Environment-friendly treatment device for industrial waste rubber

A technology for environmental protection treatment and waste rubber, applied in the treatment of hydrocarbon oil, gas treatment, petroleum industry, etc., can solve problems such as large environmental pollution, and achieve the effect of important environmental protection value and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

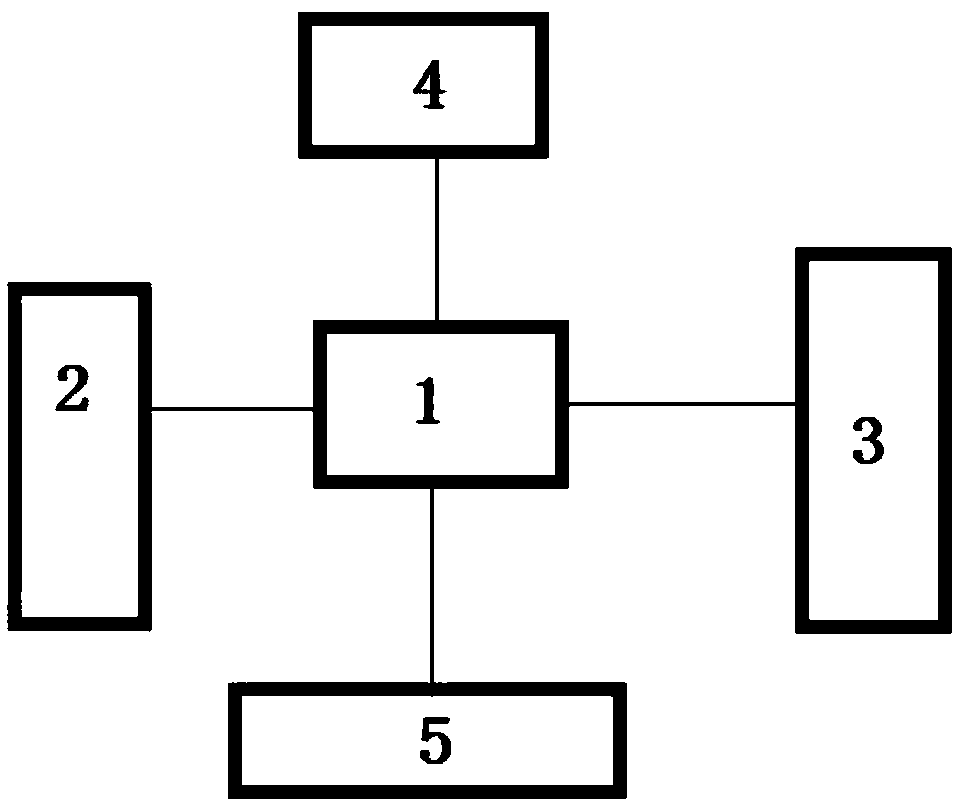

[0027] 1. If Figure 1 to Figure 5 Shown, a kind of industrial waste rubber environment-friendly treatment device, it comprises microwave cracking system 1, airtight oxygen barrier feed transmission system 2, waste gas purification treatment system 3, hot air circulation system 4 and discharge system 5; Described airtight oxygen barrier Feed transmission system 2, exhaust gas purification treatment system 3, hot air circulation system 4 and discharge system 5 are all connected to microwave cracking system 1;

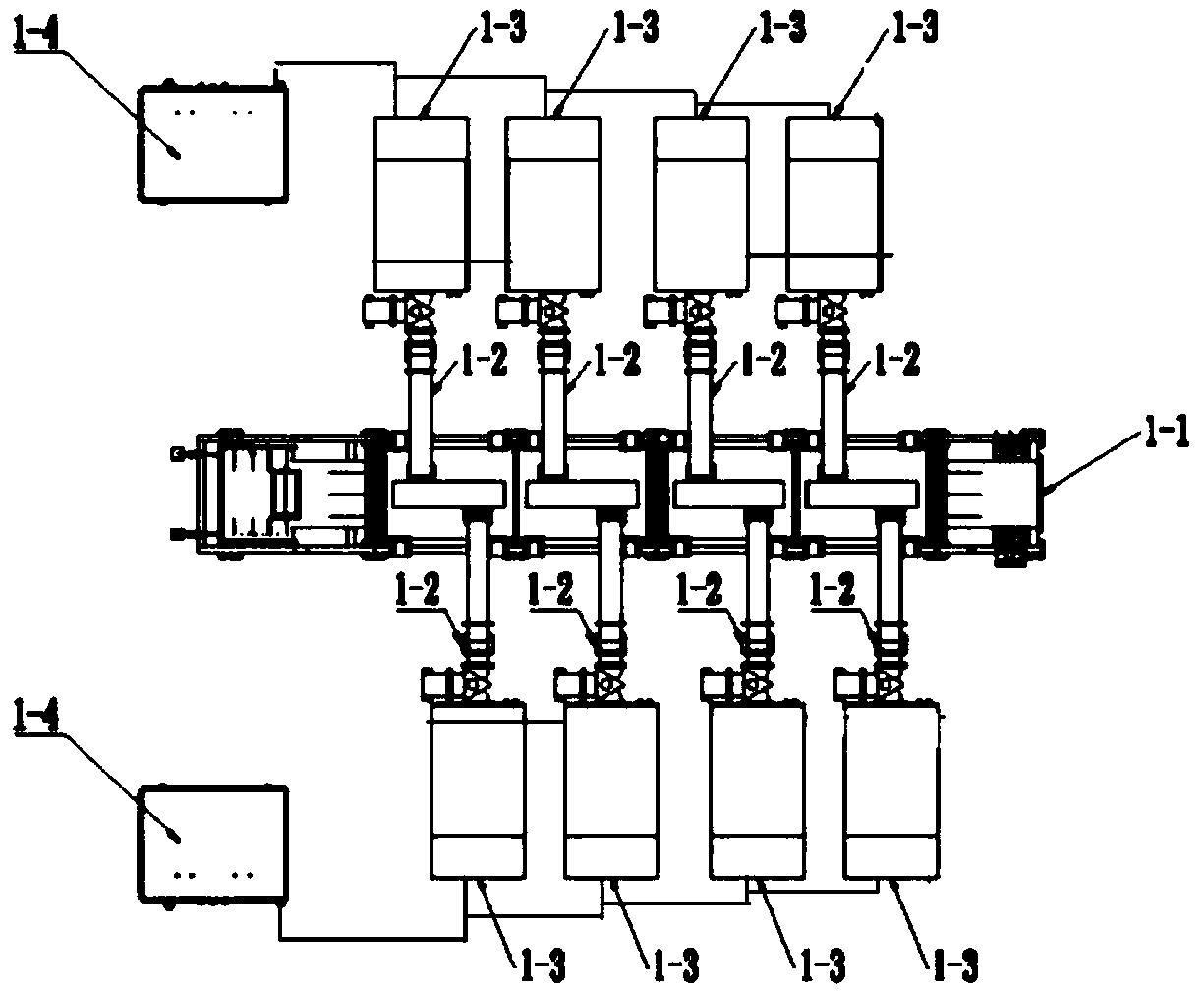

[0028] The microwave cracking system 1 includes a microwave cracking cavity 1-1, a waveguide transmission system 1-2, a microwave generator 1-3 and a microwave power supply 1-4; the waveguide transmission system 1-2 is installed on the microwave cracking cavity 1-1 , the microwave generator 1-3 is connected with the waveguide transmission system 1-2, and the microwave power supply 1-4 is connected with the microwave generator 1-3; the microwave generator 1-3 converts the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com