Cement-dispersing retarder for high-temperature-resistant oil well and preparation method of retarder

A technology of oil well cement and high temperature resistance, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of inability to seal oil, gas and water layer protection casing, affect cementing quality and construction safety, thickening transition time Long and other problems, to achieve the effects of short thickening transition time, simple and easy synthesis process, and extended thickening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

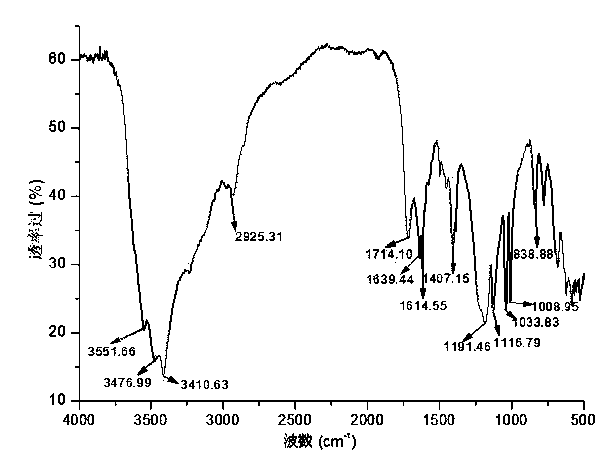

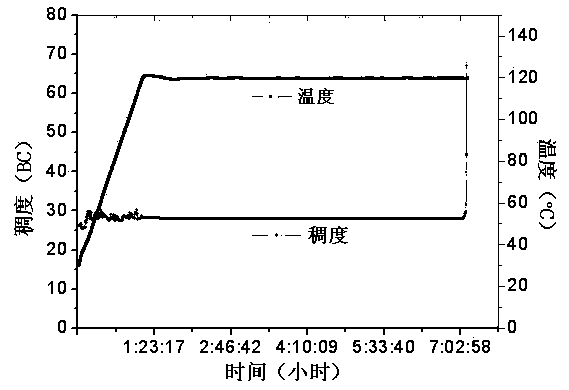

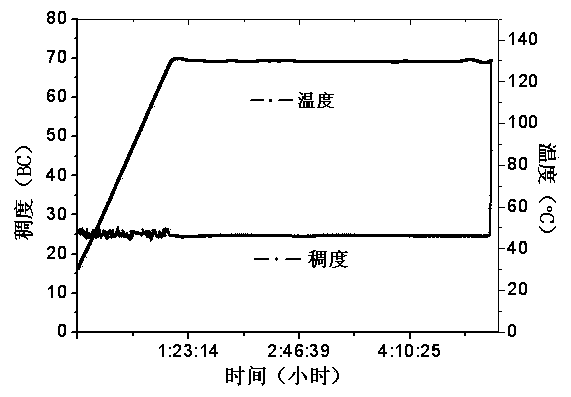

Method used

Image

Examples

Embodiment 1

[0031] First weigh 11.3g of sodium styrene sulfonate and dissolve it in 50ml of deionized water; then weigh 0.94g of 2-hydroxyethyl methacrylate and 3.76g of itaconic acid and dissolve it in 50ml of deionized water, adjust the pH with a certain concentration of NaOH solution Value to neutral for use; finally weigh 0.32g of potassium persulfate and dissolve in 20ml of deionized water for use.

[0032] Raise the temperature of the constant temperature water bath to 60°C, adjust the rotation speed of the stirring rod to about 200r / min, transfer the sodium styrene sulfonate solution into the three-necked bottle, and then add the mixed solution of 2-hydroxyethyl methacrylate and itaconic acid, Potassium persulfate solution is moved into the constant pressure separatory funnel respectively, feeds nitrogen into the container to remove oxygen, after 10min, start to drip reaction monomer and initiator solution in the reaction container and control its rate of addition at 1 drop / second, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com