Anhydrous sodium sulfate production system and production method

A production system and production method technology, applied in chemical instruments and methods, alkali metal sulfites/sulfites, alkali metal compounds, etc., can solve the problems of high production cost of Yuanming powder and low production quality of Yuanming powder. , to avoid pulverization pollution and chromium pollution, save heat energy consumption cost, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

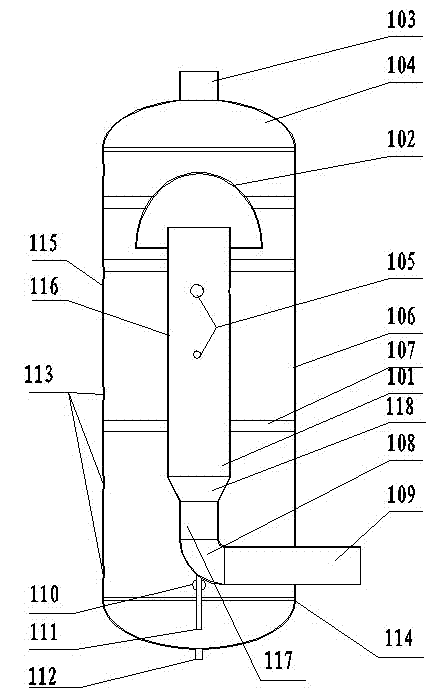

Image

Examples

Embodiment 1

[0040] Embodiment 1 produces Yuanming powder according to aforementioned method, and concrete process parameter is as follows:

[0041] The temperature of the reduction tower is 85°C, the temperature of the reactor is controlled at 80°C, and the reaction time is 5 hours; the time for flocculation and precipitation is 10 hours; 90°C, cycle cleaning cycle 50 hours, cleaning time 2 hours.

[0042] The filtration part can be divided into two steps of pressurized plate frame thermal filtration and deep layer filtration. The content of insoluble matter is reduced to less than 0.005%, and the content of calcium and magnesium ions is less than 0.01%. 0.01%.

Embodiment 2

[0043] Embodiment 2 According to the aforementioned method, the Yuanming powder is produced, and the concrete process parameters are as follows:

[0044] The temperature of the reduction tower is 75°C, the temperature of the reactor is controlled at 75°C, and the reaction time is 3 hours; the time for flocculation and precipitation is 8 hours; 80-℃, cycle cleaning cycle 24 hours, cleaning time 1 hour.

Embodiment 3

[0045] Embodiment 3 produces Yuan Mingfen according to aforementioned method, and concrete process parameter is as follows:

[0046]The temperature of the reduction tower is 95°C, the temperature of the reactor is controlled at 95°C, and the reaction time is 8 hours; the time for flocculation and precipitation is 12 hours; 100°C, cycle cleaning cycle 72 hours, cleaning time 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com