Temperature-adaptive high-temperature retarder suitable for oil and gas well cementing, preparation method thereof and cementing cement slurry

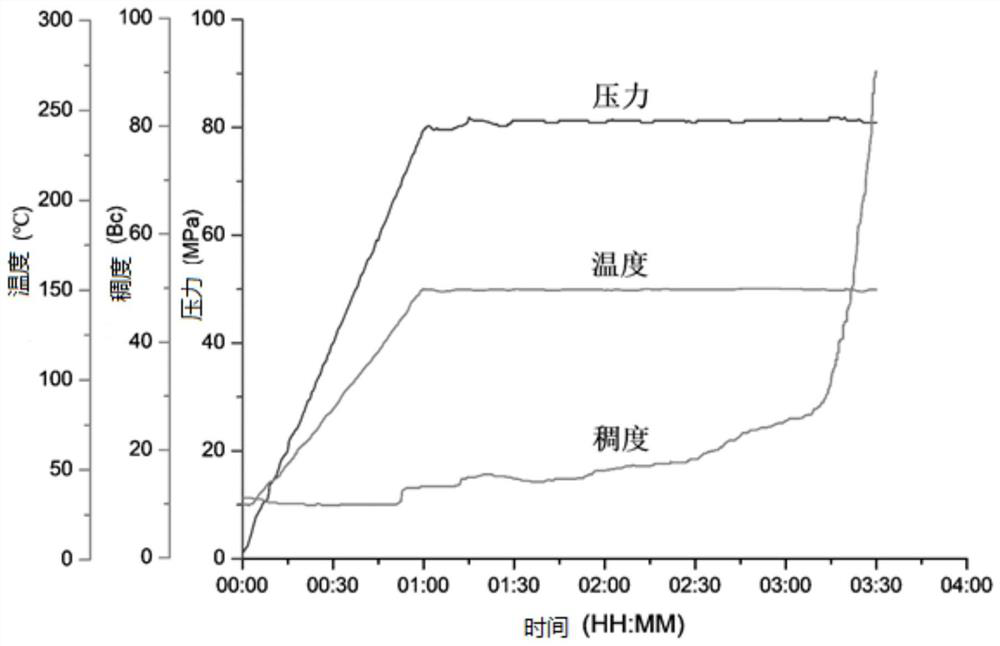

A technology for cementing cement slurry and retarder, which is used in the preparation of high-temperature retarder and in the field of cementing cement to achieve strong retardation, control high-temperature thickening time, and prolong thickening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In the present invention, a rigid hydrophobic monomer is developed by increasing the length of the alkyl chain in the monomer, and the rigid hydrophobic monomer is a rigid hydrophobic long-chain alkyl monomer, which can endow the The thermal thickening ability of synthetic polymer, so the present invention utilizes allyl chloride and N, N-dimethyl long-chain alkyl tertiary amine (long-chain alkyl number is the even number of 14-24) to synthesize a kind of rigid hydrophobic long-chain The alkyl-containing quaternary ammonium salt type monomer is used as a rigid hydrophobic monomer, and the specific synthesis method includes the following steps:

[0047] (1) Add fatty alcohol and an appropriate amount of catalyst into the reactor, heat the reactor, and when the temperature is 130°C, feed monomethylamine into the reactor at a flow rate of 35kg / h-50kg / h for 75-85min, and finally the reactor Keep the reaction temperature at 180-200°C, and the reaction time is 5-7h, so as to ...

Embodiment 1

[0084] This embodiment is to illustrate the temperature-adaptive high-temperature retarder prepared by the method of the present invention.

[0085] The preparation steps are as follows:

[0086] (1) Weigh 41.4 parts of 2-acrylamide-2-methylpropanesulfonic acid, 52 parts of itaconic acid, 4.95 parts of N,N-dimethylacrylamide, 6 parts of hydrophobic monomer, and use deionized water Dissolved, the total mass concentration of monomers in the solution is 35%, and the pH value is adjusted to 4 by a sodium hydroxide solution with a concentration of 5 mol / L;

[0087]Wherein, the rigid hydrophobic monomer has the structure shown in formula (IX), and, R 6 is H, n is 21;

[0088]

[0089] (2) Adjust the temperature of the water bath to 70° C., and install the reaction device, which includes three-necked flask, precision booster electric stirrer, constant pressure dropping funnel and other main components. Transfer the mixed solution of sodium styrene sulfonate, itaconic acid and h...

Embodiment 2

[0096] This embodiment is to illustrate the temperature-adaptive high-temperature retarder prepared by the method of the present invention.

[0097] The high-temperature retarder was prepared according to the same method as in Example 1, except that: 2-acrylamide-2-methylpropanesulfonic acid, itaconic acid, N,N-dimethyl Acrylamide and Hydrophobic Monomers.

[0098] As a result, the prepared high-temperature retarder is marked as S2.

[0099] Wherein, the structure contained in the high temperature retarder S2 is:

[0100] [CH 2 CHM 4 ] p -[M 1 CH 2 CHCH 2 m 1 ] q -[CM 2 HCH 2 ] m -[CH 2 CM 3 HCl - ] n ; among them, M 1 for-COOH, M 2 for-CONHC(CH 3 ) 2 CH 2 SO 3 H, M 3 for-[NCH 2 (CH 3 ) 2 (CH 2 ) n CH 3 ] + ,M 4 for-CON(CH 3 ) 2 ;

[0101] Wherein, p=9.59%, q=47.93%, m=40.26%, n=2.22%; and

[0102] The weight average molecular weight of the high temperature retarder S2 is 170,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com