Cement retarder and method for direct preparation of same by using semi-hydrated phosphogypsum

A technology of cement retarder and hemihydrate gypsum, which is applied in the field of cement additive preparation, can solve the problems of inconvenient application, storage and transportation, inconvenient production operation, and increased energy consumption, so as to increase economic and environmental benefits, simplify production process, The effect of stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

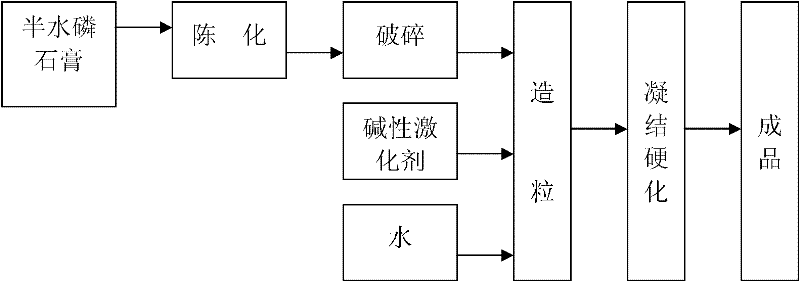

Method used

Image

Examples

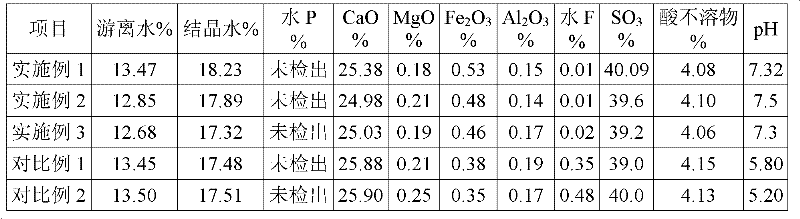

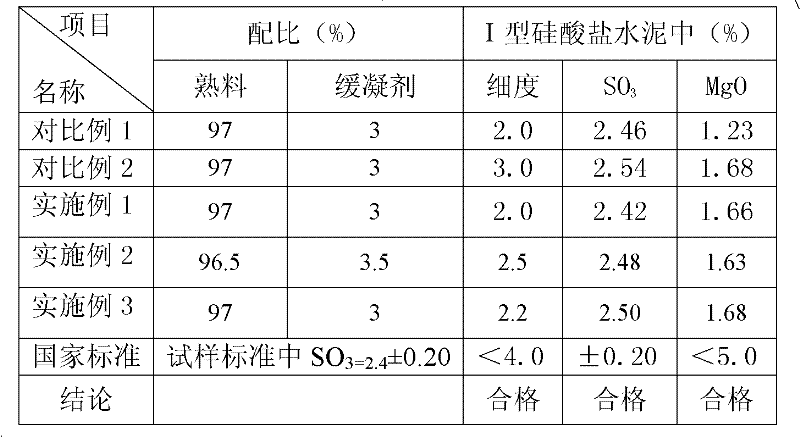

Embodiment 1

[0020] Use 90kg of by-product hemihydrate gypsum in the production of wet-process phosphoric acid as raw material for aging. After the hemihydrate gypsum is converted into dihydrate gypsum and the conversion rate reaches 50%, it is crushed and dispersed, and the dispersed gypsum is packed into The storage hopper, together with 2.5kg of quicklime and 18kg of water, are input into the granulator at the same time for mixing and granulation. The semi-finished product after granulation is transported to the warehouse through the belt, and naturally cured and air-dried to obtain the cement retarder product.

Embodiment 2

[0022] Use 80kg of by-product hemihydrate gypsum in the production of wet-process phosphoric acid as raw material for aging. After the hemihydrate gypsum is converted into dihydrate gypsum and the conversion rate reaches 80%, it is crushed and dispersed, and the dispersed gypsum is packed into The storage hopper, together with 2.0kg of quicklime and 15kg of water, are input into the granulator at the same time for mixing and granulation. The semi-finished product after granulation is transported to the warehouse through the belt, and naturally cured and air-dried to obtain the cement retarder product.

Embodiment 3

[0024] Use 85kg of by-product hemihydrate gypsum in the production of wet-process phosphoric acid as raw material for aging. After the hemihydrate gypsum is converted into dihydrate gypsum and the conversion rate reaches 70%, it is crushed and dispersed, and the dispersed gypsum is packed into The storage hopper, together with 2.3kg of quicklime and 16kg of water, is input into the granulator at the same time for mixing and granulation. The semi-finished product after granulation is transported to the warehouse through the belt, and naturally cured and air-dried to obtain the cement retarder product.

[0025] After the above-mentioned examples 1-3 are granulated, the product has a certain strength after leaving the granulator, and the compressive strength of the product is 3-5 MPa after 5 minutes, and its breakage rate is less than 10% when it falls freely from a 1-meter-high test platform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com