Concrete admixture for roads

A concrete admixture and admixture technology, applied in the field of concrete, can solve problems affecting the quality and process of highway engineering, single admixture performance, improper use of admixtures, etc., to reduce wear rate, improve compatibility, and improve flow performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

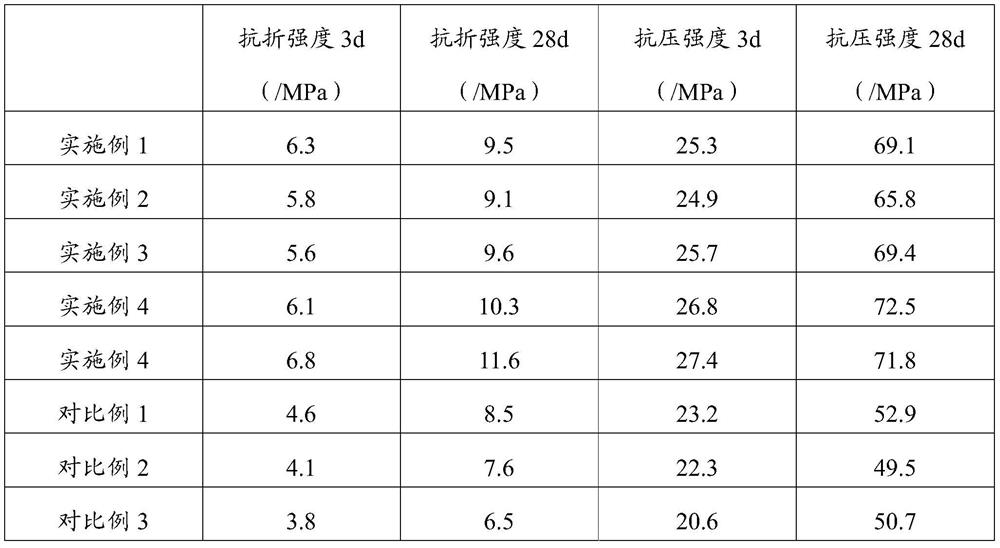

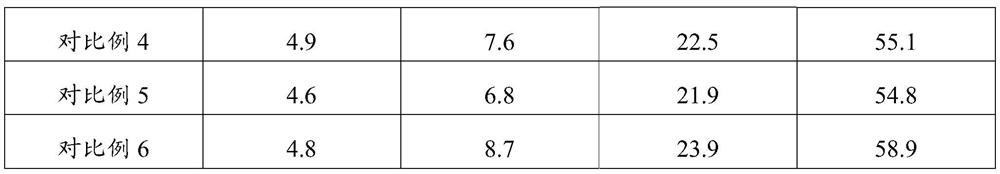

Examples

Embodiment 1

[0026] A concrete admixture for roads, characterized in that the admixture includes the following materials in parts by weight: 5 parts of triethanolamine, 8 parts of ethylene glycol, 2 parts of silicone defoamer, 15 parts of silicone anti-seepage and water repellent 15 parts, 15 parts of anti-wear agent, 3 parts of sodium nitrate, 1 part of polyolamine, 12 parts of isooctyl phosphate, 13 parts of emulsifier, 10 parts of triethylene glycol.

[0027] The antiwear agent is vulcanized rapeseed oil.

[0028] The preparation method of described organosilicon defoamer comprises the following steps:

[0029] 1) Reflux reaction of silicone oil and hydrophobic silica at 150-160°C for 1-2h to obtain white viscous silicone paste;

[0030] 2) Mix the silicone paste obtained in step 1) with graphene oxide modified silicone oil, silicon dioxide, allyl glycidyl ether and fatty acid, and then stir at 1000-2000r / min for 20-40min to obtain a prefabricated paste;

[0031] 3) Put the prefabrica...

Embodiment 2

[0036] A concrete admixture for roads, characterized in that the admixture includes the following materials in parts by weight: 15 parts of triethanolamine, 16 parts of ethylene glycol, 9 parts of silicone defoamer, 35 parts of silicone anti-seepage and water repellent 25 parts, 25 parts of antiwear agent, 3-19 parts of sodium nitrate, 10 parts of polymeric alcohol amine, 18 parts of isooctanyl phosphate, 15 parts of emulsifier, and 25 parts of triethylene glycol.

[0037] The antiwear agent is vulcanized lard.

[0038] The emulsifier includes sodium ligninate, nonionic surfactant and water.

[0039] The preparation method of described organosilicon defoamer comprises the following steps:

[0040] 1) Reflux reaction of silicone oil and hydrophobic silica at 150-160°C for 1-2h to obtain white viscous silicone paste;

[0041] 2) Mix the silicone paste obtained in step 1) with graphene oxide modified silicone oil, silicon dioxide, allyl glycidyl ether and fatty acid, and then s...

Embodiment 3

[0047] A concrete admixture for roads, characterized in that the admixture includes the following materials in parts by weight: 14 parts of triethanolamine, 15 parts of ethylene glycol, 8 parts of silicone defoamer, 30 parts of silicone anti-seepage and waterproofing agent 23 parts, 23 parts of antiwear agent, 10 parts of sodium nitrate, 7 parts of polyolamine, 17 parts of isooctyl phosphate, 14 parts of emulsifier, 20 parts of triethylene glycol.

[0048] The antiwear agent is vulcanized rapeseed oil.

[0049] The preparation method of described organosilicon defoamer comprises the following steps:

[0050] 1) Reflux reaction of silicone oil and hydrophobic silica at 150-160°C for 1-2h to obtain white viscous silicone paste;

[0051] 2) Mix the silicone paste obtained in step 1) with graphene oxide modified silicone oil, silicon dioxide, allyl glycidyl ether and fatty acid, and then stir at 1000-2000r / min for 20-40min to obtain a prefabricated paste;

[0052] 3) Put the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com