Method for treating waste acetonitrile water with high salt content in zero-discharge mode and special device of method

A special device and high salt content technology, applied in the field of environmental engineering, can solve the problem of high oxygen utilization rate, achieve high oxygen utilization rate, strengthen biological denitrification, and start quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

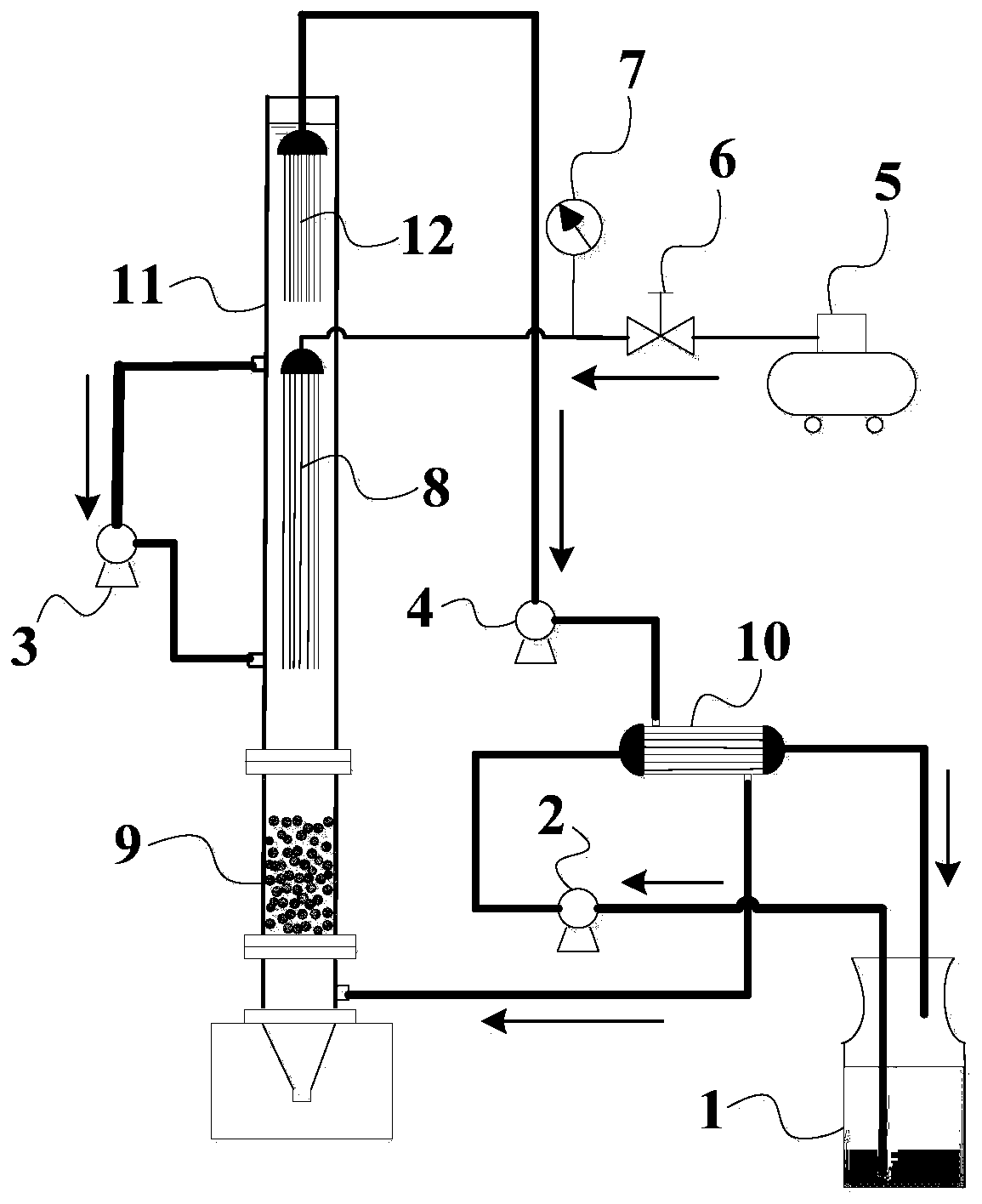

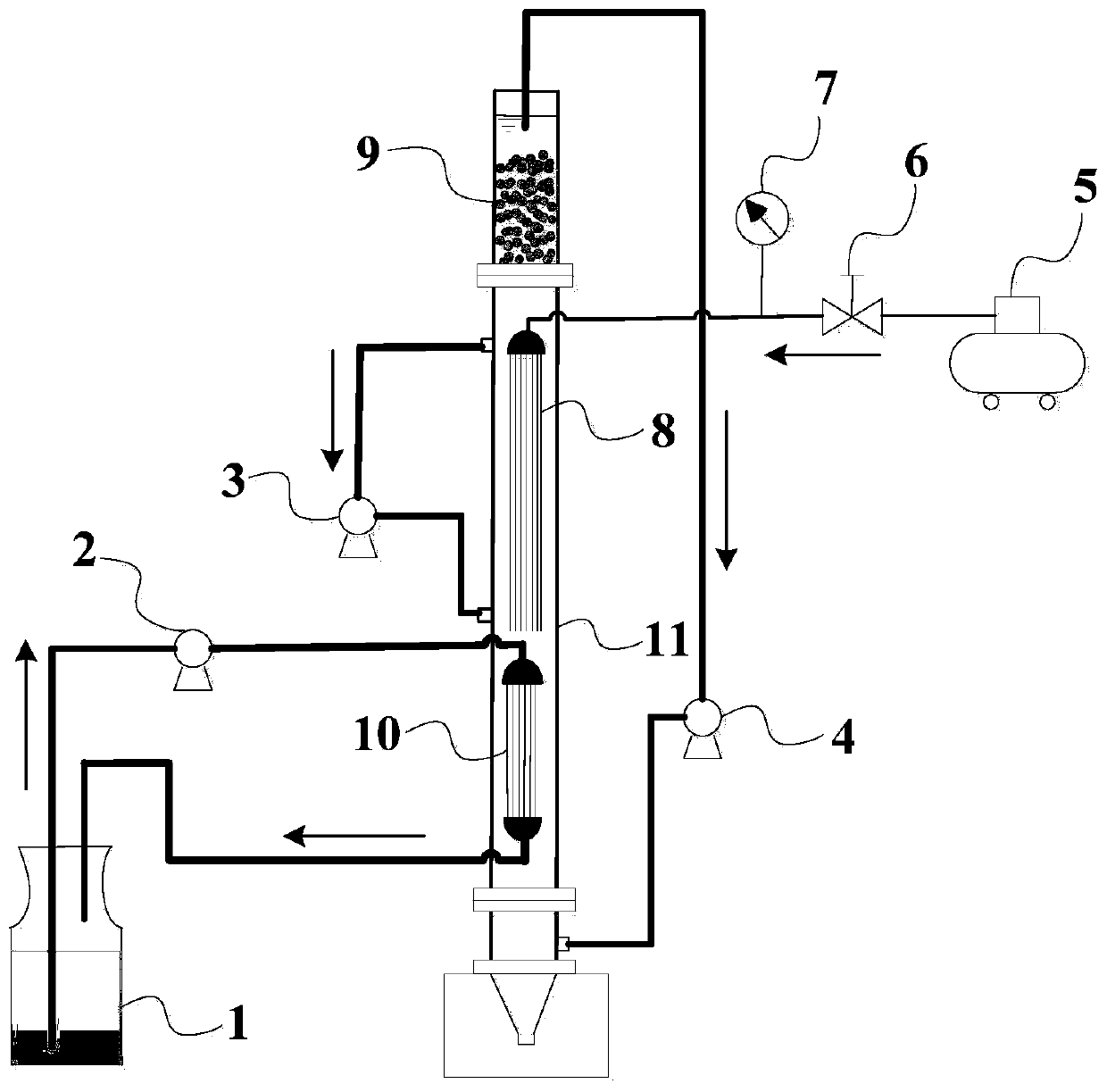

[0034] like figure 1Shown, is the integrated membrane aeration biological reaction system (IMABS) that is used for the highly saline acetonitrile waste water of zero discharge treatment, comprises feed liquid bottle 1, air compressor 5, membrane separator 10 and bioreactor 11; The liquid bottle 1 is connected to the tube side of the membrane separator 10 through the feed liquid pump 2 and the pipeline to form a loop; a membrane aeration zone 8 and a non-aeration zone 9 are arranged in the bioreactor 11, and the membrane separator 10 is set in the bioreactor 11. Inside the reactor 11, located below the membrane aeration zone 8, the air compressor 5 communicates with the membrane aeration zone 8 through a ball valve 6 and a pressure gauge 7; ceramsite is provided in the non-aeration zone 9.

[0035] The integrated membrane aeration biological reaction system uses the feed liquid pump 2 to flow the high-salt acetonitrile wastewater in the feed liquid bottle 1 from one end of the ...

Embodiment 2

[0041] The thickened sludge and an amount of salt-free acetonitrile waste water that will be retrieved are added in the reaction system of embodiment 1, so that the VSS of the sludge in the bioreactor is 3g / L, and the concentration of acetonitrile is 250mg / L. Under the conditions of 25±1°C, no circulation, no reflux, aeration pressure of 0.01MPa and membrane separator not activated, the bioreactor will be aerated for 2 days to domesticate the activated sludge, so that the membrane aeration area and the non-aeration area Different types of acetonitrile degrading bacteria as well as nitrifying and denitrifying bacteria are produced.

[0042] It was determined that the acetonitrile concentration in the IMABS bioreactor decreased to 17 mg / L after 2 days of stuffy exposure, and the TOC in the bioreactor continued to decrease from 185 mg / L to 20 mg / L, while the ammonia nitrogen concentration increased by 10 mg / L, indicating that the bioreactor Microbes in the reactor began to degrad...

Embodiment 3

[0045] Carry out the treatment of high-salt acetonitrile wastewater in the successfully started reaction system of embodiment 2, treatment condition is: high-salt acetonitrile wastewater 1L, acetonitrile concentration is 500mg / L, and salt content is 5% in terms of NaCl, and temperature is 25±1℃, the aeration pressure is 0.01MPa, the circulation ratio is 1, the reflux ratio is 1, HRT B 24h, HRT M It is 36min.

[0046] The reaction system was run for 5 days. It has been determined that the separation rate of acetonitrile in the membrane separator of IMABS is 40%, no acetonitrile is detected in the bioreactor, and the removal rate of acetonitrile is 100%. TOC, TN and ammonia nitrogen in the bioreactor of IMABS at the end of the working condition are respectively 0.8mg / L , 3mg / L and 2.6mg / L. By detecting the conductivity of high-salt acetonitrile wastewater in the feed bottle of IMABS, it was found that the conductivity in the feed bottle did not change significantly during the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com