Sulfate-corrosion-resistant waterproof mortar and preparation method thereof

A waterproof mortar and sulfate-resistant technology, which is applied in the field of energy-saving and environmentally friendly concrete materials, can solve the problems of not having anti-corrosion properties, no anti-corrosion mortar, self-repairing and impermeability properties combined, and achieve significant economic and environmental benefits , improve the structure and appearance, and increase the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

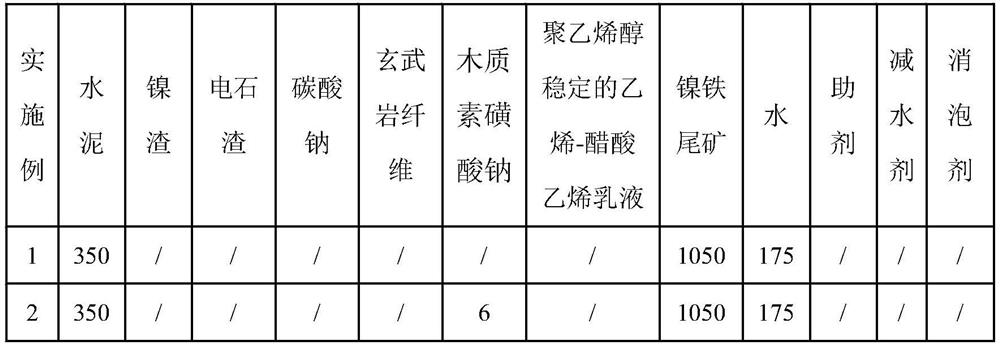

[0032] Embodiment 1: A kind of sulfate-resistant waterproof mortar of the present invention and preparation method, each component is calculated in parts by weight, 350 parts of Portland cement and 175 parts of water are weighed and placed in a mortar stirring pot for mixing and stirring for 40s, Then slowly add 1050 parts of nickel-iron tailings, mix and stir evenly to obtain the control mortar.

Embodiment 2

[0033] Embodiment 2: A kind of sulfate-resistant waterproof mortar and preparation method of the present invention, each component is calculated in parts by weight, weigh 350 parts of Portland cement, 175 parts of water, and 6 parts of sodium lignosulfonate and place them in the mortar. Mix and stir in the mortar stirring pot for 40s, then slowly add 1050 parts of nickel-iron tailings, mix and stir evenly to obtain the control group mortar.

Embodiment 3

[0034]Embodiment 3: A kind of sulfate-resistant waterproof mortar of the present invention and preparation method, each component is calculated by weight, weigh 350 parts of Portland cement, 175 parts of water, polyvinyl alcohol-stabilized ethylene-vinyl acetate 45 parts of the emulsion was placed in a mortar stirring pot and mixed for 40s, then 1050 parts of nickel-iron tailings were slowly added, and the mortar of the control group was obtained by mixing and stirring evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com