Zero-discharge treatment method and system for coking ammonia distillation wastewater

A technology of ammonia distillation wastewater and treatment method, which is applied in the directions of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. The problem of low removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

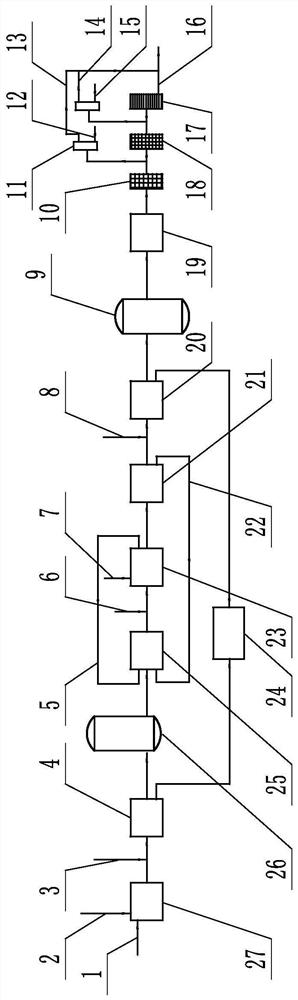

Image

Examples

Embodiment 1

[0064] Ammonia distillation wastewater from a coking plant: COD is 4000mg / L, volatile phenol is 400mg / L, cyanide is 15mg / L, sulfide is 75mg / L, ammonia nitrogen is 1100mg / L.

[0065] Adopt processing method provided by the invention to process:

[0066] The wastewater to be treated is firstly added with 50mg / L ozone and then enters the ozone pre-oxidation tank, and the pre-oxidation time is 30 minutes;

[0067] Add 50mg / L polyaluminium and 3mg / L cationic polyacrylamide to the ozone pre-oxidized effluent and enter the air flotation. The hydraulic retention time of the air flotation is 20 minutes, and the air-water volume ratio is 500:1;

[0068] The air floats out of the water into the electrocatalytic oxidation unit for 10 minutes of oxidation, and the current density between the plates is 5.0mA / cm 2 , the distance between the plates is 10cm;

[0069] The electrocatalytic oxidation effluent enters the anoxic / aerobic biological pool, and the sludge concentration is maintained ...

Embodiment 2

[0077] Ammonia distillation wastewater from a coking plant: COD is 6000mg / L, volatile phenol is 840mg / L, cyanide is 30mg / L, sulfide is 120mg / L, ammonia nitrogen is 1500mg / L.

[0078] Adopt processing method provided by the invention to process:

[0079] The waste water to be treated is firstly added with 80mg / L ozone and then enters the ozone pre-oxidation tank, and the pre-oxidation time is 45 minutes;

[0080] Add 70mg / L polyaluminium and 5mg / L cationic polyacrylamide to the ozone pre-oxidized effluent and enter the air flotation. The hydraulic retention time of the air flotation is 30 minutes, and the air-water volume ratio is 500:1;

[0081] The air floats out of the water into the electrocatalytic oxidation unit for 40 minutes of oxidation, and the current density between the plates is 15mA / cm 2 , the distance between the plates is 6cm;

[0082]The electrocatalytic oxidation effluent enters the anoxic / aerobic biological pool, and the sludge concentration is maintained a...

Embodiment 3

[0090] Ammonia distillation wastewater from a coking company: COD is 8000mg / L, volatile phenol is 1100mg / L, cyanide is 40mg / L, sulfide is 150mg / L, ammonia nitrogen is 2000mg / L.

[0091] Adopt the treatment method provided by the present invention to process: the waste water to be treated first enters the ozone pre-oxidation tank after adding 100mg / L ozone, and the pre-oxidation time is 60 minutes;

[0092] Add 100mg / L polyaluminium and 6mg / L cationic polyacrylamide to the ozone pre-oxidized effluent and enter the air flotation. The hydraulic retention time of the air flotation is 40 minutes, and the air-water volume ratio is 500:1;

[0093] The air floats out of the water and enters the electrocatalytic oxidation unit for 60 minutes of oxidation. The current density between the plates is 20mA / cm 2 , the distance between the plates is 3cm;

[0094] The electrocatalytic oxidation effluent enters the anoxic / aerobic biological pool, and the sludge concentration is kept at about 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com