Borosiloxane and preparation method thereof

A technology of polyborosiloxane and siloxane monomers, which is applied in the field of borosiloxane and its preparation, can solve the problems of low heat resistance temperature, influence on the development of high-tech fields, poor adhesion, etc., and achieves excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

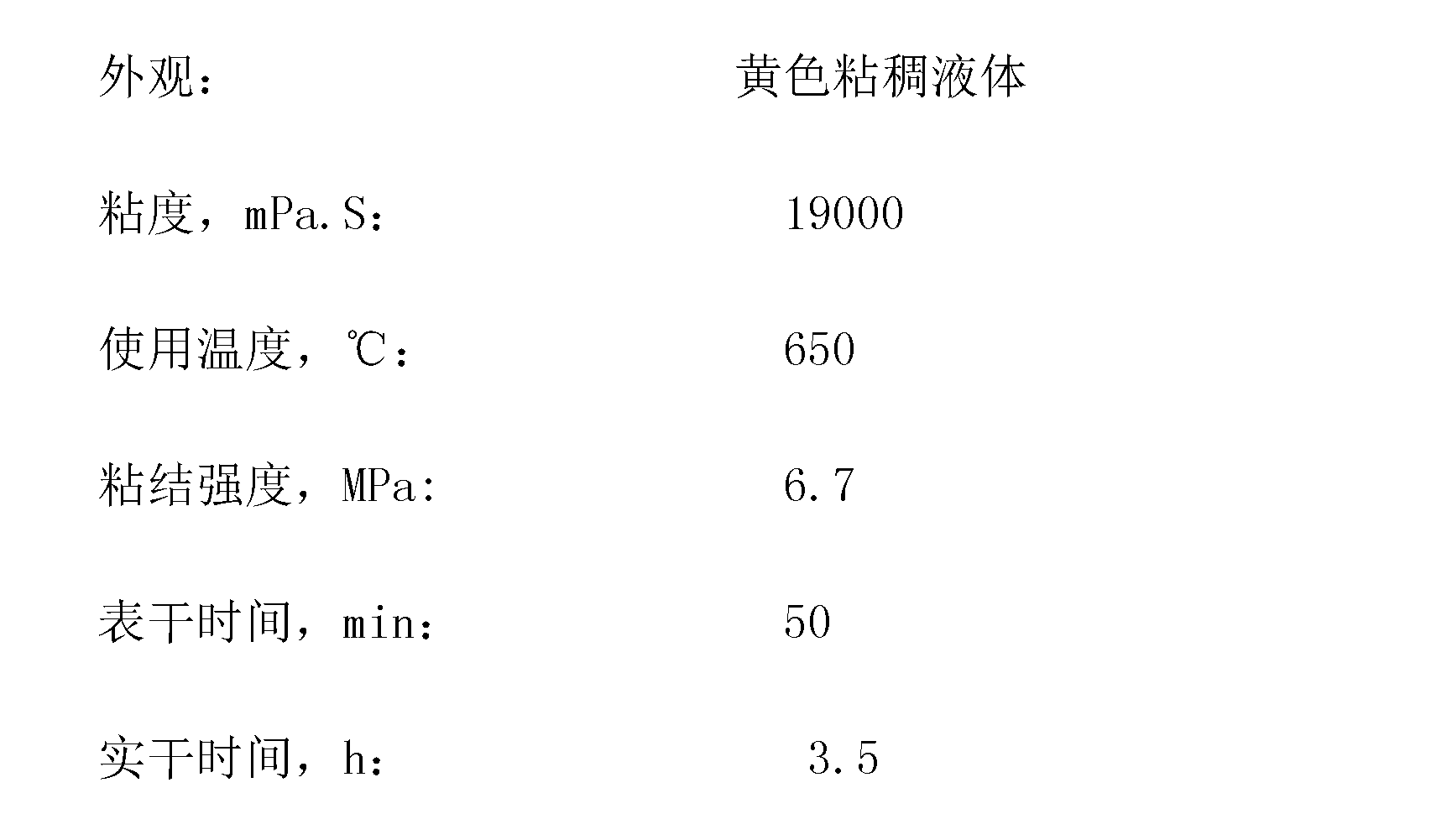

Embodiment 1

[0028] 1. Preparation of hydrolyzate

[0029] a. Weigh 13.6g of ethyl orthosilicate, 28.9g of methyltriethoxysilane, 36.4g of dimethyldiethoxysilane, 18.7g of phenyltriethoxysilane, 12.4g of monomethyltrichlorosilane g, 43.2g of methylethoxydichlorosilane, 34.8g of monophenyltrichlorosilane, and 16.7g of diphenyldichlorosilane were mixed uniformly, placed in a clean container, and set aside.

[0030] b. Weigh 1020g of the hydrolyzing agent into the reaction vessel according to the preparation plan, add 17.9g of boric acid at room temperature, after fully dissolving, keep the temperature at 25~30°C, add the above mixed monomers dropwise while stirring, and carry out the hydrolysis reaction. 4h after the dropwise addition is completed, slowly raise the temperature to T=55~65°C, stir for 1h, let it stand for 45min, separate the lower layer of acid water, and use 2% NaHCO 3 The solution was washed until the pH value of the system was 6.0~7.0. It was washed twice with saturated N...

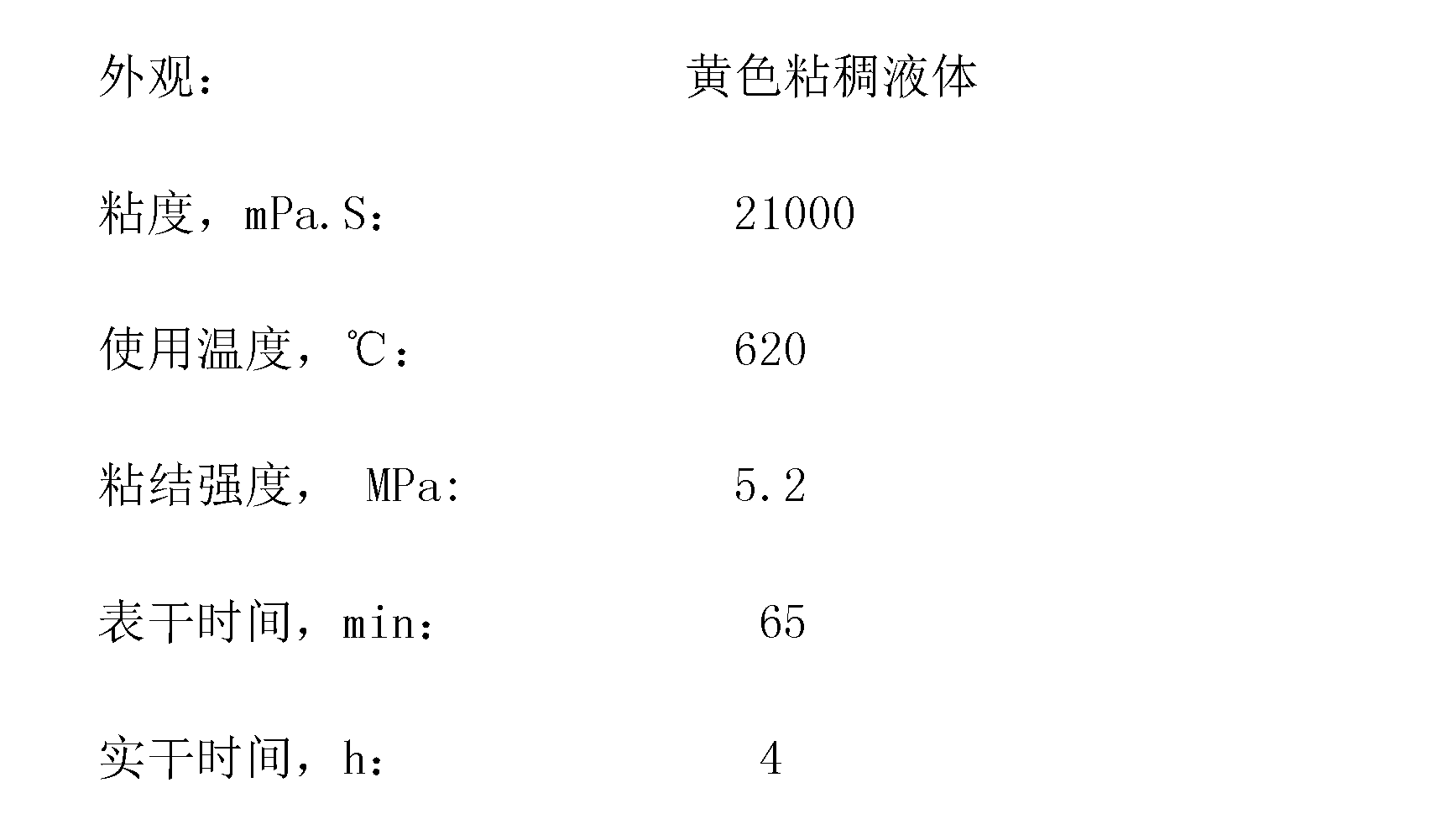

Embodiment 2

[0038] 1. Preparation of hydrolyzate

[0039] a. Weigh 18.4g of methyltriethoxysilane, 32.4g of dimethyldiethoxysilane, 27.0g of phenyltriethoxysilane, 17.3g of monomethyltrichlorosilane, 17.3g of methylethoxydi 13.2g of chlorosilane, 19.8g of monophenyltrichlorosilane, and 26.7g of diphenyldichlorosilane were mixed uniformly, placed in a clean container, and set aside.

[0040] b. Weigh 1086g of the hydrolyzing agent into the reaction vessel according to the preparation plan, slowly add the above mixed monomers dropwise under the condition of stirring at room temperature, and at the same time slowly inject 14.8g of boron trifluoride gas to carry out the hydrolysis reaction. After 3.5 hours of dropwise addition, slowly raise the temperature to T=55~65°C, stir for 1 hour, let it stand for 45 minutes, separate the lower layer of acidic water, and wash with 2% NaHCO3 solution until the pH value of the system is 6.0~7.0. It was washed twice with saturated NaCl solution to obtain ...

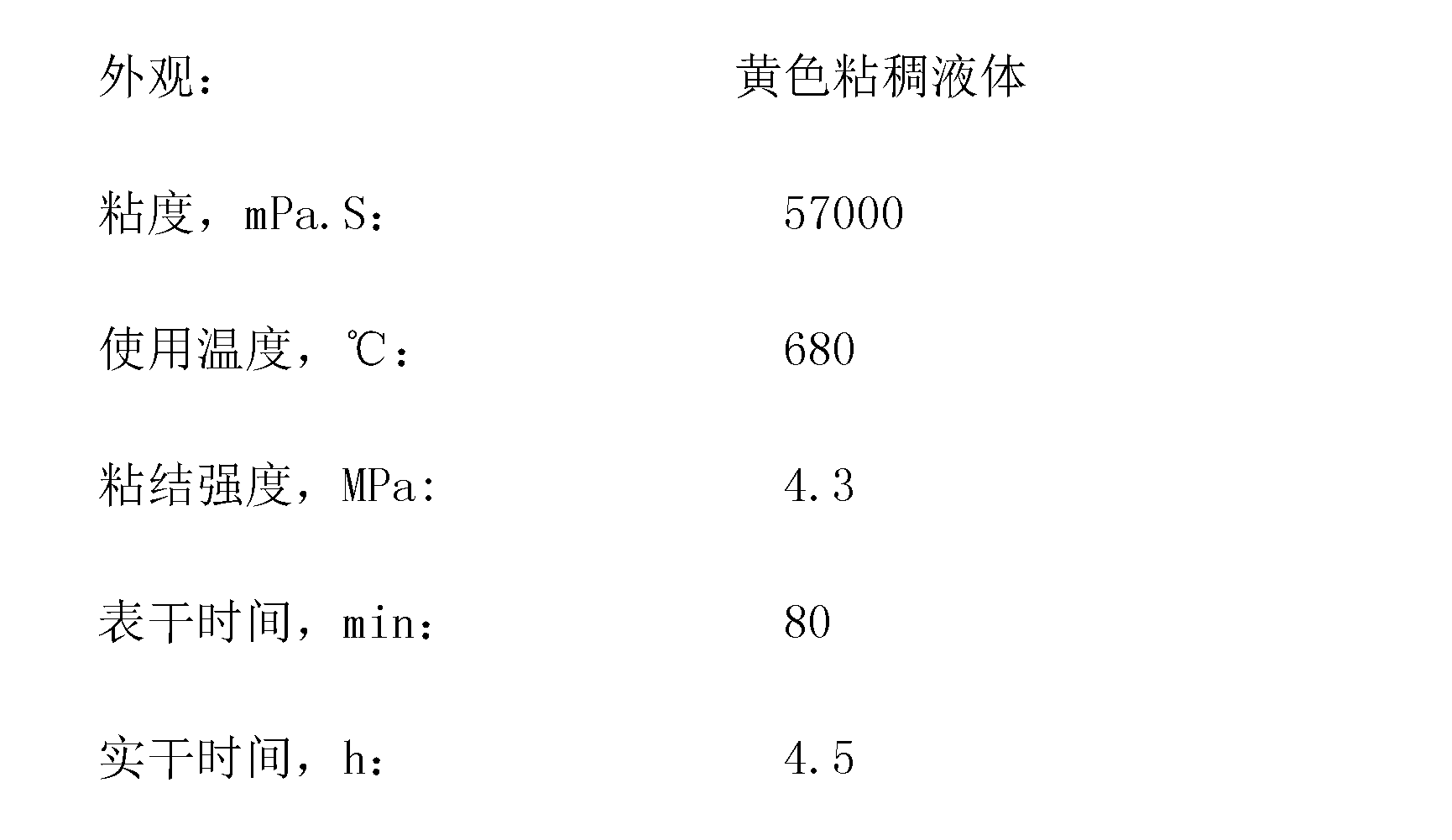

Embodiment 3

[0048] 1. Preparation of hydrolyzate

[0049] a. Weigh 23.3g of dimethyldiethoxysilane, 31.4g of methyltriethoxysilane, 12.8g of monomethyltrichlorosilane, 18.7g of phenyltriethoxysilane, and 18.7g of monomethyltrichlorosilane 25.3g, 12.1g of methylethoxydichlorosilane, 18.0g of monophenyltrichlorosilane, and 28.4g of diphenyldichlorosilane were mixed evenly, placed in a clean container, and set aside.

[0050] b. Weigh 990g of hydrolysis agent into the reaction vessel according to the preparation plan, add 19.2g of boric acid at room temperature, after fully dissolving, keep the temperature at 20°C, add the above mixed monomers dropwise under stirring, and carry out the hydrolysis reaction. After 5.5 hours of dropwise addition, slowly raise the temperature to T=65°C, stir for 1 hour, let it stand for 45 minutes, separate the lower layer of acid water, and use 2% NaHCO 3 The solution was washed until the pH value of the system was 6.0~7.0. It was washed twice with saturated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com