Preparation method of water-containing pesticide preparation and water-containing pesticide preparation

A technology for pesticide preparation and hot fogging agent, which is applied in the field of pesticide preparation processing, can solve the problems of cumbersome processing of pesticide preparations, prone to creaming during processing, poor storage stability, etc., and achieves good storage stability, improved preparation stability and particle size. Narrow distribution of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

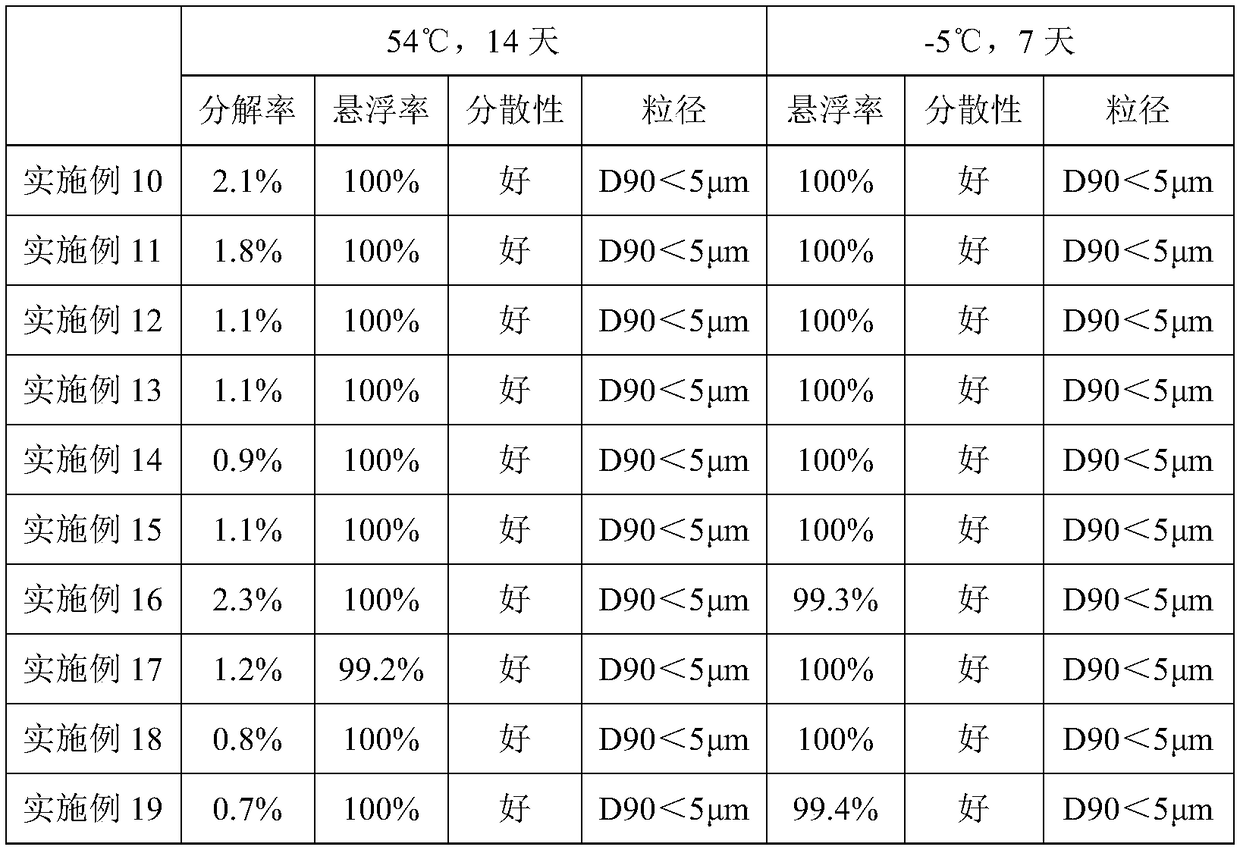

Examples

preparation example Construction

[0021] The invention provides a method for preparing a water-containing pesticide preparation, wherein the water-containing pesticide preparation includes a dispersible oil suspension, an oil-suspended thermal mist, and a film-expanding oil.

[0022] When the aqueous pesticide formulation is a dispersible oil suspension concentrate, the dispersible oil suspension concentrate includes the following raw material components by weight percentage:

[0023] 1% to 50% active ingredient; 5% to 20% emulsifier; 0.1% to 2% wetting agent; 0.2% to 4% dispersant; 0.02% to 0.4% defoamer; 1% to 15% water; 0.5% to 3% thickening agent; oil base, the amount of oil base is to supplement the total amount of the dispersible oil suspending agent to reach 100%. In addition, the dispersible oil suspension may further contain a stabilizer, and the weight percentage of the stabilizer is not more than 2%.

[0024] The preparation method of this dispersible oil suspension concentrate at least comprises t...

Embodiment 1

[0074] A preparation method of a fluorine-containing thiazolidinone dispersible oil suspension, comprising the following steps:

[0075] (1) Preparation of 50% fluthiazolidin water concentrated suspension: according to the percentage by weight, 50% fluthiapiprofen, 1% fatty alcohol ethoxylate, 2% alkyl naphthalene sulfonate sodium salt, high Molecular carboxylate 1%, organic silicon defoamer 0.2%, and deionized water are fully mixed and then sand-milled until the average particle size is 1-5 μm, and then filtered to obtain a water-concentrated suspension.

[0076] (2) Preparation of the continuous oil phase: according to weight percentage, 4% of calcium dodecylbenzenesulfonate, 6% of fatty alcohol polyoxyethylene ether, 1.5% of organic bentonite, 1% of white carbon black, Methyl oleate was supplemented to 90%, stirred and mixed evenly to obtain a continuous oil phase.

[0077] (3) Preparation of 5% thiazolidinone dispersible oil suspension: according to weight percentage, 10%...

Embodiment 2

[0079] A preparation method of a fluorine-containing thiazolidinone dispersible oil suspension, comprising the following steps:

[0080] (1) The preparation of 50% thiazolidone aqueous concentrated suspension is the same as that in Example 1.

[0081] (2) Preparation of the continuous oil phase: according to weight percentage, calcium dodecylbenzenesulfonate 3%, castor oil polyoxyethylene ether 4%, sorbitan polyoxyethylene polyoxypropylene 7 %, organic bentonite 1%, white carbon black 1%, soybean oil to make up to 80%, stir and mix evenly to obtain a continuous oil phase.

[0082] (3) Preparation of 10% thiazolidinone dispersible oil suspension: according to weight percentage, under 800rpm rotating speed, 20% of the water concentrated suspension obtained in step (1) and the continuous oil phase obtained in step (2) Mix and stir evenly to obtain 10% fluthiazolidone dispersible oil suspension concentrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com