Separate crystallization method for extracting recyclable high-purity sodium sulfate and sodium chloride from high-salinity wastewater

A technology for high-salt wastewater and sodium chloride, which is applied in chemical instruments and methods, alkali metal chloride, alkali metal sulfite/sulfate dehydration, etc., can solve the problem of high operating pressure, high operation and maintenance costs of nanofiltration membranes, Membrane short service life and other issues, to achieve good economic and social benefits, ease the pressure on enterprises, high process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

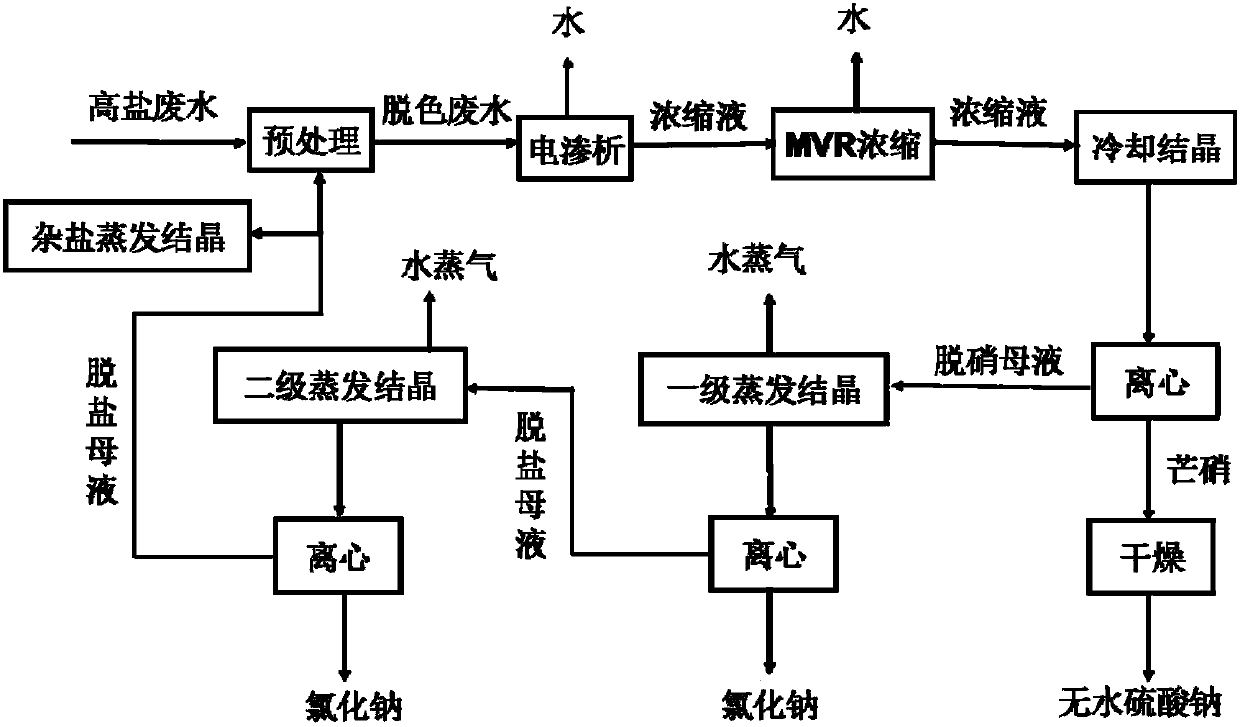

Method used

Image

Examples

Embodiment 1

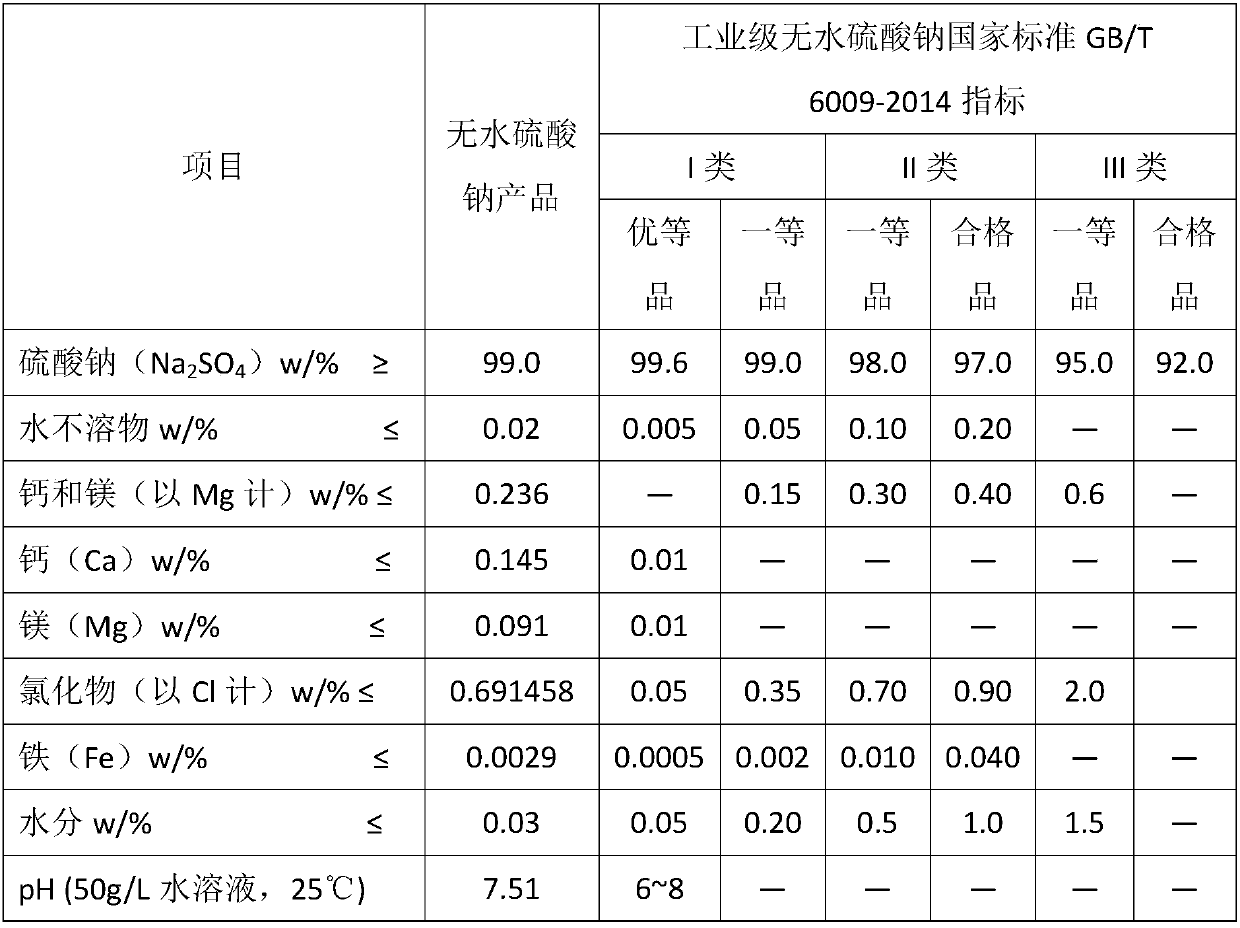

[0030] The mass flow rate of high-salt wastewater fed by a coal chemical enterprise is 1000kg / h. After analysis, the mass fraction of sodium chloride is 2.28%, the mass fraction of sodium sulfate is 0.72%, and the COD value is 500mg / L.

[0031] 1. Pretreatment of high-salt wastewater, using activated carbon for decolorization pretreatment, the amount of activated carbon added is 7g / L wastewater, the COD removal rate is 75%, and insoluble impurities, Ca 2+ , Mg 2+ , silicate and other soluble substances;

[0032]2. The pretreated high-salt wastewater feed wastewater is first concentrated by electrodialysis, and the mass flow rate of the separated water is 833.33kg / h, and then concentrated by a mechanical vapor recompression (MVR) device, and the mass flow rate of the separated water is 55.90kg / h, the mass fraction of sodium chloride after twice concentration is 20.58%, and the mass fraction of sodium sulfate is 6.5%;

[0033] 3. Send the concentrated solution to the crystalli...

Embodiment 2

[0049] The mass flow rate of high-salt wastewater fed by a coal chemical enterprise is 1000kg / h. After analysis, the mass fraction of sodium chloride is 7.61%, the mass fraction of sodium sulfate is 2.38%, and the COD value is 580mg / L.

[0050] 1. Pretreatment of high-salt wastewater, using activated carbon for decolorization pretreatment, the amount of activated carbon added is 8g / L wastewater, the COD removal rate is 80%, and insoluble impurities, Ca 2+ , Mg 2+ , silicate and other soluble substances;

[0051] 2. The pretreated high-salt wastewater feed wastewater is first concentrated by electrodialysis, and the mass flow rate of the separated water is 444.44kg / h, and then concentrated by a mechanical vapor recompression (MVR) device, and the mass flow rate of the separated water is 185.78kg / h, the mass fraction of sodium chloride after twice concentration is 20.1%, and the mass fraction of sodium sulfate is 6.33%;

[0052] 3. The concentrated solution is sent to the crys...

Embodiment 3

[0060] The mass flow rate of high-salt wastewater fed by a coal chemical enterprise is 1000kg / h. After analysis, the mass fraction of sodium chloride is 3.10%, the mass fraction of sodium sulfate is 1.80%, and the COD value is 600mg / L.

[0061] 1. Pretreatment of high-salt wastewater, using activated carbon for decolorization pretreatment, the amount of activated carbon added is 9g / L wastewater, the COD removal rate is 85%, and insoluble impurities, Ca 2+ , Mg2+, silicate and other soluble substances;

[0062] 2. The pretreated high-salt wastewater feed wastewater is first concentrated by electrodialysis, and the mass flow rate of the separated water is 750.00kg / h, and then concentrated by a mechanical vapor recompression (MVR) device, and the mass flow rate of the separated water is 50.00kg / h, after concentration, the mass fraction of sodium chloride is 15.5%, and the mass fraction of sodium sulfate is 9.0%;

[0063] 3. The concentrated solution was sent to the crystallizer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com