Separated flotation tank-capacitive deionization membrane distillation technology combined electroplating wastewater purification and recycling process system

A capacitive deionization and process system technology, which is applied in the field of electroplating wastewater purification and reuse process system combined with split air flotation tank-capacitive deionization membrane distillation technology, can solve the problem of deteriorating effluent quality, ammonia nitrogen removal rate is only about 70%, Reduce ammonia nitrogen removal rate and other problems, achieve the effect of efficient interception and recycling, novel system structure, and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] (6) Preparation of high-performance electrodes: Activated carbon fiber, graphite and polyvinylidene fluoride were respectively selected as the electrode material, conductive agent and binder of the capacitive deionization membrane distillation reactor electrode, and activated carbon fiber, graphite and polyvinylidene fluoride were prepared according to Proportional mixing and vigorous stirring for 1-2 hours to fully mix, vacuum degassing of the mixed solution for 20 minutes and then transfer to the pourer, choose graphite sheet as the collector plate, place the collector plate on the film laminating machine, and use the film laminating machine to The mixed slurry is pressed on the surface of the graphite sheet, left to solidify for 2-3 days, and then the electrode is dried in a vacuum oven at 150°C for 24 hours to prepare a high-performance electrode plate.

[0028] (7) Preparation of excellent conductive distillation film: select polytetrafluoroethylene as the substrate...

Embodiment 1

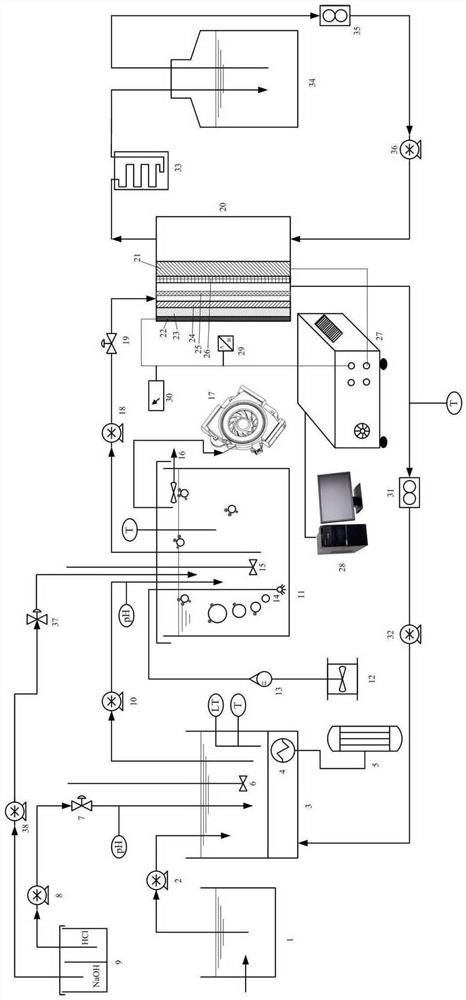

[0031] like figure 1 As shown, a separate air flotation tank-capacitive deionization membrane distillation technology combination electroplating wastewater purification and reuse process system, including sequentially connected water inlet pool 1, membrane distillation heating pool 3, air flotation pool 11, capacitive deionization membrane distillation Reactor 20, condenser 33 and clean water tank 34, the first sewage pump 2 is provided on the connecting pipeline between the water inlet tank 1 and the membrane distillation heating tank 3; the membrane distillation heating tank 3, the air flotation tank 11 and the capacitive deionization membrane distillation The second sewage pump 10, the third sewage pump 18, and the first circulation pump 32 form a circulation system between the reactors 20; the capacitive deionization membrane distillation reactor 20 and the clean water pool 34 are connected to form a circulation structure through two connecting pipes, and the two A second ...

Embodiment 2

[0039] The electroplating wastewater produced by an electroplating factory in Jiangsu was treated with the above devices and processes.

[0040] (1) The electroplating waste water produced by the electroplating factory is passed into the membrane distillation heating pool 3 for heat treatment, and the temperature of the waste water is controlled at about 75°C.

[0041] (2) After the temperature of the electroplating wastewater rises to 75° C., the pH value of the wastewater in the heating pool is adjusted to about 5 through the pH online monitoring sensor, the computer program and the pH adjustment pool 9 .

[0042] (3) After the water temperature and pH are adjusted, the electroplating wastewater enters the air flotation tank 11 through the second sewage pump 10 for pretreatment. The water temperature is controlled at 60±5°C, the pH is between 11 and 13, and the air flotation treatment is carried out for 60 minutes. The gas removed by the air flotation tank, including volatil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com