High-temperature low-density cement and applications thereof

A low-density cement and high-temperature strength technology, applied in the field of building materials, can solve the problems of lower production efficiency and recovery rate, ineffective isolation of formations, and cement stone strength decline, so as to increase crude oil production and ensure that the strength does not decline performance, good rheological effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The high-temperature low-density cement of the present invention consists of 30%-70% of cement base materials, 14%-40% of lightening materials, 14%-30% of high-temperature strength stabilizers, and 0.02%-0.10% of high-temperature retarders.

[0013] Among them, the high-temperature retarder is sodium salt of organic acid, specifically sodium polyhydroxycaproate; the high-temperature stabilizer material is one or a combination of micro-silicon and silicon fume; the lightening material is fly ash, micro-beads , diatomite, bentonite or a combination of several; the cement base material is a silicate cementitious material.

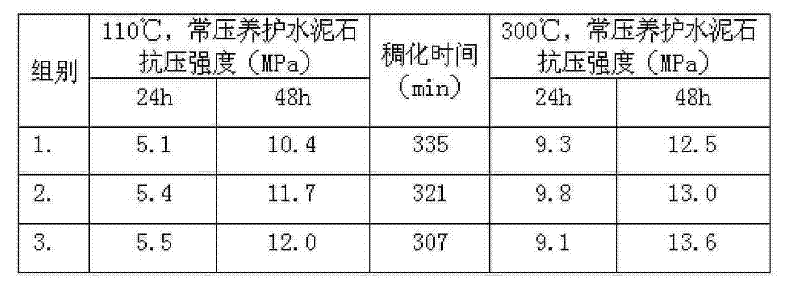

[0014] The beneficial effect of the cement of the present invention is demonstrated below by component screening data.

[0015] The mixed cement was made into a slurry, and the compressive strength of the cement stone at 110°C and normal pressure for 24h and 48h was investigated respectively; the thickening time at 110°C, 80Mpa, and 50min heating condit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com