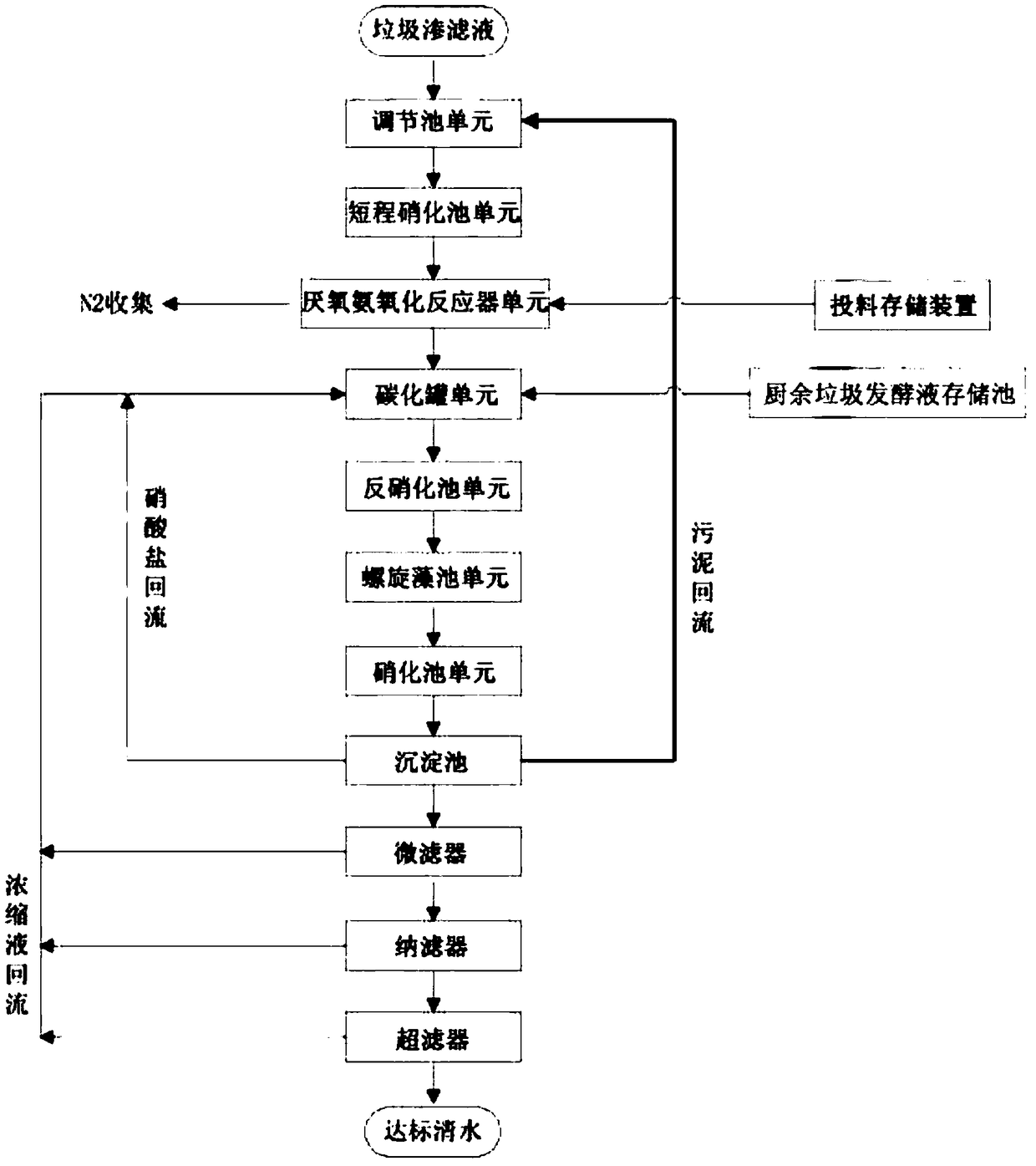

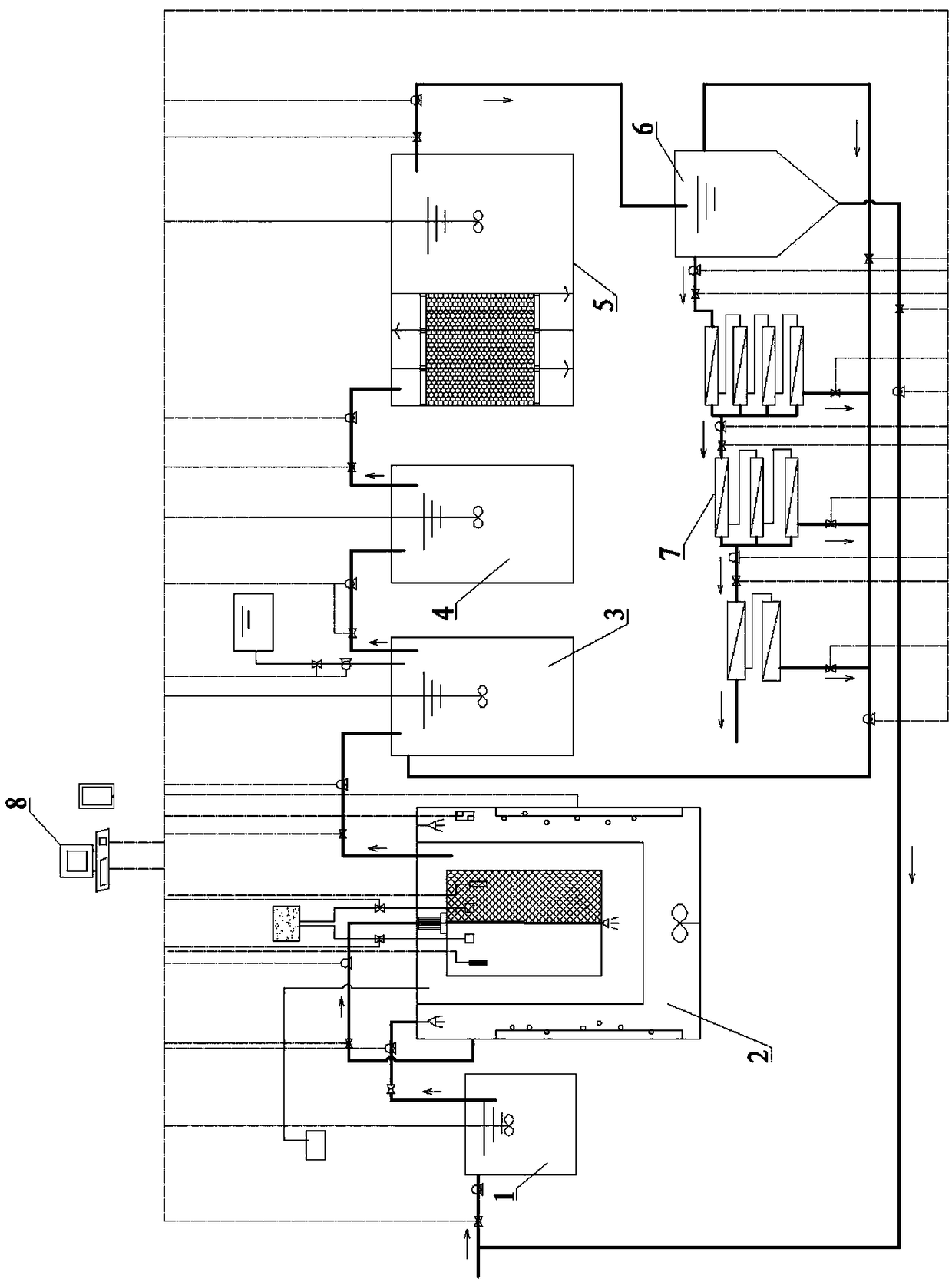

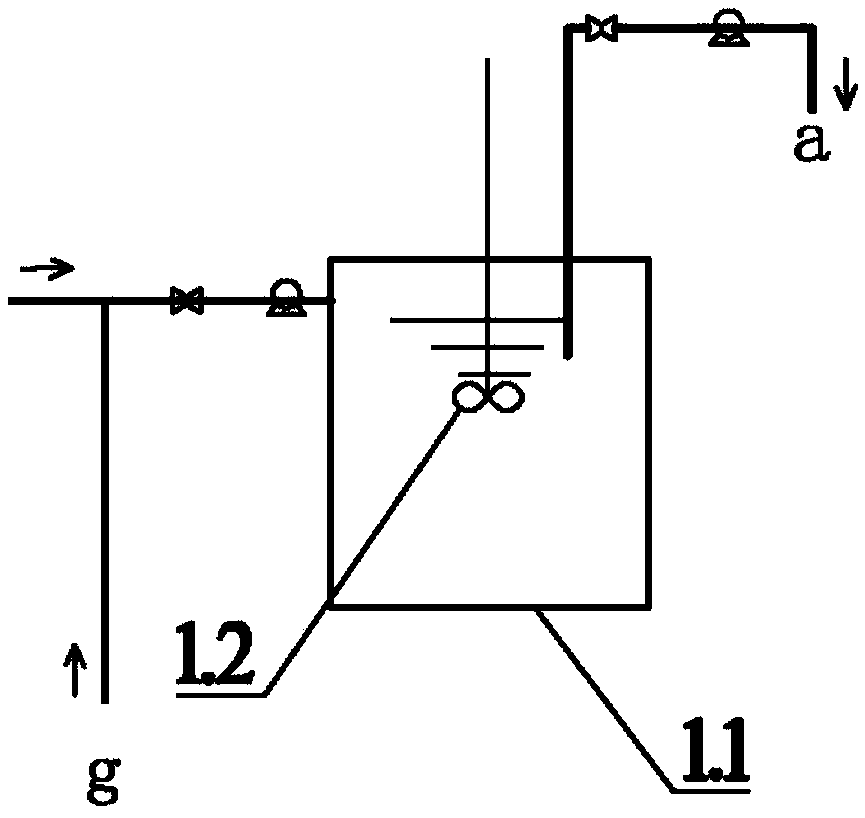

Zero emission treatment device and method for late-stage landfill leachate

A landfill leachate, zero-discharge technology, applied in the field of environmental engineering, can solve the problems of long process start-up time, weaken the activity of bacteria, reduce the service life of the filter membrane, etc., to solve the problem of retention and amplification, reduce the hydraulic retention time, The effect of reducing energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0072] Shanniuwu domestic waste landfill in Lin'an District, the landfill has a history of 20 years. The water quality of landfill leachate is as follows: COD=20000mg / L, BOD=510000mg / L, NH 4 + -N=2500mg / L, TN=2500mg / L, SS=2000mg / L, TP=42mg / L;

[0073] After being treated by the present invention, the effluent water quality is as follows: COD=90mg / L, BOD=25mg / L, NH 4 + -N=20mg / L, TN=32mg / L, SS=23mg / L, TP=1mg / L, reaching the "Discharge Standard of Pollutants for Domestic Waste Landfill Sites" (GB16889-2008).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com