Zero-emission process of nickel hydrometallurgy wastewater containing heavy metals, oil and high-concentration mixed salts

A hydrometallurgical, high-concentration technology, applied in metallurgical wastewater treatment, alkali metal sulfite/sulfate dehydration, alkali metal compounds, etc., to achieve long service life, simple recycling process, low power consumption and operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

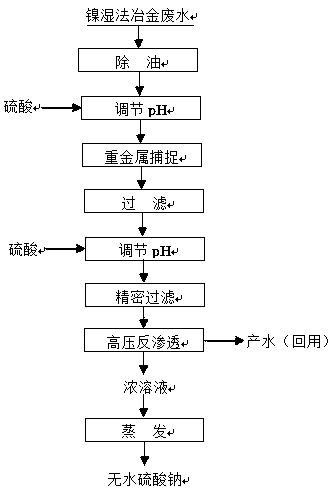

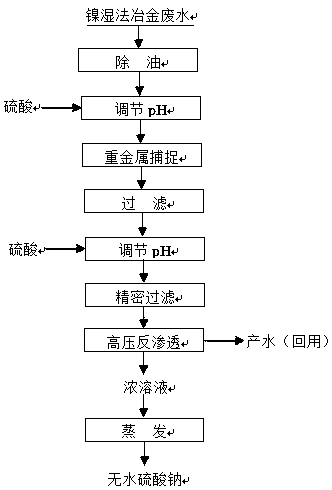

[0034] Such as figure 1 As shown, a kind of complex system nickel hydrometallurgical waste water of the present invention is resourceful and zero-discharge treatment method, comprises the following steps:

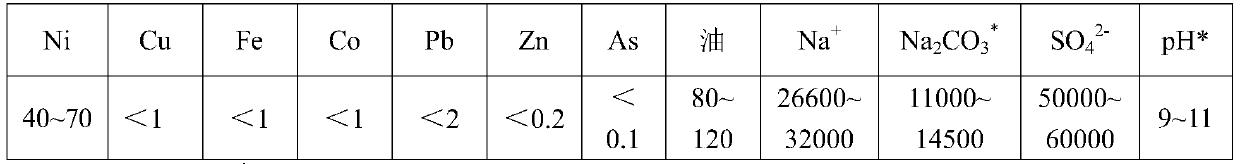

[0035] The average daily discharge of wastewater from a nickel hydrometallurgy system in a company is 1600m 3 , the typical chemical composition is as follows (mg / L):

[0036]

[0037] Note: Na 2 CO 3 *is the partially incompletely dissolved carbonate particles in the wastewater; pH* is dimensionless

[0038] The specific wastewater index of the present embodiment: Ni49mg / L, oily substance 91mg / L, Na + 29.98g / L, SO 4 2- 55.13g / L, Na 2 CO 3 11.85g / L, pH10.2, and other indicators are the same as the above table.

[0039] 1) When the waste water is sent to the oil removal material equipped with HPE-308, its lipophilic group will destroy the water film on the surface of the emulsified oil or soluble oil molecules, and capture the small oil droplets in the water to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com