Treatment system and method for realizing zero emission of landfill leachate and fermented biogas slurry

A technology of landfill leachate and treatment system, which is applied in the field of treatment system to realize zero discharge of landfill leachate and fermentation biogas slurry, can solve the problems of underutilization of valuable resources, complicated and lengthy process, poor biodegradability, etc. The effect of solving the problem of wastewater pollution, low energy consumption and suitable carbon-nitrogen ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

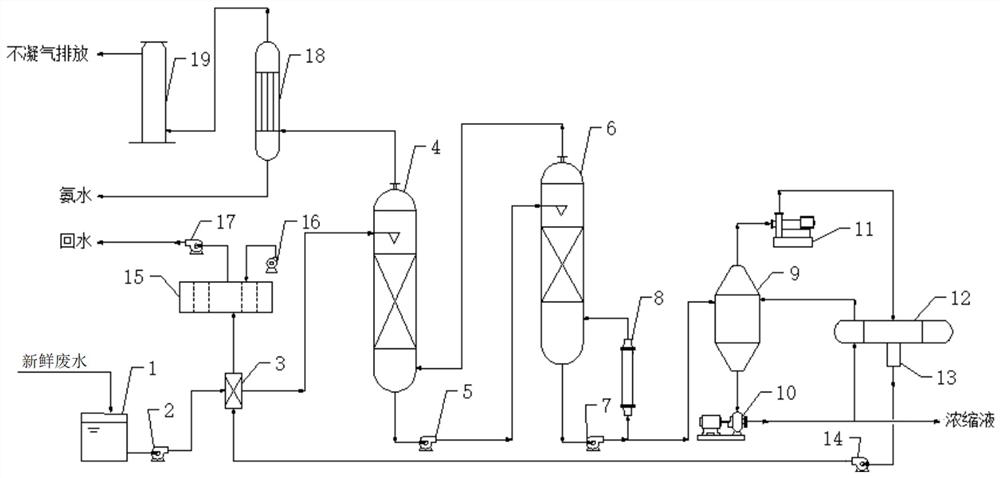

[0035] A method for treating landfill leachate and fermented biogas slurry using a treatment system for realizing zero discharge of landfill leachate and fermented biogas slurry according to the present invention comprises the following steps:

[0036] (1) The fresh wastewater composed of landfill leachate and fermented biogas slurry is sent from outside to the buffer tank 1, and then sent to the feed water preheater (plate-and-frame heat exchanger) 3 by the feed pump 2, where Perform heat exchange with the condensate of the MVR steam generated by the MVR evaporator 9, and further cool the MVR condensate while initially preheating the waste water to obtain preheated waste water;

[0037] (2) The preheated waste water is sent into the tower from the waste water inlet on the upper part of the analysis tower 4, and the stripping distillation process is adopted in the analysis tower 4 to strip part of the ammonia nitrogen in the waste water to obtain the stripped waste water; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com