Multi-effect evaporation concentration technology, multi-effect evaporation crystallization technology and multi-effect evaporation concentration device of solution containing sulfuric acid and sulfate

A multi-effect evaporation and evaporative crystallization technology, which is applied in the directions of multi-effect evaporation, solution crystallization, alkali metal sulfite/sulfate dehydration, etc., can solve the problems of low efficiency, high investment, and many equipments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

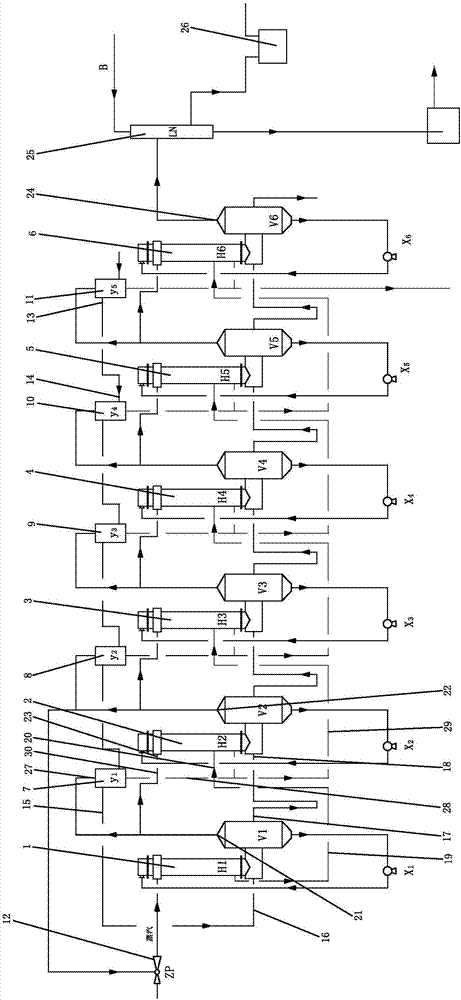

[0213] like figure 1 As shown, a multi-effect evaporation concentration device containing sulfuric acid and its salt solution, evaporating sulfuric acid and its salt solution into an acid bath, including 1-effect evaporator 1, 2-effect evaporator 2, 3-effect evaporator 3, 4-effect Evaporator 4, 5-effect evaporator 5, 6-effect evaporator 6, 1-6 effect circulation pump corresponding to 1-6 effect evaporator, 1-stage preheater 7 corresponding to 1-5 effect evaporator, 2nd stage preheater 8, 3rd stage preheater 9, 4th stage preheater 10, 5th stage preheater 11 and steam injection extractor 12;

[0214] The acid outlet pipe of the next stage preheater is connected with the acid inlet pipe of the upper stage preheater (for example, the acid outlet pipe 13 of the 5th stage preheater is connected with the acid inlet pipe 14 of the 4th stage preheater), 1 The acid outlet pipe 15 of the stage preheater is connected with the acid inlet pipe 16 of the first effect evaporator, and the aci...

Embodiment 2

[0224] like figure 2 As shown, a multi-effect evaporation crystallization device containing sulfuric acid and its salt solution, evaporating sulfuric acid and its salt solution is an acid bath, including a 1-effect evaporator 31, a 2-effect evaporator 32, a 3-effect evaporator 33 and a 4-effect evaporator Evaporator 34, 1-4 effect circulating pump corresponding to 1-4 effect evaporator, 1-stage preheater 35 corresponding to 1-4 effect evaporator, 2-stage preheater 36, 3-stage preheater 37 and 4-stage preheater 38, 5-effect evaporative crystallizer 39, and 6-effect evaporative crystallizer 40. The evaporative crystallizer is provided with an evaporative crystallization circulation pump, and the acid outlet pipe of the next stage preheater is connected to the upper stage The acid inlet pipe of the preheater is connected (for example, the acid outlet pipe 41 of the 4th stage preheater is communicated with the acid inlet pipe 42 of the 3rd stage preheater);

[0225] The acid out...

Embodiment 3

[0236] like image 3 As shown, a multi-effect evaporation and crystallization device containing sulfuric acid and its salt solution evaporates sulfuric acid and its salt solution—acidic water (including two baths), including a 1-effect evaporator 73, a 2-effect evaporator 74, and a 3-effect evaporator Evaporator 75, 4-effect evaporator 76, 5-effect evaporator 77, 6-effect evaporator 78, 7-effect evaporator crystallizer 79; 1-6 effect circulation pump corresponding to 1-6 effect evaporator, and 7-effect evaporator Evaporation and crystallization circulating pump corresponding to crystallizer 79, first-stage preheater 80 corresponding to 1-4 effect evaporators, second-stage preheater 81, third-stage preheater 82, fourth-stage preheater 83, and acid Bath preheater 84 .

[0237] The material flow is as follows: 80°C acidic water enters from the 4th-stage preheater 83, preheats to 109°C through the 4th, 3rd, 2nd, and 1st-stage preheaters, enters the 1-effect evaporator to evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com