Method for preparing food browning inhibitor from cedar pine needles

A technology of inhibitors and pine needles, applied in the functions of food ingredients, food preparation, food extraction, etc., can solve the problems of affecting product quality and product quality decline, and achieve the effects of good inhibitory effect, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Crush 100 g of dried cedar pine needles with an average particle size of 300 μm, add 1000 mL of n-hexane according to the ratio of solid to liquid 1 g: 10 mL, shake at room temperature for 12 hours, and filter and separate the n-hexane extract;

[0036] (2) Add 1000mL of methanol with a concentration of 50wt% to the above-mentioned defatted pine needles according to the ratio of material to liquid 1g: 10mL as an extractant, shake at room temperature for 24 hours, separate the supernatant, and concentrate and dry the supernatant to obtain methanol extract 15g, the yield is 15%;

[0037] (3) Suspend the above-mentioned methanol extract in 20mL of methanol with a concentration of 50wt%, put it on a macroporous adsorption resin Diaion HP-20 chromatographic column (weight is 500g), and elute with methanol-water gradient, the concentration is 0wt%, 15wt% %, 30wt%, 40wt%, 60wt%, 100wt% methanol, the elution flow rate is 3mL / min;

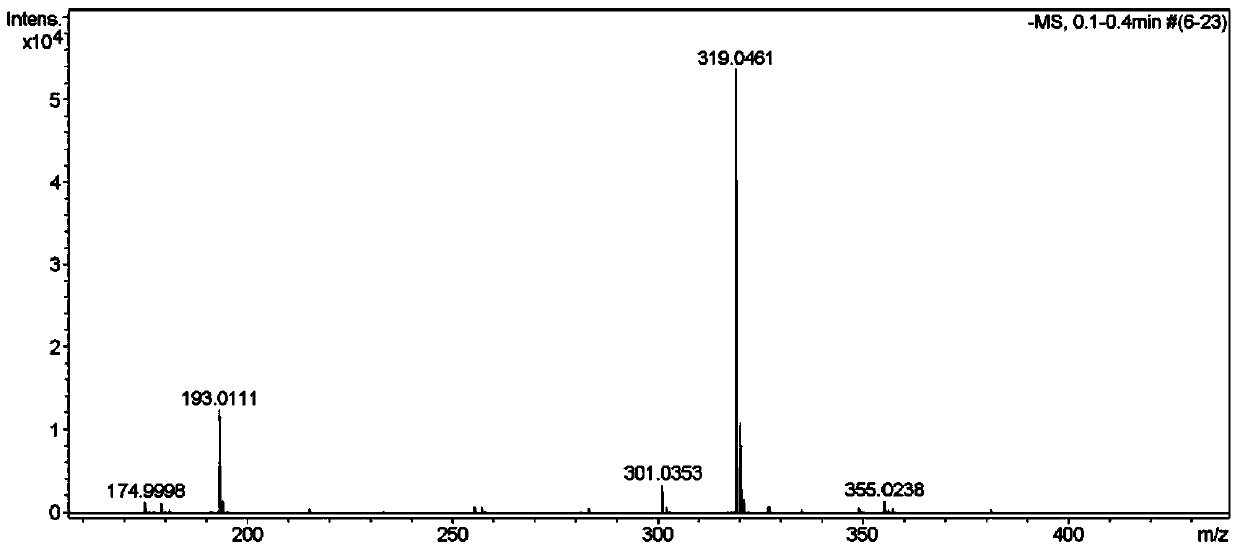

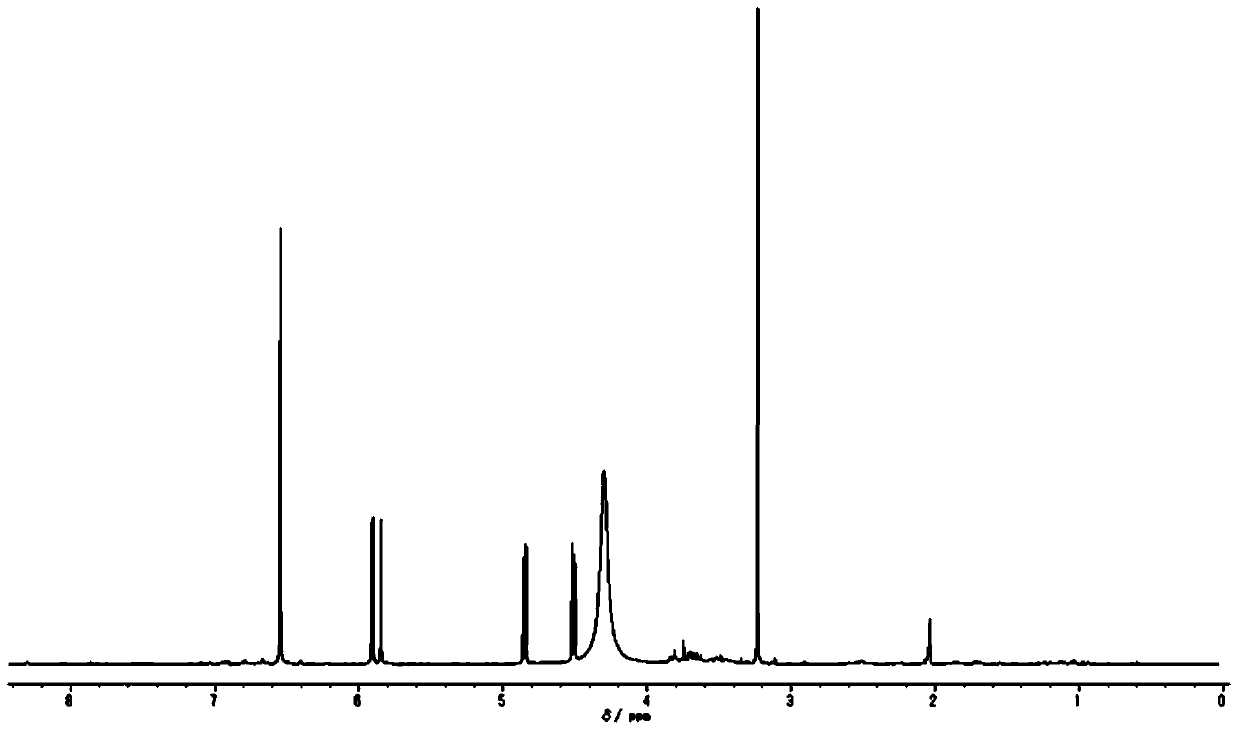

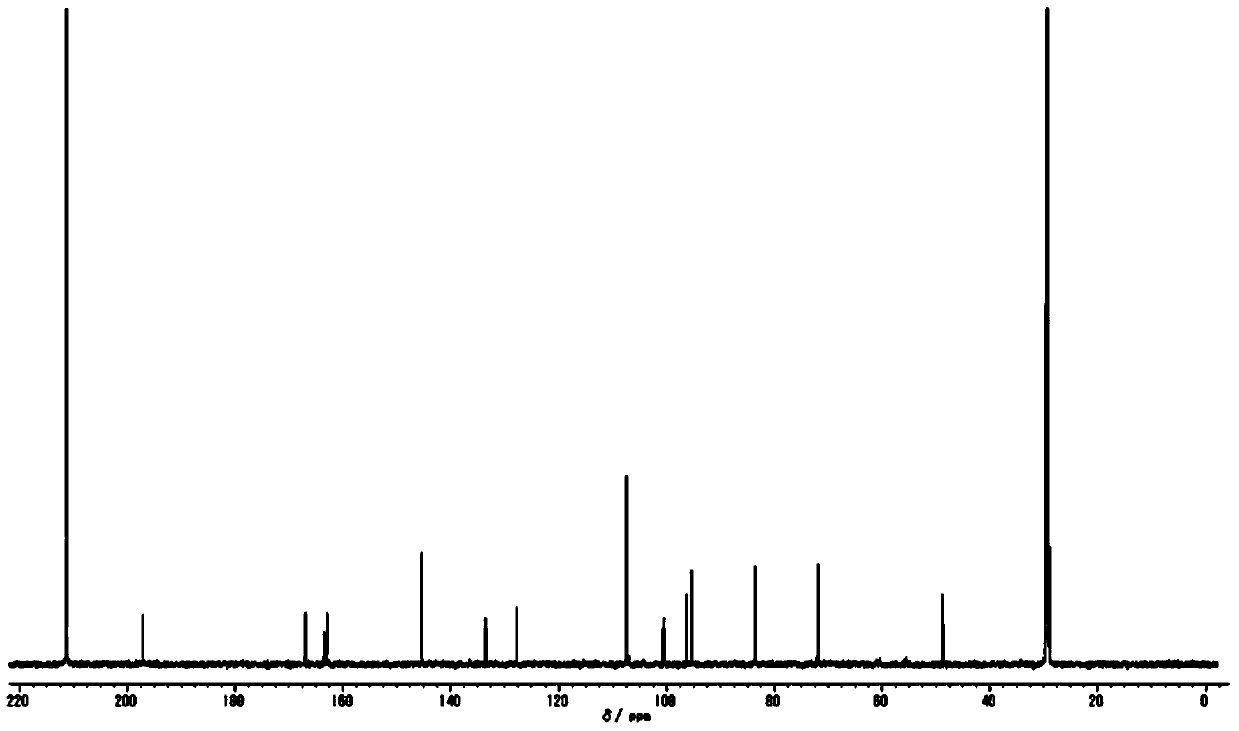

[0038] (4) Collect the above 40% methanol...

Embodiment 2

[0040] (1) Crush 100 g of dried cedar pine needles with an average particle size of 400 μm, add 1500 mL of n-hexane according to the ratio of solid to liquid 1 g: 15 mL, shake at room temperature for 18 h, and filter and separate the n-hexane extract;

[0041] (2) Add 2000mL of methanol with a concentration of 60wt% to the above-mentioned defatted pine needles according to the ratio of material to liquid 1g: 20ml as an extractant, shake at room temperature for 36h, separate the supernatant, and concentrate and dry the supernatant to obtain methanol extract 22g, the yield is 22%;

[0042](3) Suspend the above-mentioned methanol extract in 25mL of methanol with a concentration of 50wt%, put it on a macroporous adsorption resin Diaion HP-20 chromatography column (weight is 500g), and elute with methanol-water gradient, with a concentration of 0wt%, 15wt% %, 30wt%, 40wt%, 60wt%, 100wt% methanol, the elution flow rate is 4mL / min;

[0043] (4) Collect the above 40% methanol eluate,...

Embodiment 3

[0045] (1) Crush 100 g of dried cedar pine needles with an average particle size of 500 μm, add 2000 mL of n-hexane according to the ratio of solid to liquid 1 g: 20 mL, shake at room temperature for 24 hours, and filter and separate the n-hexane extract;

[0046] (2) Add 3000mL of methanol with a concentration of 70wt% to the above-mentioned defatted pine needles according to the ratio of material to liquid 1g: 30ml as an extractant, shake at room temperature for 48h, separate the supernatant, and concentrate and dry the supernatant to obtain methanol extract 20g, the yield is 20%;

[0047] (3) Suspend the above-mentioned methanol extract in 30mL of methanol with a concentration of 50wt%, put it on a macroporous adsorption resin Diaion HP-20 chromatography column (weight is 500g), and elute with methanol-water gradient, with a concentration of 0wt%, 15wt% %, 30wt%, 40wt%, 60wt%, 100wt% methanol, the elution flow rate is 5mL / min;

[0048] (4) Collect the above 40% methanol el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com