallizing, centrifuging while heating, and drying to obtain the reagent level anhydrous sodium sulfate. The method for recovering the reagent level anhydrous sodium sulfate is simple in operation and is mild in process conditions, and can be used for effectively removing various kinds of impurities in the raffinate with a comprehensive recovering rate of above 90 percent; and the obtained reagent level anhydrous sodium sulfate accords with the analytically pure standards of chemical reagents through testing. According to the invention, through processing and comprehensively utilizing the raffinate, the reagent level anhydrous sodium sulfate is recovered, and the purposes of saving energy, reducing emission, reducing environmental pollution and lowering production cost are achieved.

Owner:GUANGDONG GUANGHUA SCI TECH

Separation recycling method for aluminum electrolysis refractory electrolyte

InactiveCN109972175AFully recycleSimple and fast operationSulfate/bisulfate preparationAlkali metal sulfite/sulfate dehydrationElectrolysisFiltration

The invention discloses a separation recycling method for an aluminum electrolysis refractory electrolyte. The method includes the following steps that (1) the aluminum electrolysis refractory electrolyte is levigated and constituents are analyzed; (2) a sulfuric acid solution is prepared; (3) powder and the sulfuric acid solution are reacted at the temperature of 100-300 DEG C, gas is exhausted out and a solid material residues; (4) the solid material is cooled and dissolved with water; (5) filtering is performed; (6) when LiF and KF are not contained, Al(OH)3 precipitated from NaOH is added;(7) after Ca(OH)2 and Na2SO4 are added and reacted, filtering is performed; (8) when the LiF and the KF are contained, NaOH is added so that the pH value can reach 7-8, and then filtering is conducted after a Na2CO3 solution is added for reacting, or filtering is conducted after NaOH is added for reacting; and (9) mixed filter liquor is subjected to evaporation, concentration and filtration and raffinate is subjected to evaporation and dehydration. The separation recycling method is easy to operate, all useful constituents can be separated and resources can be fully recycled.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

Processing of cobaltous sulpha/dithionate liquors derived from cobalt resource

ActiveUS20180155208A1Thiosulfates/dithionites/polythionitesManganese oxides/hydroxidesDithionateSulfide

A process for water removal and / or recycling of sodium sulfate and / or sodium dithionate containing liquors derived from processing cobalt resource material essentially free of lithium comprising the steps of precipitation of cobalt as cobaltous carbonate or cobaltous hydroxide followed by removal thereof from the liquor, crystallization of sodium sulfate and sodium dithionate and removal of the crystals, followed by heating of the crystals to anhydrous sodium sulfate, sulphur dioxide and water and then separating the anhydrous sodium sulfate.

Owner:ROCHER MANGANESE INC

Equipment and method for preparing anhydrous sodium sulfate

ActiveCN105480990ANo phase changeRaise the gradeAlkali metal sulfite/sulfate dehydrationCentrifugationSalting out

The invention discloses equipment for preparing anhydrous sodium sulfate. The equipment is characterized by comprising a closed cycle membrane concentration system, a salting out system, a conveying pump and a normal temperature crystallization system which are sequentially connected; the closed cycle membrane concentration system is used for conducting concentration on inlet liquor containing sodium sulfate and discharging concentrated liquor containing supersaturated sodium sulfate, the salting out system is used for changing a sodium chloride-sodium sulfate-water ternary system in the concentrated liquor into an unstable system, the conveying pump is used for conveying the concentrated liquor discharged by the salting out system to the normal temperature crystallization system, and the normal temperature crystallization system is used for conducting normal temperature crystallization and centrifugation on the concentrated liquor conveyed by the conveying pump so as to obtain the anhydrous sodium sulfate. The invention further provides a method for preparing the anhydrous sodium sulfate. According to the method, the evaporation process is omitted, crystallization is conducted at a normal temperature, anhydrous sodium sulphate is obtained, phase change of water does not occur in the whole process, energy consumption is low in the production process, product quality is good, and the high-grade anhydrous sodium sulphate can be obtained.

Owner:SHANGHAI LYMAX ENVIRONMENTAL TECH CO LTD

Method for preparing high-purity NCM salt by recycling waste lithium batteries

InactiveCN111484066AEfficient recyclingReduce material consumptionCobalt sulfatesAlkali metal sulfite/sulfate purificationManganese sulphateIron removal

The invention relates to the technical field of waste lithium battery recycling. The invention discloses a method for preparing high-purity NCM salt by recycling waste lithium batteries. The method comprises the following steps: S1, a pretreatment process, the pretreatment process mainly comprises the following steps: carrying out crushing, screening, leaching, impurity removal and other pretreatments on each waste lithium battery raw material, including the steps of crushing and screening, leaching reaction, iron and aluminum removal, washing and filter pressing and the like; and S2, an extraction procedure: the procedure comprises the procedures of copper extraction, manganese extraction, cobalt extraction, nickel extraction and the like, a filtrate treated in the pretreatment procedureis mainly extracted, copper, manganese, cobalt, nickel and other metal elements are extracted, and a copper sulfate solution, a lithium sulfate solution, a manganese sulfate solution, a cobalt sulfatesolution and a nickel sulfate solution are obtained after extraction. According to the process technology, material consumption is reduced, the resource utilization rate is increased, efficient recycling of metal resources such as nickel, cobalt and manganese is achieved, the yield of nickel, cobalt and manganese can reach 98%, and the yield of copper and lithium can reach 90%.

Owner:湖北中环新材料科技有限公司

Recovery processing method of waste alkaline liquor in ethylene plant

ActiveCN102452673AEmission reductionImprove product qualityAlkali metal sulfite/sulfate purificationMultistage water/sewage treatmentChemical industryPetrifaction

The invention provides a recovery processing method of waste alkaline liquor in an ethylene plant. The method comprises the following steps: (1) under the condition of wet oxidation, carrying out wet oxidation on waste alkaline liquor with air or oxygen so as to obtain oxidized liquid; (2) neutralizing the oxidized liquid so as to obtain a neutralized liquid; (3) crystallizing the neutralized liquid by adopting an evaporation and crystallization method so as to obtain anhydrous sodium sulfate containing entrained water; (4) returning a part of evaporation mother liquid back to a neutralization unit, and carrying out non-biochemical treatment on another part of evaporation mother liquid; and (5) drying the anhydrous sodium sulfate containing entrained water so as to obtain the anhydrous sodium sulfate product. By using the method, the technical problem that high-content salt still generates impact on a biochemical treatment system after the ethylene waste alkaline liquor is deodorized and diluted through wet oxidation and then is subjected to biochemical treatment can be solved; and the method provided by the invention can be used for the fields of petrifaction, chemical industry, environmental conservation, comprehensive resource utilization, light industry and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method for recycling sodium sulfate from waste alkali liquor in ethylene unit

ActiveCN102452674AEmission reductionImprove product qualityAlkali metal sulfite/sulfate purificationMultistage water/sewage treatmentEvaporationPetrochemical

The invention discloses a processing method for recycling sodium sulfate from waste alkali liquor in an ethylene unit, wherein the method comprises the following steps: (1), performing wet oxidation on waste alkali liquor with air or oxygen under wet oxidation conditions to obtain oxidation liquid; (2), neutralizing the oxidation liquid to obtain neutralized liquid; (3), crystallizing out sodium sulfate decahydrate from the neutralized liquid by a freezing crystallization method; (4), performing biochemical treatment on frozen mother liquor; (5), performing vaccum evaporation to dry the sodium sulfate decahydrate to obtain anhydrous sodium sulfate products, and returning evaporation mother liquor to the neutralizing unit. The method solves the technical problem that waste alkali liquor of ethylene after being processed by deodorization, dilution and biochemical treatment still contains high-salt which can cause an impact to the biochemical treatment system. The method can be applied in fields like petrochemical, chemical engineering, environment protection, comprehensive utilization of the resources and light industries.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sodium chloride and sodium sulfate mixed waste salt resource reutilization method

PendingCN113371736AAvoid pollutionImprove separation efficiencySemi-permeable membranesAlkali metal sulfite/sulfate purificationFlue gasEnvironmental engineering

The invention relates to the field of waste treatment, and discloses a sodium chloride and sodium sulfate mixed waste salt resource reutilization method which comprises the steps of co-treatment, dissolution treatment, nanofiltration membrane filtration, evaporative crystallization and the like. According to the method, the sodium sulfate body can be recycled, and organic matters contained in the waste salt can be fully utilized to burn to produce heat to supply energy to the cement kiln so that the aim of full resource utilization is fulfilled; according to the invention, the use amount of water in the process can be reduced, the energy consumption in the evaporative crystallization process is reduced, and the treatment cost is saved; according to the method, the organic matters in the waste salt are decomposed by fully utilizing heat generated by the cement kiln, then volatile organic matters generated by the decomposed organic matters are mixed with air along with flue gas and then enter the cement kiln to be fully combusted, heat is provided for the cement kiln, combustion is complete, harmless emission is achieved, and the purpose of green treatment is achieved.

Owner:浙江红狮环保股份有限公司

Method for preparing large grain anhydrous sodium sulfate

InactiveCN101007640AExtended induction periodEnhanced interface energyAlkali metal sulfite/sulfate dehydrationPhosphatePolyethylene glycol

The invention discloses a making method of large-particle anhydrous sodium sulfate, which comprises the following steps: adding 0.01%-10% surface activator with one or more of dodecyl phosphate ester, dodecyl sodium benzosulfonate, dodecyl dimethyl amine oxide, phenylethene or carbowax; adding water under 60-260 deg.c; keeping the constant density of solution to react 1.5-3.0h; stopping heating; filtering; drying; obtaining 80% product over 40 order.

Owner:HEBEI UNIVERSITY

Manufacturing technique of high-purity thenardite

InactiveCN101844781ASave cleanup timeIncrease productivityAlkali metal sulfite/sulfate dehydrationChemistrySodium nitrate

The invention relates to a manufacturing technique of high-purity thenardite. The manufacturing technique comprises the steps: removing mechanical impurities in original sodium nitrate solution which has certain concentration and is conveyed under a well by a three-stage pipeline filter under the monitoring of a DCS automatic monitoring system and regulation of an AK liquid balance flow meter, using a twelve-stage ion exchanger for refining and purifying treatment to obtain refined sodium nitrate solution with extremely-low impurity content, adjusting a pH value thereof, inputting the refined sodium nitrate solution into a continuous crystallization technique system, carrying out continuous solid-liquid separation by a primary centrifugal machine, then inputting the treated sodium nitrate solution into a multi-stage spiral type vacuum dryer for drying and removing water, inputting the sodium nitrate solution into a fluidized bed for treatment, obtaining the high-purity thenardite and finally inputting the obtained high-purity thenardite into an automatic packaging machine procedure for packaging.

Owner:四川省川眉芒硝有限责任公司

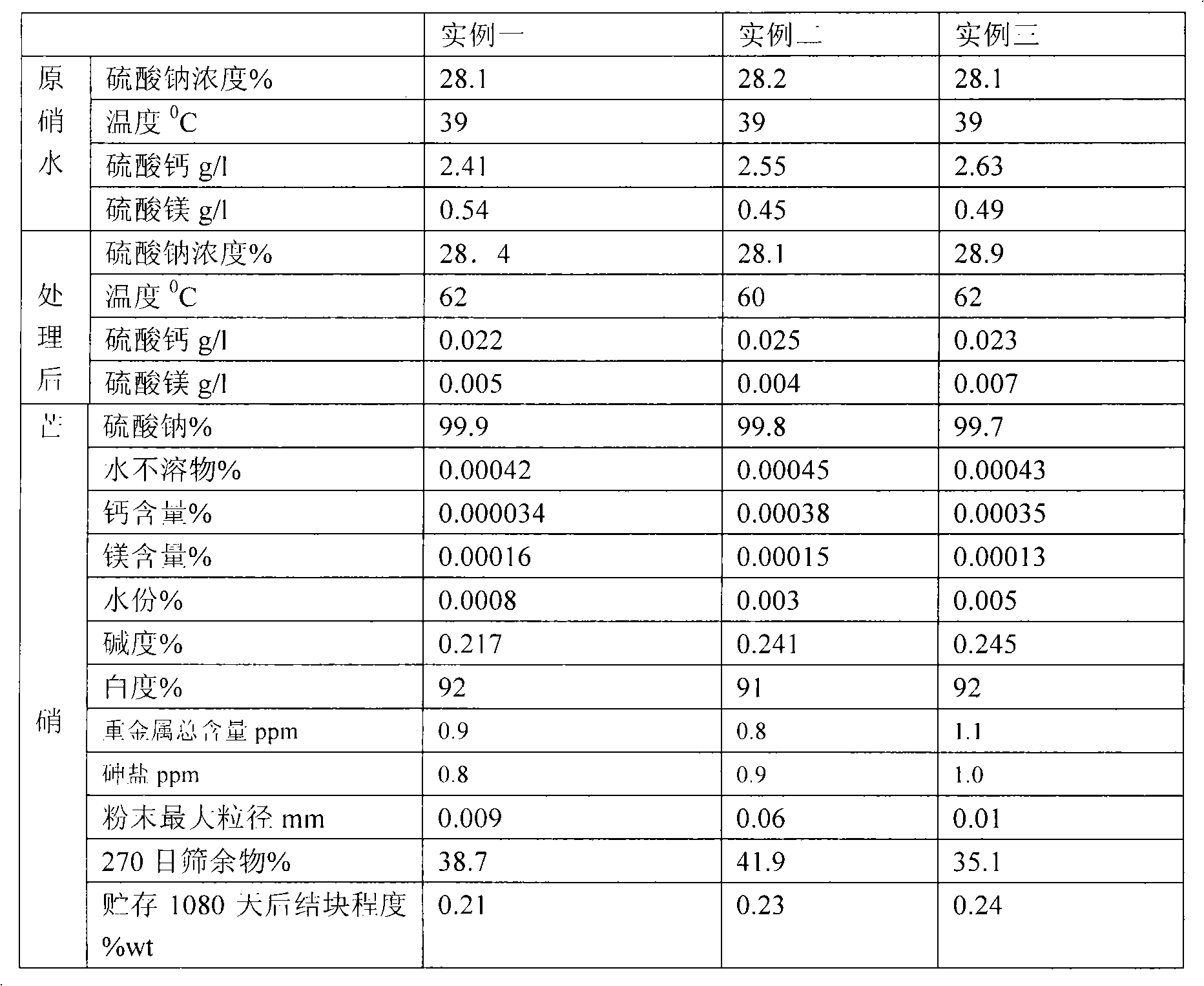

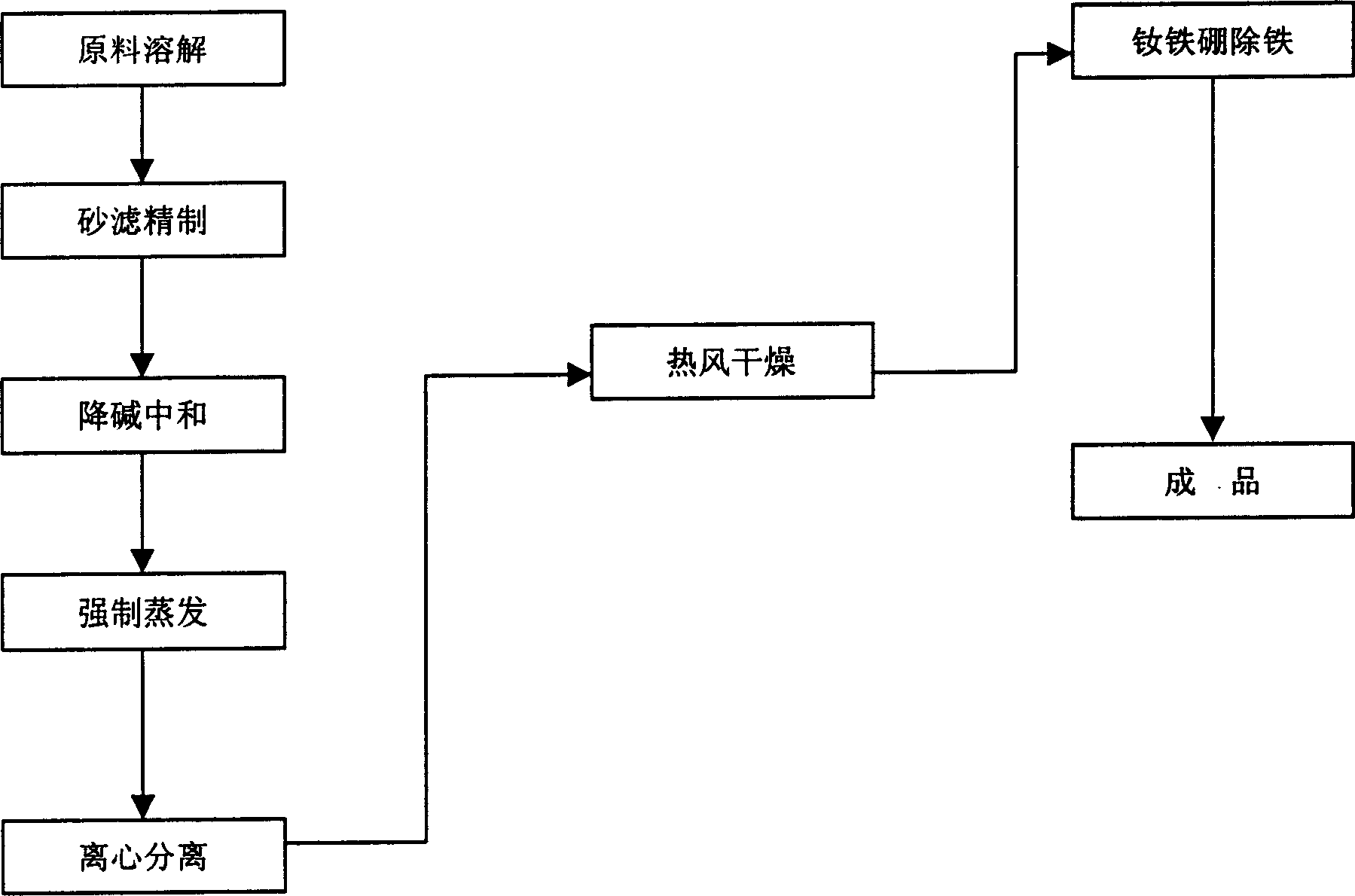

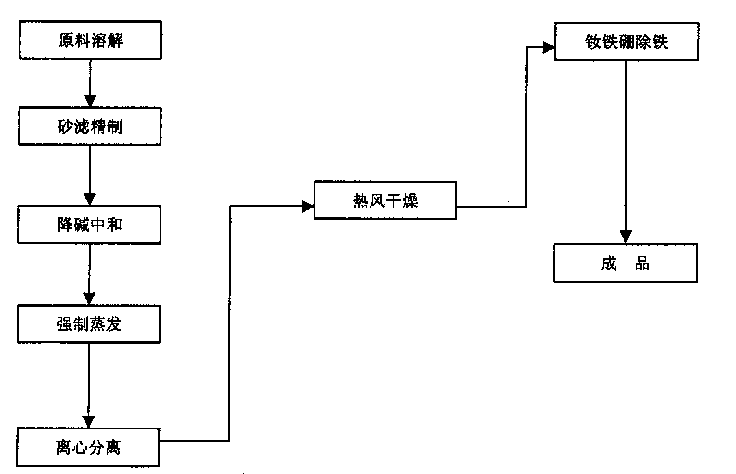

Method of producing neutral high quality anhydrous sodium sulfate using natucal salt lake sodium sulfate decahydrate

InactiveCN1475443AHigh purityHigh whitenessAlkali metal sulfite/sulfate purificationAlkali metal sulfite/sulfate dehydrationSalt lakeEvaporation

A process for preparing the refined neutral sodium sulphate from the sodium mirabilite of natural salt lake includes dissolving raw material, sand filtering, adding ammonium sulfate, forced evaporation, centrifugal separation, hot-air drying and magnetically removing iron. Its advantages are high purity (more than 99.3%), high whiteness (90%) and pH value 6-8.

Owner:INNER MONGOLIA YUANXING ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com