Preparation method of high-temperature-resistant modified retarder

A technology of retarder and high temperature resistance, which is applied in the field of preparation of high temperature resistant modified retarder, can solve the problem that the retarder does not have the ability to adapt to high temperature conditions, and achieve the effect of improving thermal stability and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

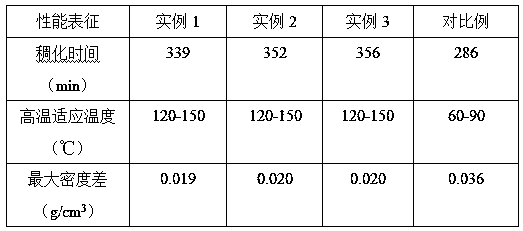

Examples

Embodiment Construction

[0030] In parts by weight, 45-50 parts of silicon carbide whiskers, 120-130 parts of acetone and 3-5 parts of sodium dodecyl benzene sulfonate were weighed and placed in a mortar, ground and dispersed and the dispersion slurry was collected, and then In parts by weight, weigh 45-50 parts of dispersion slurry, 10-15 parts of plasticizer DOP, 25-30 parts by mass of 10% polyvinyl alcohol solution and 1-2 parts of dimethyl silicone oil and place them in a beaker , stir and mix and let stand for 3-5 hours to get the matrix slurry, the matrix will be cast into sheets and dried naturally, and then the sheet will be lifted, and the thickness of the sheet will be controlled to be 300-350 μm. Trichloromethylsilane is used as source material, argon is used as diluent gas, hydrogen is used as carrier gas, and the molar ratio of trichloromethylsilane to hydrogen is controlled to be 1:10. coating layer, and then the deposited coating layer is used as a matrix material for casting treatment, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube chief | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com