Nano coating protective pipe and its coating manufacture process

A nano-coating and protective pipe technology, which is applied in damage protection, pipeline anti-corrosion/rust protection, pipeline protection, etc. It can solve the problem that powder coating and liquid coating cannot be applied in one line, and the pipe diameter and specification change little. Steel pipe coating is prone to pinholes and other problems, achieving excellent high temperature corrosion resistance, eliminating internal stress, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

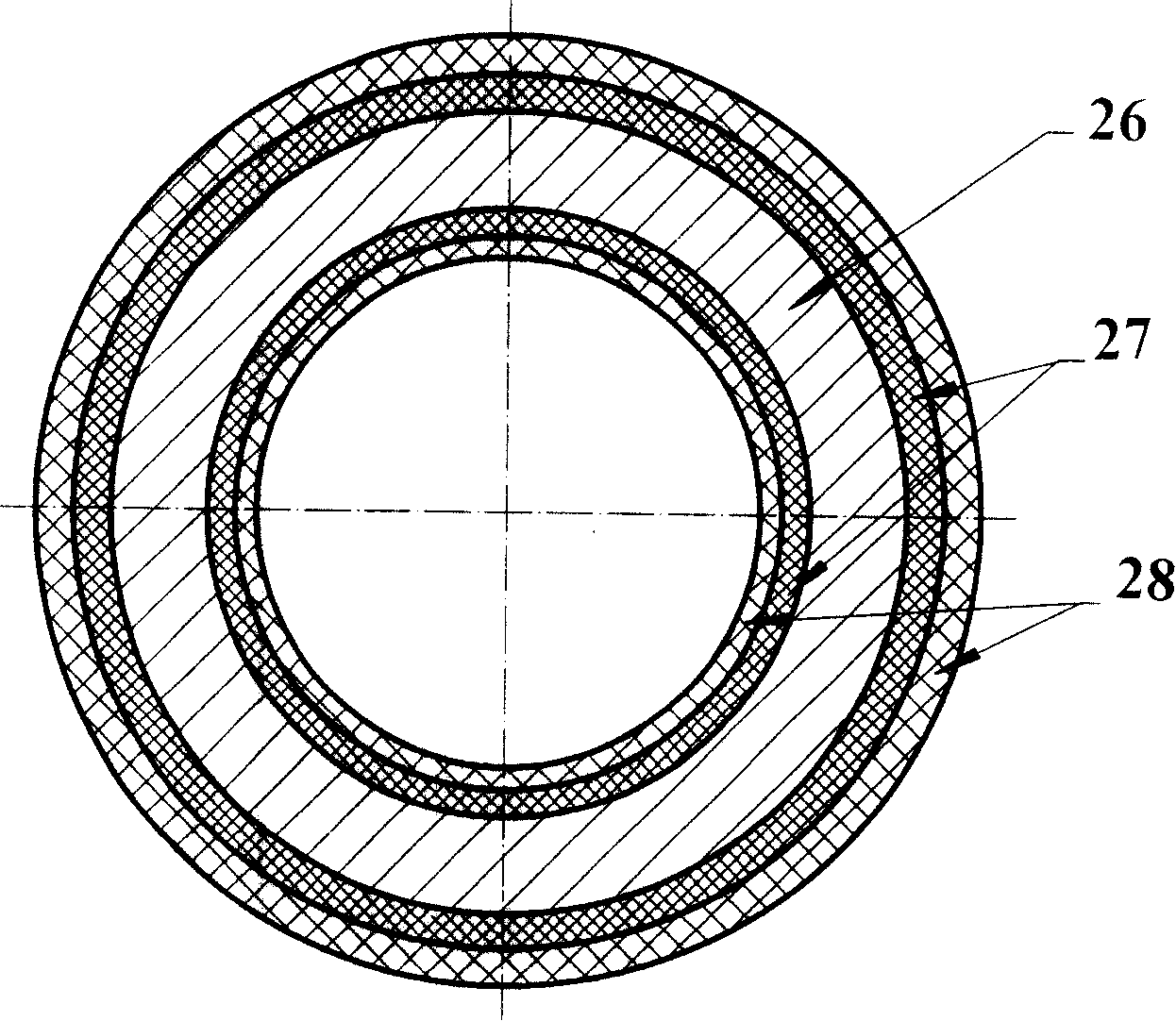

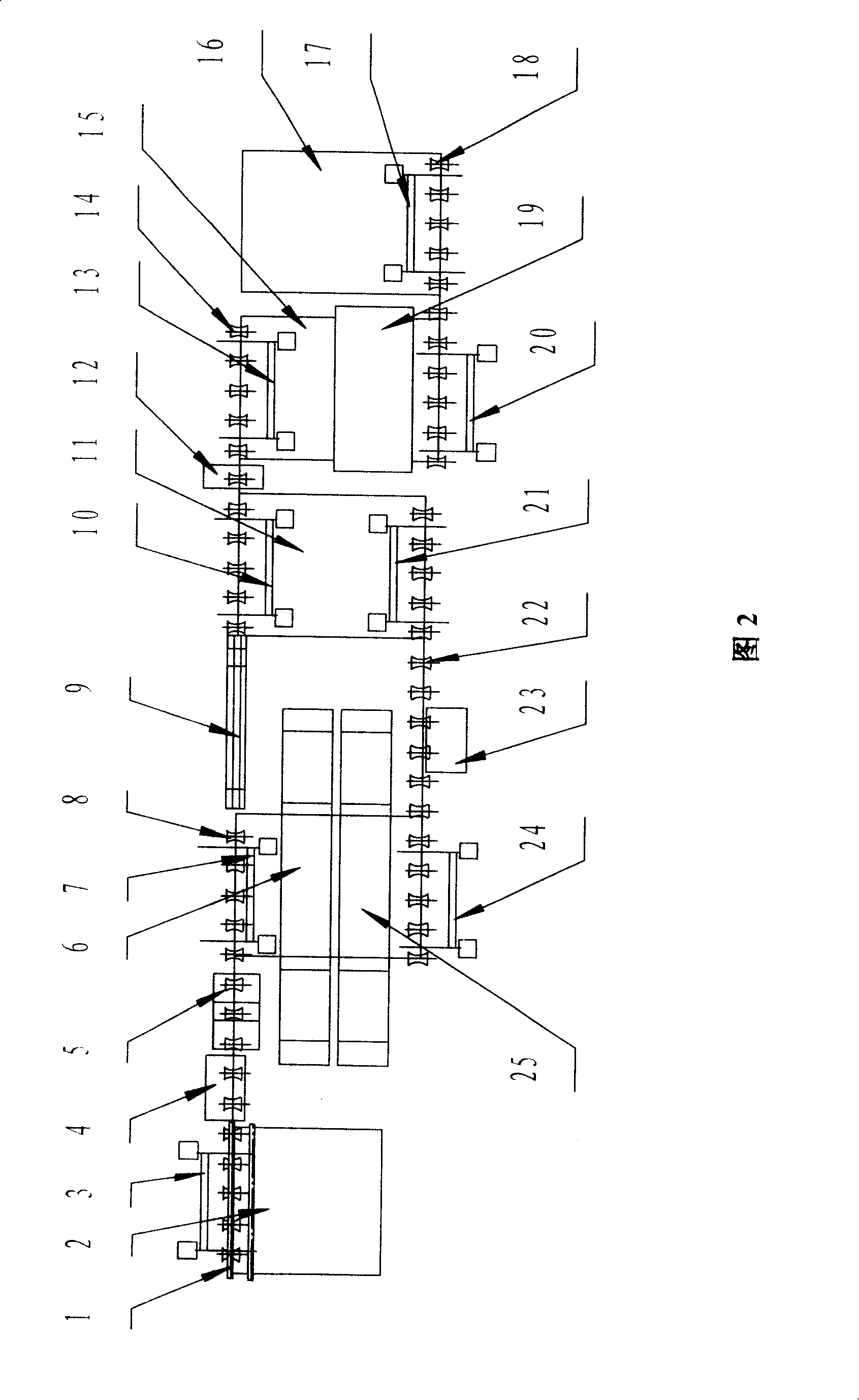

[0096] Production implementation of Ф73×5.51 anti-scaling water injection pipe

[0097] Choose a liquid epoxy-based ordinary coating with good water resistance as the basic coating, add titanium nano-flakes as a modifier and a coupling agent to prepare a titanium nano-scale basic coating, the thickness of the basic coating is 100 μm, and the functional layer is a liquid epoxy-based ordinary coating. The coating is prepared by adding titanium nanoscale flakes with a thickness of 10-40nm and a radial direction of 0.5-10μm as a modifier and a coupling agent to prepare a titanium nanoscale functional coating. The thickness of the functional layer is 80μm. The nano-coating protective water injection pipe has Good anti-corrosion and anti-scaling functions, used for anti-corrosion and anti-scaling of water injection well pipes.

[0098] Production Process:

[0099] Put the Ф73×5.51 steel pipe on the raw material pipe rack, replace the small sandblasting port, replace the small spray...

Embodiment 2

[0109] Production implementation of Ф139.7×7.72 anti-corrosion oil casing

[0110] Choose powder epoxy-based ordinary coatings with good anti-corrosion properties, add titanium nano-flakes as modifiers and coupling agents, and prepare titanium nano-scale powder base coatings. The thickness of the base coating is 200 μm, and the functional layer is liquid epoxy-based titanium nano-scales Coating, the thickness of the functional layer is 50 μm, the nano-coating protects oil casings with good anti-corrosion and anti-scaling functions, and is used for anti-corrosion and anti-scaling of oil well casings.

[0111] Production Process:

[0112] Put the Ф139.7×7.72 steel pipe on the raw material pipe rack, use a small sandblasting port, use a small spray gun, adjust the distance from the top of the drying furnace to the upper part of the steel pipe to 80-120mm, and finally turn on the automatic or manual control system. The steel pipe will be operated according to the following proced...

Embodiment 3

[0121] Production implementation of Ф630×7 anti-wax (drag reduction) oil transportation and air pipes

[0122] The inner coating of the tube is made of liquid epoxy novolac-based titanium nanoscale coating with good oil resistance as the base layer. The thickness of the base coating is 50 μm. The functional layer is liquid epoxy based wax-proof glass nanoscale coating. The coating is made of modified epoxy powder titanium nano-scale coating with good weather resistance and anti-corrosion performance. It is a combination of base layer and functional layer. The thickness of the outer coating is 500 μm. Excellent anti-corrosion, anti-wax, and drag-reducing functions, used for drag reduction and external anti-corrosion of oil and gas pipelines without wear and corrosion.

[0123] Production Process:

[0124] Put the Ф630×7 steel pipe on the raw material pipe rack, use a large sandblasting port, use a large spray gun, adjust the distance from the top of the drying furnace to the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com