Zero-discharge treatment process and device for high-salt-content industrial wastewater

A technology of industrial waste water and treatment process, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve difficult waste water zero discharge, high operating cost, large investment in industrial waste water, etc. problem, to achieve the effect of low production cost, advanced technology and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

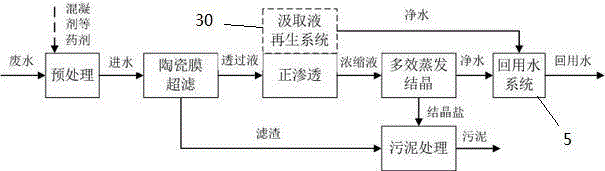

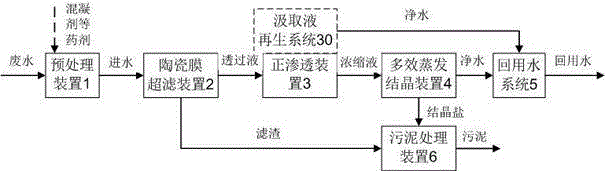

[0022] Such as figure 1 As shown, a zero-discharge treatment process for high-salt industrial wastewater includes the following steps:

[0023] S1. Pretreatment: pretreat high-salt industrial wastewater, and form high-priced metal ions into precipitates by adjusting the pH. Other types of precipitants can also be added as needed, and coagulants, oxidants, etc. can be added when necessary. The main purpose of this step is to make high-valent metal ions form insoluble precipitates, and form insoluble particles together with other impurities or coagulants in the water;

[0024] S2. Ceramic membrane filtration. After pretreatment, the industrial wastewater enters the submerged ceramic membrane tank, in which insoluble particles are trapped by the ceramic membrane to form sediment, and the water treated by the ceramic membrane enters the subsequent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com