Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Extend thickening time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement retardant and its application

The present invention belongs to the field of cement technology, and is especially one kind of cement retardant and its application. The cement retardant is prepared with 2-acrylamido -2-methyl propyl sulfonic acid 20-50 wt%, itaconic acid 30-70 wt% and sodium hypophoshorate 10-20 wt%, and through mixing to react while adding water in 180-230 wt% and ammonium persulfate in 0.5-4 wt% at 65-92 deg.c for 1-4 hr. The cement retardant is added into cement mortar and used at circulation temperature lower than 95 deg.c to prolong the thickening time of cement mortar effectively.

Owner:天津恒信石油技术开发有限公司

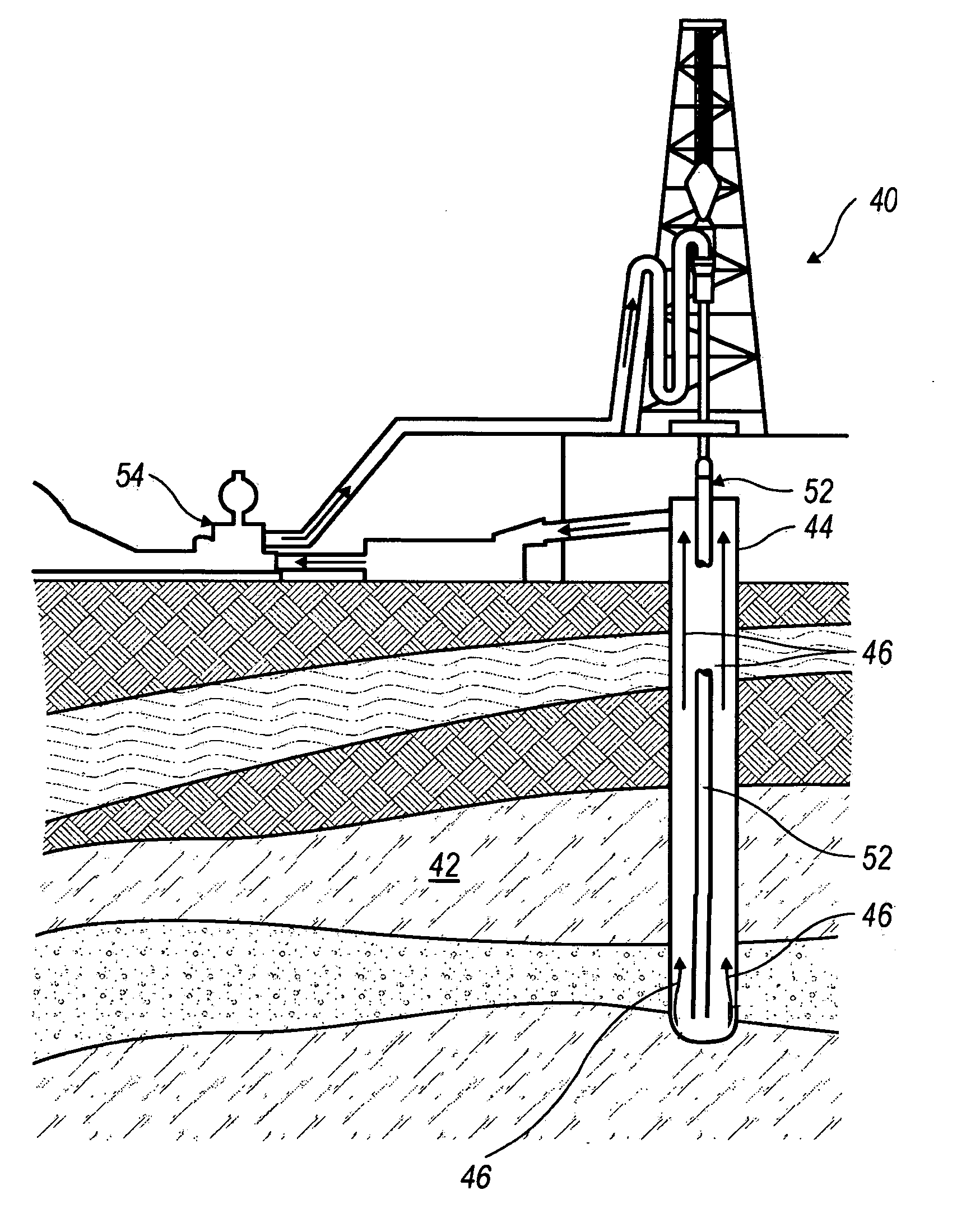

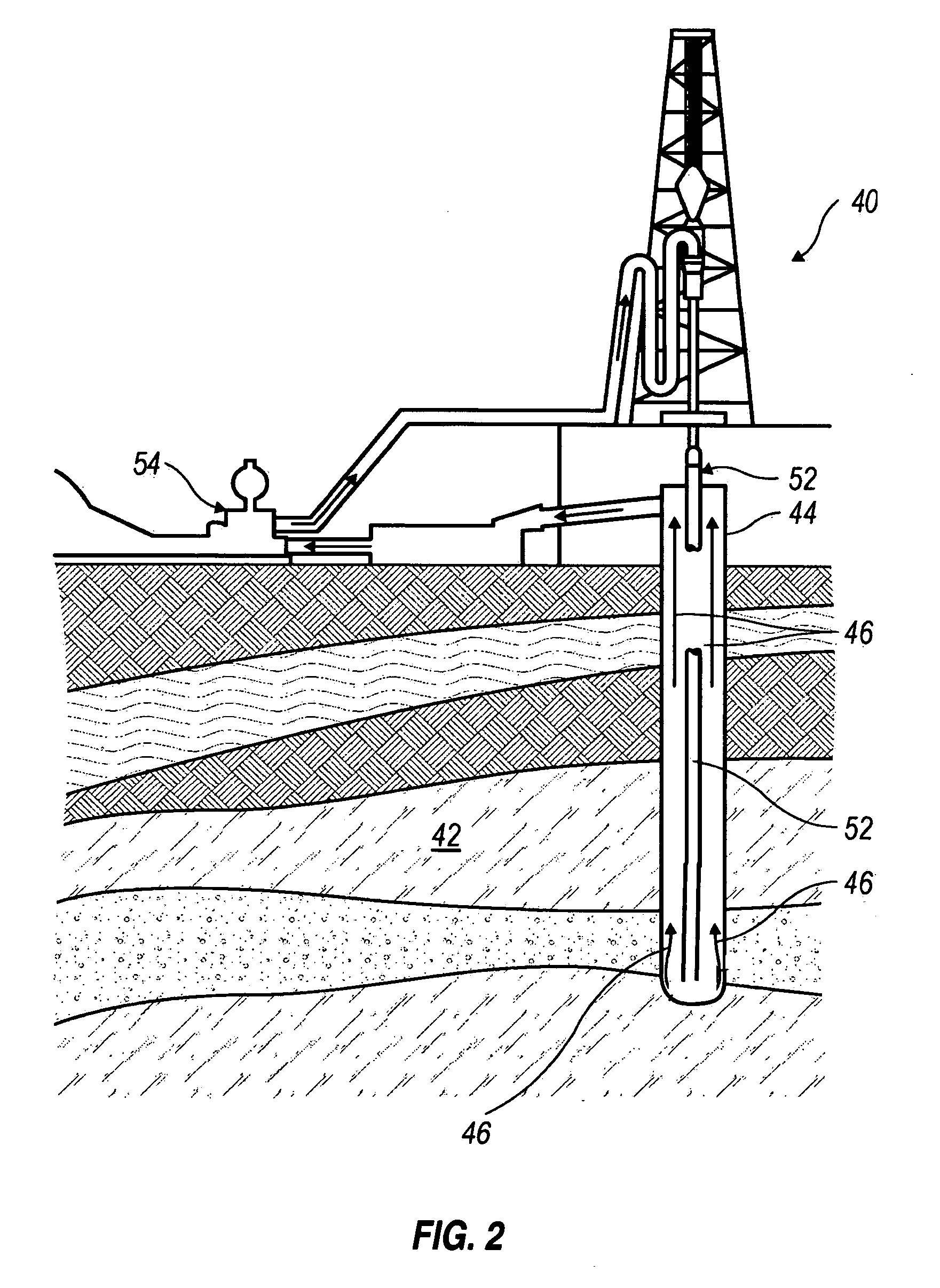

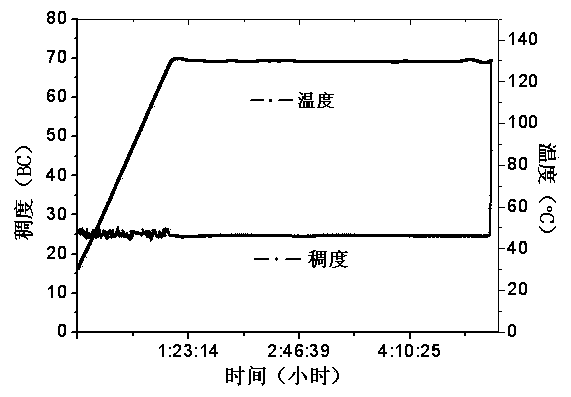

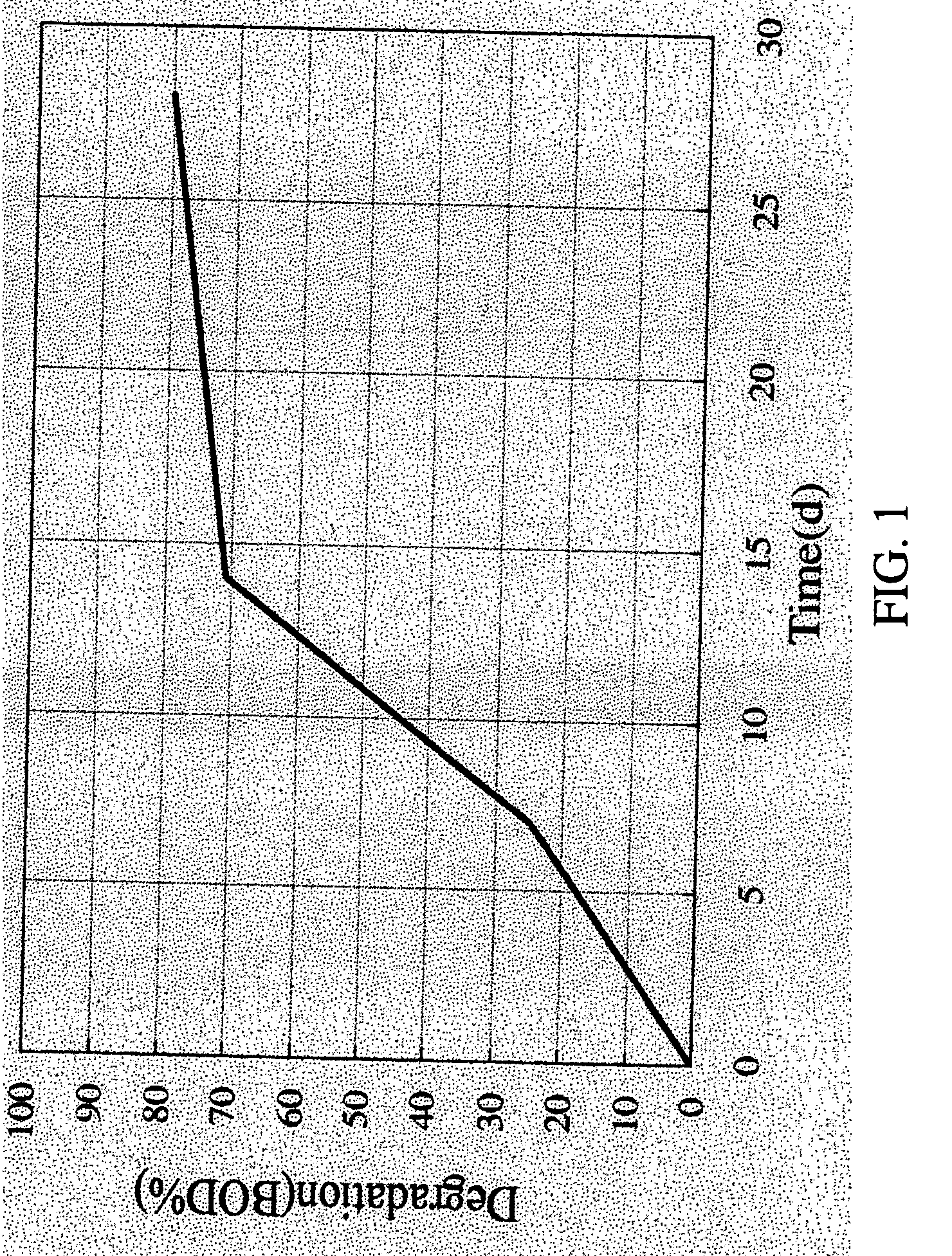

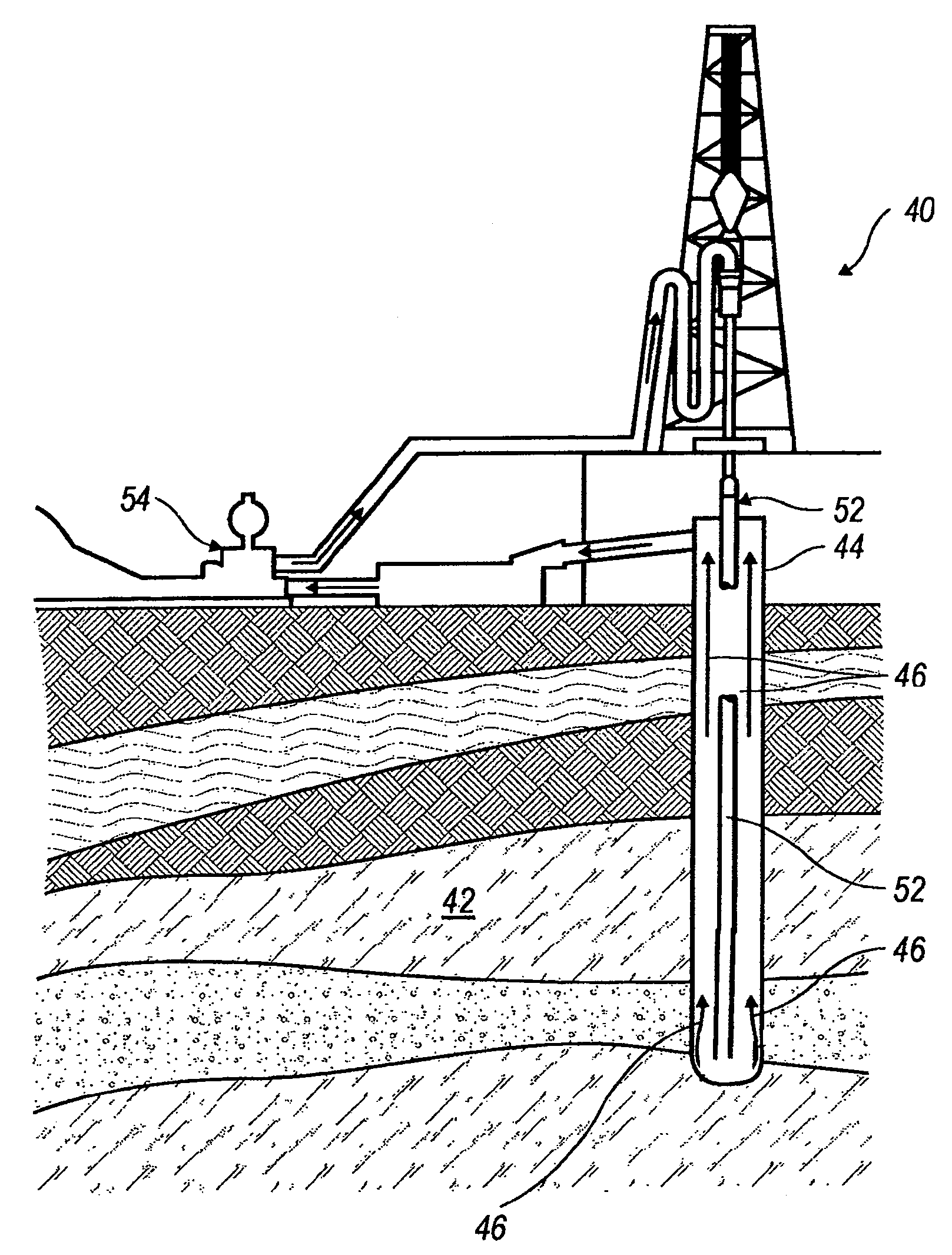

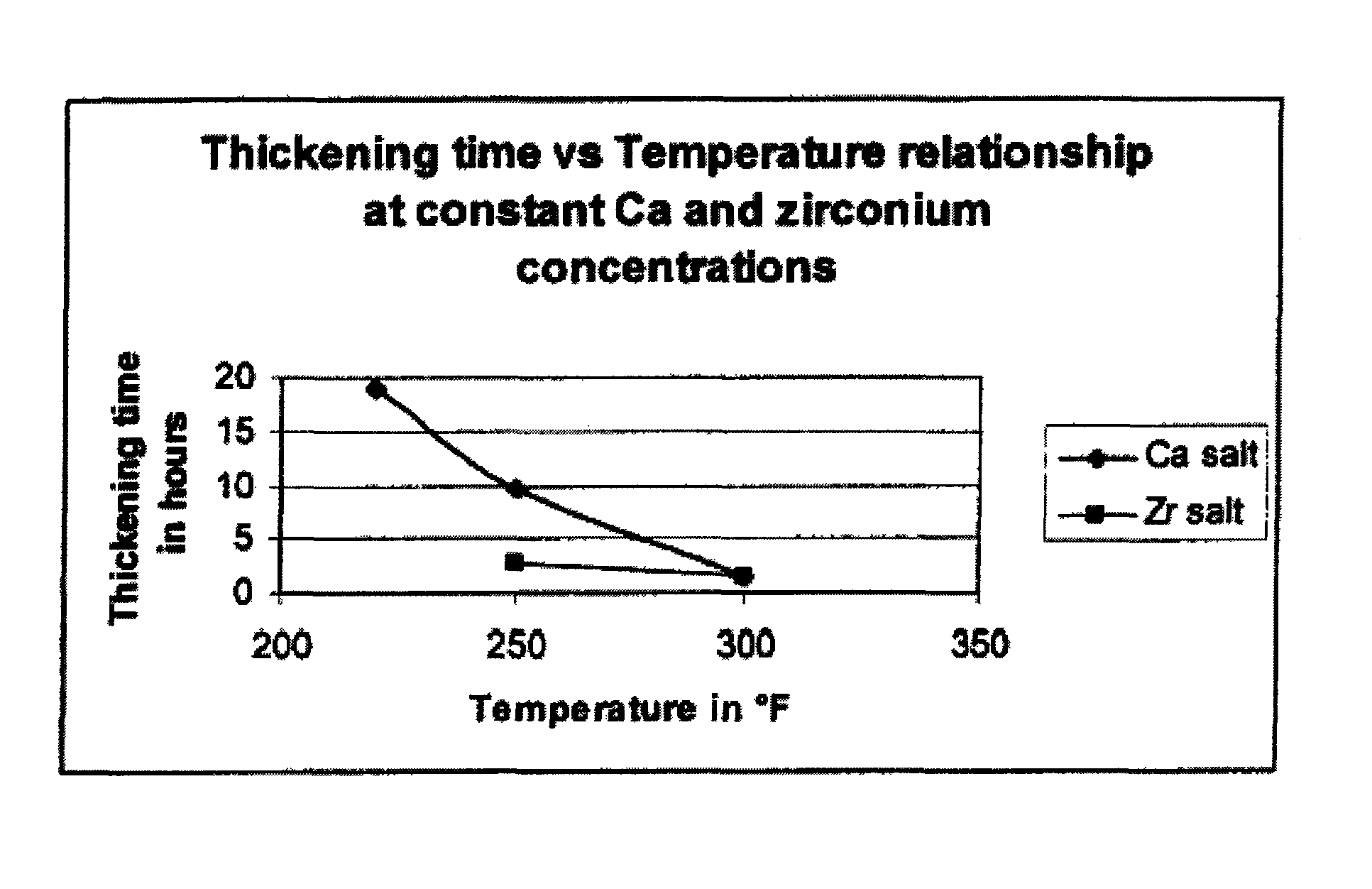

Methods of retarding the setting of a cement composition using biodegradable monomers

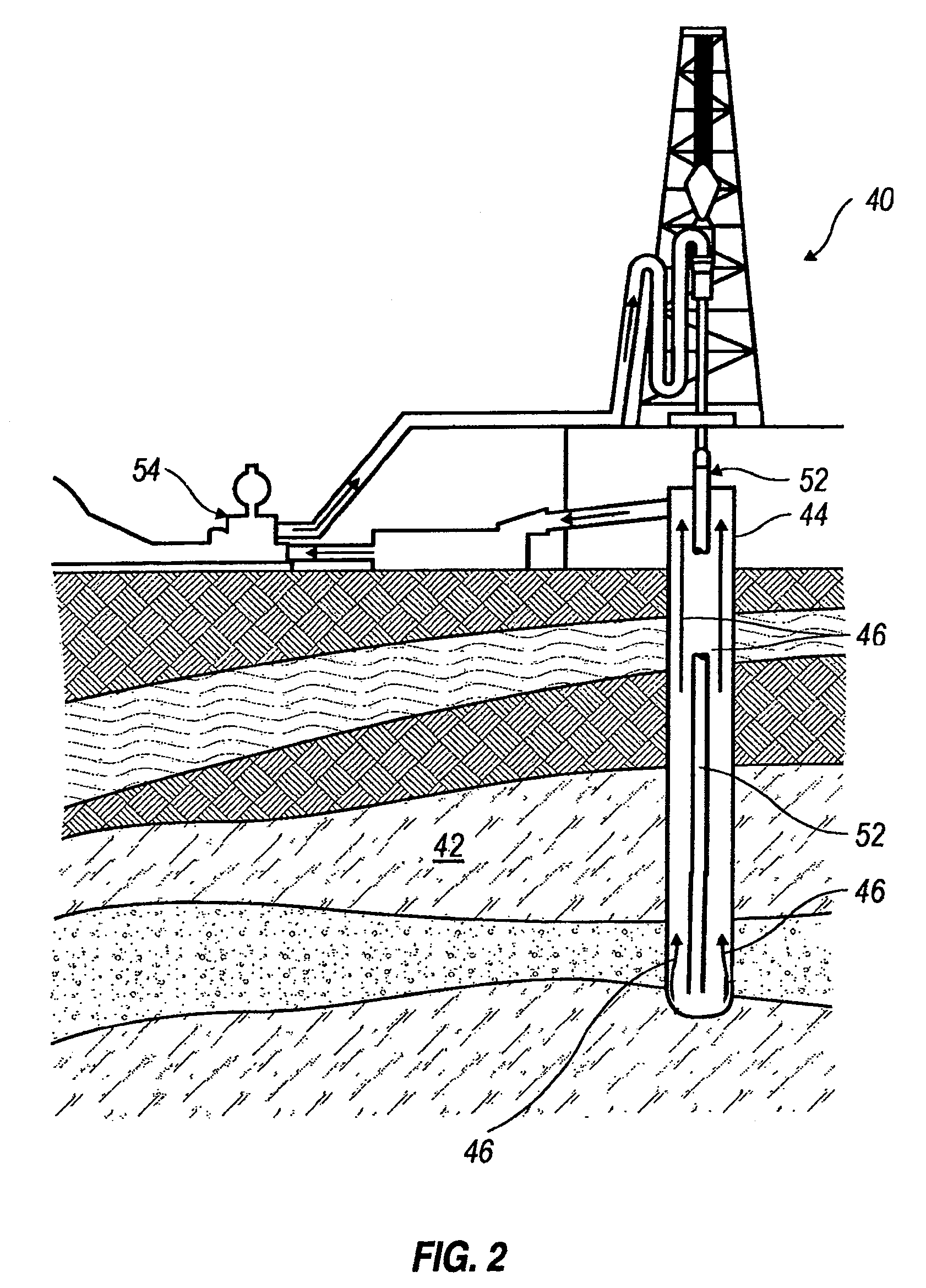

ActiveUS20060289162A1Improve abilitiesExtend thickening timeDrilling compositionSealing/packingIminodisuccinic acidMonomer

Methods of retarding the setting of a cement composition comprise including one or more secondary amines substituted with a carboxyl group or salts thereof (e.g., 3-hydroxy N,N′-iminodisuccinic acid) in the cement composition. The inclusion of such materials in cement compositions may be highly beneficial. In wellbores having BHCT's of less than or equal to about 250° F., the use of the secondary amine as the set retarder ensures that the thickening time of the cement composition is sufficient to allow the cement composition to be pumped to its desired downhole location. Further, the secondary amine may be used in combination with conventional set retarders to enhance the ability of those retarders to increase the thickening time of the cement composition at higher BHCT's, e.g., from about 250° F. to about 525° F.

Owner:HALLIBURTON ENERGY SERVICES INC

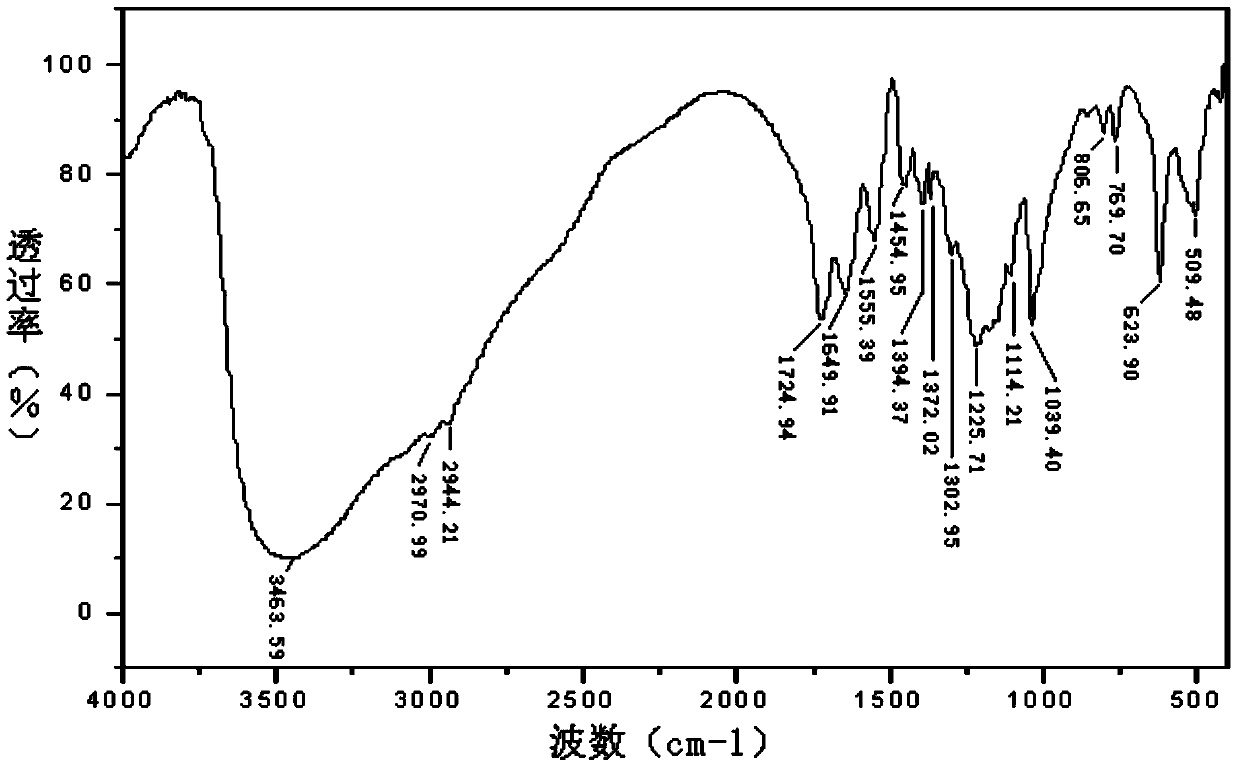

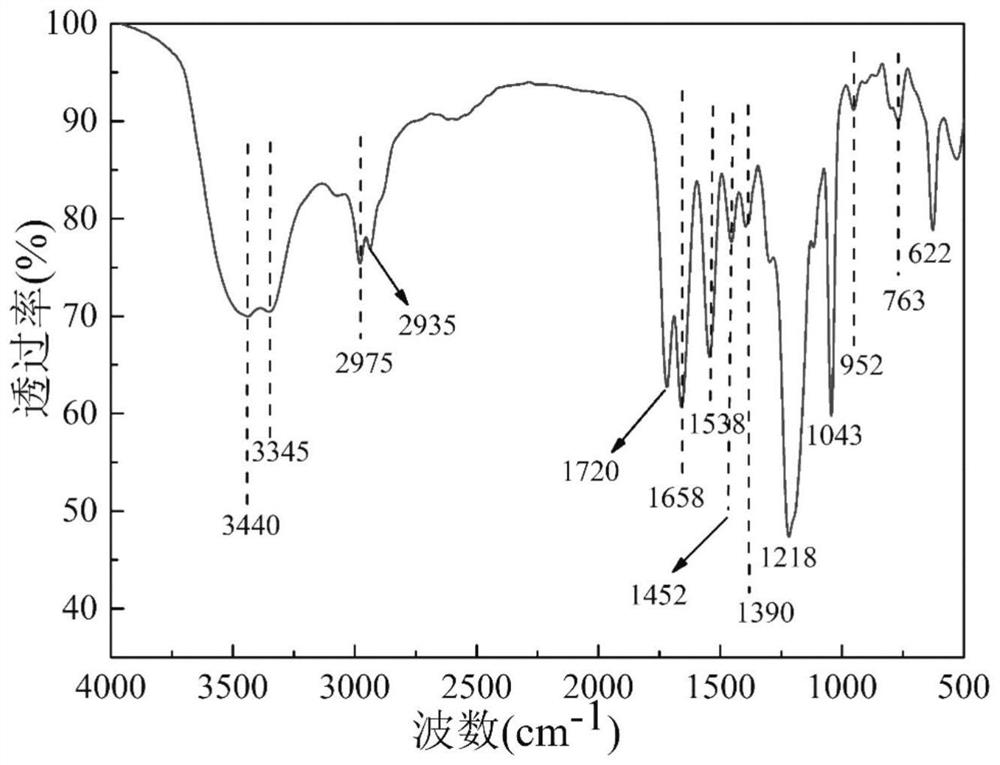

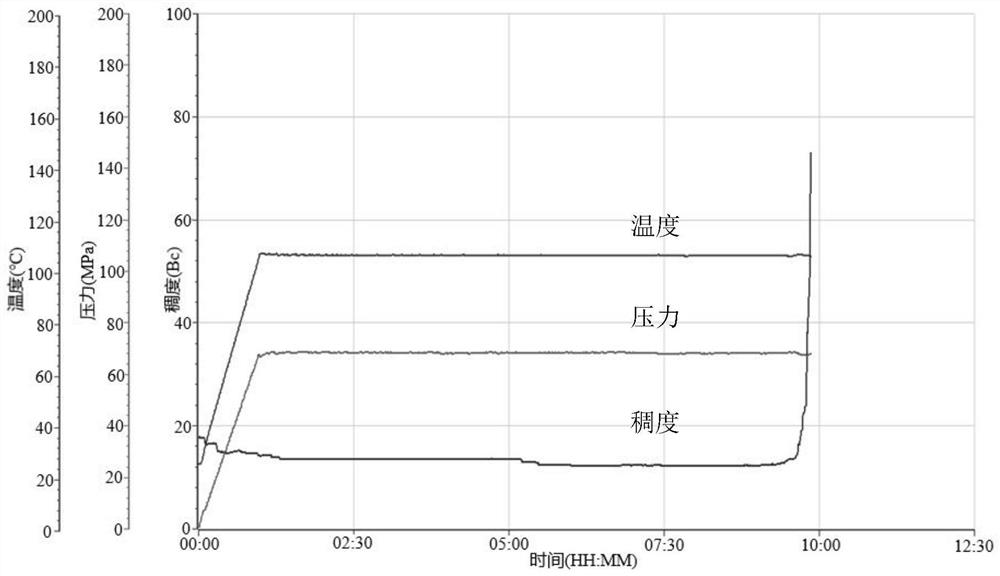

Cement-dispersing retarder for high-temperature-resistant oil well and preparation method of retarder

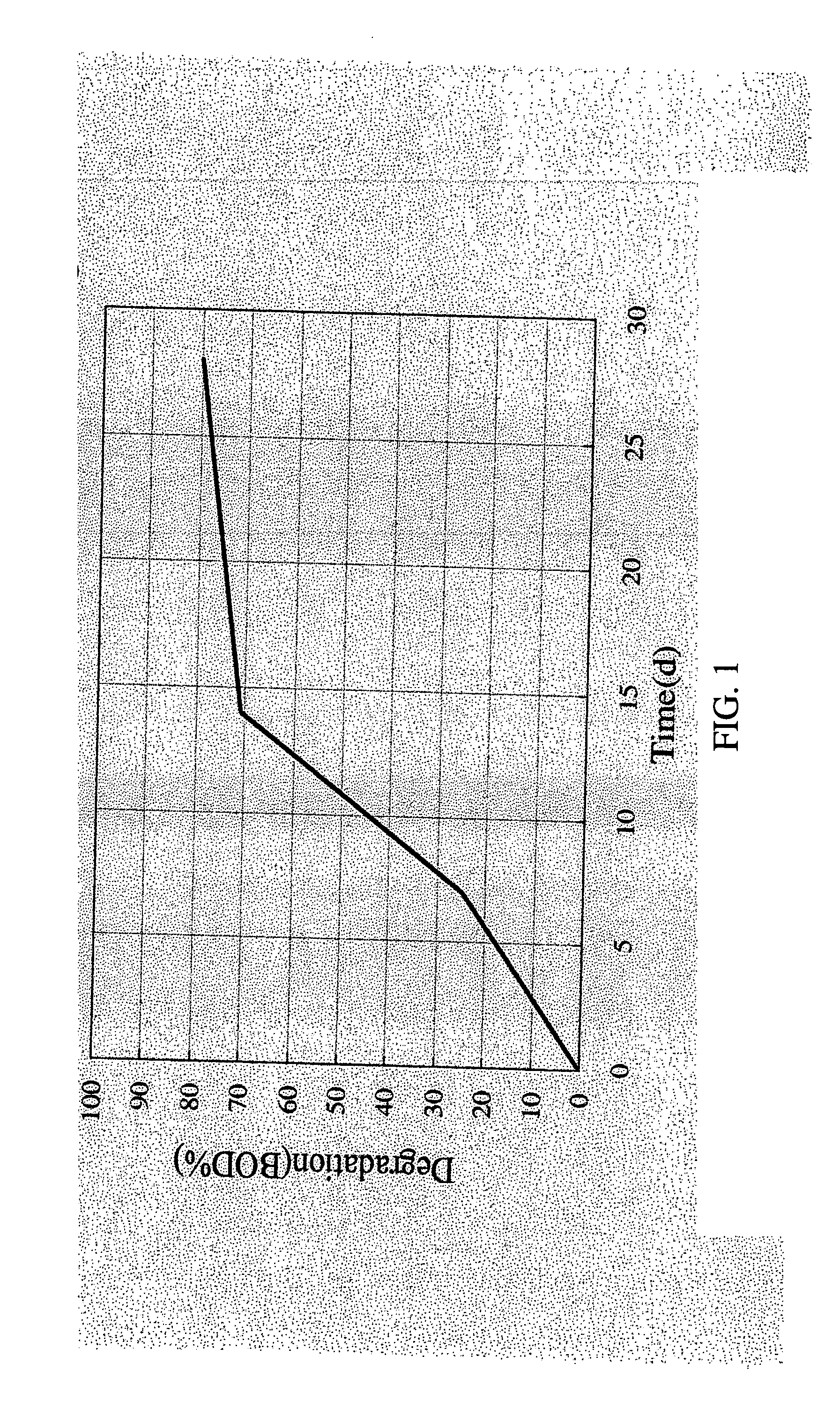

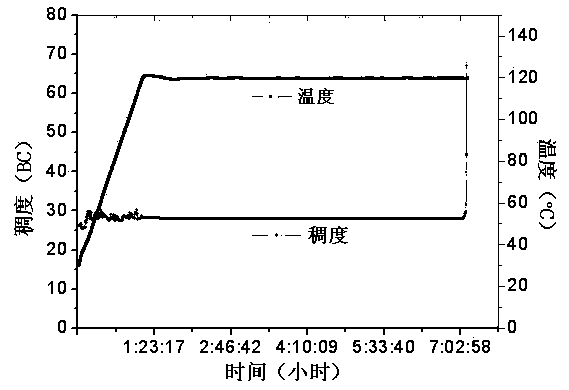

ActiveCN104327813AThe synthesis process is simpleExtend thickening timeDrilling compositionIonItaconic acid

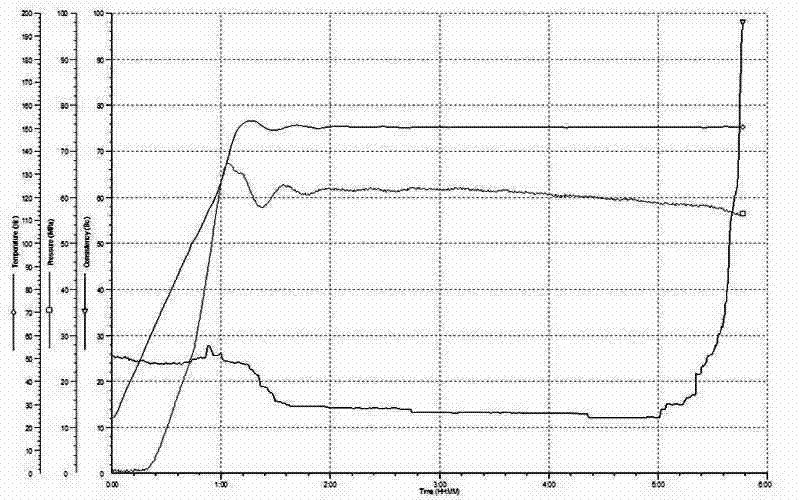

The invention discloses a cement-dispersing retarder for a high-temperature-resistant oil well and a preparation method of the retarder. The cement-dispersing retarder comprises three structure units, namely sodium p-styrenesulfonate, methacrylic acid-2-hydroxyl ethyl ester and itaconic acid, and the viscosity-average molecular weight is 30000-50000. The preparation method comprises the following steps of (1) respectively dissolving sodium p-styrenesulfonate, methacrylic acid-2-hydroxyl ethyl ester and itaconic acid in deionized water, mixing and adjusting pH to be neutral; (2) introducing nitrogen to remove oxygen, reacting for 4-6 hours in water bath with the temperature of 50-70 DEG C based on potassium persulfate as an initiating agent; and (3) cooling obtained slightly-viscous solution, purifying, drying and grinding, thereby obtaining the cement-dispersing retarder for the high-temperature-resistant oil well. The cement-dispersing retarder disclosed by the invention has the advantages that the thickening time can be effectively prolonged under the high-temperature condition, the right-angled thickening phenomenon is obvious, the compatibility with other oil-well cement admixtures is good, the strength of cement stone can also be rapidly developed under the low-temperature condition, the preparation method is reliable in principle and simple to operate and has wide market prospect.

Owner:PETROCHINA CO LTD

Cement compositions comprising biodegradable monomers for retarding the setting thereof

InactiveUS20060288910A1Improve abilitiesExtend thickening timeDrilling compositionIminodisuccinic acidBiodegradable polymer

Cement compositions may comprise one or more secondary amines substituted with a carboxyl group or salts thereof (e.g., 3-hydroxy N,N′-iminodisuccinic acid) for retarding the setting of such compositions. The inclusion of such materials in cement compositions may be highly beneficial. In wellbores having BHCT's of less than or equal to about 250° F., the use of the secondary amine as the set retarder ensures that the thickening time of the cement composition is sufficient to allow the cement composition to be pumped to its desired downhole location. Further, the secondary amine may be used in combination with conventional set retarders to enhance the ability of those retarders to increase the thickening time of the cement composition at higher BHCT's, e.g., from about 250° F. to about 525° F.

Owner:HALLIBURTON ENERGY SERVICES INC

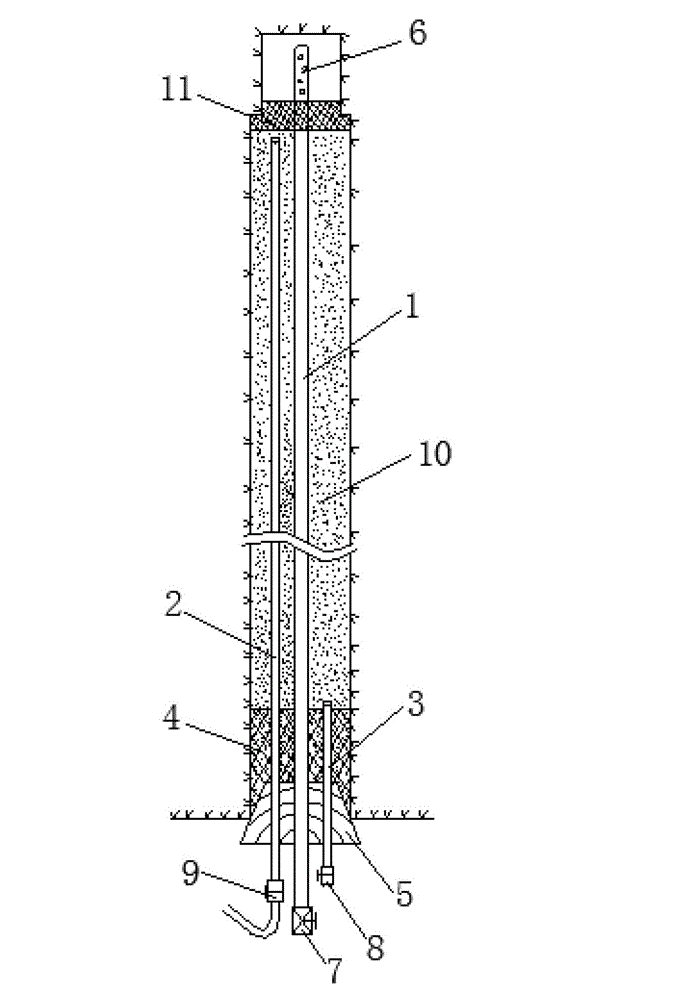

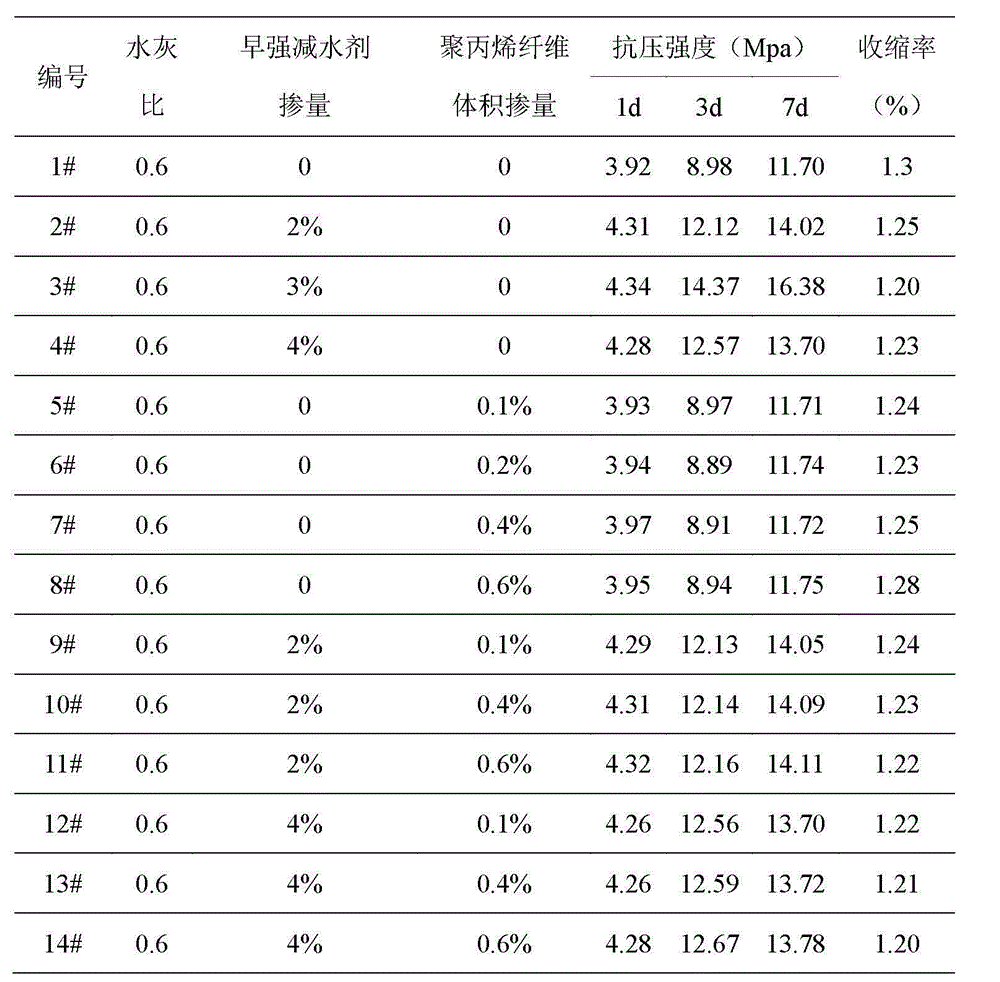

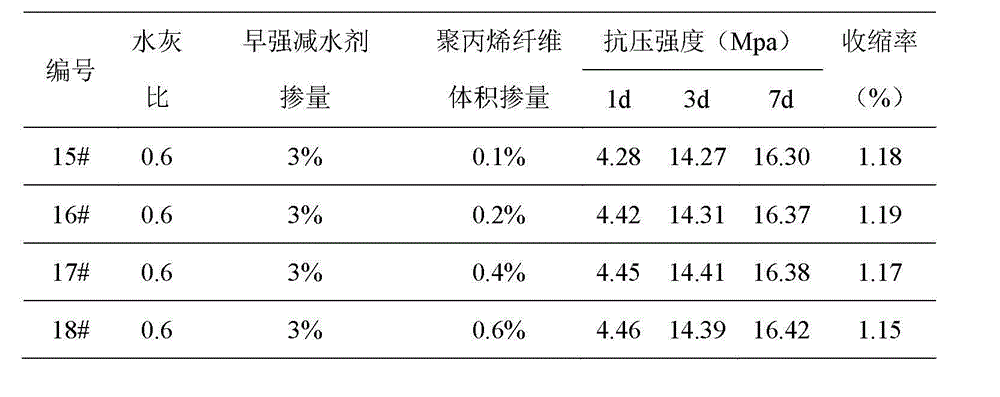

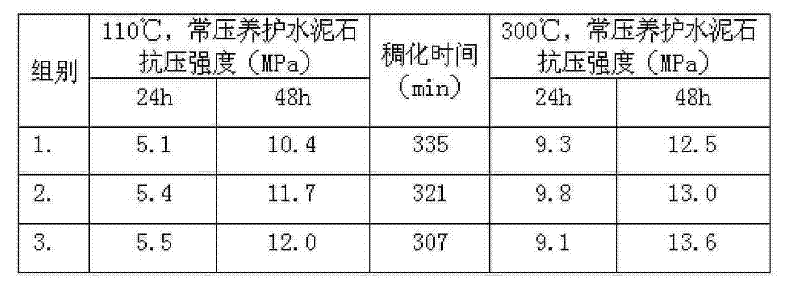

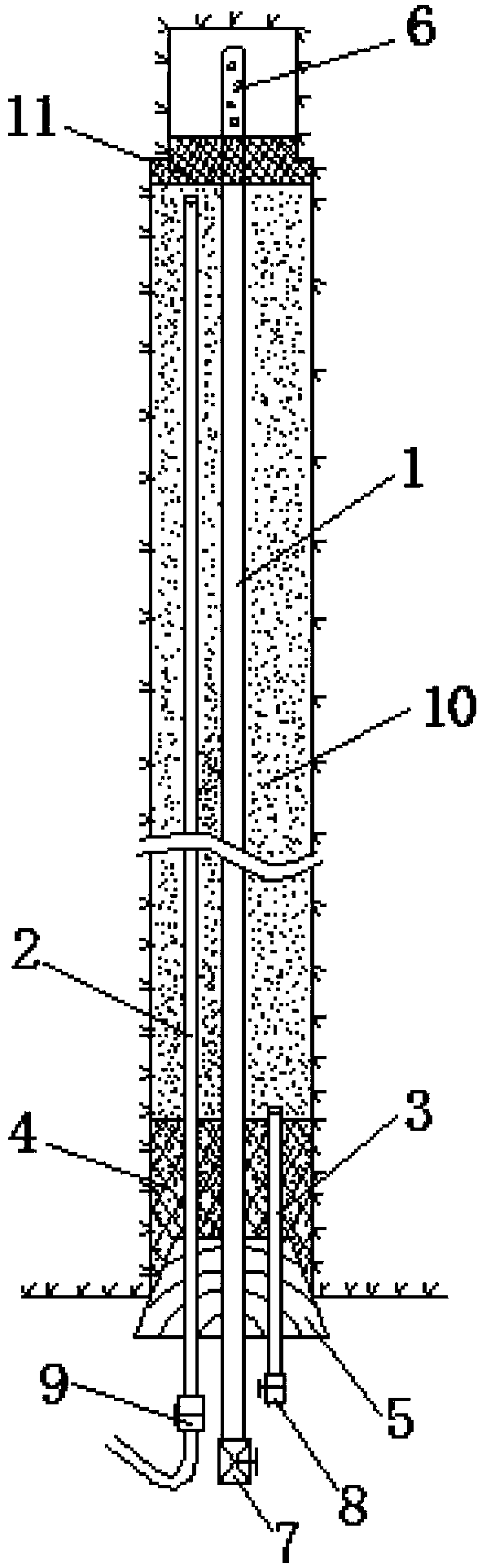

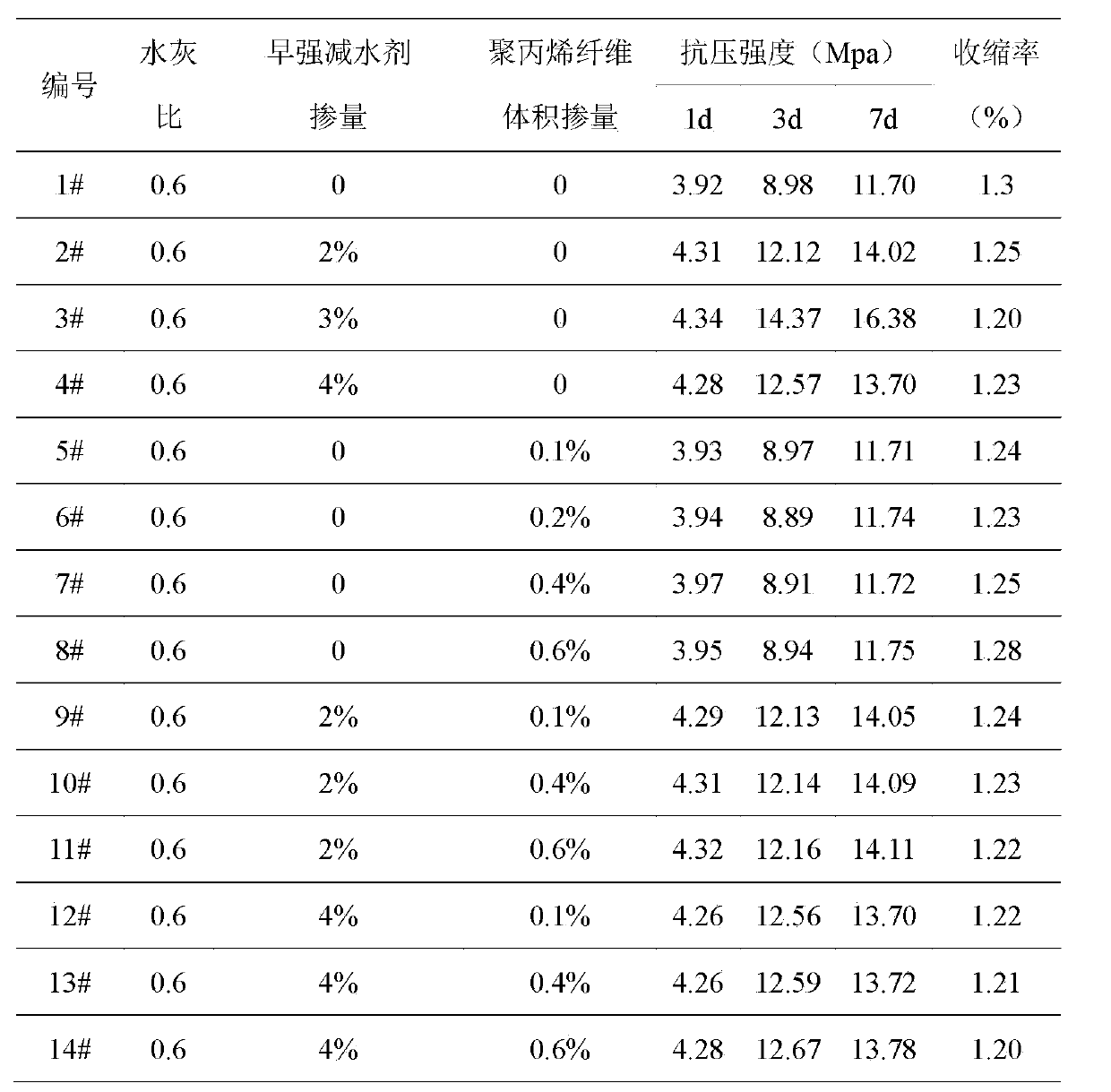

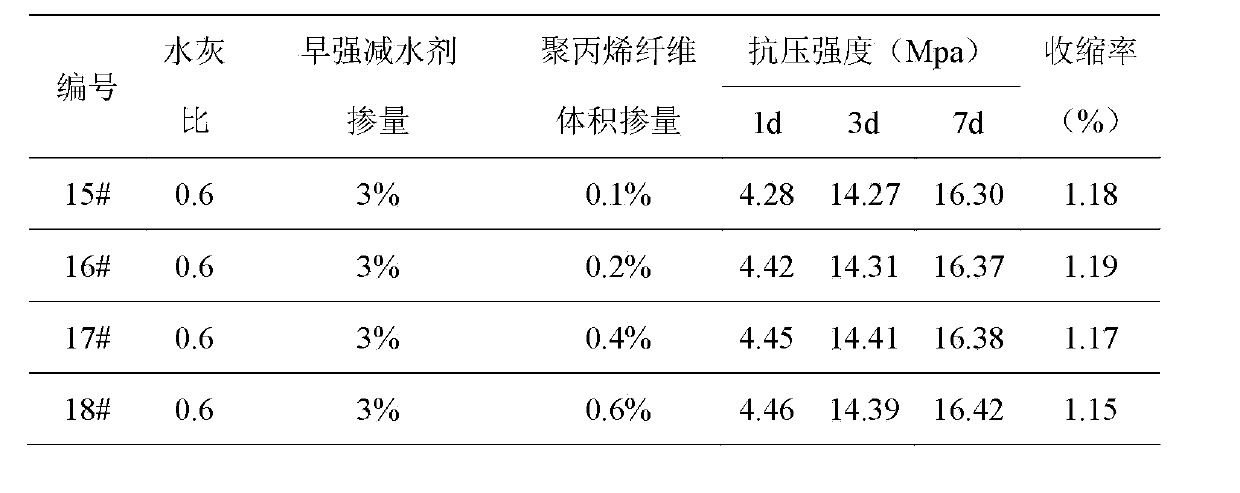

Underground high-pressure hydraulic fracturing hole sealing material for coal mine and hole sealing technology

ActiveCN102977869AImprove toughnessImprove impact resistanceDrilling compositionSealing/packingYarnAdhesive

The invention provides an underground high-pressure hydraulic fracturing hole sealing material for a coal mine and a hole sealing technology. The hole sealing material comprises the following components by weight: 100 parts of cement, 2 to 4 parts of Ms type early-strength slushing agent, 0.08 to 0.5 parts of polypropylene fiber, and 60 parts of water. The hole sealing technology comprises the following steps in sequence: drilling a hole on a coal-rock mass; constructing until reaching the a top plate at a coal seam; expanding the hole to a bottom plate at the coal seam; feeding a grouting pipe to the bottom plate at the coal seam; arranging a grout returning pipe to the front end of a blocking section of a hole port; blocking the hole port section through AB adhesive and cotton yarn; feeding the hole sealing material into the hole through the grouting pipe; closing a check valve of the grout returning pipe after returning the grout through the grout returning pipe; continuously grouting; completely draining the grout in the grouting pipe once water flows form a fracturing hole; grouting at the second time after the grout is condensed; and finally solidifying. The underground high-pressure hydraulic fracturing hole sealing material for the coal mine has the advantages of being less in contraction, and high in compressive strength and impact toughness; the hole sealing material is high in sealing performance and resistance to high pressure under the effect of high-pressure hydraulic fracturing impact load; simultaneously, the hole sealing material is low in cost and the construction is convenient; and the hole sealing technology is simple, the hole sealing depth meets the requirement, and the success rate is high.

Owner:CHONGQING UNIV

High-temperature low-density cement and applications thereof

ActiveCN101747009AHigh strengthHigh compressive strengthSolid waste managementDrilling compositionOil productionTemperature resistance

The invention relates to a high-temperature low-density cement and applications thereof, belonging to the field of building materials. The high-temperature low-density cement provided by the invention has excellent high temperature resistance and comprises the following components in percentage by weight: 30%-70% of cement substrate, 14%-40% of lightening material, 14%-30% of high-temperature strength stabilizer and 0.02%-0.10% of high-temperature retarder, wherein the high-temperature retarder is organic acid sodium salt, and the high-temperature strength stabilizer material is one of micro silicon and silicon powder or the combination of micro silicon and silicon powder. The cement has the characteristics of simple construction processes, high pulping rate, excellent high temperature resistance and the like, can be applied to special environments such as oil well cementing and the like, and can obviously improve well cementing quality and crude production rate. When the cement of the invention is used for well cementing operation and high-temperature oil production operation, the well cementing construction performance can be ensured, and the unabated performance of the strength of the cement stone at high temperature can be ensured.

Owner:JIAHUA SPECIAL CEMENT

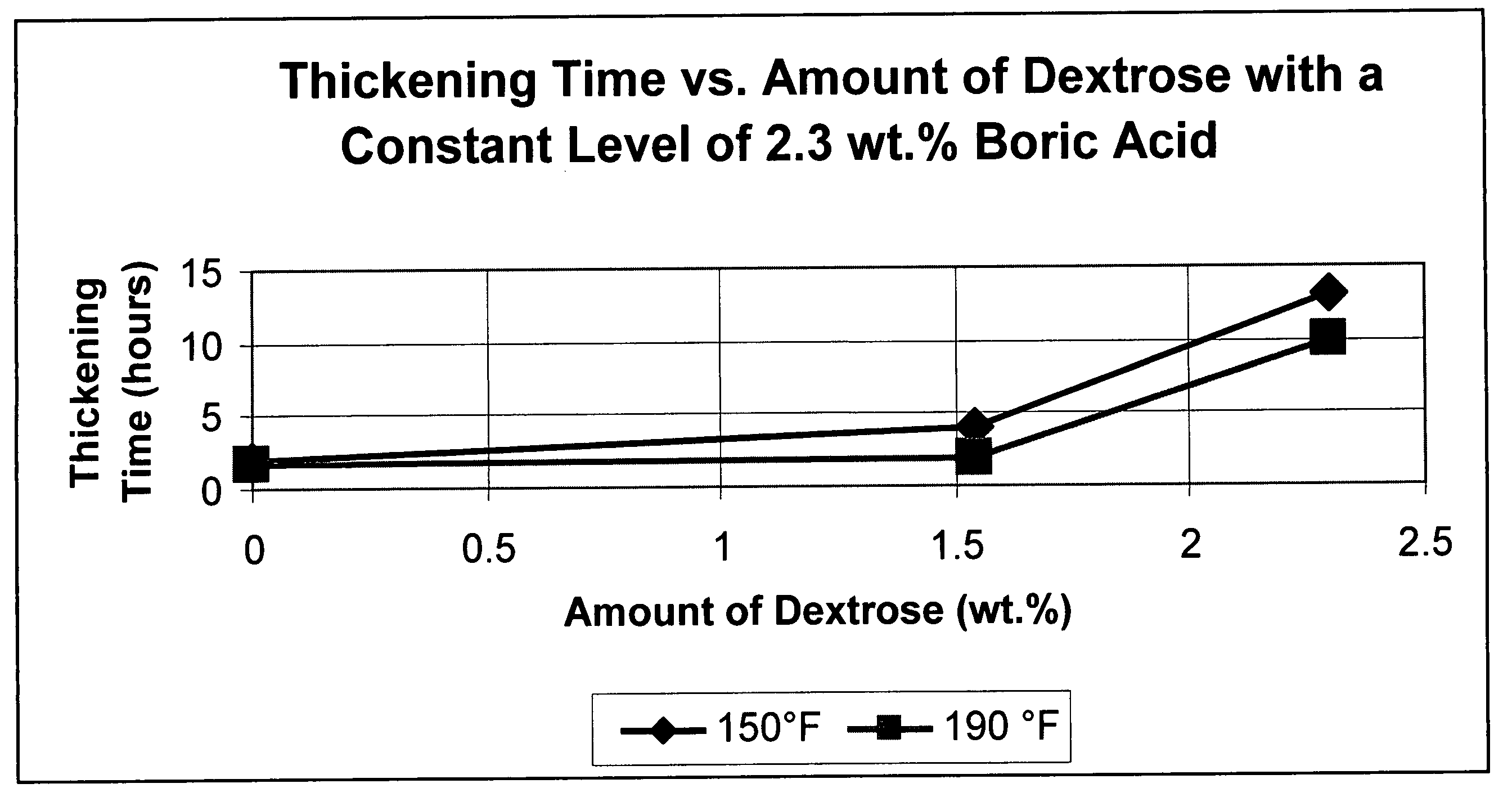

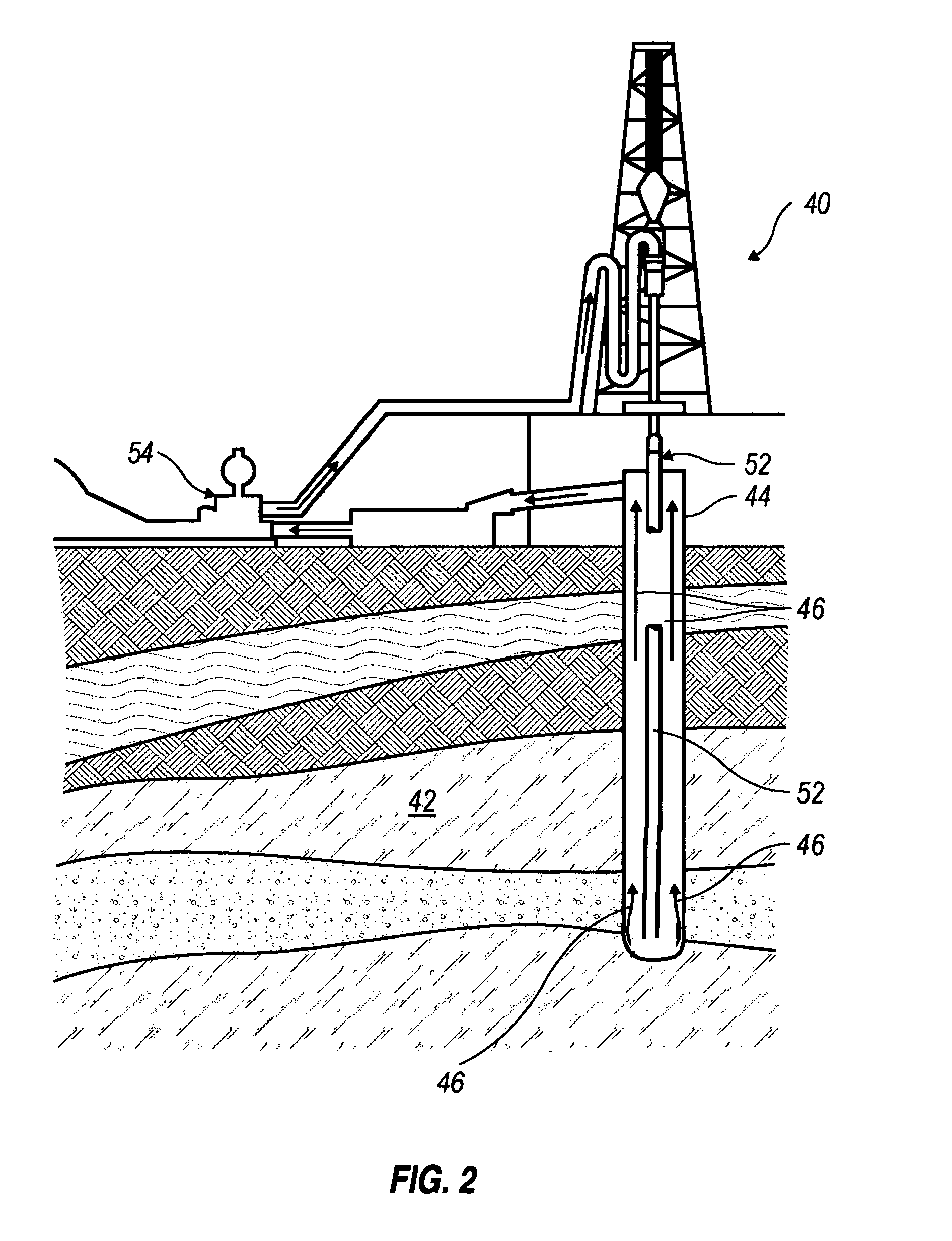

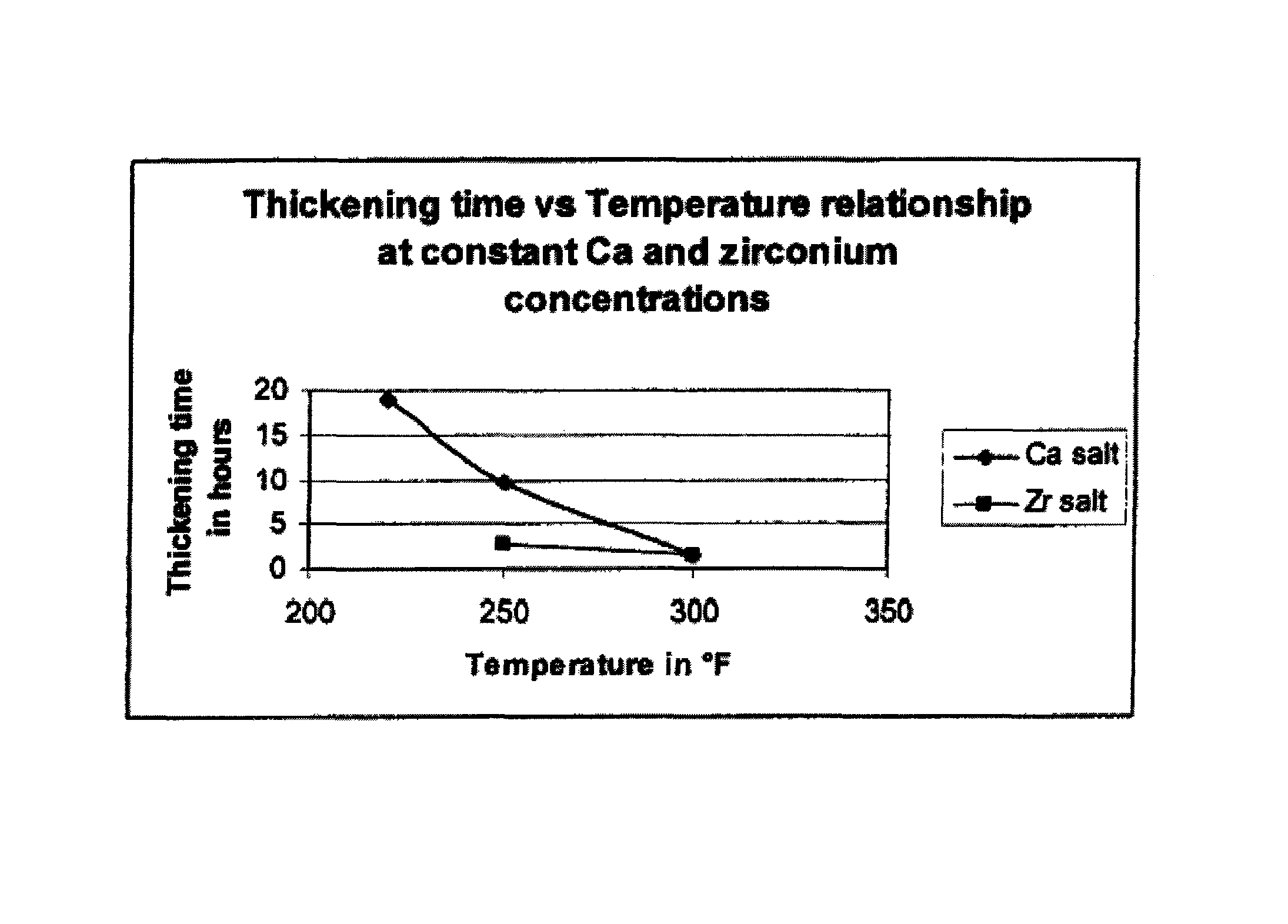

Methods of increasing the thickening times of phosphate-based cementitious compositions in high-temperature wellbores

A wellbore may be cemented by preparing a cementitious composition comprising water, a metal oxide or hydroxide compound, a phosphate compound, a borate compound, and a sugar, followed by displacing the cementitious composition into the wellbore. The metal oxide or hydroxide compound reacts with the phosphate compound in the wellbore to set into a hard mass. The synergistic effect of the borate compound and the sugar may increase a thickening time of the cementitious composition to in a range of from about 2 hours to about 11 hours at ambient temperatures in the wellbore. As such, the thickening time is sufficient to allow the cementitious composition to be placed in its desired location in the wellbore before setting.

Owner:HALLIBURTON ENERGY SERVICES INC

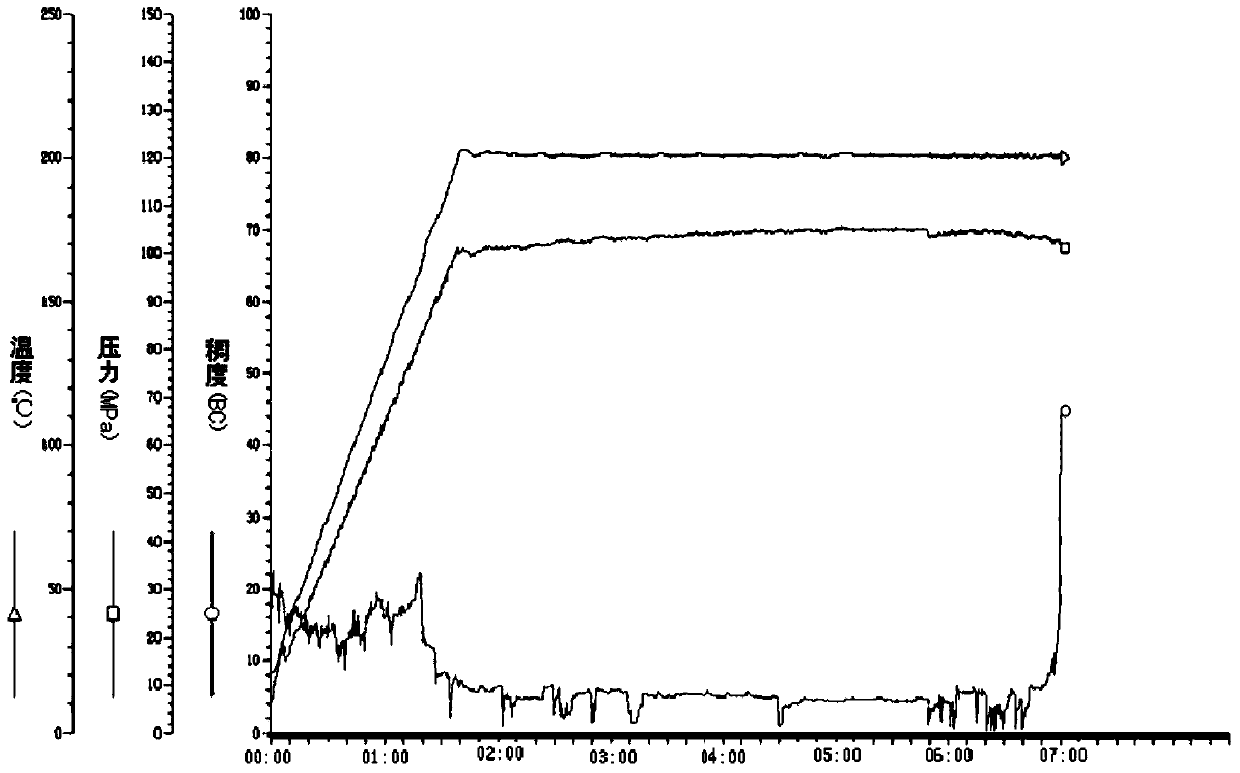

Oil well cement high temperature retarder

ActiveCN101597487ASuitable for a wide temperature rangeMeet the needs of drilling and completion engineeringDrilling compositionSulfonateWell drilling

The invention relates to an oil well cement high temperature retarder applied to the technical field of oil field well drilling and completion. The invention is characterized in that: the retarder is composed of 1 part by weight of water, 0.005-0.030 part by weight of hydroxycarboxylic acid and salt thereof, 0.005-0.010 part by weight of cellulose derivative and 0.0001-0.0010 part by weight of sulfonate. The high temperature retarder has wide applicable temperature range, can be applied to cement paste systems with various densities, has strong compatibility with a plurality of admixture systems, and does not influence the performance of cement paste. The cement paste prepared by the retarder is stable, the thickening transition time is short, and the thickening time is adjustable; the hardened cement paste has rapidly developed compression strength and is suitable for the requirement of well cementation engineering.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Preparation and application methods of high temperature resistant cement retarder

ActiveCN103739779AWide application temperature rangeRapid development of strengthDrilling compositionPolymer scienceOxygen

The invention discloses preparation and application methods of a high temperature resistant cement retarder. The preparation method comprises the steps of dissolving 2-acrylamido-2-methyl propanesulfonic acid accounting for 40-60% of the total monomer by mass, itaconic acid accounting for 20-40% of the total monomer by mass and maleic acid accounting for 10-20% of the total monomer by mass into water with mass 2-4 times the total mass of the monomer, removing oxygen, adding an initiator ammonium persulfate accounting for 1.5-3% of the total monomer by mass, reacting at 75-100 DEG C for 3-6 hours, and then cooling the reactant to the room temperature, thus obtaining the high temperature resistant cement retarder. The high temperature resistant cement retarder prepared by the method can be used in the temperature range of 100-230 DEG C, is insensitive in additive amount, has short thickening transition time, is well matched with other oil well cement additives, does not have adverse effects on strength development of set cement, and has good salt resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

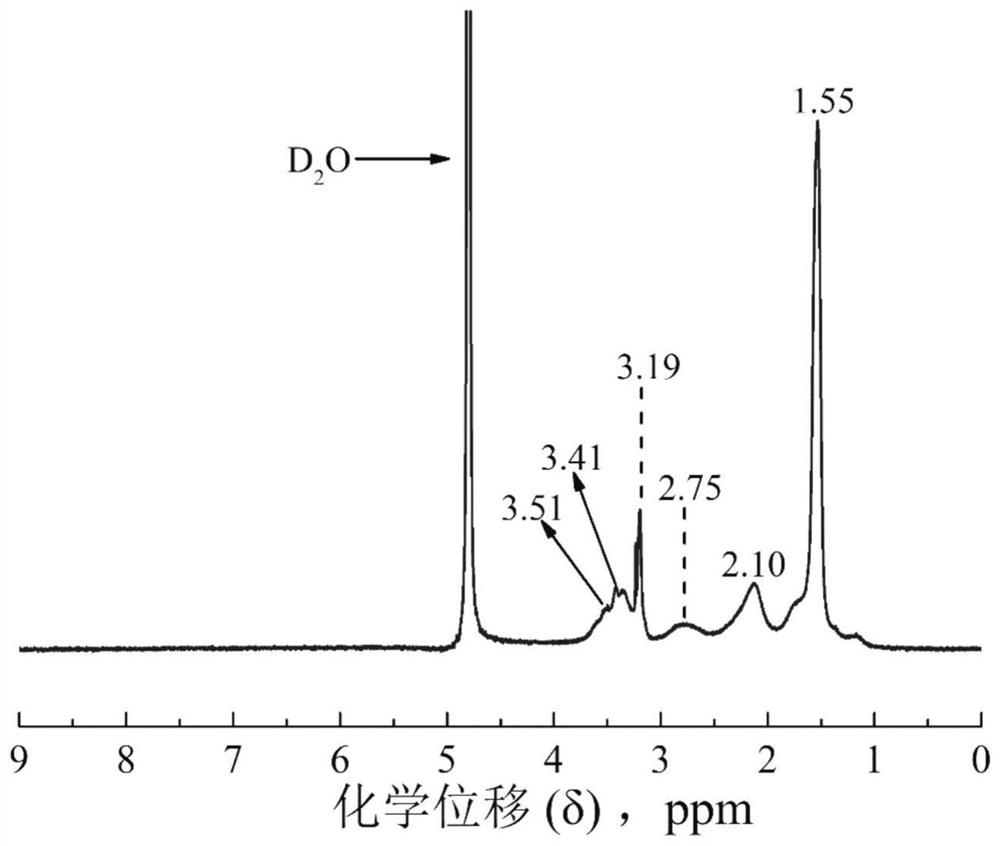

Method for preparing binary copolymer retarder for oil and gas well cementing

The invention which discloses a method for preparing a binary copolymer retarder for oil and gas well cementing relates to the technical field of methods for preparing cement corrosion inhibitors for oil and gas wells. The method of the invention comprises the following steps: 1, respectively weighing 2-acrylamide-2-methylpropanesulfonic acid and itaconic acid according to a mass ratio of 73-75:25-27, and dissolving above monomers in deionized water, wherein the mass of deionized water accounts for 200% of the total mass of the monomers; 2, adjusting the pH value of a solution obtained in step 1 to 5-6 by a sodium hydroxide solution with the mass-volume concentration of 50%; 3, placing a solution obtained in step 2 in a three-neck flask, carrying out water bath at a constant temperature, and heating to 60-65DEG C; and 4, adding an initiator to a solution obtained in step 3 drop by drop, and continuously reacting for 4-6h to obtain final products, wherein the mass of the initiator accounts for 1.0-2.0% of the total mass of the monomers. The method of the invention has the advantages of simple process, low cost and less raw material, and the retarder prepared through the method can satisfactorily solve a technical problem "over retardation" of a high temperature cement mortar at a middle temperature of 50-180DEG C.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

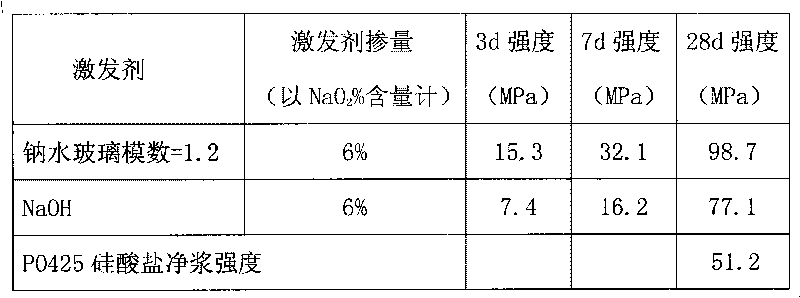

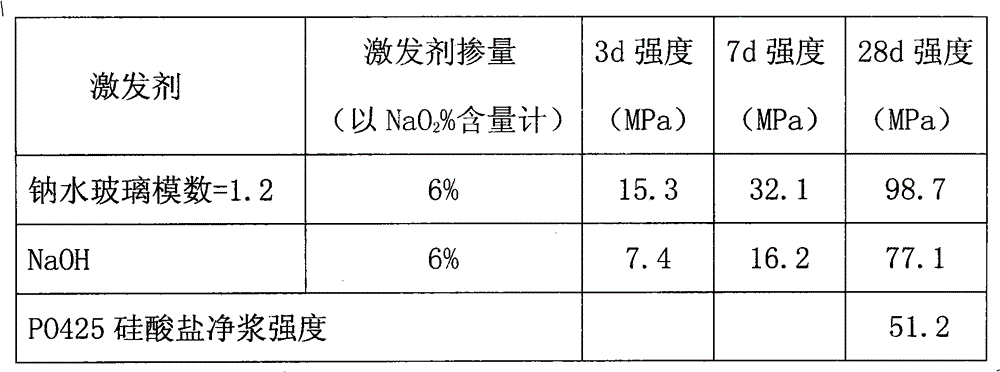

Phosphorous slag aerated concrete and preparation method thereof

ActiveCN101708981AEmission reductionLow costSolid waste managementClinker productionSlagThermal insulation

The invention discloses a phosphorous slag aerated concrete. The concrete is characterized by consisting of a binding material, an exciting agent, an air entraining agent and water which are mixed, wherein the binding material consists of 60 to 100 weight percent of phosphorous slag and 0 to 40 weight percent of pulverized fuel ash; the exciting agent is water glass with modulus of 1.0 to 1.6; the water glass accounts for 5 to 8 weight percent of the binding material based on the weight of Na2O; the air entraining agent is aluminum powder or simple substance silicon; the using amount of the aluminum powder is 0.1 to 0.2 weight percent of the binding material; the using amount of the simple substance silicon is 0.05 to 0.1 weight percent of the binding material; and the weight ratio of theusing amount of the water to the using amount of the binding material is 0.28 to 0.32. The phosphorous slag aerated concrete product is prepared by taking the industrial waste slag such as the phosphorous slag and the like as the binding material and mixing the phosphorous slag, the exciting agent, the air entraining agent and the water. The phosphorous slag aerated concrete has the advantages that: the preparation process is simple without vapor-pressure process, so that the equipment investment can be greatly reduced; and the product is a sealed porous structure and has the characteristics of light weight, high strength, low thermal conductivity, good thermal insulation property and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

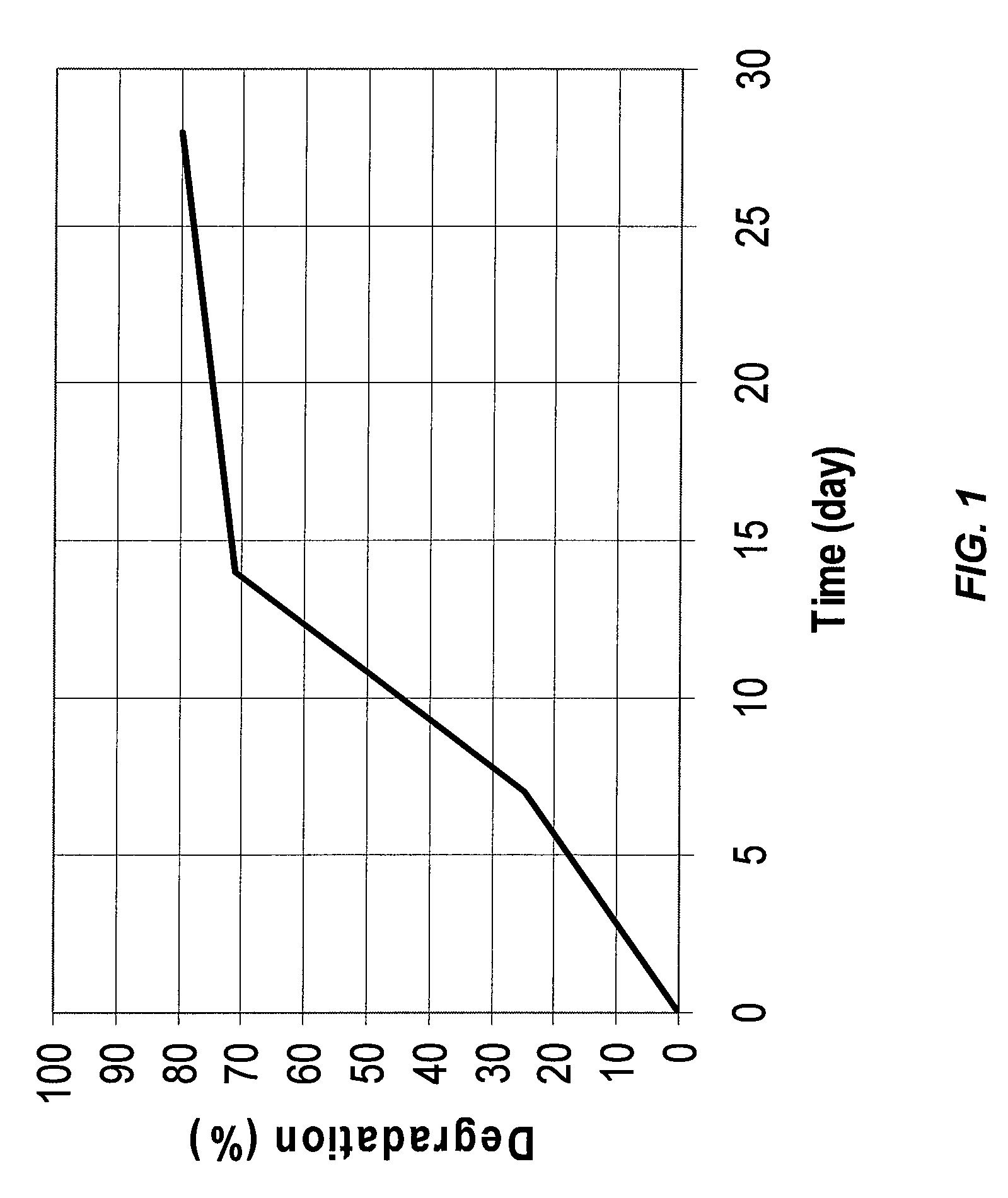

Methods of retarding the setting of a cement composition using biodegradable monomers

ActiveUS7350574B2Slow effectReduce biodegradationDrilling compositionSealing/packingIminodisuccinic acidBiodegradable polymer

Methods of retarding the setting of a cement composition comprise including one or more secondary amines substituted with a carboxyl group or salts thereof (e.g., 3-hydroxy N,N′-iminodisuccinic acid) in the cement composition. The inclusion of such materials in cement compositions may be highly beneficial. In wellbores having BHCT's of less than or equal to about 250° F., the use of the secondary amine as the set retarder ensures that the thickening time of the cement composition is sufficient to allow the cement composition to be pumped to its desired downhole location. Further, the secondary amine may be used in combination with conventional set retarders to enhance the ability of those retarders to increase the thickening time of the cement composition at higher BHCT's, e.g., from about 250° F. to about 525° F.

Owner:HALLIBURTON ENERGY SERVICES INC

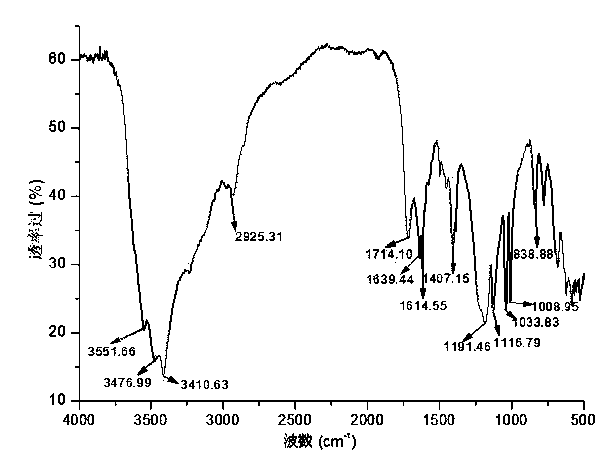

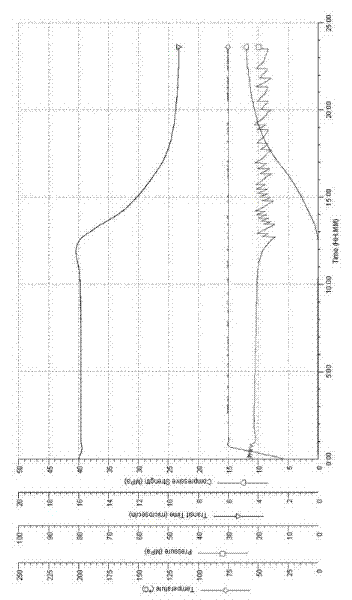

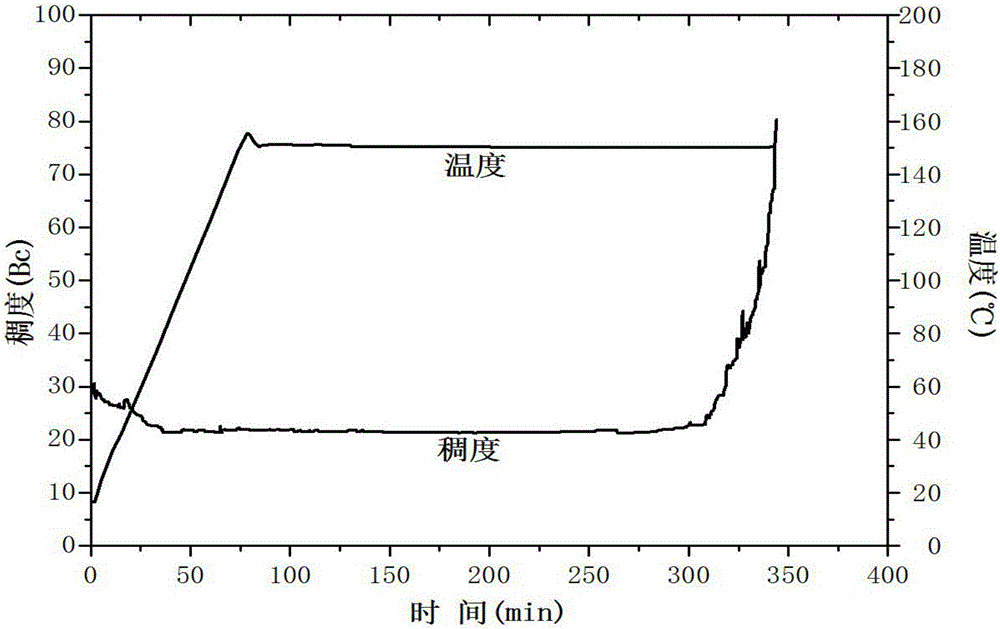

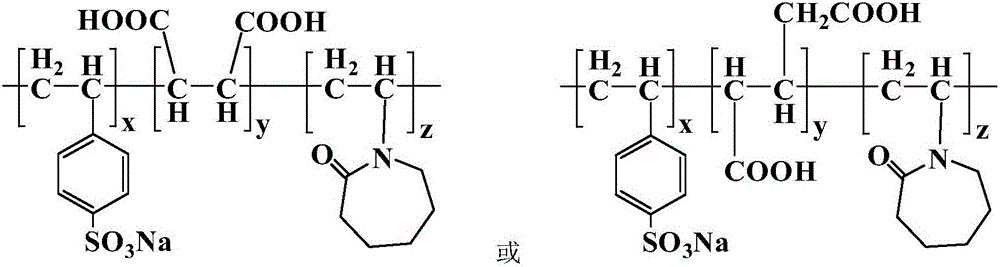

High-temperature-resistant oil-well cement retarder and preparation method thereof

InactiveCN106085389AIncrease success rateEasy to operateDrilling compositionViscous liquidPotassium persulfate

The invention discloses a high-temperature-resistant oil-well cement retarder and a preparation method thereof. The cement retarder comprises three structural units of sodium p-styrenesulfonate, maleic acid or itaconic acid, and N-vinylcaprolactam. The preparation method for the cement retarder comprises the following steps: (1) mixing odium p-styrenesulfonate, maleic acid or itaconic acid, and N-vinylcaprolactam according to the mass ratio of 10-17:2-7:1-3, dissolving in deionized water, controlling the total mass concentration of the monomers in the solution to be 10-20%, and adjusting the pH value of the solution to be 4-9; (2) introducing nitrogen into a reactor for removing oxygen, and adding an initiator potassium persulfate into the reaction system after the temperature of the reaction system raises to 55-70 DEG C; and (3) reacting 3-7 h, cooling the yellow slightly-viscous liquid product to room temperature, and performing purification, drying and crushing. The cement retarder possesses high-temperature resistance as well as high-temperature settlement stability, and the preparation method of the cement retarder has reliable principle, is convenient to operate, and possesses wide market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Thickener and super high-density cement paste based on thickener

ActiveCN103773341ADensity meetsImprove performanceDrilling compositionMicrofine cementMining engineering

The invention discloses a thickener and a super high-density cement paste based on the thickener. The thickener comprises the following components in parts by weight: 80-90 parts of iron ore powder, 5-10 parts of manganese mineral powder, 5-10 parts of G-grade superfine cement and 5-10 parts of silica fume. The super high-density cement paste provided by the invention is stable in performance, and low in water loss, has certain anti-gas channeling ability and ideal thickening transition time, and can form strong set cement. A high-pressure hydrocarbon reservoir can be effectively controlled, jump-out of an oil gas is avoided, and the cementing quality can be better improved.

Owner:四川川庆井下科技有限公司

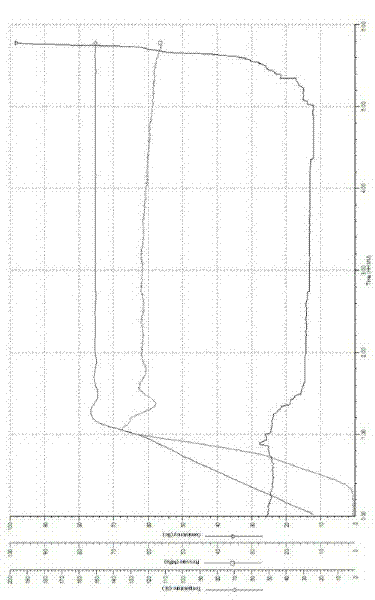

High-temperature-resistant cement paste system for ultradeep wells

InactiveCN107162512AFix unstable performanceReduce dehydrationDrilling compositionCement pasteCopolymer

The invention discloses a high-temperature-resistant cement paste system for ultradeep wells. The high-temperature-resistant cement paste system for ultradeep wells comprises the following components in parts by weight: 100 parts of cement, 6-18 parts of high-temperature water-loss control agent, 25-40 parts of silica sand, 6-15 parts of high-temperature retarder, 3-5 parts of high-temperature stabilizer and 0.4-2 parts of dispersant. The high-temperature water-loss control agent adopts a copolymer water-loss control agent of which the maximum temperature resistance is 180-230 DEG C; and the high-temperature retarder adopts a retarder of which the maximum temperature resistance is 180-230 DEG C. The high-temperature-resistant admixtures are added into the cement paste, thereby solving the problem of unstable properties of the cement paste at high temperature.

Owner:四川宏升石油技术开发有限责任公司

Modified resin, application of modified resin in plugging agent, high-temperature plugging agent and application of high-temperature plugging agent in plugging of high-temperature discarded well

PendingCN113637293AImprove liquiditySuitable epoxy valueDrilling compositionSealing/packingEpoxyPolymer science

The invention belongs to the technical field of petroleum drilling engineering chemical agents, and particularly relates to modified resin and application thereof, and a high-temperature plugging agent and application thereof. The modified resin comprises the following components in parts by mass: 95-105 parts of an epoxy resin mixture, 10-20 parts of a diluent, 5-15 parts of an emulsifier, 4-8 parts of a coupling agent and 1-3 parts of a defoaming agent, the epoxy resin mixture is composed of epoxy resin and water-borne epoxy resin, and the mass ratio of the solvent type epoxy resin to the water-borne epoxy resin is (1-3): (1-5). The high-temperature-resistant solid-free plugging agent prepared by taking the modified resin as a key component overcomes the problems that a pure resin system is easy to generate a flash coagulation phenomenon under an ultrahigh-temperature condition, the thickening time is shortened and the stability of a plugging system cannot be guaranteed.

Owner:CNOOC ENERGY TECH & SERVICES

Well cementation material suitable for low-temperature environment and production method of well cementation material

ActiveCN110105030AImprove liquidity impactReduce the rate of hydrationDrilling compositionPortland cementUltimate tensile strength

The invention provides a well cementation material suitable for a low-temperature environment and a production method of the well cementation material. The well cementation material is prepared by mainly mixing 75-89% of portland cement clinker, 1-8% of sulphoaluminate cement clinker, 1-8% of high-alumina cement clinker, 2-4% of dihydrate gypsum, 0.5-1.2% of a dispersing agent and 1-4% of a retarder by weight. The well cementation material has the advantages that selected raw materials of raw meal cooperate with one another, on the basis of meeting the early strength, the later strength is ensured, the hydration rate is also slowed down to a certain extent, the setting time is prolonged, time guarantee is provided for radial grouting, and the risk ratio of blockage caused by the generationof cement plugs during grouting is reduced.

Owner:葛洲坝石门特种水泥有限公司

Retarder for high-temperature-resistant cement paste system

InactiveCN107418534AExtend thickening timeReduced hydration rateDrilling compositionItaconic acidCement paste

The invention discloses a retarder for a high-temperature-resistant cement paste system. The retarder comprises the following components: monomers consisting of 2-acrylamido-2-methylpropanesulfonic acid, acrylamide, maleic acid and itaconic acid in a mass ratio of (18-24): (9-21): (6-12): (6-12); an initiator accounting for 6%-8% of the total mass of the monomers; and monomer borax accounting for 3%-5% of the total mass of the monomers. A polymer formed by the above components is a quadripolymer which solves the problem of rapid hydration of cement paste at a high temperature; and the quadripolymer synthesized by using a simple synthetic process has better retarding effect compared with the same mass of a terpolymer or bipolymer.

Owner:四川宏升石油技术开发有限责任公司

Cement compositions comprising biodegradable monomers for retarding the setting thereof

Cement compositions may comprise one or more secondary amines substituted with a carboxyl group or salts thereof (e.g., 3-hydroxy N,N′-iminodisuccinic acid) for retarding the setting of such compositions. The inclusion of such materials in cement compositions may be highly beneficial. In wellbores having BHCT's of less than or equal to about 250° F., the use of the secondary amine as the set retarder ensures that the thickening time of the cement composition is sufficient to allow the cement composition to be pumped to its desired downhole location. Further, the secondary amine may be used in combination with conventional set retarders to enhance the ability of those retarders to increase the thickening time of the cement composition at higher BHCT's, e.g., from about 250° F. to about 525° F.

Owner:HALLIBURTON ENERGY SERVICES INC

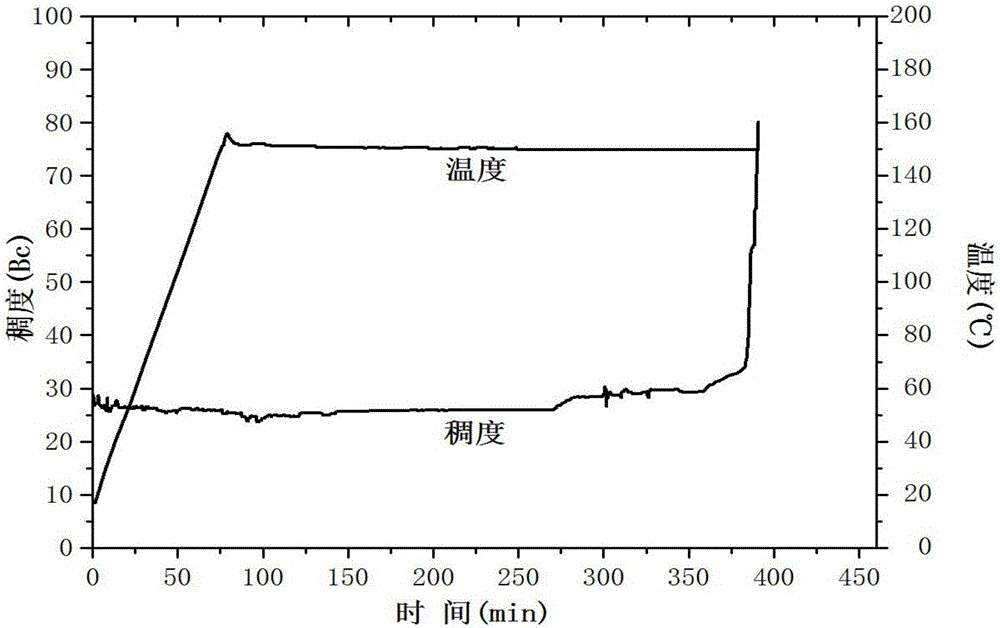

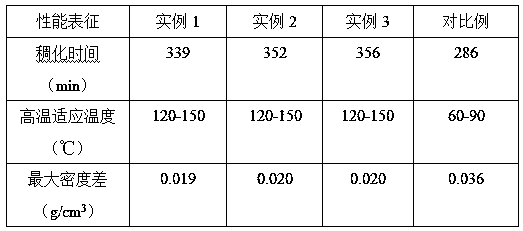

High-temperature oil well cement retarder capable of inhibiting abnormal gelling, and preparation method thereof

ActiveCN111662409ARaw materials are easy to getSimple preparation processDrilling compositionFunctional monomerMeth-

The invention discloses a high-temperature oil well cement retarder capable of inhibiting abnormal gelling, and a preparation method thereof. The preparation method comprises the steps: (1) dissolving2-acrylamide-2-methylpropanesulfonic acid and unsaturated carboxylic acid monomers in deionized water, stirring to uniformity, and adjusting the pH value to 5-6; (2) adding a sterically hindered functional monomer and a cationic functional monomer into a solution obtained in step (1), uniformly stirring, and heating to 55-65 DEG C; and (3) dissolving an initiator in deionized water to prepare a solution, adding the solution into a solution obtained in step (2) while stirring, carrying out heat preservation at 55-65 DEG C for 20-40 minutes, heating to 70-85 DEG C, and carrying out a constant-temperature reaction for 2-4 hours to obtain the high-temperature oil well cement retarder capable of inhibiting abnormal gelling. The retarder disclosed by the invention can inhibit the phenomena of bulging and core wrapping of cement paste in a temperature interval of 120-150 DEG C, does not influence the strength development of set cement, and is good in comprehensive performance of the cement paste.

Owner:TIANJIN UNIV

Wellbore servicing compositions and methods of using same

InactiveUS8685901B2Extend thickening timeSolid waste managementFlushingService compositionMaterials science

Owner:HALLIBURTON ENERGY SERVICES INC

Preparation method of high-temperature-resistant modified retarder

The invention relates to a preparation method of a high-temperature-resistant modified retarder, belonging to the technical field of sealing materials. According to the technical scheme, a silicon carbide whisker is utilized for modification, and a laminar matrix material is prepared through coating, so that on one hand, a polymer is endowed with the rigidity and thermal stability of an organic material, namely a laminar matrix substance, through the addition of the laminar matrix substance; on the other hand, the partial polymer is inserted among laminar inorganic material slice layers, the partial thermal decomposition effect is effectively shielded by the slice layer structures, and the micromolecule motion caused during the thermal decomposition is impeded, so that the polymer represents good heat stability. According to the retarder prepared by virtue of the scheme, polar groups are effectively released to the surface of cement particles to form an adsorption layer, and the adsorption layer is capable of preventing the contact between the cement and water so as to decrease the cement hydration speed and achieve a retarding effect, so that the heat stability of the material isimproved.

Owner:蒋留平

Deep continental scientific drilling high-temperature resistant cementing material

InactiveCN102838973AExtend thickening timeImprove rheologyDrilling compositionScientific drillingHigh pressure

The invention relates to a deep continental scientific drilling high-temperature resistant cementing material which is characterized in that a formula comprises the following raw materials in percentage by weight: 1 class G cement in basic unit as well as 50% of ganister sand, 5% of silica fume, 4% of compound retarder, 1% of borax, 40% of water, 4% of sulfonated tannin and 0.08% of n-octyl alcohol which are in 1 basic unit of the class G cement in percentage by weight. According to the deep continental scientific drilling high-temperature resistant cementing material, in order to enable the continental scientific drilling construction to be carried out smoothly and the cementing quality to meet the standard, appropriate initial consistency in high temperature and pressure is developed, favorable flowability, stability and thickening time and less water loss are achieved, and a cement calculus body with higher strength is provided, so that the performance requirement of the cementing material and the cement calculus body after condensation in high temperature and pressure is satisfied.

Owner:CHANGCHUN INST OF TECH

High-temperature high-pressure well cementation additive

InactiveCN109609108AReduce the density difference between upper and lowerHigh compressive strengthDrilling compositionPotassium hydroxideHigh pressure

The invention discloses a high-temperature high-pressure well cementation additive. The high-temperature high-pressure well cementation additive comprises a component A and a component B, the component A comprises, by weight, 20 parts of a water reducing agent, 5 parts of hydroxyethyl bisphosphonic acid, 1 part of zeolite powder and 30 parts of water, and the component B comprises, by weight, 5 parts of coconut shell powder, 0.5 part of sugarcane powder, 3 parts of sodium carboxymethylcellulose, 2 parts of zinc acrylate, 5 parts of polyvinylpyrrolidone and 200 parts of water. A method for preparing the coconut shell powder comprises the steps that a 4 M sulphuric acid aqueous solution 10 times of the total mass of smashed materials is added to the smashed materials, soaking is carried outfor 2 h, the smashed materials are placed in a vacuum drying box of 120 DEG C to be dried, and pre-treated coconut shell residues are obtained; ethyl alcohol, a titanate coupling agent and potassium hydroxide are added to the pre-treated coconut shell powder, the materials are mixed, recirculation is carried out for 6 h, the materials are placed in the vacuum drying box of 120 DEG C to be dried, smashing is carried out, and the coconut shell powder is obtained. According to the high-temperature high-pressure well cementation additive, by means of the joint action of the component A and the component B, the thickening time of the cement mud is effectively prolonged.

Owner:BEIJING DADE GUANGYUAN PETROLEUM TECH SERVICE

Low-temperature-resistant modified cement and preparation method thereof

The invention provides low-temperature-resistant modified cement and a preparation method thereof. The modified cement is prepared from the following raw materials in parts by weight: 150 to 300 parts of Portland cement, 30 to 80 parts of fly ash, 20 to 30 parts of diatomite, 10 to 40 parts of bentonite, 15 to 40 parts of gypsum powder, 20 to 50 parts of calcium fluoride mineral powder and 5 to 10 parts of an early strength agent. The raw materials adopted by the invention are low in cost, so that the cement has relatively long thickening time at low temperature, the construction requirement is met, and meanwhile, the cement strength at low temperature is high.

Owner:河北承大环保科技有限公司

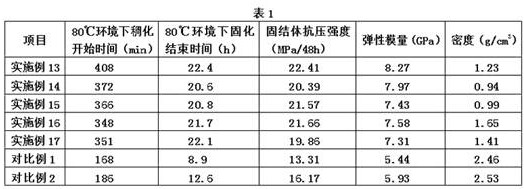

Retarding thermosetting resin gelling composition and preparation method thereof

InactiveCN112457829AHigh densityHigh compressive strengthDrilling compositionPolymer scienceFirming agent

The invention relates to the technical field of preparation of thermosetting resin for oil drilling, in particular to a retarding thermosetting resin gelling composition and a preparation method thereof, the retarding thermosetting resin gelling composition comprises metal oxide, phosphate, thermosetting resin, a resin curing agent, a fluid loss agent, a composite regulator and water, the composite regulator is formed by compounding an octadecyl acrylate-styrene-maleic anhydride copolymer, sodium alkyl benzene sulfonate and porous glass beads according to a weight ratio of 3: 2 to 5: 1. The preparation method comprises six steps. The retarding thermosetting resin gelling composition obtained by the invention has the effect of prolonging the thickening time, the initial setting time under the environment of about 80 DEG C is 4-6 hours after mixing, the overall setting can be completed within 24 hours, the density of the composition is 0.8-1.8 g / cm<3>, the compressive strength of a solidified body can reach 22.4 MPa / 48 hours, and the elastic modulus can reach 8.27 GPa.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Phosphorous slag aerated concrete and preparation method thereof

ActiveCN101708981BEmission reductionLow costSolid waste managementClinker productionSlagThermal insulation

The invention discloses a phosphorous slag aerated concrete. The concrete is characterized by consisting of a binding material, an exciting agent, an air entraining agent and water which are mixed, wherein the binding material consists of 60 to 100 weight percent of phosphorous slag and 0 to 40 weight percent of pulverized fuel ash; the exciting agent is water glass with modulus of 1.0 to 1.6; the water glass accounts for 5 to 8 weight percent of the binding material based on the weight of Na2O; the air entraining agent is aluminum powder or simple substance silicon; the using amount of the aluminum powder is 0.1 to 0.2 weight percent of the binding material; the using amount of the simple substance silicon is 0.05 to 0.1 weight percent of the binding material; and the weight ratio of theusing amount of the water to the using amount of the binding material is 0.28 to 0.32. The phosphorous slag aerated concrete product is prepared by taking the industrial waste slag such as the phosphorous slag and the like as the binding material and mixing the phosphorous slag, the exciting agent, the air entraining agent and the water. The phosphorous slag aerated concrete has the advantages that: the preparation process is simple without vapor-pressure process, so that the equipment investment can be greatly reduced; and the product is a sealed porous structure and has the characteristics of light weight, high strength, low thermal conductivity, good thermal insulation property and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A kind of densifier and ultra-high density cement slurry based on the densifier

ActiveCN103773341BImprove void fill rateDensity meetsDrilling compositionMicrofine cementHigh density

The invention discloses a densifier and an ultra-high-density cement slurry based on the densifier. The weight composition of the densifier is: 80-90 parts of iron ore powder, 5-10 parts of manganese ore powder, and 5 parts of G-grade superfine cement. -10 parts, microsilica fume 5-10 parts. The ultra-high-density cement slurry provided by the invention has stable performance, low water loss, certain anti-air channeling ability, relatively ideal thickening transition time and can form cement stone with strong strength. It can effectively control high-pressure oil and gas layers, avoid oil and gas escape, and better improve the quality of cementing.

Owner:四川川庆井下科技有限公司

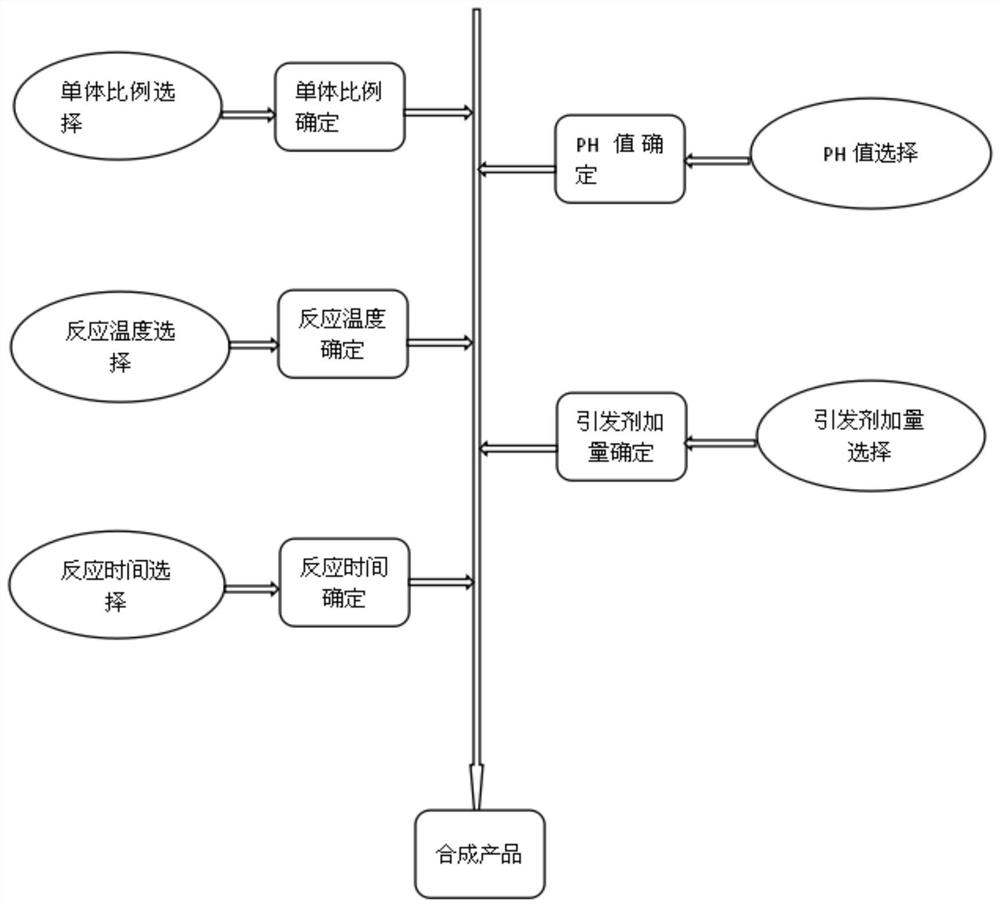

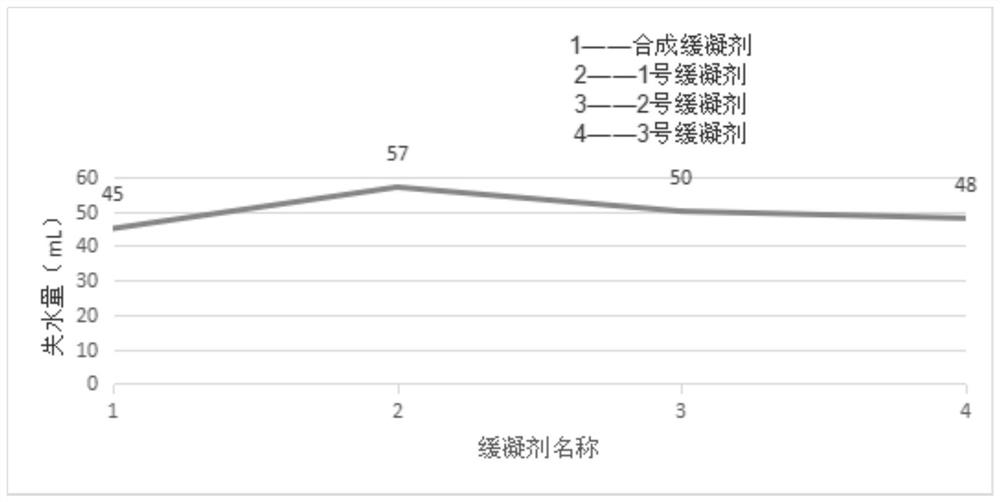

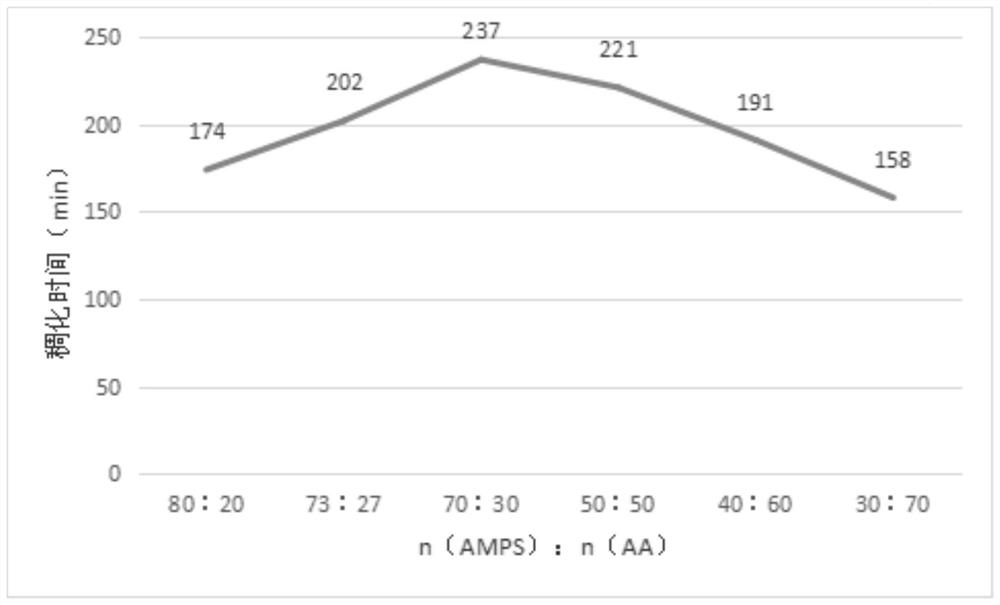

Retarder with water loss reduction function and preparation method thereof

PendingCN112250791ASame thickening timeReduce the temperatureDrilling compositionReaction temperatureSodium hydrogen sulphite

The invention discloses a retarder with a water loss reduction function, which comprises AMPS (2-acrylamido-2-methylpropanesulfonic acid), AA (acrylic acid) and an initiator, wherein the monomer molarratio of AMPS to AA is (30-80): (20-70), wherein the initiator is a redox initiator, the initiator is a redox body of ammonium persulfate-sodium hydrogen sulfite, and the addition amount of the redoxbody is 0.5%-2.5% of the mass of the monomer. In addition, the invention further discloses a preparation method of the retarder with the water loss reduction function. According to the present invention, by researching the monomer ratio, the reaction pH value, the reaction temperature, the initiator addition amount and the reaction time, various parameters during the retarder preparation are precisely controlled, such that the prepared retarder can provide the thickening time prolonging effect on the cement slurry while the water loss of the cement slurry is not affected.

Owner:中石化石油工程技术服务有限公司 +1

Underground high-pressure hydraulic fracturing hole sealing material for coal mine and hole sealing technology

ActiveCN102977869BGuaranteed inflowDepth of protectionDrilling compositionSealing/packingYarnAdhesive

The invention provides an underground high-pressure hydraulic fracturing hole sealing material for a coal mine and a hole sealing technology. The hole sealing material comprises the following components by weight: 100 parts of cement, 2 to 4 parts of Ms type early-strength slushing agent, 0.08 to 0.5 parts of polypropylene fiber, and 60 parts of water. The hole sealing technology comprises the following steps in sequence: drilling a hole on a coal-rock mass; constructing until reaching the a top plate at a coal seam; expanding the hole to a bottom plate at the coal seam; feeding a grouting pipe to the bottom plate at the coal seam; arranging a grout returning pipe to the front end of a blocking section of a hole port; blocking the hole port section through AB adhesive and cotton yarn; feeding the hole sealing material into the hole through the grouting pipe; closing a check valve of the grout returning pipe after returning the grout through the grout returning pipe; continuously grouting; completely draining the grout in the grouting pipe once water flows form a fracturing hole; grouting at the second time after the grout is condensed; and finally solidifying. The underground high-pressure hydraulic fracturing hole sealing material for the coal mine has the advantages of being less in contraction, and high in compressive strength and impact toughness; the hole sealing material is high in sealing performance and resistance to high pressure under the effect of high-pressure hydraulic fracturing impact load; simultaneously, the hole sealing material is low in cost and the construction is convenient; and the hole sealing technology is simple, the hole sealing depth meets the requirement, and the success rate is high.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com