Retarder with water loss reduction function and preparation method thereof

A technology for reducing water loss and setting retarder, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve single problems, and achieve the effects of simple production process, low dosage sensitivity and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

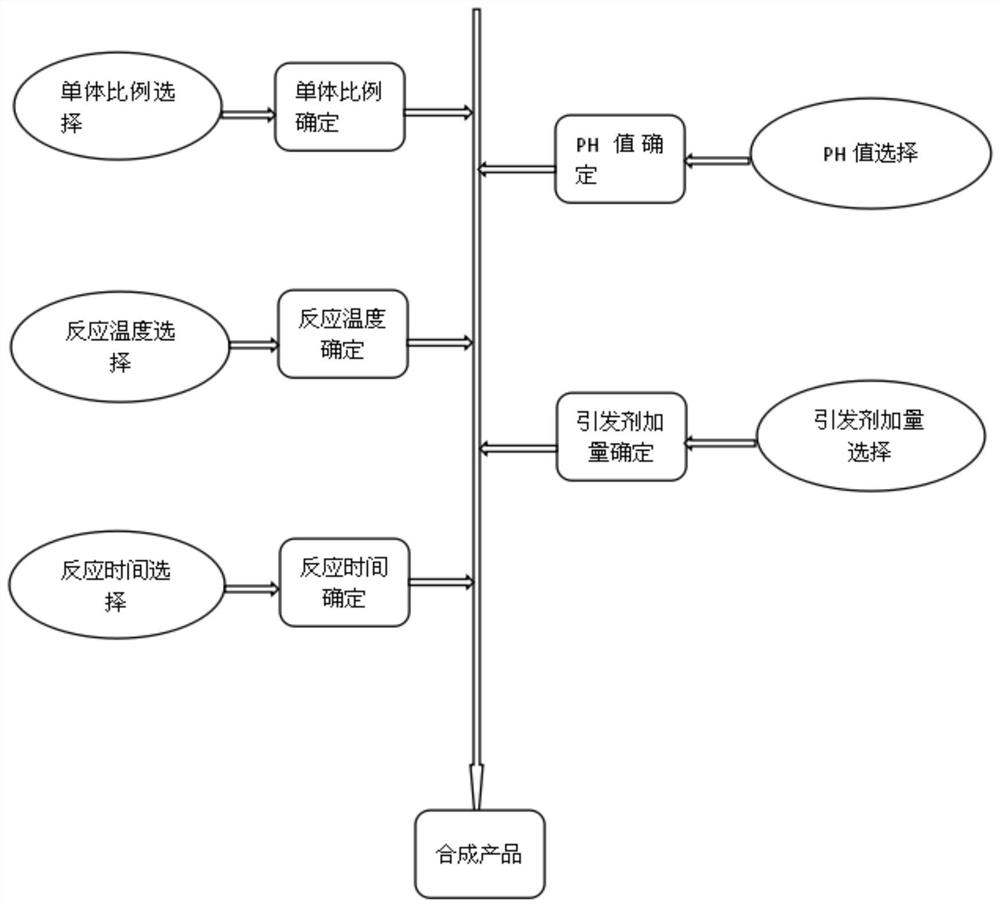

Method used

Image

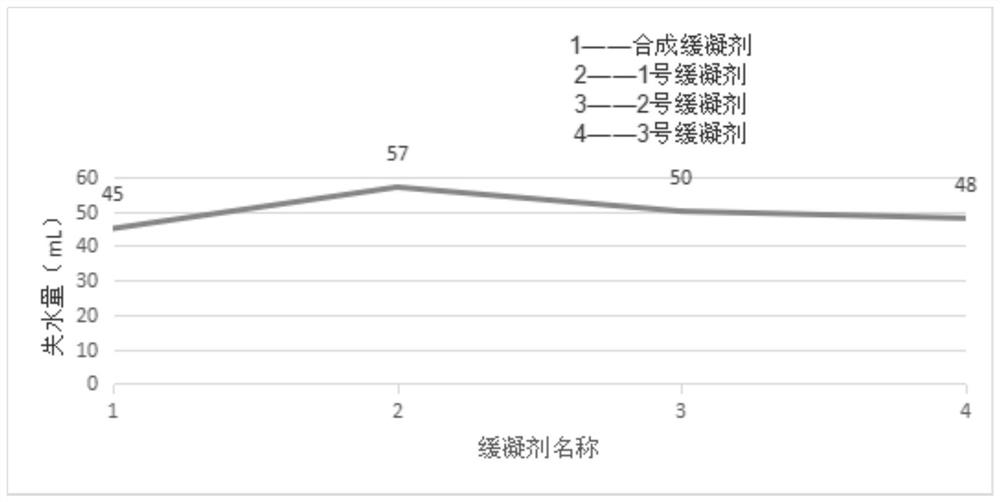

Examples

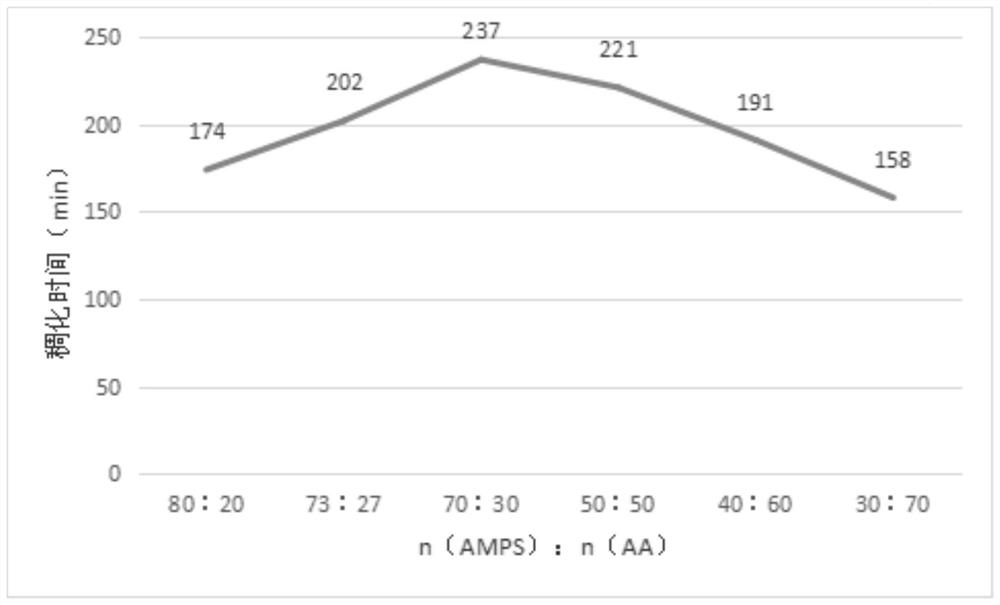

Embodiment 1

[0033] This embodiment discloses a retarder with the function of reducing water loss, including AMPS, AA and initiator, wherein the monomer molar ratio of AMPS to AA is (30-80):(20-70); It is a redox type initiator, and the initiator is a redox body of ammonium persulfate-sodium bisulfite, and its dosage is 0.5%-2.5% of the monomer mass.

[0034] In this example, the monomer molar ratio of AMPS to AA is 70:30; the amount of initiator added is 1% of the monomer mass.

Embodiment 2

[0036] This example is basically similar to Example 1, except that the monomer molar ratio of AMPS to AA is 80:20; the amount of initiator added is 0.5% of the monomer mass.

Embodiment 3

[0038] This example is basically similar to Example 1, except that the monomer molar ratio of AMPS to AA is 73:27; the amount of initiator added is 1.5% of the monomer mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com