Quick repairing material for magnesium phosphate cement and preparation method thereof

A magnesium phosphate cement and repair material technology, applied in the field of cement-based quick repair materials, can solve the problems of short time from mixing magnesium phosphate cement to final setting, difficulty in meeting construction operation and process requirements, and achieve excellent retarding effect and development The effect of small inhibitory effect and prolonged retardation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

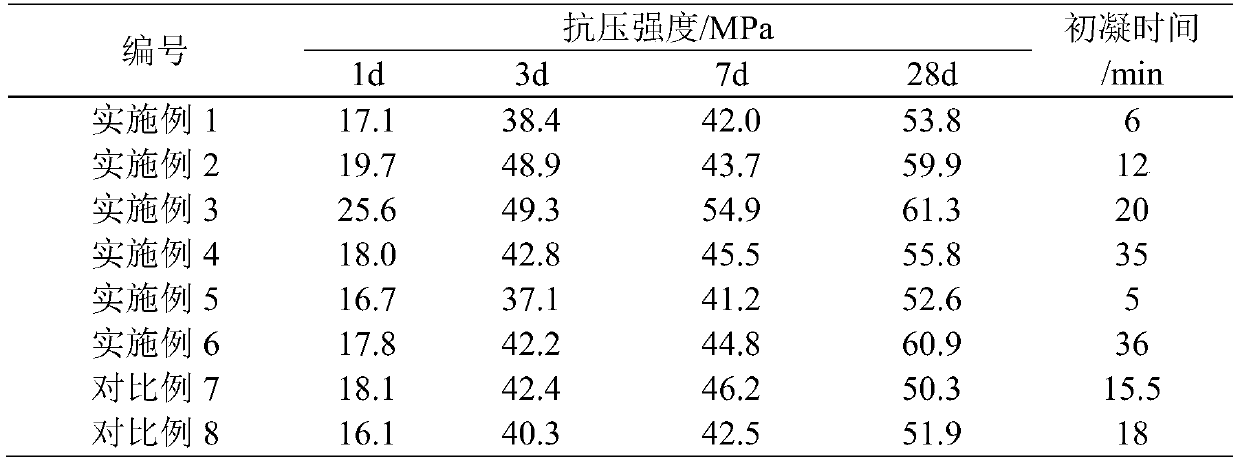

Examples

Embodiment 1

[0027] A novel quick repair material, by parts by weight, comprises the following components:

[0028] 25 parts of magnesium oxide, 17 parts of potassium dihydrogen phosphate, 0.63 parts of ethylenediaminetetraacetic acid dipotassium salt dihydrate, and 6.3 parts of water.

[0029] Preparation:

[0030] (1) Take magnesium oxide and potassium dihydrogen phosphate, and use a cement slurry mixer to stir at a slow speed for 1min to stir and mix it evenly to obtain a uniform powder;

[0031] (2) Dissolve ethylenediaminetetraacetic acid dipotassium salt dihydrate in water, and slowly add it to the above mixture, stir slowly for 1min, then stir rapidly for 2min and put it into a 40mm×40mm×40mm mold, to be tested After the block is hardened, it can be removed from the mold to obtain a new type of rapid repair material.

Embodiment 2

[0033] A novel quick repair material, by parts by weight, comprises the following components:

[0034] 25 parts of magnesium oxide, 17 parts of potassium dihydrogen phosphate, 0.84 parts of ethylenediaminetetraacetic acid dipotassium salt dihydrate, and 6.3 parts of water.

[0035] Preparation:

[0036] (1) Take magnesium oxide and potassium dihydrogen phosphate, and use a cement slurry mixer to stir at a slow speed for 1min to stir and mix it evenly to obtain a uniform powder;

[0037] (2) Dissolve ethylenediaminetetraacetic acid dipotassium salt dihydrate in water, and slowly add it to the above mixture, stir slowly for 1min, then stir rapidly for 2min and put it into a 40mm×40mm×40mm mold, to be tested After the block is hardened, it can be removed from the mold to obtain a new type of rapid repair material.

Embodiment 3

[0039] A novel quick repair material, by parts by weight, comprises the following components:

[0040] 25 parts of magnesium oxide, 17 parts of potassium dihydrogen phosphate, 1.05 parts of ethylenediaminetetraacetic acid dipotassium salt dihydrate, 6.3 parts of water.

[0041] Preparation:

[0042] (1) Take magnesium oxide and potassium dihydrogen phosphate, and use a cement slurry mixer to stir at a slow speed for 1min to stir and mix it evenly to obtain a uniform powder;

[0043] (2) Dissolve ethylenediaminetetraacetic acid dipotassium salt dihydrate in water, and slowly add it to the above mixture, stir slowly for 1min, then stir rapidly for 2min and put it into a 40mm×40mm×40mm mold, to be tested After the block is hardened, it can be removed from the mold to obtain a new type of rapid repair material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com