Synergistic treatment device for degradation-resistant organic waste water and method thereof

A technology of organic wastewater and collaborative treatment, which is applied in the direction of mechanical oscillation water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high cost, current utilization efficiency that affects the effect of plate action, and difficult operation. Achieve the effect of improving the efficiency of generating hydroxyl groups, improving the efficiency of wastewater treatment, and avoiding electrode corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

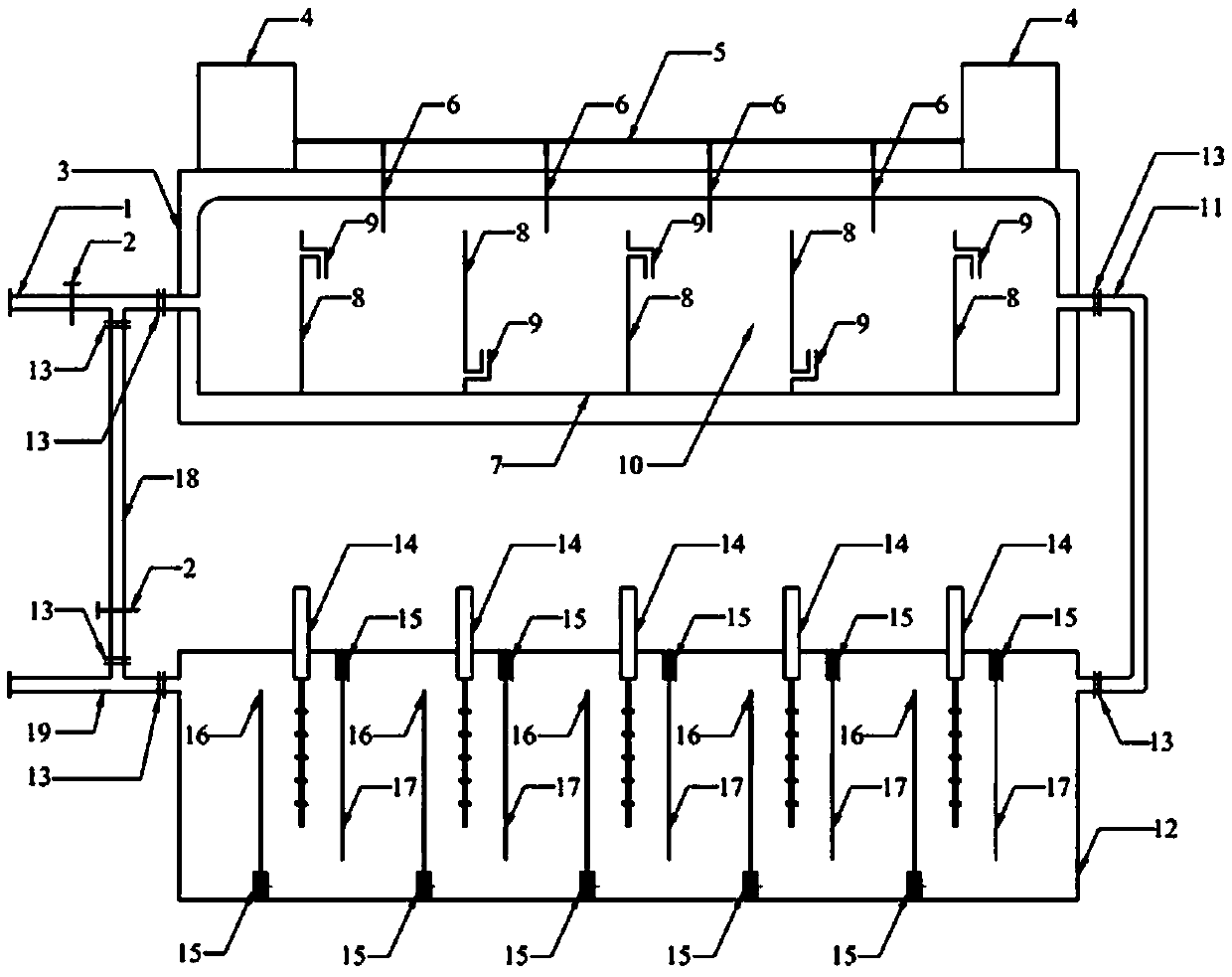

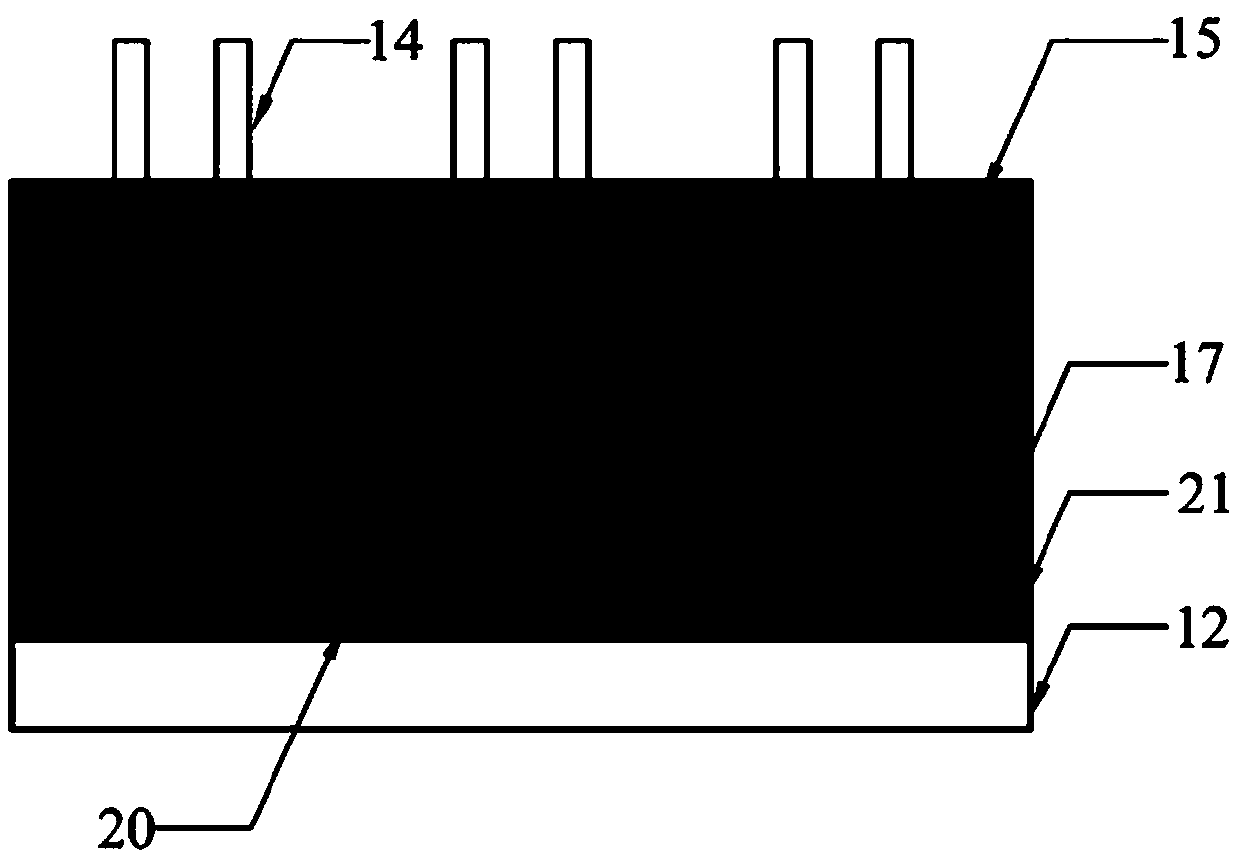

[0039] like figure 1 As shown, a co-processing device for refractory organic wastewater is composed of a microwave wastewater treatment unit and an ultrasonic co-operative electrocatalytic oxidation treatment unit connected in series. The microwave wastewater treatment unit consists of water inlet pipe (1), control valve (2), microwave reactor shell (3), microwave generator (4), waveguide main pipe (5), waveguide branch pipe (6), microwave reaction It is composed of a device (7), a reaction chamber partition (8), a water guide (9), a resonant cavity (10), and a first-stage water outlet pipe (11). The water inlet pipe (1) is directly connected with the microwave reactor (7), and a control valve (2) is arranged in the middle. The microwave reactor (7) is a stainless steel cuboid structure, and the whole chamber is divided into several resonant cavities (10) by the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com