A recovery treatment agent and treatment method for zero discharge of rolling waste liquid

A technology of recovery treatment and treatment method, which is applied in the direction of separation method, liquid separation, immiscible liquid separation, etc., can solve the problems of unrecyclable, damaged rolling oil performance, poor compatibility, etc., and achieve saving investment cost and treatment The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

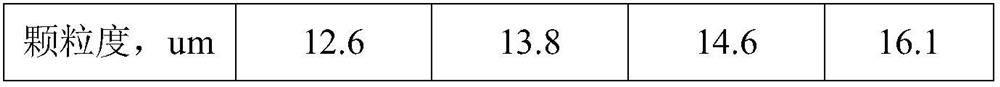

Embodiment 1

[0029] Put 2L of rolling waste emulsion into a beaker, detect that the mass percent concentration of oil in the waste emulsion is 2.5%, that is, the oil content is 50 grams, add oil-water separation oil with 1% (0.5 grams) of oil quality in the waste emulsion agent, stirred for 20 minutes;

[0030] Move the waste emulsion into the separatory funnel, let it stand for 60 minutes, release the lower clear liquid, and then pour the upper layer oil into the recovery oil storage tank;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com