A kind of advanced treatment method of epichlorohydrin waste water

A technology of epichlorohydrin and advanced treatment, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to reduce the temperature of wastewater, simplify the treatment process, and reduce the COD concentration of effluent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

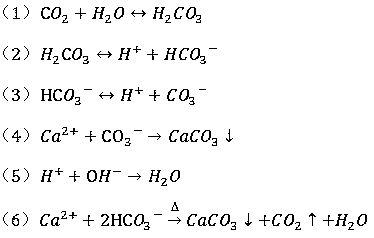

Embodiment 1

[0028] A certain enterprise produces a large amount of wastewater containing calcium ions in the production process of epichlorohydrin. The COD concentration is 1500mg / L, B / C: 0.20, the calcium ion concentration is 7500mg / L, the total salt content: 2.0%, and the temperature is 80 ℃. Adopt the method of the present invention to carry out treatment, first adopt conventional microporous aeration way to pass in excess carbon dioxide gas, then mix this part of cooling waste water with part of raw waste water to be treated, use the flow rate of raw waste water to control the temperature of mixed waste water at 60~ 70°C, and rely on the system to automatically replenish sodium hydroxide to control the pH between 7 and 8 during the mixing reaction process. The calcium ion concentration in the treated wastewater is 1400mg / L, and the removal rate is 81.3%. Then add ammonium sulfate 2600mg / L to the wastewater to produce calcium sulfate precipitation and achieve the removal of more than 9...

Embodiment 2

[0030] A certain enterprise produces a large amount of wastewater containing calcium ions in the production process of epichlorohydrin. The COD concentration is 1500mg / L, B / C: 0.20, the calcium ion concentration is 7500mg / L, the total salt content: 2.0%, and the temperature is 80 ℃. The method of the present invention is used for treatment, and the method of dissolved air flotation is adopted, and a large amount of carbon dioxide is dissolved after part of the cooling wastewater passes through the dissolved air tank. The working pressure of the dissolved air flotation is 0.4-0.6 MPa, and then released into the subsequent air flotation tank Fully mix with the original wastewater, use the flow of the original wastewater to control the temperature of the mixed wastewater at 60-70°C, and rely on the system to automatically replenish sodium hydroxide to control the pH between 7 and 8 during the mixing reaction process. After treatment The concentration of calcium ions in the wastew...

Embodiment 3

[0032] A company produces a large amount of wastewater containing calcium ions in the production process of epichlorohydrin. The COD concentration is 2500mg / L, B / C: 0.4, the calcium ion concentration is 9000mg / L, the total salt content: 3.0%, and the temperature is 100 ℃. Adopt the method of the present invention to process, adopt the mode of dissolved air flotation, dissolve a large amount of carbon dioxide after partly cooling waste water passes through dissolved air tank, the working pressure of dissolved air flotation is 0.6~0.8MPa, releases in the follow-up air flotation tank and The raw wastewater is fully mixed, and the flow rate of the raw wastewater is used to control the temperature of the mixed wastewater at 70-80°C, and the system automatically replenishes potassium hydroxide to control the pH between 7 and 8 during the mixing reaction process. The concentration of calcium ions in the wastewater is 1300mg / L, and the removal rate is 85.6%; then a small amount of amm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com