Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Achieve zero discharge treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

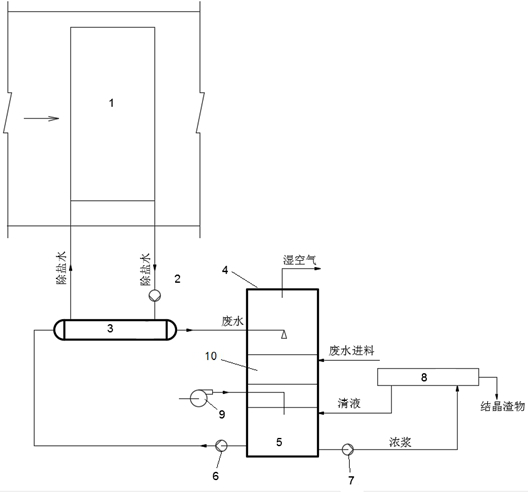

Separate crystallization method for extracting recyclable high-purity sodium sulfate and sodium chloride from high-salinity wastewater

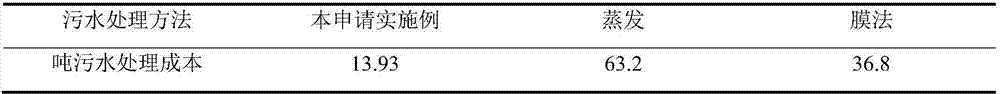

ActiveCN107867707AAchieve zero discharge treatmentReduce processing costsWater contaminantsMultistage water/sewage treatmentActivated carbonEvaporation

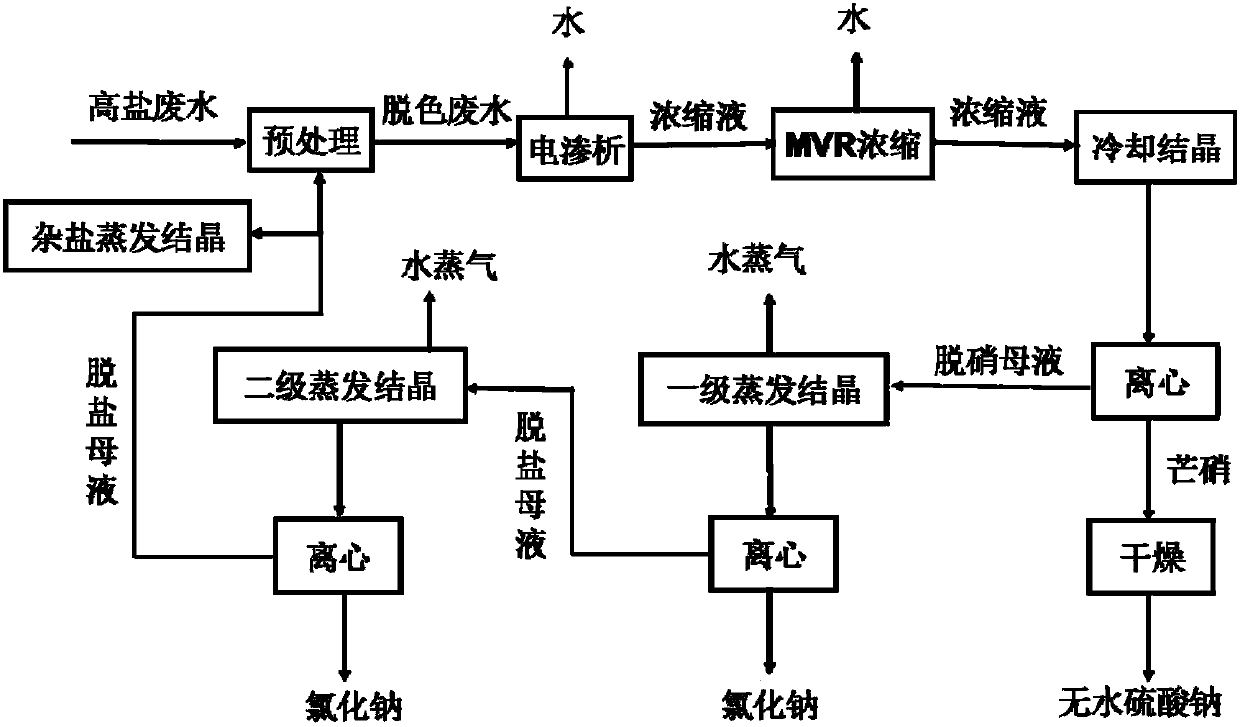

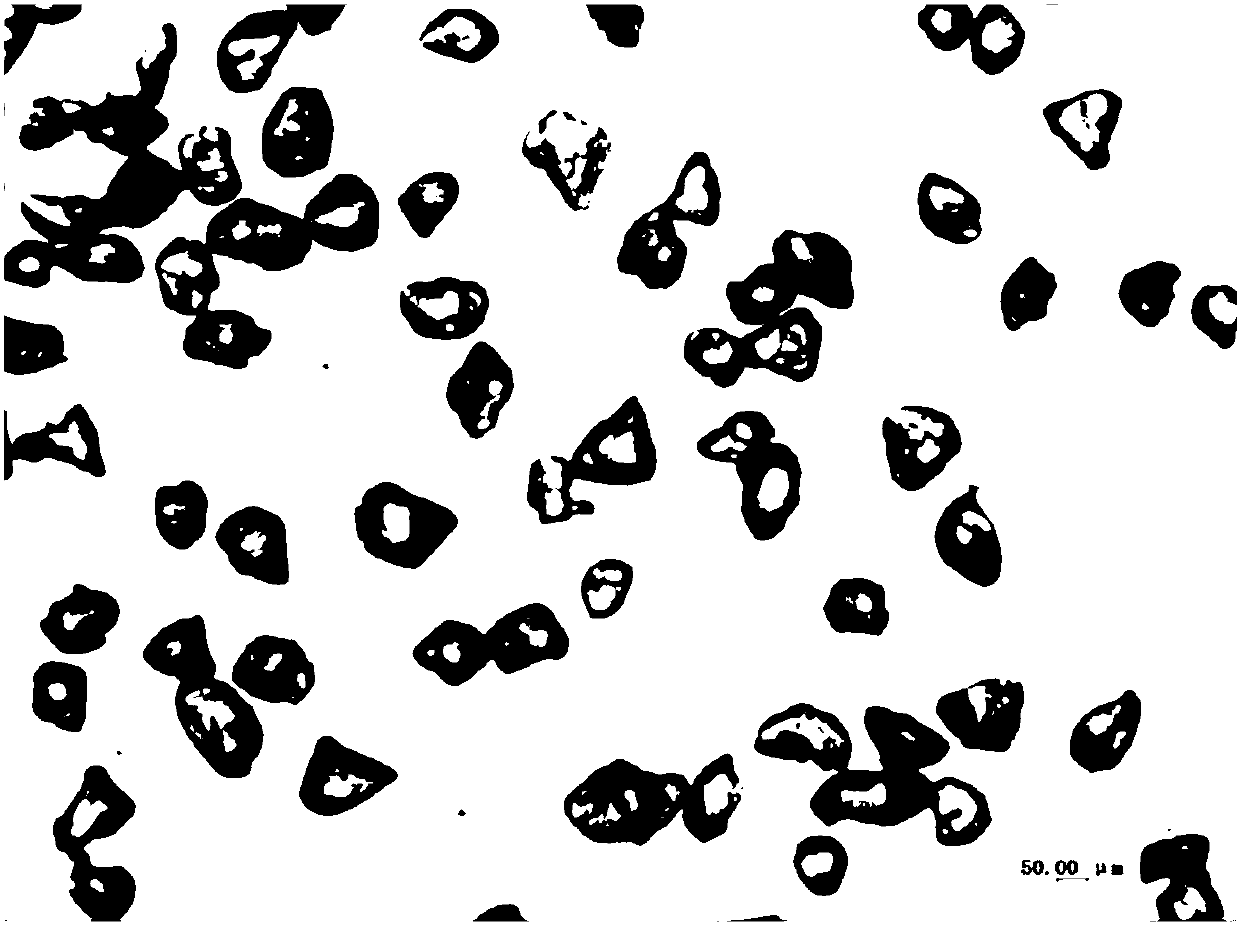

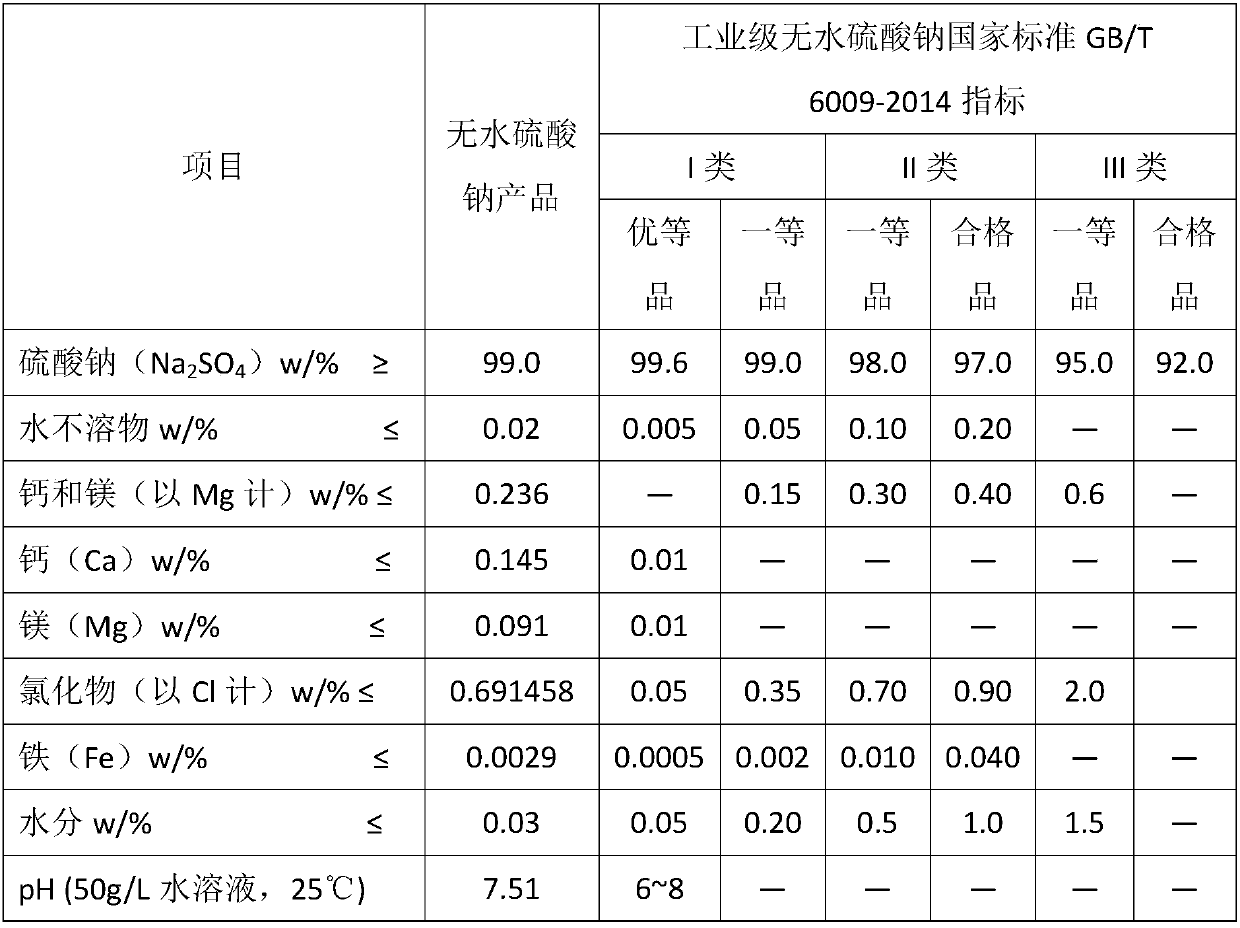

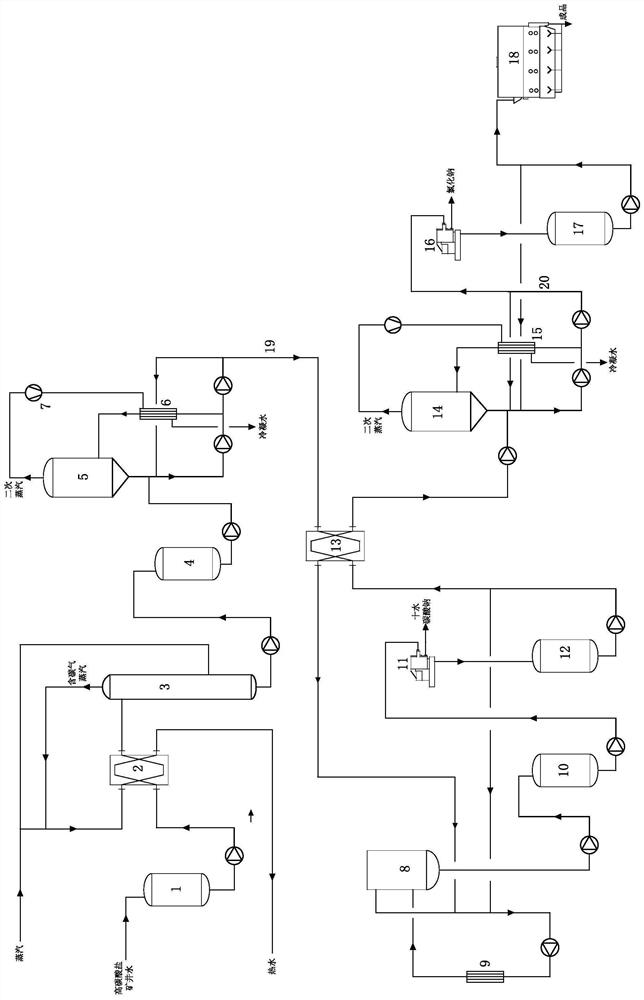

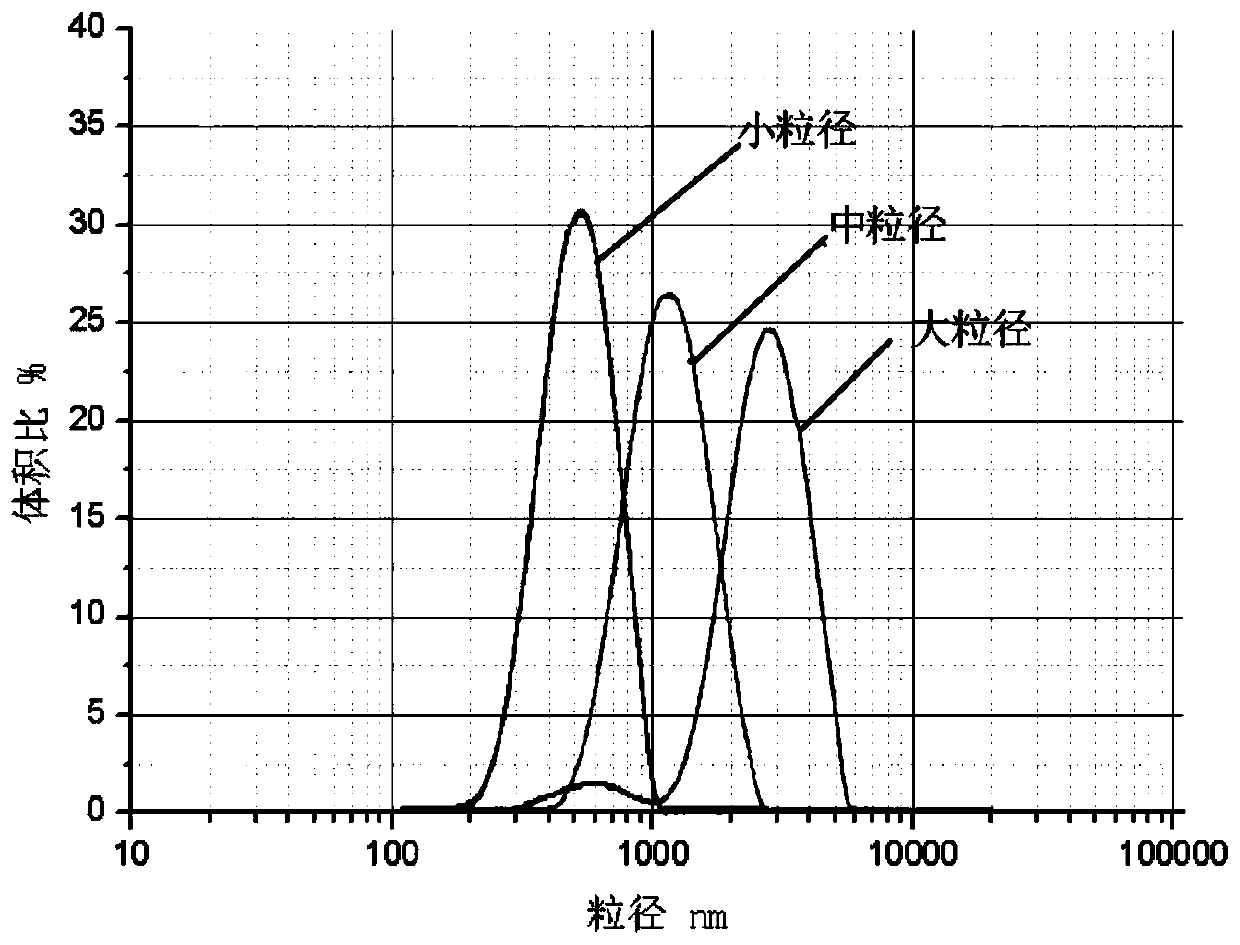

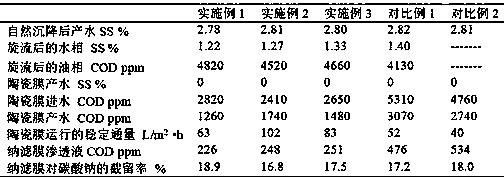

The invention relates to a separate crystallization method for extracting recyclable high-purity sodium sulfate and sodium chloride from high-salinity wastewater. Activated carbon is adopted for decolorization pretreatment, the COD can be significantly reduced, and insoluble impurities and soluble substances such as Ca<2+>, Mg<2+>, silicate and the like can be removed simultaneously; after pretreatment, the wastewater is sent to electrodialysis and mechanical steam recompression devices sequentially for concentration, and sodium sulfate and sodium chloride are approximately saturated through concentration according to the initial composition of sodium sulfate and sodium chloride in the wastewater; the concentrated wastewater is sent to a crystallizer, sodium sulfate is obtained cooling crystallization, directly extracted, washed and dried, and an anhydrous sodium sulfate product is obtained; a concentrated solution of denitration mother liquor is subjected to two-stage evaporative crystallization, and the sodium chloride product is directly extracted, washed and dried; part of mother liquor obtained after two-stage evaporation salt removal returns to the system and is mixed with fed wastewater to be recycled, the rest mother liquor is sent to a mixed salt evaporative crystallizer. The sodium sulfate and sodium chloride products reaching the national standard are obtained.

Owner:TIANJIN UNIV

Hot-dip galvanizing waste acid resource treatment method

PendingCN106587478AAchieve zero discharge treatmentIncrease profitSludge treatment by de-watering/drying/thickeningDispersed particle separationEvaporationOperating cost

The invention discloses a hot-dip galvanizing waste acid resource treatment method, which comprises: (1) adding an oxidizing agent to hot-dip galvanizing waste acid to oxidize Fe<2+> ions in the waste acid into Fe<3+> ions, adjusting the pH value of the waste acid to 4.5, generating Fe(OH)3 precipitate from the Fe<3+>, carrying out solid-liquid separation, recovering the Fe(OH)3 precipitate, and performing the next step on the filtrate; (2) adjusting the pH value of the filtrate obtained in the step (1) to 9.5, generating the corresponding insoluble salt precipitate from the heavy metal ions, carrying out solid-liquid separation, and performing the next step on the filtrate; and (3) adjusting the pH value of the filtrate obtained in the step (2) to a neutral pH value, heating and evaporating the filtrate, carrying out crystallizing precipitating and recovering on the soluble salt in the filtrate, and reusing the condensed water produced during the evaporation process. According to the present invention, with the method, the separation between the iron and the heavy metal and the efficient recovery of the iron are achieved, the heavy metal hazardous waste achieves the decrement treatment requirement, the operating cost of the whole system is reduced, the workload of the follow-up treatment unit is reduced, and the zero discharging treatment of the waste acid is achieved.

Owner:QINGDAO NORTH ENERGY & ENVIRONMENT

Ion exchange resin wastewater zero-emission treatment method

InactiveCN107512806ARealization costAchieving zero emissionsWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisChemistryZero emission

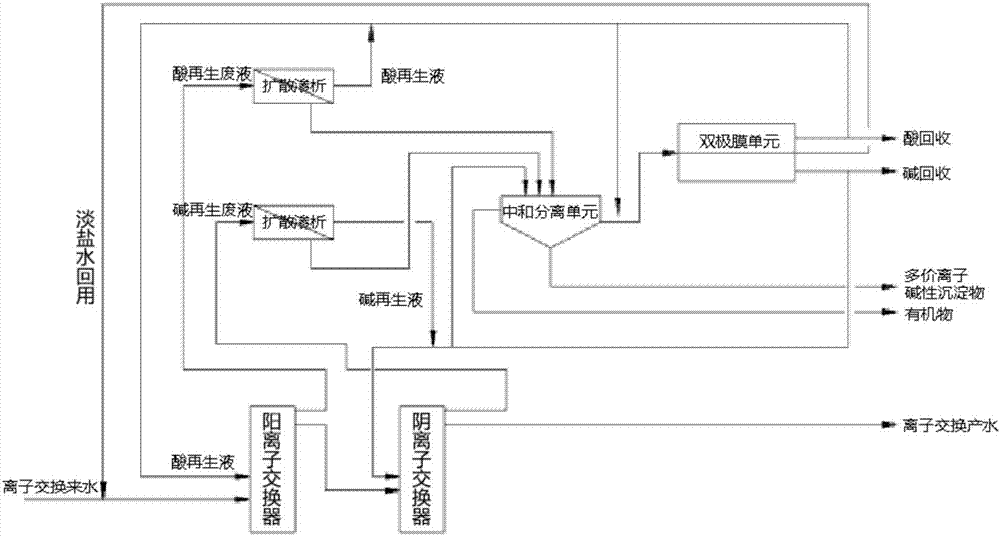

The invention provides an ion exchange resin wastewater zero-emission treatment method, relates to the field of wastewater treatment and aims to provide a low-cost environmental-friendly wastewater treatment method. The method comprises the following steps: S01, performing anion-cation exchange, namely introducing wastewater into a cation exchanger and an anion exchanger in sequence, extracting an acid regenerated waste liquid from the cation exchanger, and extracting an alkali regenerated waste liquid from the anion exchanger; S02, performing diffusion dialysis, namely introducing the acid regenerated waste liquid into a diffusion dialysis anion membrane to form an acid regenerated liquid and a waste acid liquid, and introducing the alkali regenerated waste liquid into a diffusion dialysis cation membrane to form an alkali regenerated liquid and a waste alkali liquid; S03, performing neutralization separation, namely respectively introducing a diffusion dialysis waste acid liquid and a diffusion dialysis alkali liquid into a neutralization separation unit, neutralizing the diffusion dialysis waste acid liquid and the diffusion dialysis alkali liquid, discharging organic matters through air flotation, forming a precipitate from divalent or more ions, and collecting the residue as a neutralized waste liquid; S-4, treating with a bipolar membrane, namely introducing the neutralized waste liquid into a bipolar membrane unit, finally converting into an acid regenerated liquid and an alkali regenerated liquid, and collecting the residue as light salt brine.

Owner:BEIJING TINGRUN MEMBRANE TECH DEV

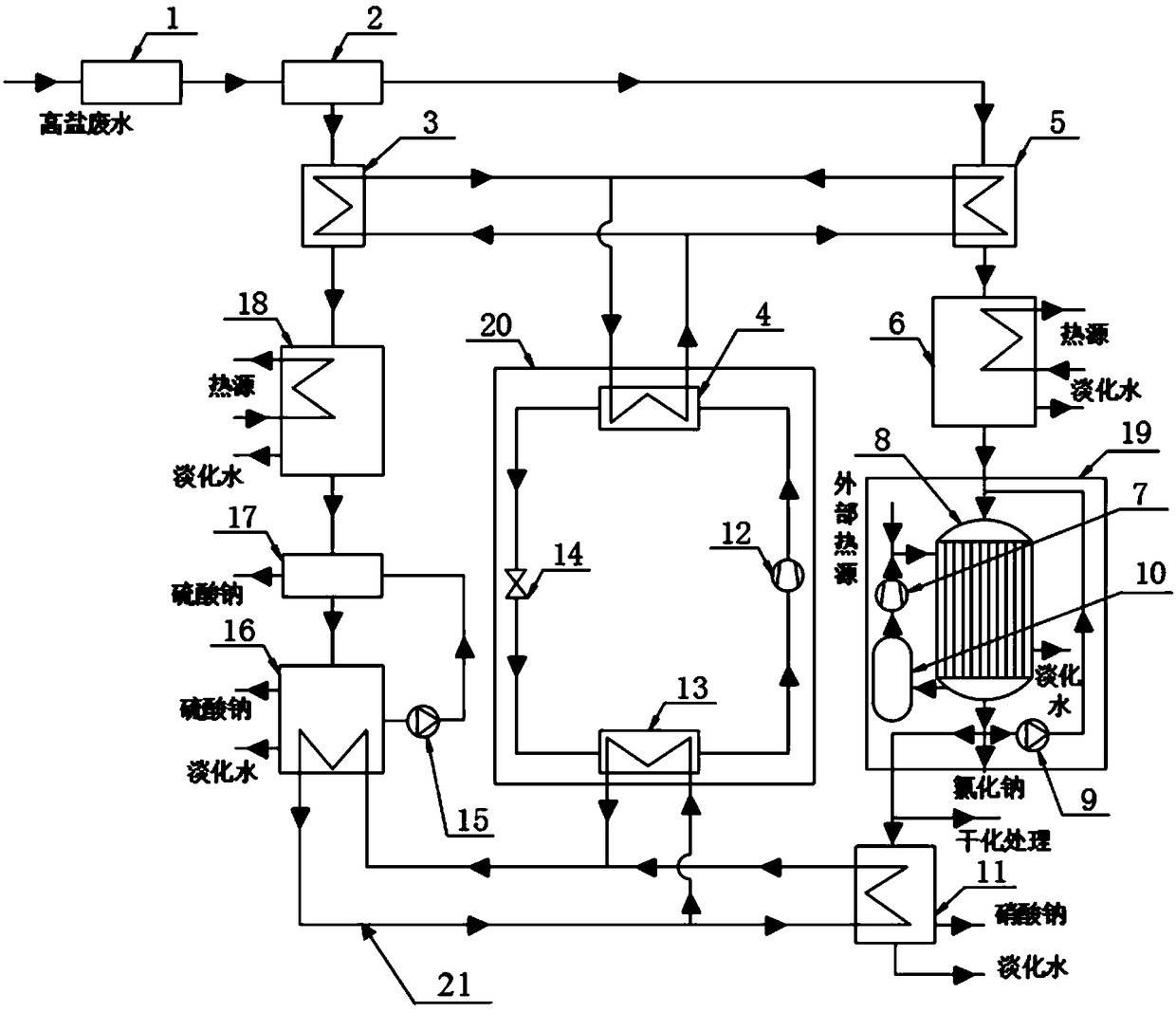

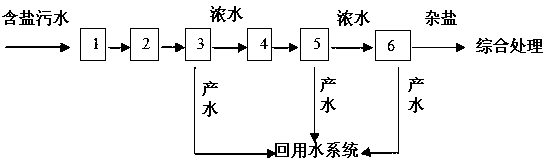

System and technology for zero discharging of high-salinity wastewater

InactiveCN109179824AReach the separation water quality standardHigh purityWater contaminantsMultistage water/sewage treatmentSolubilityWater quality

The invention discloses a system and a technology for zero discharging of high-salinity wastewater. A pre-processing system is adopted for removing hardness, basicity, heavy metal ions, COD, and the like, from high-salinity wastewater, so that the high-salinity wastewater can meet the water quality standard for nanofiltration membrane separation; nanofiltration is adopted for realizing the separation of divalent saline ions (SO42-), Na+, Cl and NO3-, and the like, in strong brine; the divalent saline ions (SO42-) exist in concentrated water; Na+, Cl and NO3- exist in generated water; a solventis added for reducing the solubility of sodium sulfate, so that high-purity sodium sulfate can be separated out; separation and recycling of desalted water and solvent are realized by crystallizing desalted water and keeping liquid state of solvent in the manner of cooling on the basis of the feature that the melting point of solvent is far lower than that of water. The system disclosed by the invention is simple in operation, high in running stability and capable of efficiently energy-saving realizing zero discharging of high-salinity wastewater.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

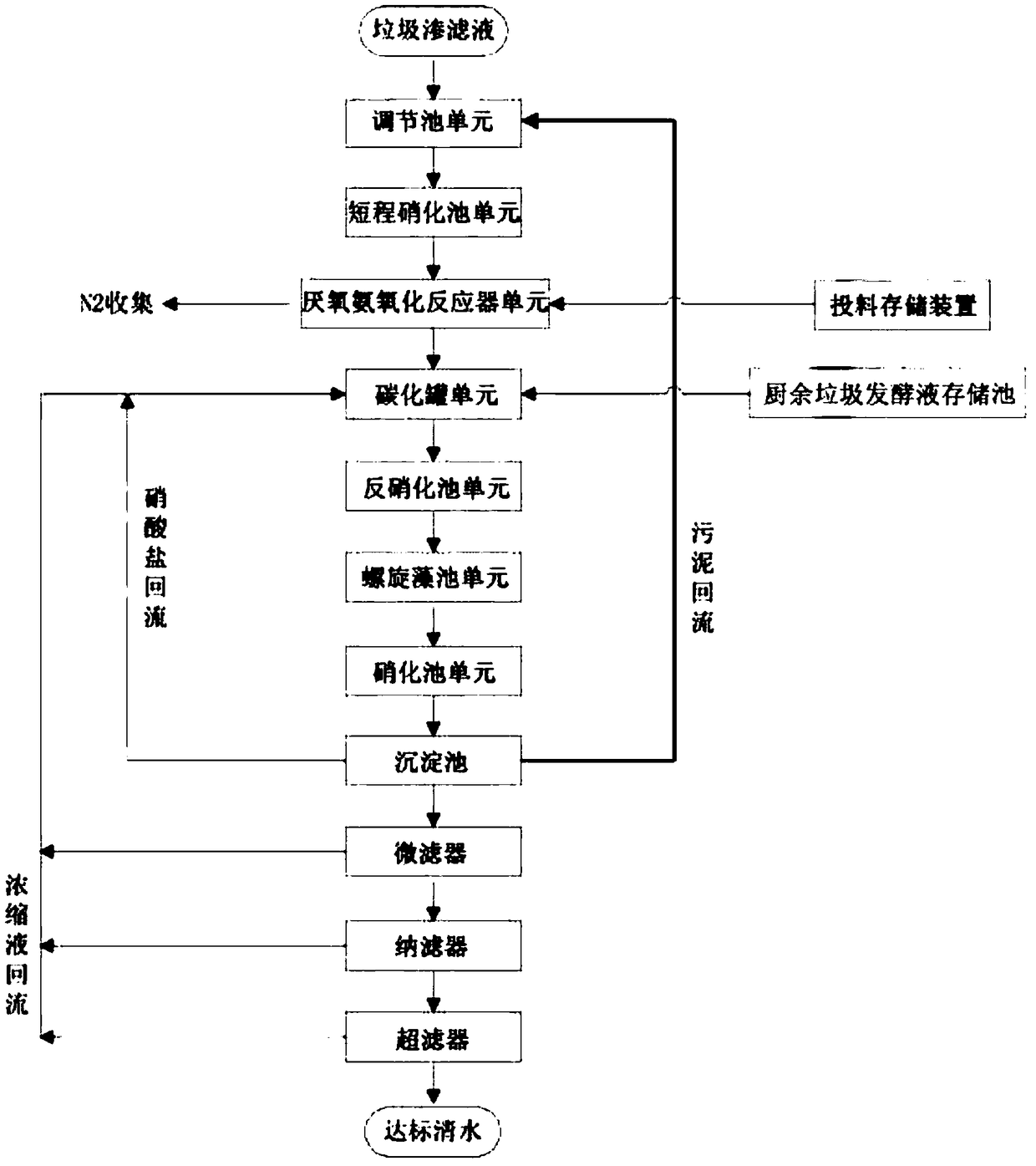

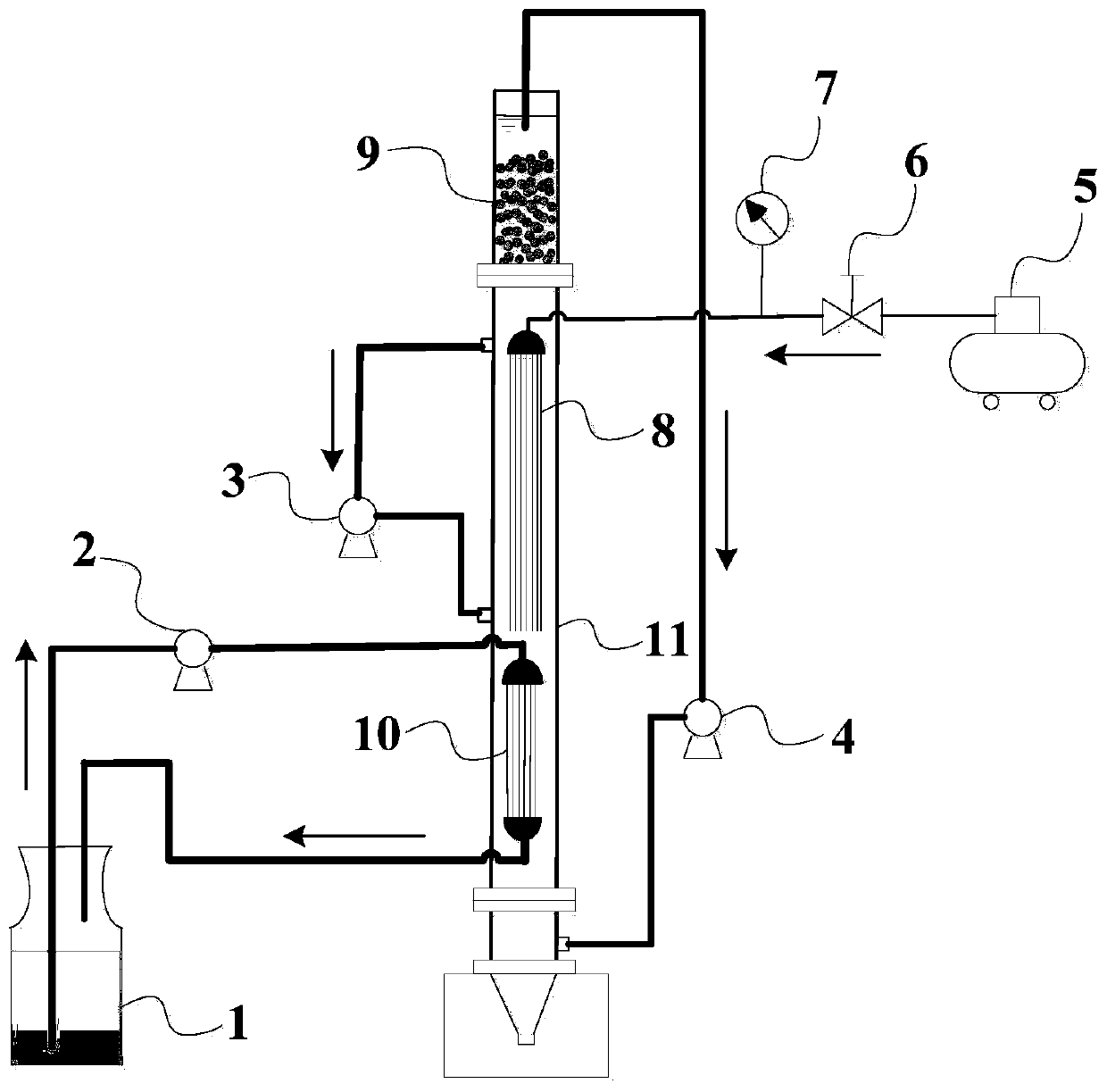

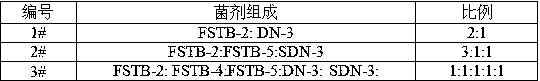

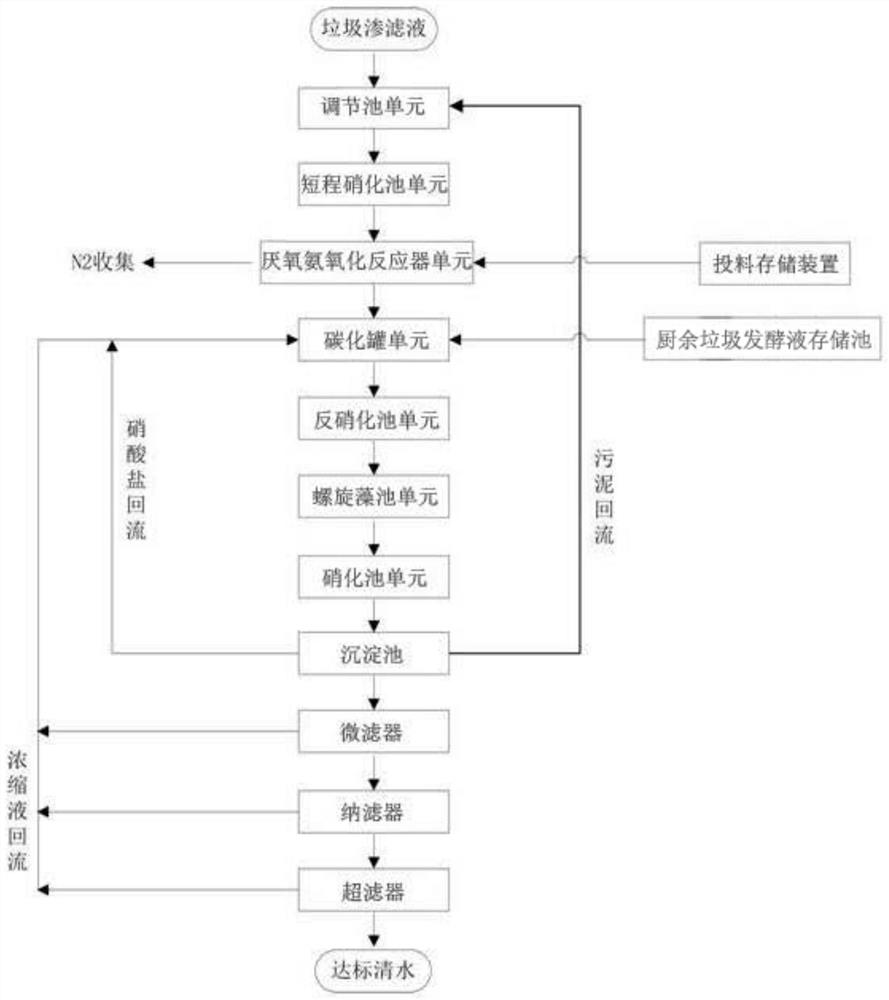

Zero emission treatment device and method for late-stage landfill leachate

ActiveCN109336325AImprove nitrogen removal rateReduce energy consumption and costsWater contaminantsMultistage water/sewage treatmentChemistryZero emission

The invention relates to the technical field of environmental engineering and aims to provide a zero emission treatment device and method for late-stage landfill leachate. The device and method can improve overall reaction efficiency of partial nitrification-anaerobic ammonia oxidation, realize zero emission treatment of the landfill leachate and remove phosphorus, organic matters and heavy metalions in the landfill leachate. According to the technical scheme, the zero emission treatment device for late-stage landfill leachate is characterized by comprising a regulating tank unit, a partial nitrification-anaerobic ammonia oxidation integrated reactor unit, a carbonization tank unit, a denitrification tank unit, a spirulina-nitrification tank unit, a sedimentation tank, a membrane filtration system unit and an intelligent control system, wherein the partial nitrification-anaerobic ammonia oxidation integrated reactor unit comprises a partial nitrification tank unit and an anaerobic ammonia oxidation reactor unit; the spirulina-nitrification tank unit comprises a spirulina tank unit and a nitrification tank unit; the membrane filtration system unit comprises a microfilter, a nanofilter and an ultrafilter.

Owner:ZHEJIANG WUTE ENVIRONMENTAL PROTECTION TECHCO

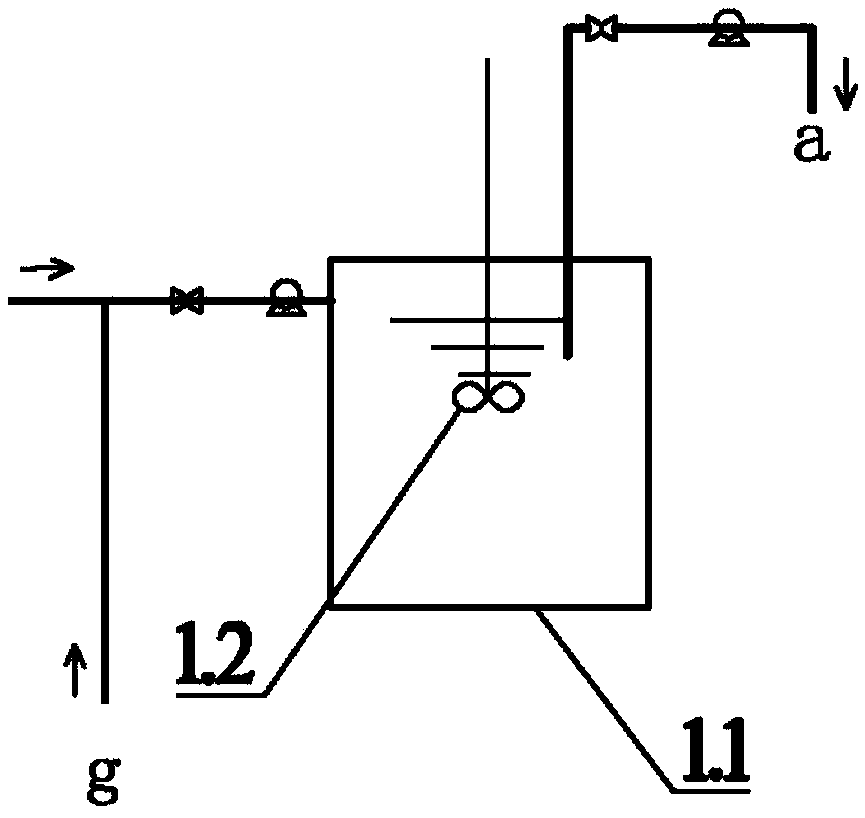

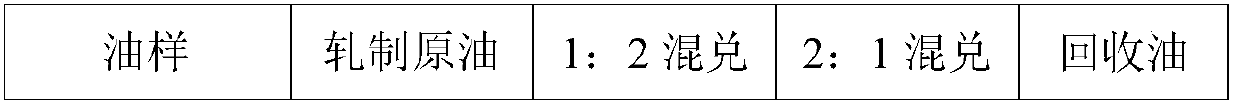

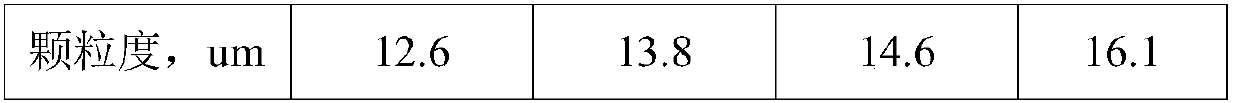

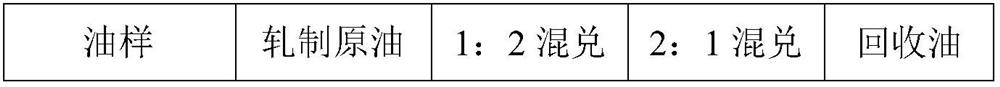

Recycling treatment agent for zero discharge of rolling waste liquid and treatment method

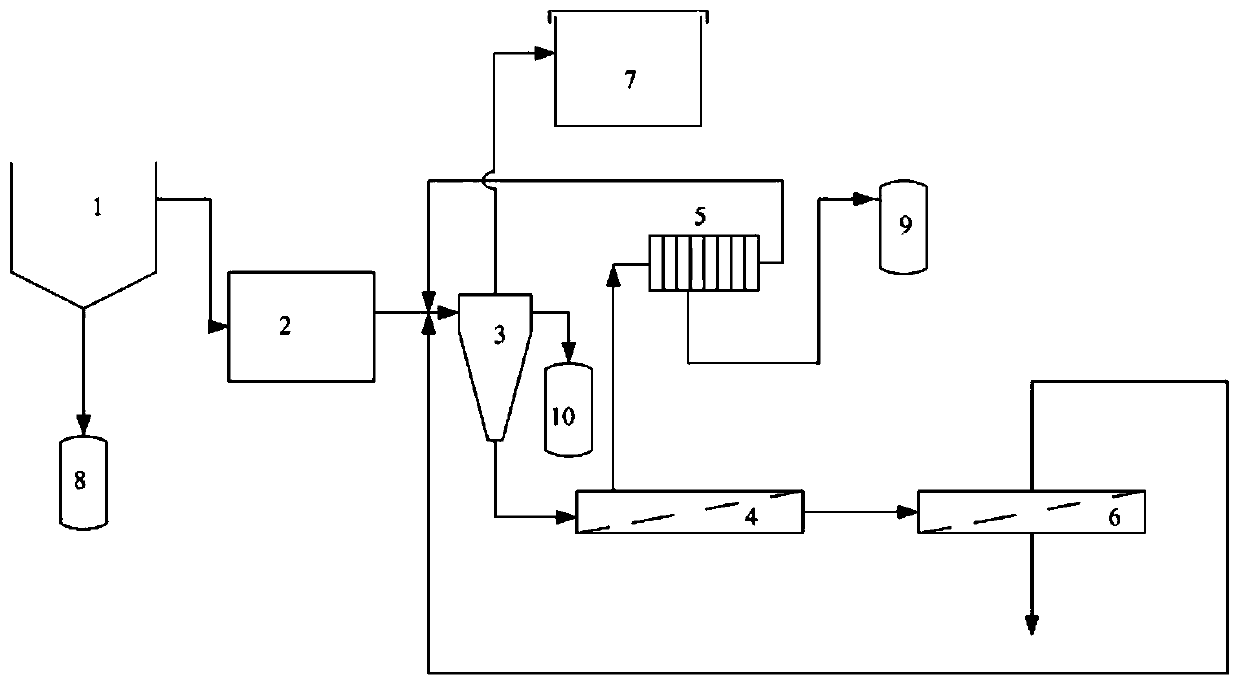

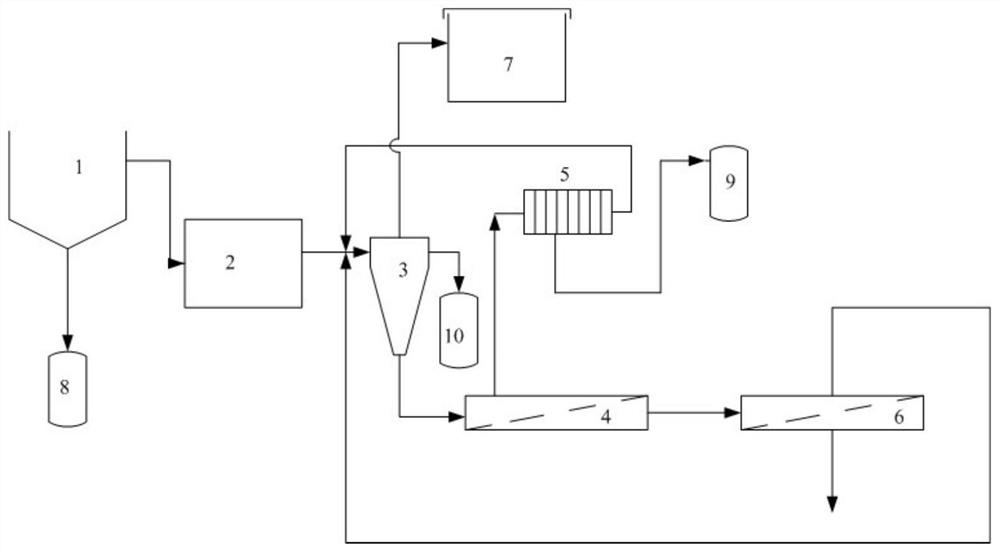

ActiveCN109609251AChange surface tensionEasy to separateFatty/oily/floating substances removal devicesNon-miscible liquid separationLiquid wasteOil phase

The invention discloses a recycling treatment agent for zero discharge of rolling waste liquid and also discloses a treatment method for achieving zero discharge of rolling waste liquid by adopting the recycling treatment. The treatment method can achieve thorough oil-water separation of rolling waste emulsion, a separated-out oil product can be mixed with rolled crude oil in proportion for reuse,a water phase can be used for daily water supplementation of a rolling mill, and accordingly zero discharge treatment of the waste emulsion is achieved. After the oil phase separated by the recyclingtreatment agent is blended with the rolled crude oil, the lubricating property of the obtained mixed oil is equivalent to the lubricating property of the rolled crude oil.

Owner:NANJING KERUN LUBRICANTS

High-recovery circulating water blowdown water desalination treatment and recycling system for thermal power plant

PendingCN109678280AAchieve zero discharge treatmentHigh reverse osmosis desalination rateWater treatment parameter controlGeneral water supply conservationWater desalinationUltrafiltration

The invention discloses a high-recovery circulating water blowdown water desalination treatment and recycling system for a thermal power plant. Specifically, an outlet of a circulating water blowdownwater pool is communicated with an inlet of an intermediate pool through a softening-coagulating clarification treatment system, wherein an outlet of the intermediate pool is communicated with the inlet of a filtering system; a clear water outlet of the filtering system is communicated with the inlet of a clear water tank; the outlet of the clear water tank is communicated with the inlet of an ultrafiltration treatment system; the outlet of the ultrafiltration treatment system is communicated with the inlet of an ultrafiltration water producing tank; the outlet of the ultrafiltration water producing tank is communicated with a roll type reverse osmosis treatment system; the clear water outlet of the roll type reverse osmosis treatment system is communicated with the inlet of a fresh watertank; a concentrated water outlet of the roll type reverse osmosis treatment system is communicated with the inlet of a disk-tube type reverse osmosis treatment system; and the clear water outlet of the disk-tube type reverse osmosis treatment system is communicated with the inlet of the roll type reverse osmosis treatment system. The system can realize zero discharge treatment of circulating water blowdown water from the thermal power plant.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

Method for treating waste acetonitrile water with high salt content in zero-discharge mode and special device of method

PendingCN109970290AEasy to handleAcetonitrile content decreasedWater contaminantsWater/sewage treatment bu osmosis/dialysisSaline waterSalt content

The invention discloses a method for treating waste acetonitrile water with high salt content in a zero-discharge mode and a special device of the method. A designed membrane aeration bioreactor system with the combination effect of two devices, namely a membrane reactor and a membrane aeration bioreactor is utilized, and acetonitrile in the waste acetonitrile water with the high salt content is separated and degraded. The method comprises the specific steps that the waste acetonitrile water with the high salt content is subjected to circulating separation treatment by the membrane separator,and the acetonitrile and salt water are obtained; the acetonitrile enters the membrane aeration bioreactor with a non-aeration area and a membrane aeration area for a degradation reaction, and water in the membrane aeration bioreactor flows back to the membrane separator for circulating separation of the acetonitrile; after acetonitrile separation by the membrane separator, the salt water can be further recycled. According to the method and the special device, the system adaptability is high, the operation is stable, it is effectively avoided that salt enters the membrane aeration bioreactor and inhibits microorganisms, zero-discharge treatment for the waste acetonitrile water with the high salt content is achieved, that is, the acetonitrile is completely separated and degraded, the salt water is recycled, there is no secondary pollution, and there is no waste water discharge of the system.

Owner:NANJING FORESTRY UNIV

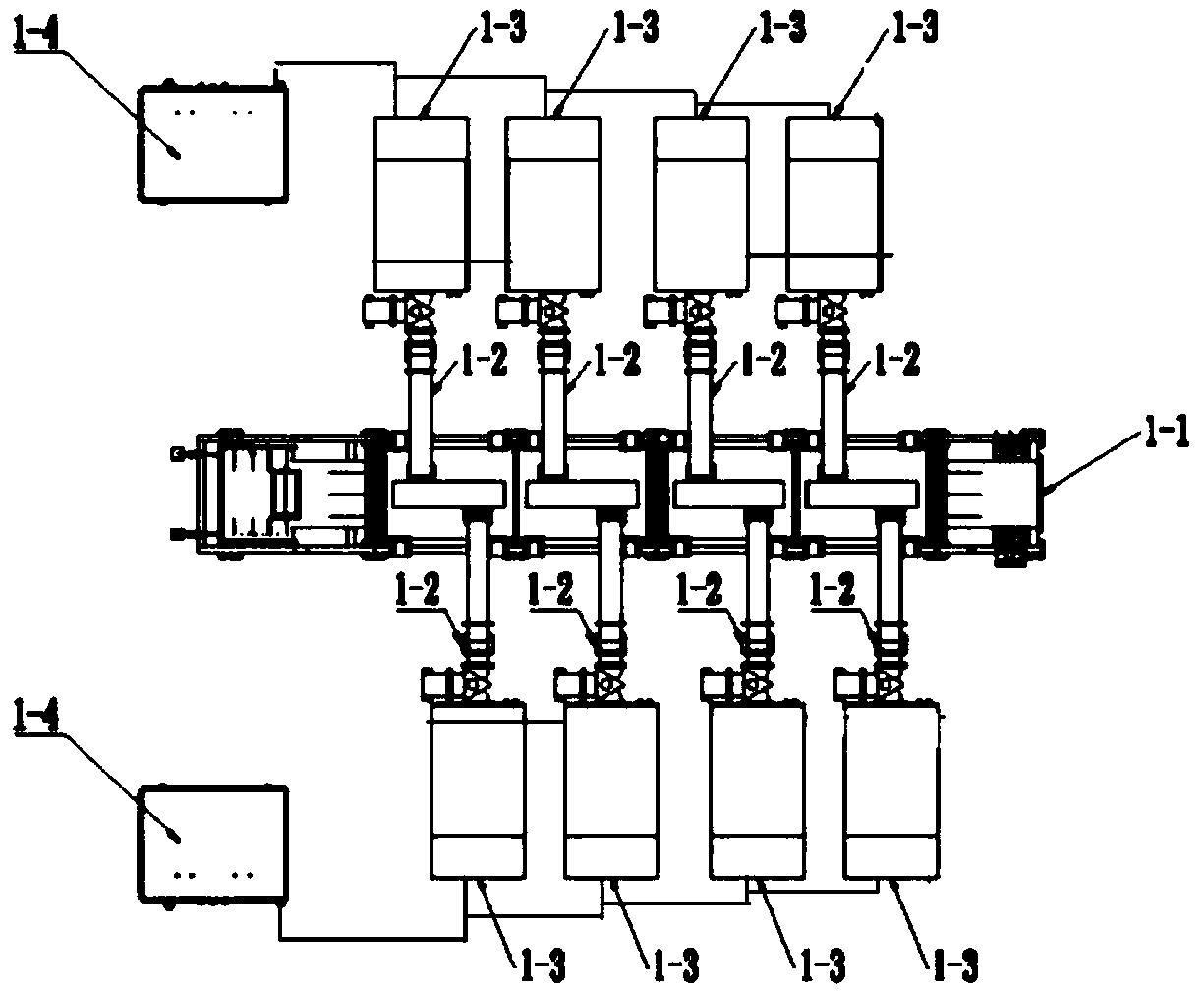

Separated flotation tank-capacitive deionization membrane distillation technology combined electroplating wastewater purification and recycling process system

ActiveCN113105057AAchieve zero discharge treatmentAvoid secondary pollutionWater contaminantsWaste water treatment from metallurgical processCyanide compoundDistillation

A separated flotation tank-capacitive deionization membrane distillation technology combined electroplating wastewater purifying and recycling process system belongs to the technical field of wastewater treatment and is formed by connecting a water inlet tank, a membrane distillation heating tank, a pH regulating tank, an air floatation tank, a capacitive deionization membrane distillation reactor, a condenser, a power supply, a computer and a clean water tank. High-salinity industrial wastewater such as electroplating wastewater is pretreated by using an air flotation method, volatile pollutants such as ammonia nitrogen and cyanide in the wastewater are efficiently removed, and heavy metals and salt substances in the wastewater are further adsorbed, intercepted and recycled through the process of a capacitive deionization membrane distillation reactor, so the heavy metals in the electroplating wastewater are efficiently intercepted and recycled, the effluent water quality is highly purified, the zero discharge treatment of the electroplating wastewater is achieved, the air flotation pretreatment process and the introduction of the electrode plate in the capacitive deionization membrane distillation reactor significantly alleviate the membrane pollution / membrane wetting trend of the distillation membrane, the service life of the distillation membrane is prolonged, and the operation cost of membrane cleaning / membrane replacement is reduced.

Owner:YANGZHOU UNIV

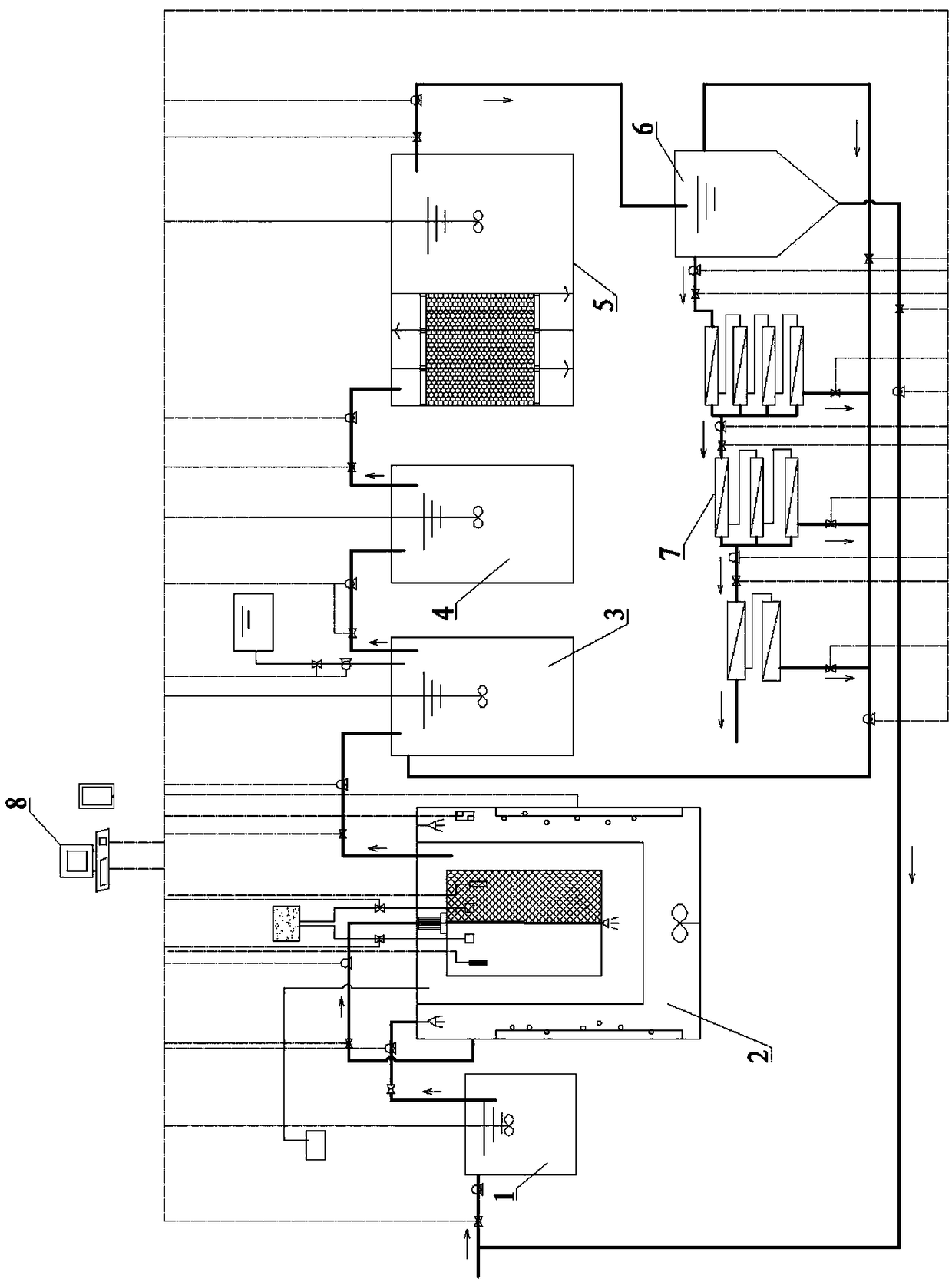

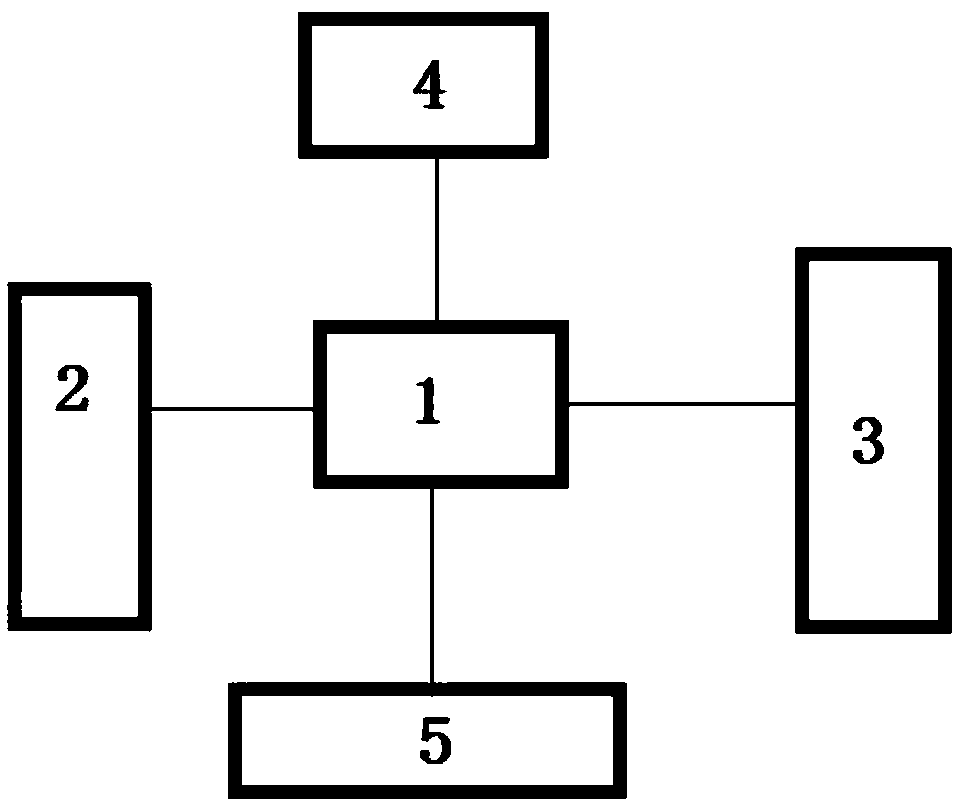

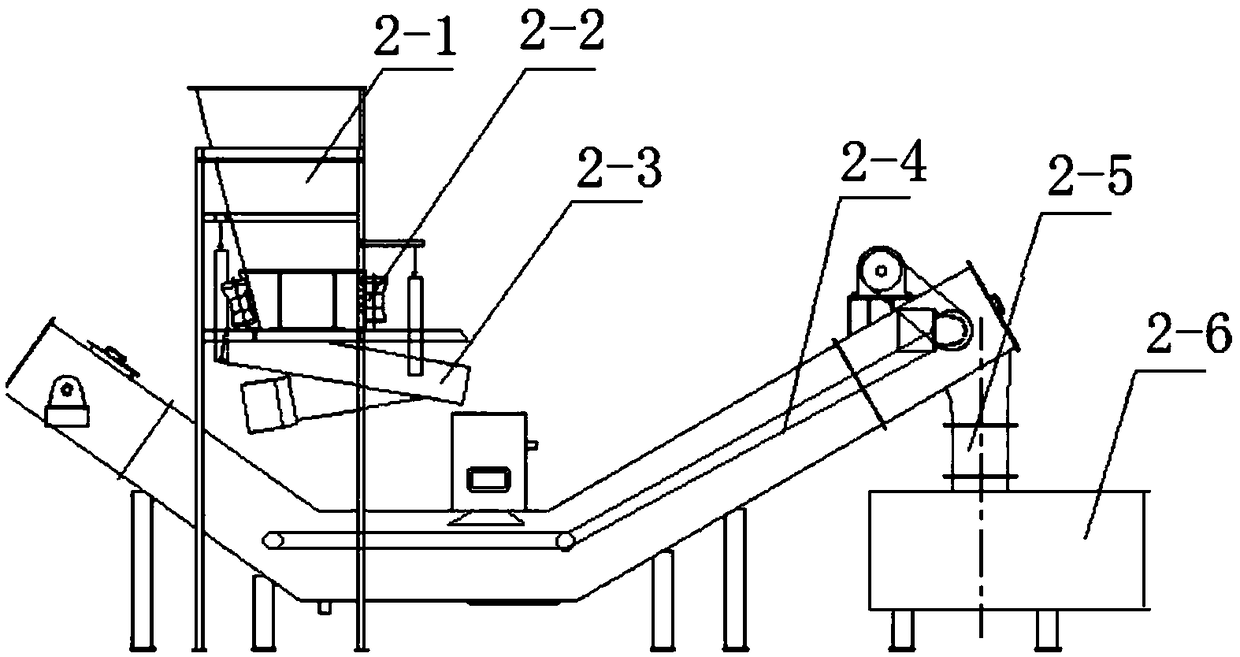

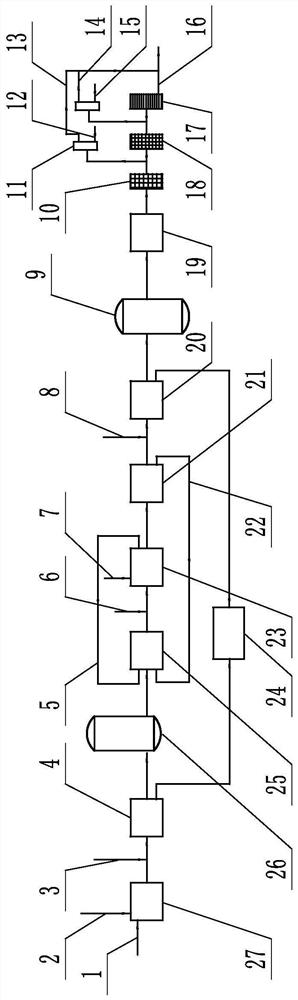

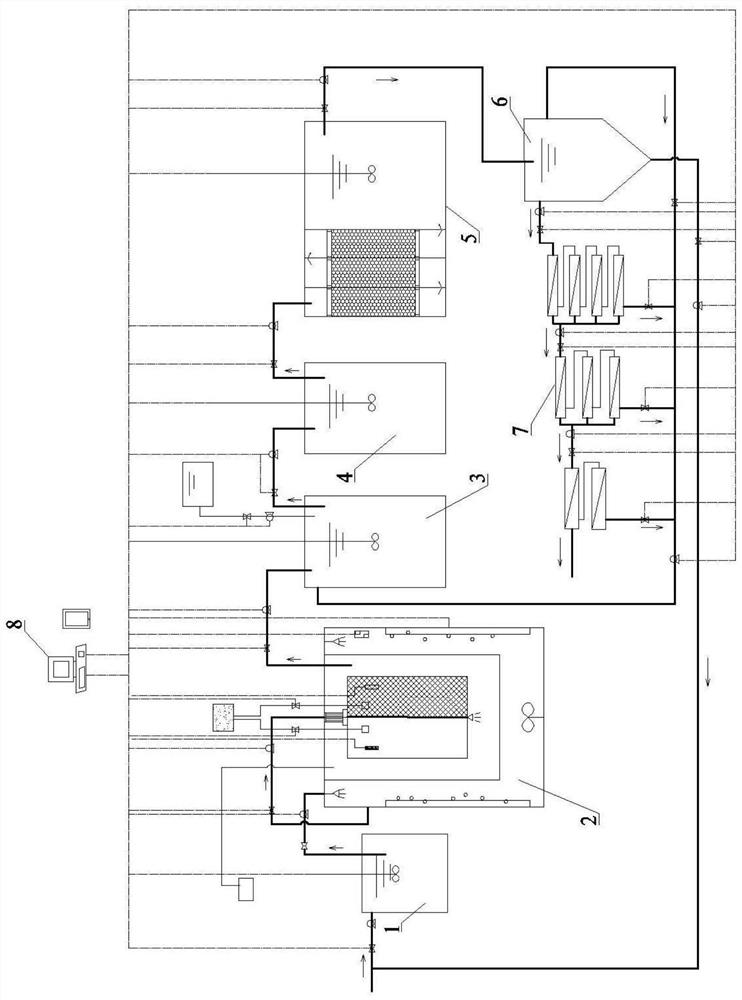

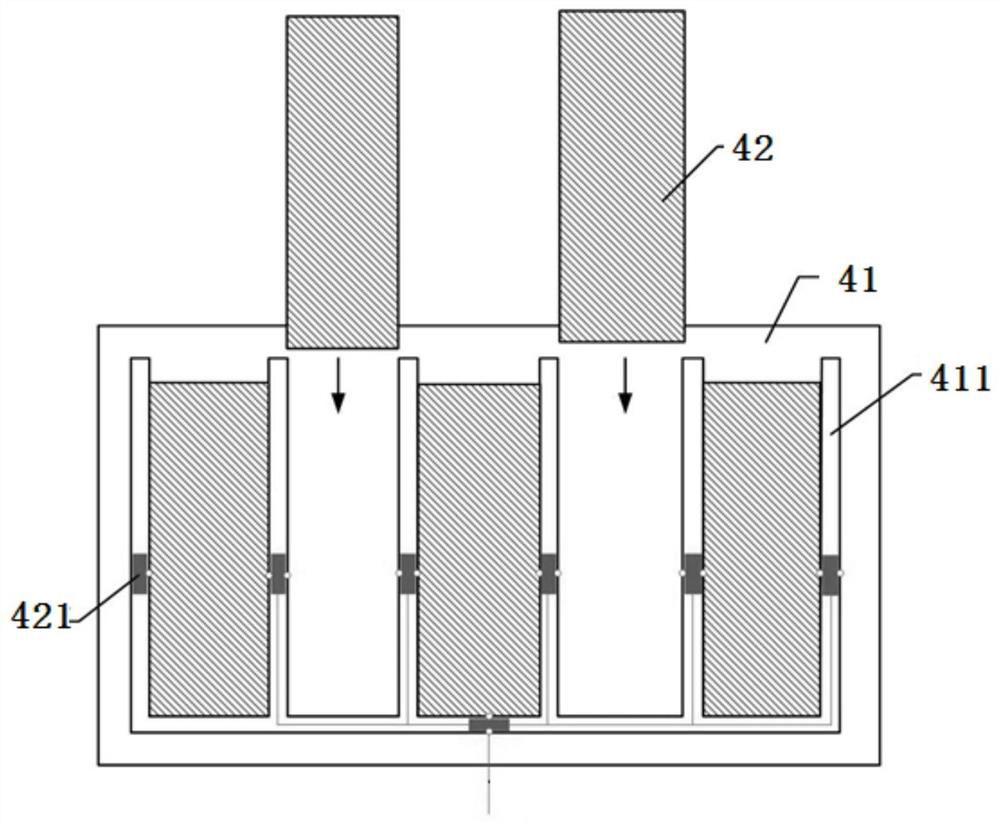

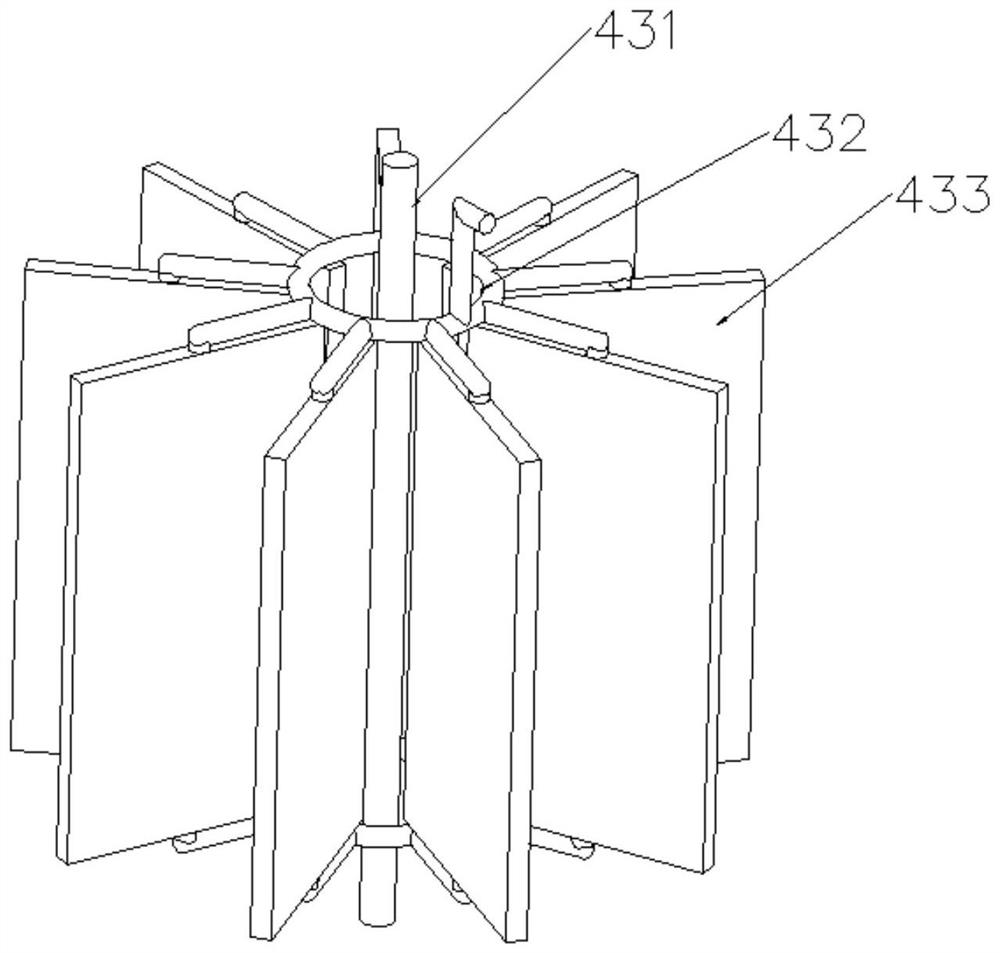

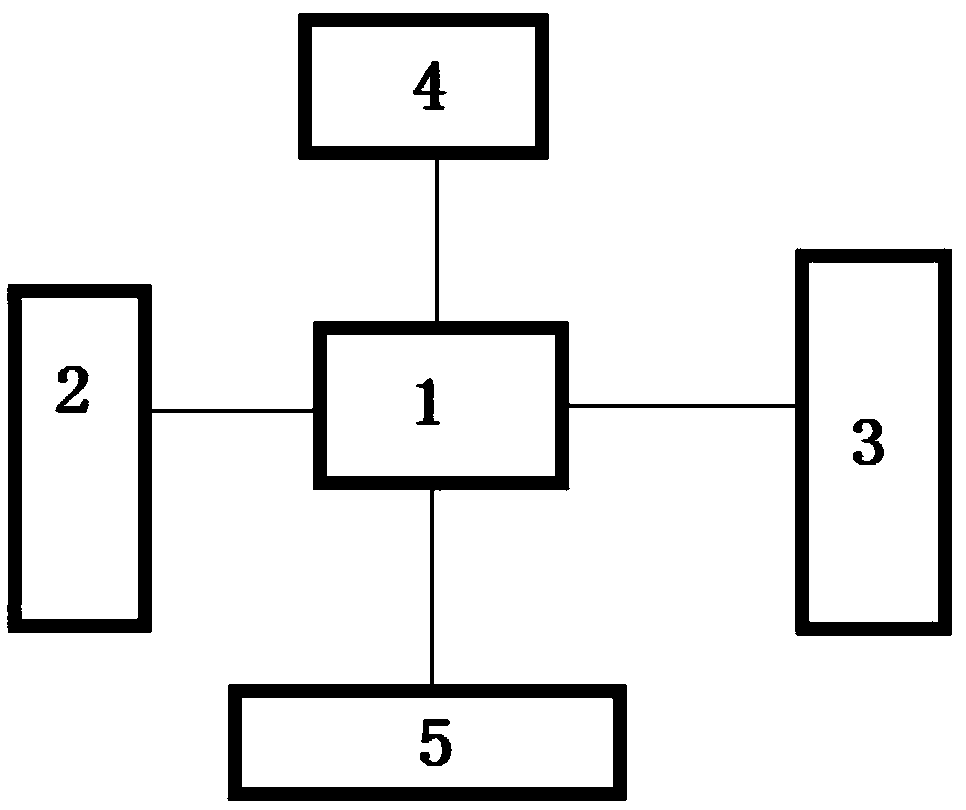

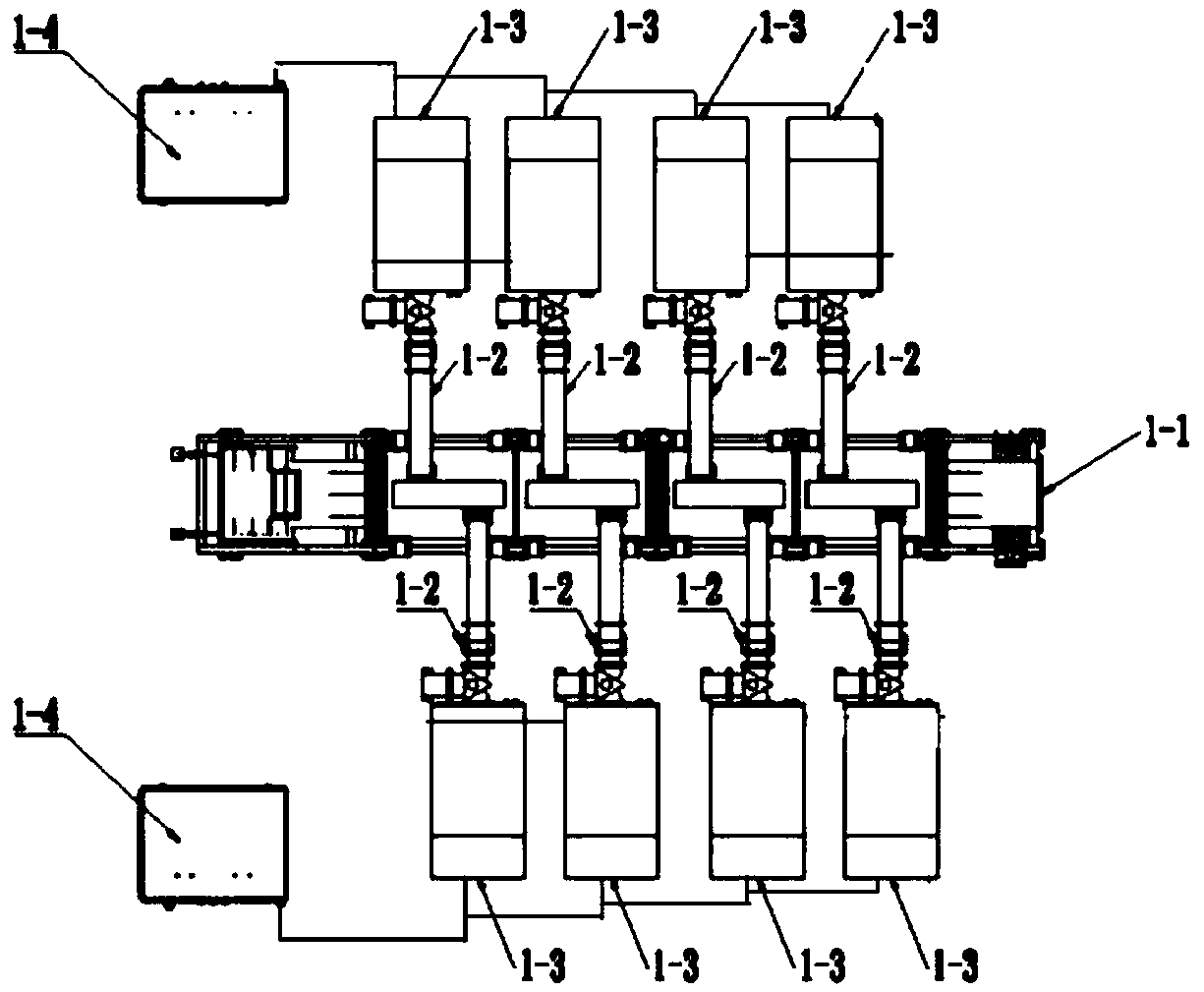

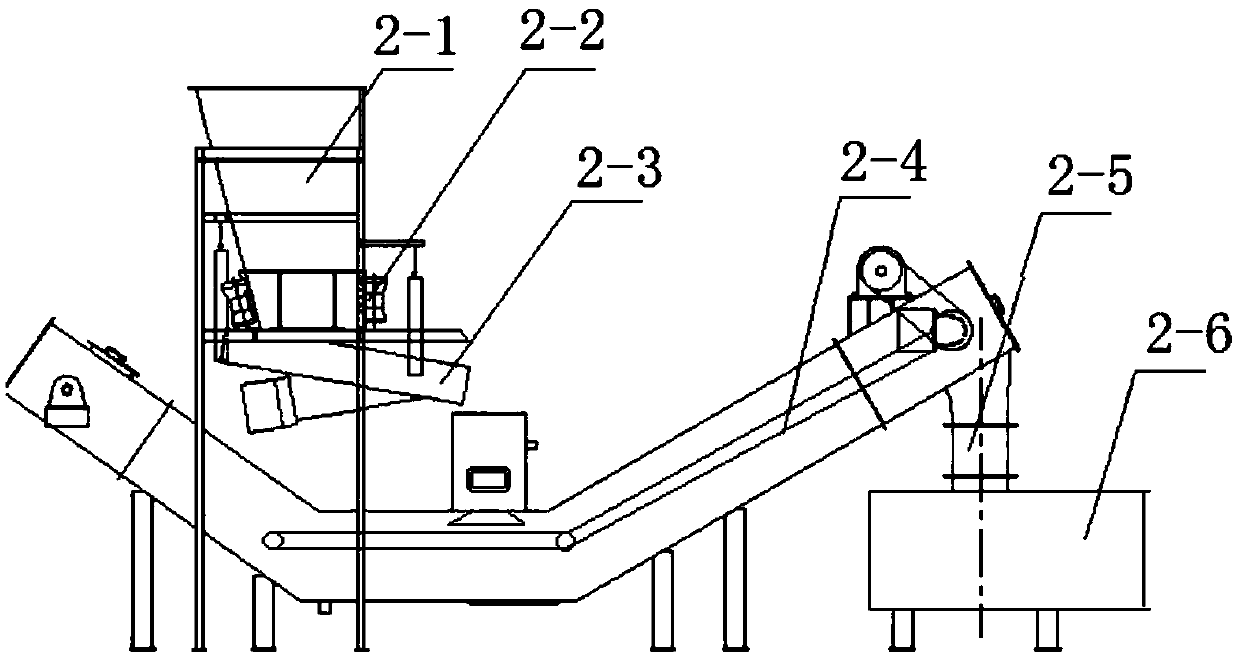

Environment-friendly treatment device for industrial waste rubber

InactiveCN108753339AEfficient Adsorption RemovalAchieve zero discharge treatmentGas treatmentDispersed particle separationOxygenSoot

The invention discloses an environment-friendly treatment device for industrial waste rubber. The device comprises a microwave cracking system (1), a closed oxygen-isolating feed transmission system (2), a waste gas purification treatment system (3), a hot air circulation system (4) and a discharge system (5). The closed oxygen-isolating feed transmission system (2), the waste gas purification treatment system (3), the hot air circulation system (4) and the discharge system (5) are all connected to the microwave cracking system (1). The environment-friendly treatment device provided by the invention has reasonable structural design and strong environmental friendliness, and adopts the microwave heating cracking and environment-friendly waste gas purification treatment system to perform high temperature cracking treatment on waste tires, and can effectively adsorb and remove pollutants such as soot, aliphatic hydrocarbon, aromatic hydrocarbon, dioxin, carbon monoxide and sulfur-containing compounds, the practicability is high.

Owner:JIANGSU LVDI ENVIRONMENTAL PROTECTION FILTER

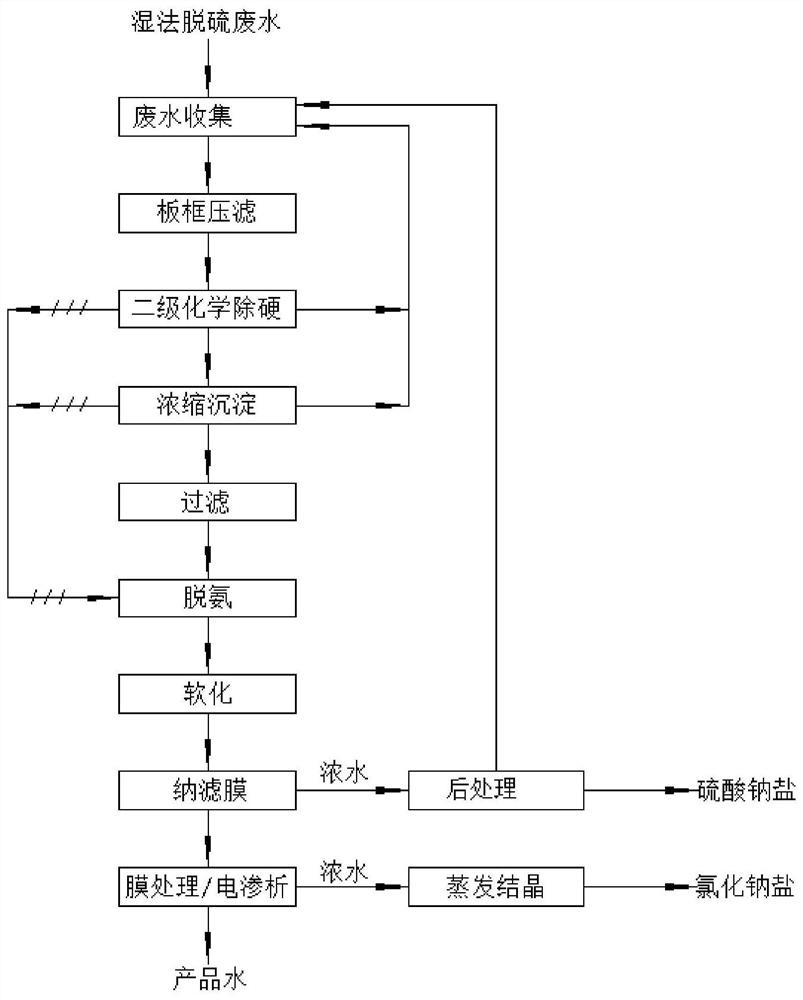

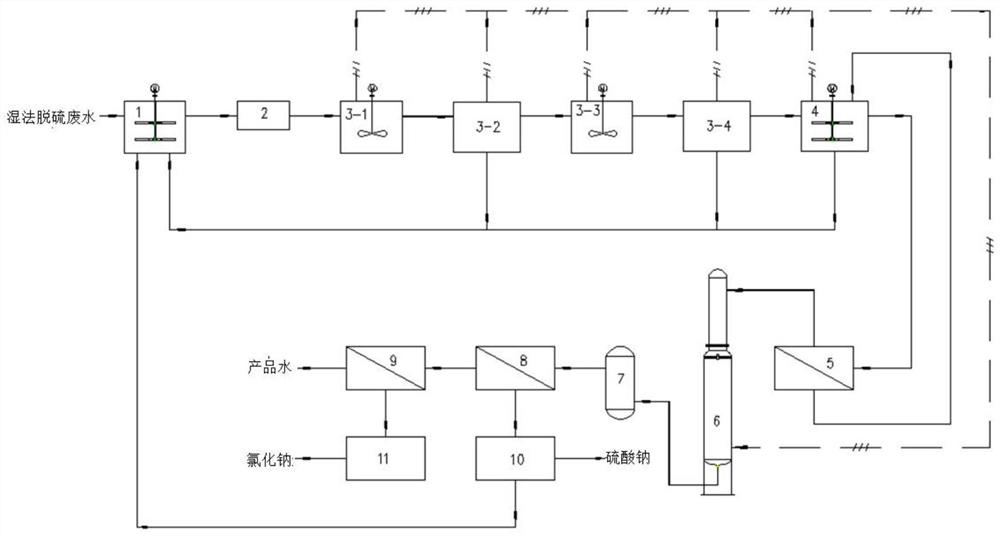

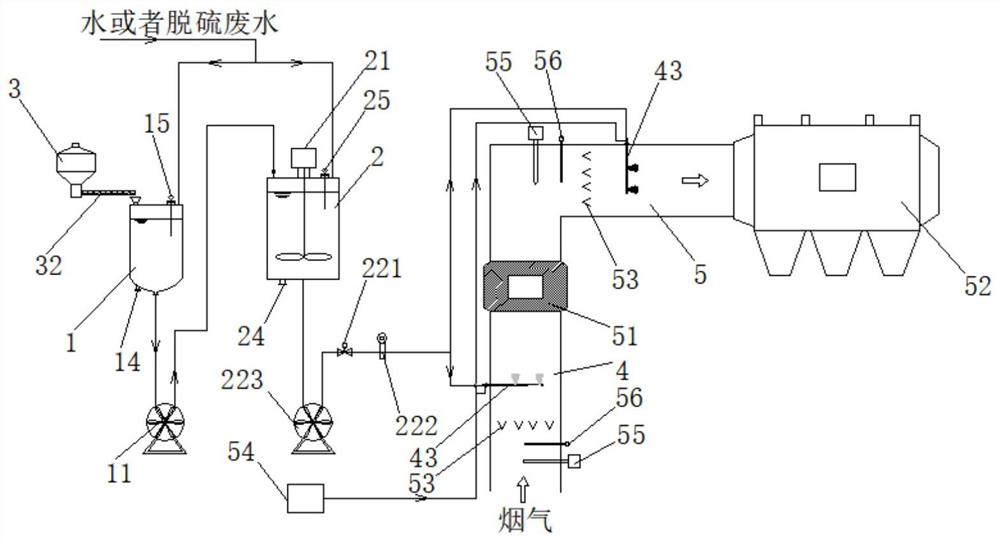

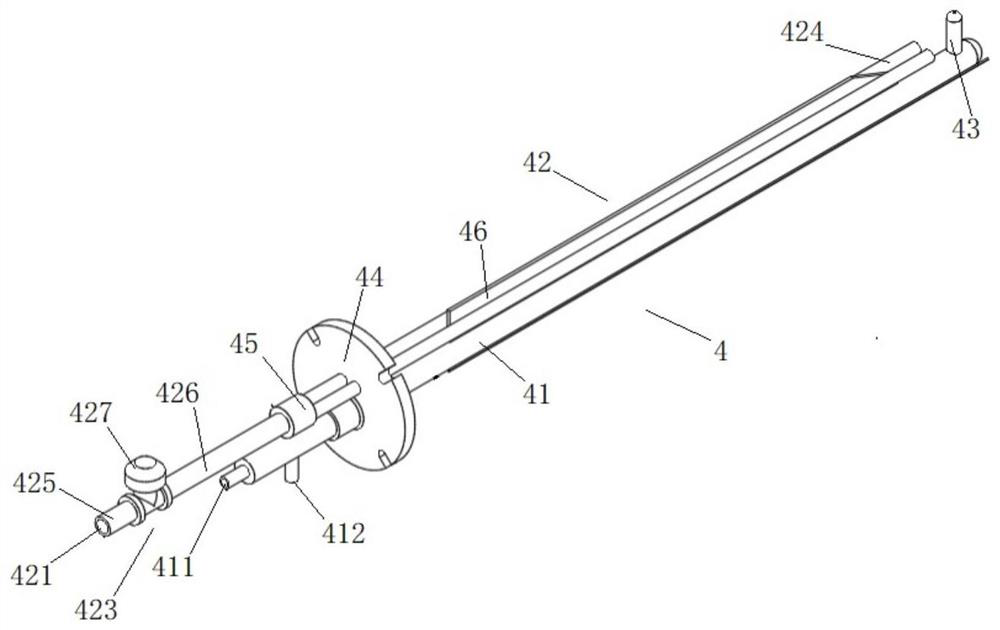

Steel wet desulphurization wastewater treatment system and method

PendingCN112794520AReduce operating burdenAchieve zero discharge treatmentAlkali metal sulfites/sulfates preparation formScale removal and water softeningNanofiltrationSULFATE ION

The invention discloses a steel wet desulphurization wastewater treatment system and method. The method comprises the following steps: carrying out plate-and-frame pressure filtration, secondary chemical hardness removal, concentration precipitation on steel wet desulfurization wastewater, conducting filtration treatment to remove impurities in the wastewater, carrying out deamination treatment to remove ammonia nitrogen in the wastewater, and carrying out softening treatment, nanofiltration membrane treatment, membrane treatment or electrodialysis treatment and evaporative crystallization treatment to obtain clear water and high-purity sodium sulfate and sodium chloride. According to the method, complex factors such as gypsum suspended solids, high hardness, high chloride ions, high ammonia nitrogen, high sulfate ions, fluorine ions, heavy metal ions and COD in the wastewater can be effectively removed, the obtained clear water can be recycled as industrial new water, and zero discharge treatment of the steel wet desulfurization wastewater is realized; and high-purity sodium chloride and sodium sulfate salt with certain economic recovery value are obtained, so that recycling of resources is realized.

Owner:中冶北方(大连)工程技术有限公司

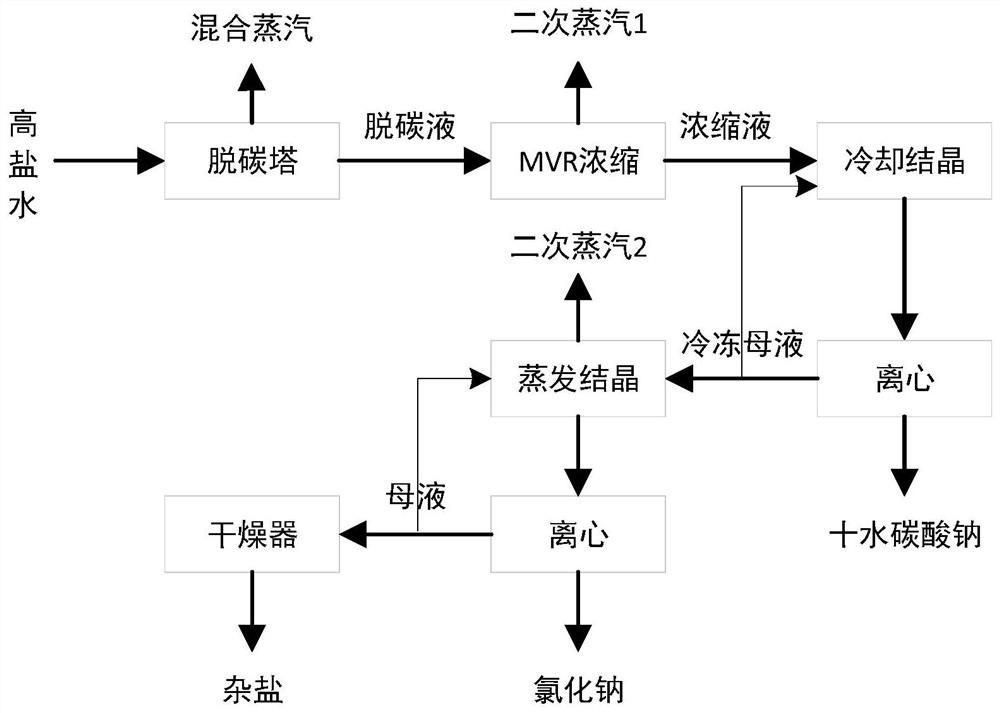

Zero-discharge treatment method and system for high-carbonate mine water

PendingCN112110591AHigh purityGuaranteed cycleWater/sewage treatment by centrifugal separationWater treatment parameter controlWastewaterWater resources

The invention relates to a high-carbonate mine water zero-emission treatment method and system. The system comprises: a decarburization unit for converting bicarbonate radicals in high-carbonate minewater into carbonate radicals and removing CO2 dissolved in the mine water; an evaporation and concentration unit for evaporating and concentrating the decarburized mine water to obtain an evaporationand concentration solution containing sodium chloride with the mass concentration of 9-11.8% and sodium carbonate with the mass concentration of 18-20.5%; a cooling crystallization unit for cooling,crystallizing and centrifugally separating the evaporation and concentration solution to obtain sodium carbonate decahydrate and a frozen mother liquor; an evaporative crystallization unit for evaporating, concentrating and centrifugally separating the frozen mother liquor to obtain sodium chloride and an evaporated mother liquor; and a drying unit for drying the evaporated mother liquor discharged by the evaporative crystallization unit to obtain miscellaneous salt. According to the method, sodium carbonate and sodium chloride in high-carbonate mine water can be recycled with low cost and high efficiency, the environmental protection pressure of enterprises is reduced, the treatment cost of the high-salt mine water is reduced, and comprehensive utilization of wastewater resources is realized.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

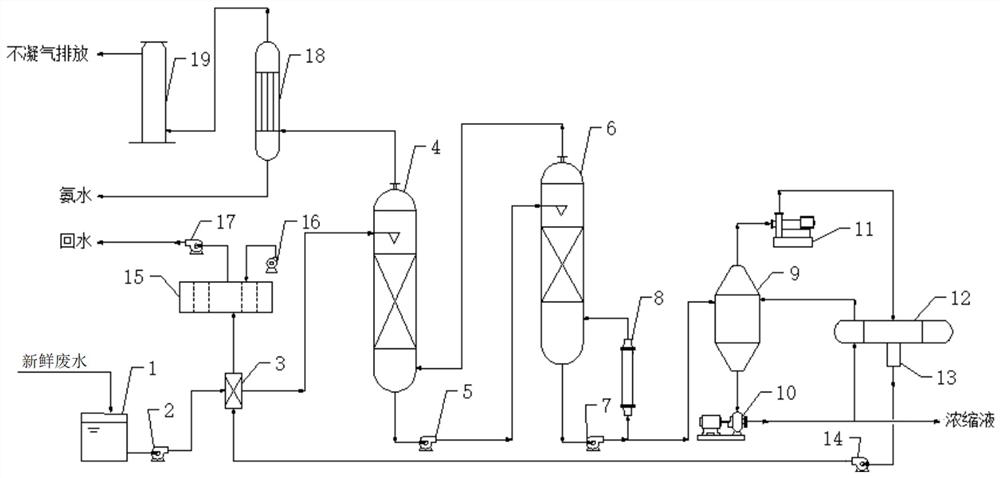

Zero discharge treatment process of industrial cleaning waste water

ActiveCN110002692AAchieve zero discharge treatmentLow viscosityWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesWastewaterSilicon

The invention relates to a zero discharge treatment process of industrial cleaning waste water, belonging to the technical field of water treatment. In order to solve the problem that there is no better treatment method for the large amount of waste water produced in the process of removing pollutants and self-oxides from the surface of silicon wafer, the invention discloses a method for treatingcleaning waste liquid. On one hand, the method can effectively recover solids such as silicon powder, on the other hand, the effective components in the cleaning liquid can be effectively recovered and utilized, and at the same time, the effect of zero discharge of the entire cleaning liquid can be realized.

Owner:济南上华科技有限公司

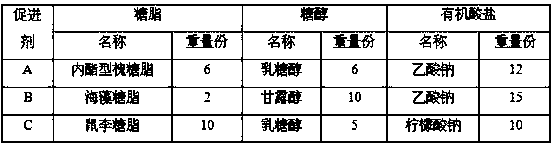

Comprehensive treating method for high-salt-content wastewater

InactiveCN108117220AReduce hardnessGuaranteed uptimeWater/sewage treatment by centrifugal separationTreatment using aerobic processesReduction treatmentMicrobial agent

The invention relates to a comprehensive treating method for high-salt-content wastewater. The comprehensive treating method comprises the following steps: (1) pre-treatment: adding a salt-tolerant bacterial agent and a growth promoter into an existing membrane bioreactor; (2) coagulation and sedimentation: carrying out coagulation and sedimentation by using a lime-soda ash softening process; (3)reduction treatment: subjecting the settled wastewater to reduction treatment in virtue of reverse osmosis; (4) biochemical treatment: adding the salt-tolerant microbial agent and the growth promoterused in the step (1); (5) concentration treatment; and (6) crystallization treatment. Compared with the prior art, the treating method of the invention achieves efficient removal of pollutants such asCOD and total nitrogen by using the salt-tolerant microbial agent and the growth promoter in the membrane bioreactor and a biochemical treatment system, and can effectively reduce membrane contamination, prolong the service life of membranes and ensure the stable operation of the system.

Owner:CHINA PETROLEUM & CHEM CORP +1

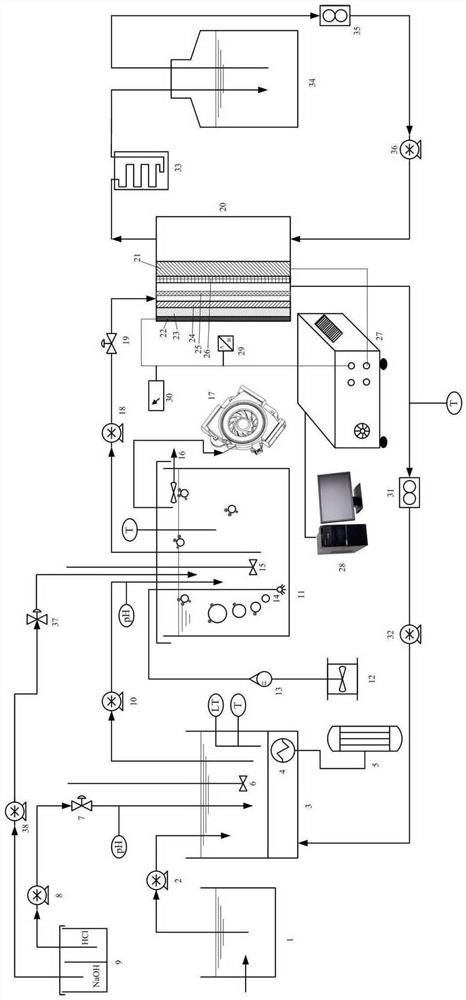

Treatment method for landfill leachate

ActiveCN105152462ASmall footprintReduce labor intensityMultistage water/sewage treatmentActivated sludgeBiofilm

The invention discloses a method for treating landfill leachate by using biofilm sponge as a biological evaporating expanding agent and a biological carrier in combination with MVC. The method adopts an MVC system, preparation of biofilm sponge and a biological evaporating system. The biofilm sponge is prepared through inoculating polyurethane sponge with activated sludge and carrying out aerating and cultivation for acclimation; the leachate is subjected to MVC evaporation treatment to generate a concentrated liquor, and the concentrated liquor is treated through biological evaporation technology. According to the invention, metabolic heat generated by degradation of organic pollutant microorganisms in the MVC concentrated liquor is utilized to evaporate water in the concentrated liquor; the biofilm sponge which is light in weight, is easily available and is short in culture period and free of secondary pollution is used as the biological evaporating expanding agent and the biological carrier, and heat in the concentrated liquor and condensate water generated by MVC treatment are utilized for the needs of a heat source in the biological evaporating process, so that heat energy in the whole system is recycled to the maximum extent. Problems in the conventional pure physical separation process are overcome, and not only can water in the leachate be evaporated, but also polluting substances in the leachate can be reduced.

Owner:KUNMING UNIV OF SCI & TECH

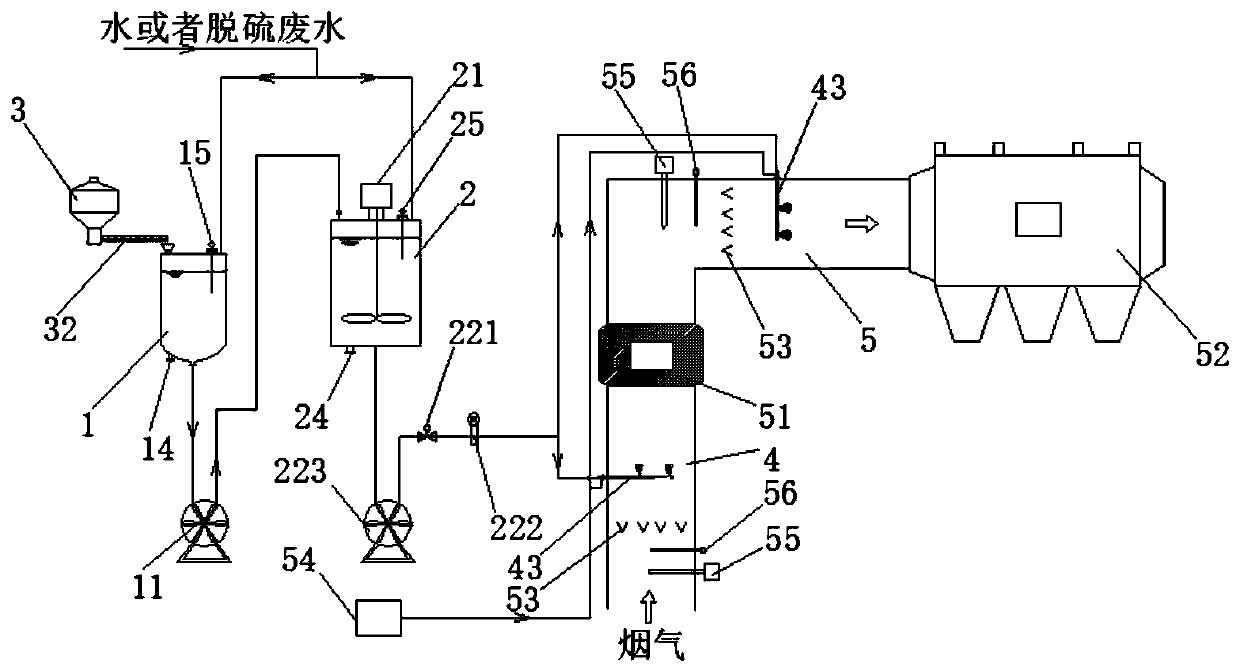

Desulfurization wastewater resourceful treatment system and desulfurization wastewater resourceful treatment method

PendingCN111039488AAchieving zero emissionsImplement resourcesWaste water treatment from gaseous effluentsMultistage water/sewage treatmentMembrane distillationProcess engineering

The invention relates to the field of desulfurization wastewater treatment, particularly to a desulfurization wastewater resourceful treatment system and a desulfurization wastewater resourceful treatment method. The desulfurization wastewater resourceful treatment system comprises a triple box mechanism, a lime milk flocculation mechanism, a mirabilite flocculation mechanism, a soda ash flocculation mechanism, a nanofiltration mechanism, a membrane distillation mechanism and a bipolar membrane electrodialysis mechanism, wherein the triple box mechanism, the lime milk flocculation mechanism, the mirabilite flocculation mechanism, the soda ash flocculation mechanism, the nanofiltration mechanism, the membrane distillation mechanism and the bipolar membrane electrodialysis mechanism are sequentially communicated, and the nanofiltration mechanism is communicated with the mirabilite flocculation mechanism. According to the desulfurization wastewater resourceful treatment system provided bythe invention, the desulfurization wastewater of a coal-fired power plant can be resourcefully utilized, and zero-discharge treatment of the wastewater can be realized.

Owner:DATANG ENVIRONMENT IND GRP

A zero-discharge treatment process for industrial cleaning wastewater

ActiveCN110002692BAchieve zero discharge treatmentLow viscosityWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesWastewaterSilicon chip

Owner:济南上华科技有限公司

Method for preparing iron oxide red by utilizing iron-containing pickling waste liquid

ActiveCN112875762AAchieve zero discharge treatmentLow running costCalcium/strontium/barium chloridesFerric oxidesIron(II) oxideFerrous

The invention relates to a preparation method of pigment-grade iron oxide red, in particular to a method for preparing iron oxide red by utilizing iron-containing pickling waste liquid. The method comprises the following process steps of: generating ferrous hydroxide, generating seed crystal delta-FeOOH, generating a-Fe2O3 crystal nucleus, carrying out in-situ reaction, preparing solid iron oxide red and calcium chloride and the like. The method effectively solves the problems of high production cost, low space-time efficiency and the like in the prior art, and has the advantages that the economic benefit is remarkable, the operation cost is low, and the product meets the relevant requirements of the national standard.

Owner:JIACHENG ENVIRONMENTAL PROTECTION ENG CO LTD

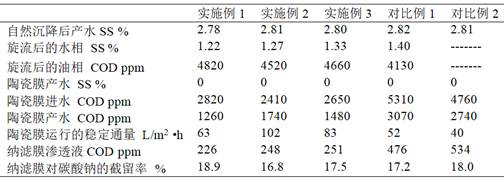

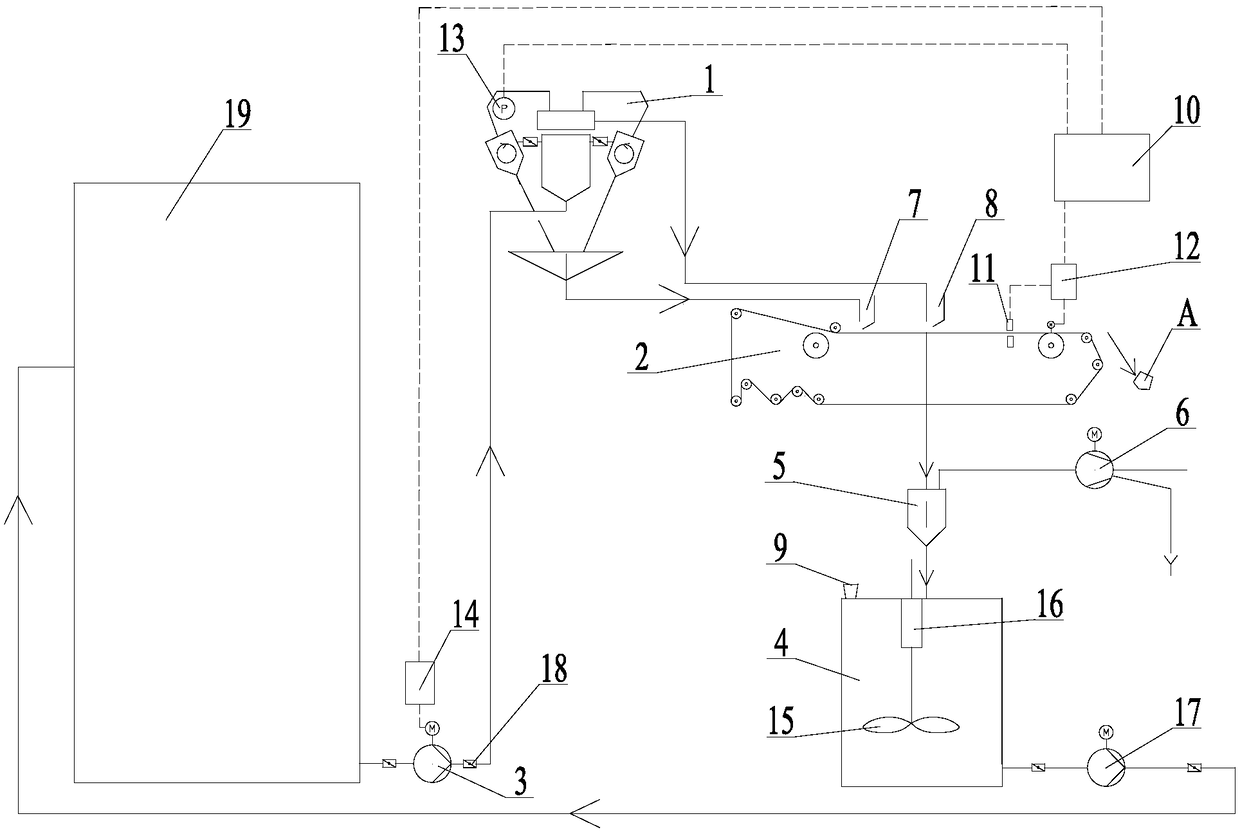

Treatment system and method for realizing zero emission of landfill leachate and fermented biogas slurry

PendingCN112142264AAvoid pollutionReduced operating and investment costsWater contaminantsMultistage water/sewage treatmentBiogasTreatment system

According to the treatment system and method for realizing zero emission of the landfill leachate and the fermented biogas slurry. The landfill leachate and the fermented biogas slurry are subjected to thermal extraction twice, most ammonia nitrogen in the wastewater is removed, and ammonia water is obtained after condensation; residual ammonia nitrogen and volatilizable small molecular COD in thewastewater are removed by adopting a mechanical vapor recompression technology (MVR for short) and a forced circulation flash evaporation technology, and the wastewater is fed into a biochemical reactor for biochemical treatment to obtain regenerated return water; and innocent treatment is performed on the residual high-concentration waste liquid. Therefore, zero emission of landfill leachate andfermented biogas slurry is realized. By adopting the system and the method disclosed by the invention, the wastewater can be completely recycled, the zero-emission treatment of high-ammonia-nitrogenand high-COD landfill leachate and fermented biogas slurry is realized, the biodegradability of the wastewater is improved, the produced ammonia water can bring certain economic benefits, the operation and investment cost of the system is reduced, the heat energy in the system is repeatedly recycled, and the system has the characteristics of low energy consumption, and high efficiency.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

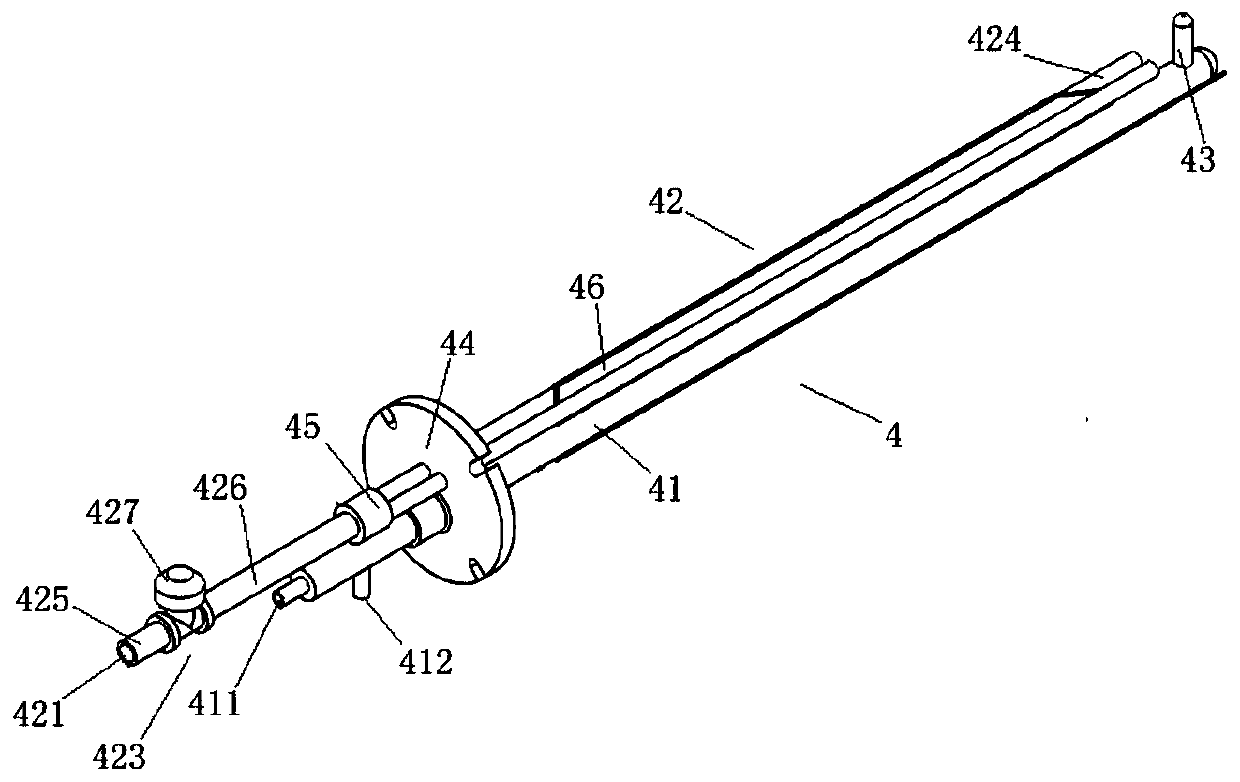

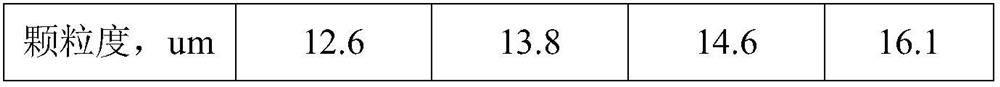

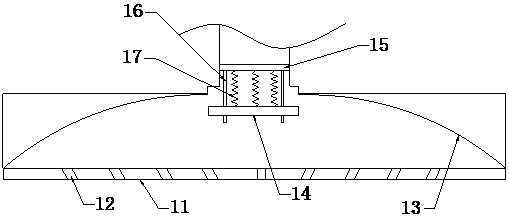

A method and device for preparing nacl industrial salt with zero discharge of desulfurization wastewater

ActiveCN104860461BReduce hardnessHigh purityMultistage water/sewage treatmentAlkali metal chloridesEvaporationWater processing

The invention provides a method for preparing NaCl industrial salt with desulphurization waste water zero discharge. First, suspensions and colloids in desulphurization waste water are aggregated into large particles and precipitate, then the waste water without suspensions and colloids is evaporated, during the initial period of evaporation, seed crystals are added into the waste water, thus substances easy to scale are precipitated, the precipitated substances easy to scale are discharged, the residual solution system is subjected to condensation, crystallization, dehydration and drying, and NaCl industrial salt with a high purity is obtained. Through a mode of addition of seed crystals, the substances easy to scale in the waste water are precipitated with the seed crystals as crystal nucleuses firstly, then the precipitated substances easy to scale are discharged, the impurity ion content in the waste water system is lowered, the waste water hardness is lowered effectively, scaling on inner surfaces of a waste water processing device can be avoided effectively, and finally production of NaCl industrial salt products with a high purity can be achieved.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

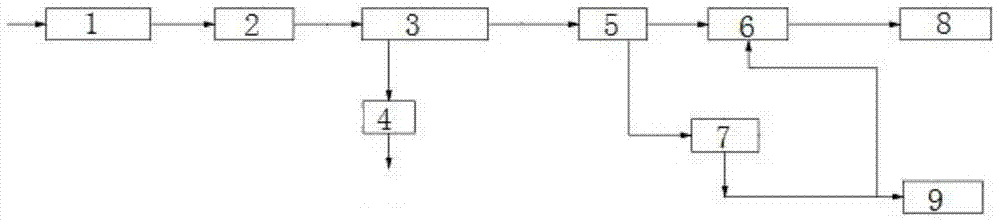

Zero-discharge treatment method and system for coking ammonia distillation wastewater

InactiveCN111807629ARealize resource utilizationImprove biodegradabilityWater contaminantsTreatment with aerobic and anaerobic processesUltrafiltrationFiltration

The invention belongs to the technical field of wastewater treatment, and particularly relates to a zero-discharge treatment method and system for coking ammonia distillation wastewater. According tothe zero-discharge treatment method for coking ammonia distillation wastewater, the coking ammonia distillation wastewater is sequentially subjected to ozone pre-oxidation, air floatation, electrocatalytic oxidation, an A / O biochemical process, precipitation, flocculation, ozone catalytic oxidation, a biological aerated filter process, ultrafiltration membrane filtration, nanofiltration membrane filtration and reverse osmosis membrane treatment; the electrocatalytic oxidation hydraulic retention time is 10-60 min; an anode plate is a lead-rhenium coating electrode, a cathode is a graphite carbon electrode, the distance between polar plates is 3-10 cm, and the current density is 5-20 mA / cm<2>. According to the treatment method, the treatment cost is low, deep treatment is achieved, the treated coking ammonia distillation wastewater is recycled, and zero emission is truly achieved. The invention further provides the coking ammonia distillation wastewater zero-discharge treatment system which is convenient to operate.

Owner:山东锐海环境科技有限公司

A treatment method for landfill leachate

ActiveCN105152462BSmall footprintReduce labor intensityMultistage water/sewage treatmentActivated sludgeEvaporation

The invention discloses a method for treating landfill leachate by using biofilm sponge as a biological evaporating expanding agent and a biological carrier in combination with MVC. The method adopts an MVC system, preparation of biofilm sponge and a biological evaporating system. The biofilm sponge is prepared through inoculating polyurethane sponge with activated sludge and carrying out aerating and cultivation for acclimation; the leachate is subjected to MVC evaporation treatment to generate a concentrated liquor, and the concentrated liquor is treated through biological evaporation technology. According to the invention, metabolic heat generated by degradation of organic pollutant microorganisms in the MVC concentrated liquor is utilized to evaporate water in the concentrated liquor; the biofilm sponge which is light in weight, is easily available and is short in culture period and free of secondary pollution is used as the biological evaporating expanding agent and the biological carrier, and heat in the concentrated liquor and condensate water generated by MVC treatment are utilized for the needs of a heat source in the biological evaporating process, so that heat energy in the whole system is recycled to the maximum extent. Problems in the conventional pure physical separation process are overcome, and not only can water in the leachate be evaporated, but also polluting substances in the leachate can be reduced.

Owner:KUNMING UNIV OF SCI & TECH

Chloride ion passivant, preparation method of passivant and treatment method for desulfurization wastewater

ActiveCN110759567AGood effectLow priceSpecific water treatment objectivesWater contaminantsWater resourcesEnvironmental engineering

The present invention provides a chloride ion passivant. The passivant comprises the following components in percentages by mass: 0.001-0.2%of an amine, 0.0001-0.01% of an ester, and the balance of water, wherein the amine is polyacrylamide and / or alkenylamine, and the ester is an acrylic acid-acrylate copolymer or an acrylic acid-AMPS-maleic anhydride terpolymer. The invention also provides a preparation method of the chloride ion passivant; and the invention also provides a treatment method for desulfurization wastewater, wherein the treatment method uses the above chloride ion passivant. According to the treatment method, after the passivant is added into the desulfurization wastewater, chloride ions are deactivated, chloride ion corrosion is inhibited, the desulfurization wastewater isconverted into non-corrosive ordinary wastewater for evaporation and crystallization treatment, so that the investment costs of the system are significantly reduced, the service life of the system isgreatly prolonged, the reliability of the system is greatly improved, no by-products appear, zero discharge treatment of the desulfurization wastewater is realized, and the water resource environmentis protected.

Owner:武汉天空蓝环保科技有限公司

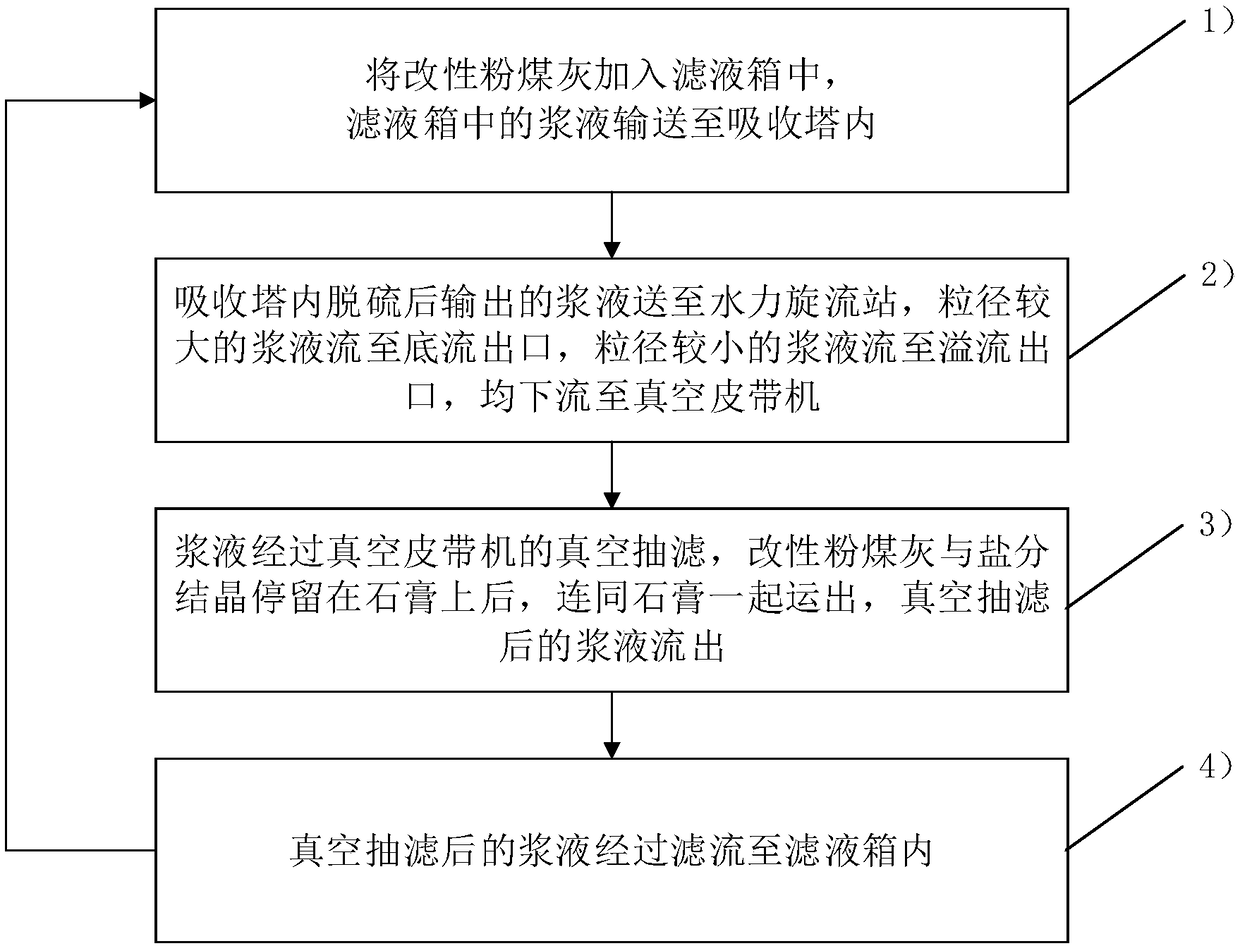

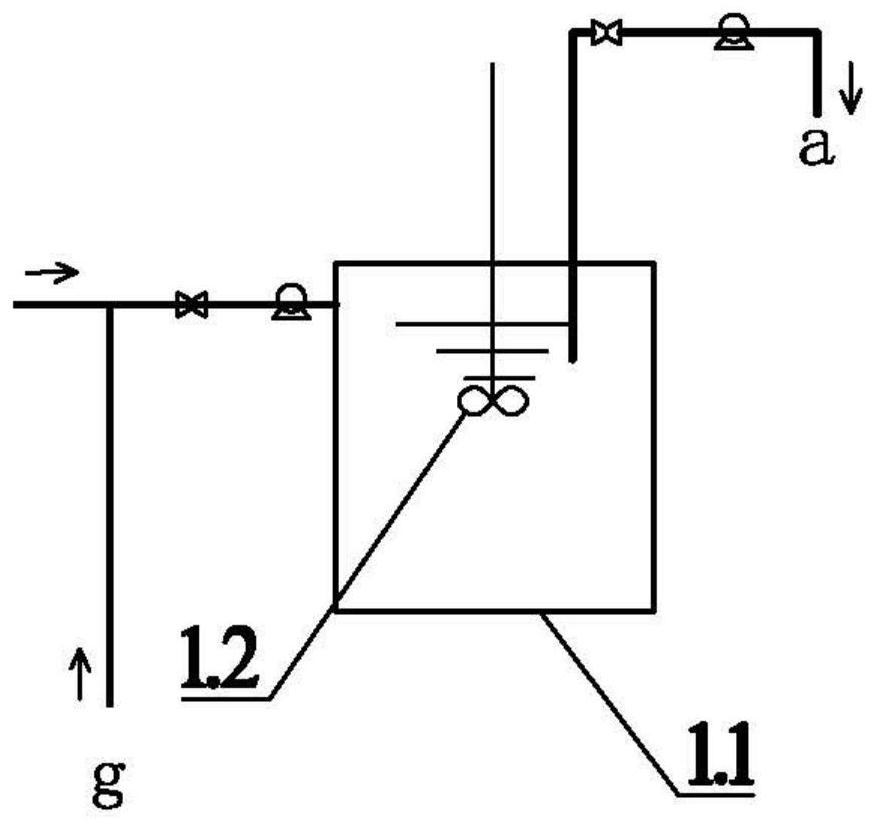

Method and system for zero release treatment of limestone-gypsum desulfurization wastewater

PendingCN108178362AAchieving zero emissionsConvenient zero-emission disposalDispersed particle separationTreatment involving filtrationFiltrationEngineering

The invention relates to a method and a system for zero release treatment of limestone-gypsum desulfurization wastewater. The method comprises steps as follows: 1) modified fly ash is added to a filtrate tank, and slurry in the filtrate tank is conveyed to an absorbing tower; 2) slurry output after desulfurization in the absorbing tower is conveyed to a hydrocyclone station, slurry with larger particle size flows to a base flow outlet and then flows to a vacuum belt machine, and slurry with smaller particle size flows to an overflow outlet and flows to the vacuum belt machine; 3) the slurry issubjected to vacuum suction filtration through the vacuum belt machine, modified fly ash and salt crystalize and stay on gypsum and are transported out together with gypsum, and slurry subjected to vacuum suction filtration flows out; 4) the slurry subjected to vacuum suction filtration flows into the filtrate tank after being filtered. Compared with the prior art, the method and the system havethe advantages that desulfurization wastewater can be very conveniently subjected to zero release treatment, a process is simple, zero release of the desulfurization wastewater can be really realized,and the method and the system have popularization value.

Owner:ZHONGDIAN HUACHUANG ELECTRIC POWER TECH RES

A zero-discharge device and method for treating late-stage landfill leachate

ActiveCN109336325BImprove nitrogen removal rateAchieve zero discharge treatmentWater contaminantsMultistage water/sewage treatmentFiltrationCarbonization

The invention relates to the technical field of environmental engineering. The purpose is to provide a device and method for zero-discharge treatment of late landfill leachate, which can improve the overall reaction efficiency of short-range nitrification-ANAMMOX, realize zero-discharge treatment of landfill leachate, and can remove landfill leachate Phosphorus, organic matter and heavy metal ions in the The technical solution is: a device for treating late-stage landfill leachate with zero discharge, which is characterized in that it includes a regulating tank unit, a short-range nitrification-anammox integrated reactor unit, a carbonization tank unit, a denitrification tank unit, a spirulina-nitrification Pool unit, sedimentation tank, membrane filtration system unit and intelligent control system; the short-range nitrification-anammox integrated reactor unit includes a short-range nitrification tank unit and anammox reactor unit; the spirulina-nitration tank unit It includes a spirulina pool unit and a nitrification pool unit; the membrane filtration system unit includes a microfilter, a nanofilter and an ultrafilter.

Owner:ZHEJIANG WUTE ENVIRONMENTAL PROTECTION TECHCO

Ship ballast water treatment system based on electro-catalysis and membrane distillation integrated device

ActiveCN113247990AMeeting fresh water needsEfficient oxidative degradationGeneral water supply conservationWater treatment compoundsWater sourceBallast water treatment

The invention discloses a ship ballast water treatment system based on an electro-catalysis and membrane distillation integrated device. The ship ballast water treatment system comprises a ship engine cooling pool, and a hot side heating device, a hot side water tank, an electro-catalysis and membrane distillation reactor, a cold side water tank and a penetrating fluid cooling system which are sequentially connected through pipelines. The system further comprises a direct-current power supply used for supplying power to the electro-catalysis and membrane distillation reactor, and a clean water storage tank is connected with the cold side water tank. According to the ship ballast water treatment system, an electrocatalytic oxidation technology and a membrane distillation process are scientifically coupled into an integrated ship ballast water treatment device by adopting a submerged reaction tank method, and the system has the advantages of high organic matter degradation efficiency, high ammonia nitrogen removal rate, high desalination efficiency, good effluent quality, effective alleviation of membrane distillation membrane pollution / membrane wetting, prolonged service life of the distillation membrane, realization of ship ballast water source treatment and reuse, effective solving of ship part fresh water demands, and mitigation of port sewage and wastewater treatment pressure.

Owner:YANGZHOU UNIV

Activated carbon processing environmental protection treatment device

InactiveCN108467039BIndustrial productionAchieve zero discharge treatmentOther chemical processesCarbon compoundsActivated carbonMicrowave pyrolysis

The invention discloses an environment-friendly treatment device for activated carbon processing. The device comprises a microwave pyrolysis system (1), a closed oxygen-isolated feeding and conveyingsystem (2), a waste gas purification treatment system (3), a hot air circulating system (4) and a discharging system (5), wherein the closed oxygen-isolated feeding and conveying system (2), the wastegas purification treatment system (3), the hot air circulating system (4) and the discharging system (5) are all connected with the microwave pyrolysis system (1). The device is reasonable in structural design and high in environmental friendliness, can perform high-temperature pyrolysis treatment on waste tires by the aid of the microwave heating pyrolysis and environment-friendly waste gas purification treatment systems, can effectively adsorb and remove dust, carbon monoxide, sulfur-containing compounds and other pollutants in waste gas and is high in practicability.

Owner:江苏中机绿洲环保工程有限公司

A recovery treatment agent and treatment method for zero discharge of rolling waste liquid

ActiveCN109609251BAchieve zero discharge treatmentReduce processing costsFatty/oily/floating substances removal devicesNon-miscible liquid separationOil canThermodynamics

Owner:NANJING KERUN LUBRICANTS

Chloride ion passivator, preparation method and desulfurization wastewater treatment method

ActiveCN110759567BCorrosion resistanceGood effectSpecific water treatment objectivesWater contaminantsChloride corrosionPolyacrylamide

Owner:武汉天空蓝环保科技有限公司

System and process for realizing zero discharge of wastewater by contacting dry and cold carrier gas with hot wastewater

ActiveCN114105239ACutting costsLow running costWater treatment parameter controlGeneral water supply conservationWastewaterWater resource management

The invention discloses a system and a process for realizing zero discharge of wastewater by contacting dry and cold carrier gas with hot wastewater, comprising: a heat exchange device for heating wastewater, a wastewater outlet of which is connected with a spray layer at the top of an evaporation device; the bubbling device is arranged in the evaporation device, and a nozzle of the bubbling device is inserted into wastewater; an inlet of the fan is communicated with a gas source, an outlet of the fan is connected with a gas inlet of the bubbling device, and the fan is used for providing dry and cold carrier gas for the bubbling device; the straight-through flow guide device comprises a plurality of liquid distribution elements which are vertically arranged in parallel, and the straight-through flow guide device is arranged in the evaporation device and located above the preset liquid level of the wastewater. The dry and cold carrier gas is subjected to shallow bubbling below the wastewater liquid level of the evaporation device through the bubbling device to generate a main concentration process. The temperature and the humidity of the carrier gas after the main concentration process are increased, the evaporation efficiency of the waste water is reduced, at the moment, secondary heat exchange and mass transfer are carried out on the carrier gas and the sprayed waste water in the straight-through flow guide device, and the straight-through flow guide device can be effectively prevented from being scaled and blocked.

Owner:SHANDONG GUOSHUN CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com