Preparation and application methods of high temperature resistant cement retarder

A high-temperature-resistant cement and retarder technology, applied in the field of cement additives, can solve the problems of negative impact on the safety of cementing operations, etc., and achieve the effects of wide application temperature range, good salt water resistance, and no volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 2-acrylamido-2-methylpropanesulfonic acid, 25% itaconic acid and 15% maleic acid that account for 60% of the total mass of the monomer in water that is 3 times the total mass of the monomer. Introduce nitrogen to remove oxygen for 20 minutes, add initiator ammonium persulfate accounting for 2% of the total mass of the monomer, react at 80°C for 3 hours, and then cool to room temperature to obtain the high temperature resistant cement retarder.

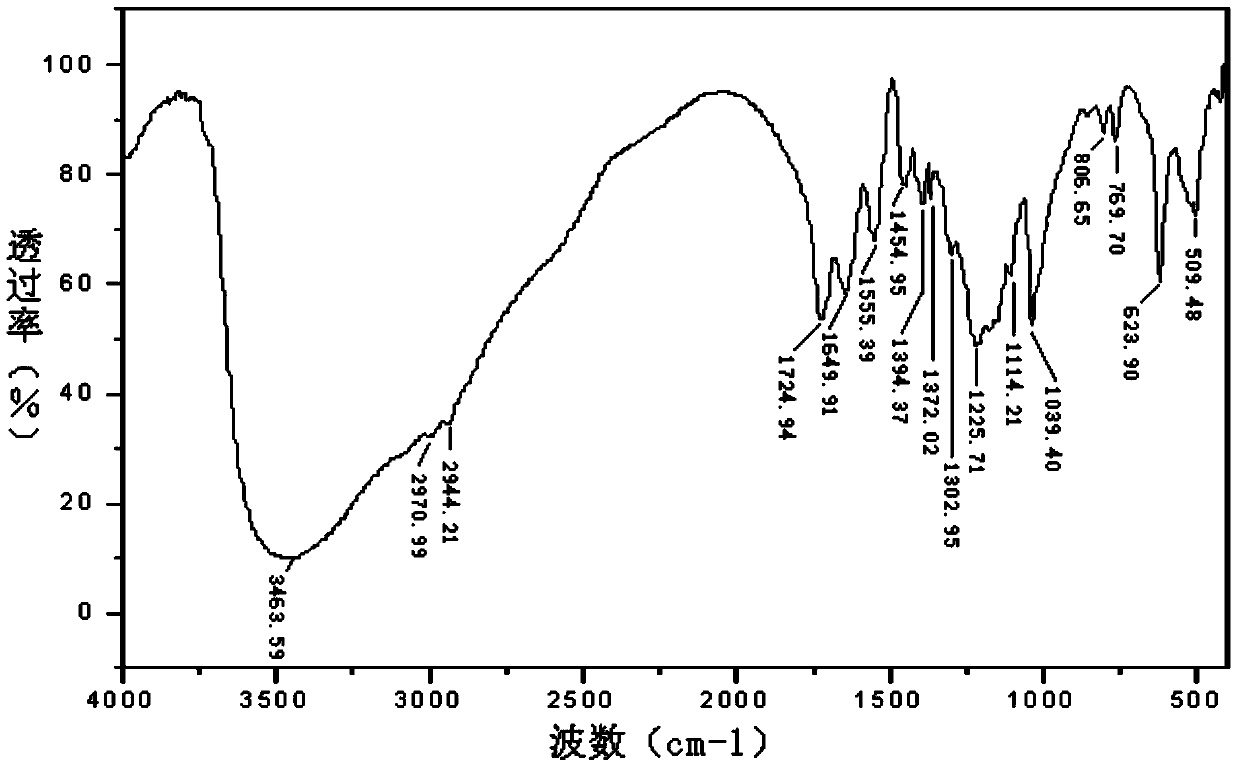

[0025] The infrared spectrum of the high temperature resistant cement retarder is as follows figure 1 As shown, of which 3463.59cm -1 It is the stretching vibration absorption peak of N-H in 2-acrylic acid amido-2-methylpropanesulfonic acid; 2970.99cm -1 、2944.21cm -1 is the stretching vibration absorption peak of carboxylic acid C-H; 1724.94cm -1 It is the stretching vibration absorption peak of carboxylic acid C=O; 1649.91cm -1 It is the stretching vibration absorption peak of C=O in the amide group; 1555.39cm -1...

Embodiment 2

[0033] Dissolve 2-acrylamido-2-methylpropanesulfonic acid, 30% itaconic acid and 20% maleic acid that account for 50% of the total mass of the monomer in water that is 4 times the total mass of the monomer. Nitrogen was added to deoxygenate for 30 minutes, an initiator ammonium persulfate accounting for 3% of the total mass of the monomer was added, reacted at 80°C for 4 hours, and then cooled to room temperature to obtain the high temperature resistant cement retarder.

[0034] Then use NaOH aqueous solution to adjust the pH of the above-mentioned high temperature resistant cement retarder to 6, and its storage time can exceed two years.

Embodiment 3

[0036] 2-acrylamido-2-methylpropanesulfonic acid, 40% itaconic acid and 20% maleic acid that account for 40% of the total mass of the monomers are dissolved in water that is 3 times the total mass of the monomers. Nitrogen was added to deoxygenate for 20 minutes, an initiator ammonium persulfate accounting for 2% of the total mass of the monomer was added, reacted at 80°C for 3 hours, and then cooled to room temperature to obtain the high temperature resistant cement retarder.

[0037] Then use sodium carbonate aqueous solution to adjust the pH=6.8 of the above-mentioned high temperature resistant cement retarder, and its storage time can exceed two years.

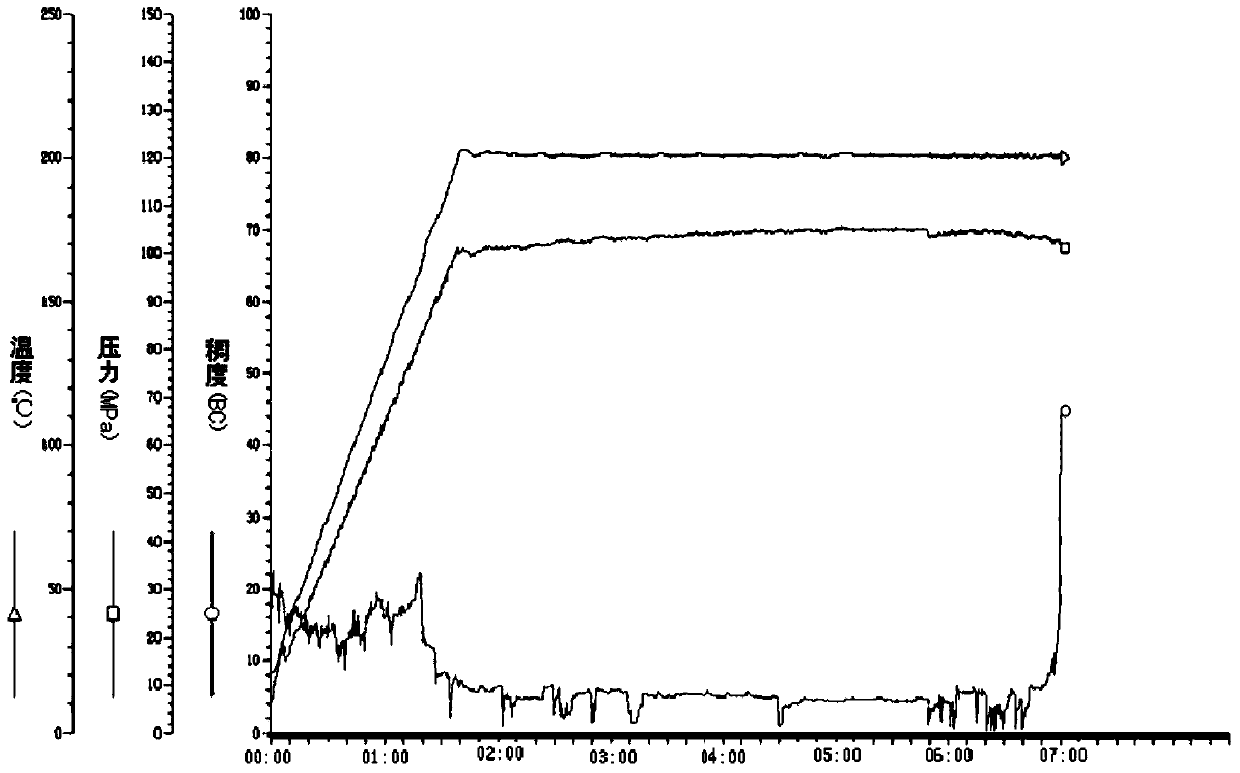

[0038] The properties of the high-temperature-resistant cement retarder obtained in Examples 2 and 3 are the same as those obtained in Example 1. It can be used in the temperature range of 100 to 230 ° C, the addition amount is not sensitive, the thickening transition time is short, and it is similar to Other oil well ceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com