Water-based acrylic finish paint

A water-based acrylic and topcoat technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of high production cost, high price, and difficult development, and achieve the effect of facilitating construction and film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

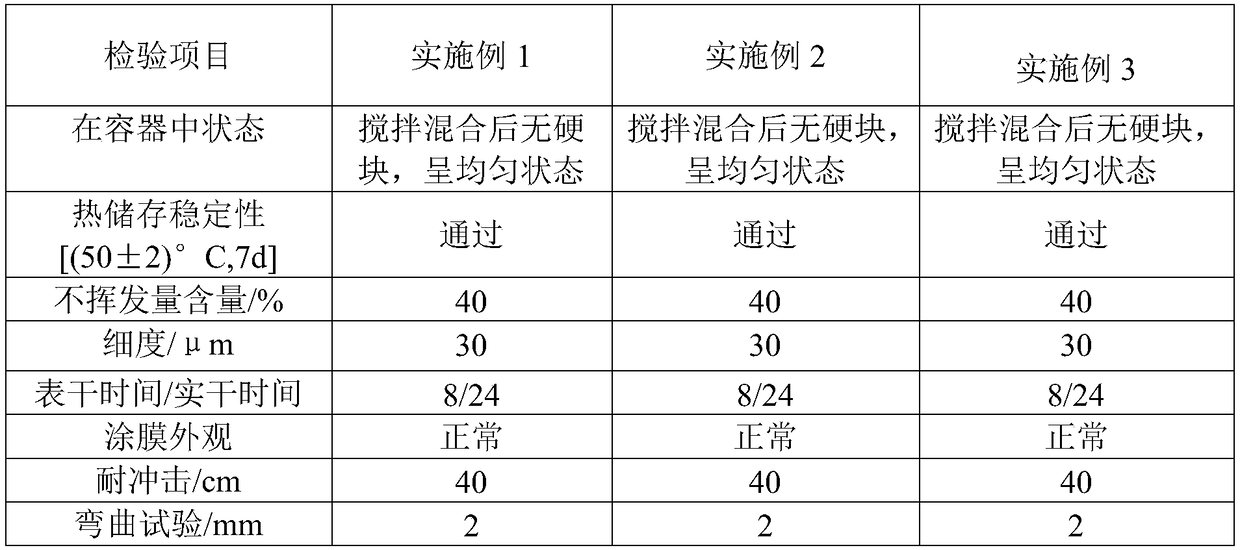

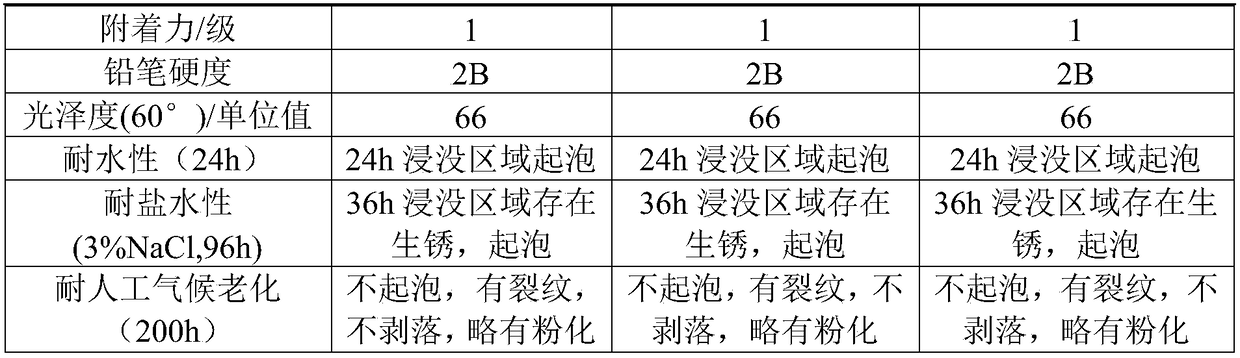

Examples

Embodiment 1

[0026] A water-based acrylic topcoat, comprising the following components in parts by weight: 29.4 parts of water-based acrylic acid, 0.4 parts of dry mixed material, 30.0 parts of deionized water, 3.4 parts of ethylene glycol butyl ether, 0.5 parts of dispersant, and 0.3 parts of defoamer 3.7 parts of titanium dioxide, 13.0 parts of 2% EW bentonite pregel, 4.0 parts of attapulgite, 8.8 parts of light chrome yellow, 9.5 parts of medium chrome yellow, 3.0 parts of iron oxide yellow, 3.4 parts of pH regulator, film-forming aid 5.6 parts of agent, 0.1 part of substrate wetting agent, 0.2 part of leveling agent, 0.4 part of anti-flash rust agent, 0.3 part of thickener, 8.0 parts of deionized water; the preparation method of the 2% EW bentonite pregel is It is prepared by mixing deionized water and bentonite at a ratio of 98:2 by weight, and dispersing them uniformly through high-speed shearing.

Embodiment 2

[0028] A water-based acrylic topcoat, comprising the following components in parts by weight: 31.0 parts of water-based acrylic acid, 1.1 parts of dry mixed material, 30.0 parts of deionized water, 3.0 parts of ethylene glycol butyl ether, 0.1 part of dispersant, and 0.2 parts of defoamer 1.2 parts of titanium dioxide, 9.0 parts of 2% EW bentonite pregel, 3.1 parts of attapulgite, 2.3 parts of light chrome yellow, 5.23 parts of medium chrome yellow, 2.0 parts of iron oxide yellow, 1.5 parts of pH regulator, film-forming aid 2.27 parts of agent, 0.3 part of substrate wetting agent, 0.3 part of leveling agent, 0.5 part of anti-flash rust agent, 0.9 part of thickener, 6.0 parts of deionized water; the preparation method of the 2% EW bentonite pregel is It is prepared by mixing deionized water and bentonite at a ratio of 98:2 by weight, and dispersing them uniformly through high-speed shearing.

Embodiment 3

[0030] A water-based acrylic topcoat, comprising the following components in parts by weight: 24.0 parts of water-based acrylic acid, 1.1 parts of mixed dry material, 21.0 parts of deionized water, 2.2 parts of ethylene glycol butyl ether, 0.4 parts of dispersant, and 0.4 parts of defoamer 3.0 parts of titanium dioxide, 12.0 parts of 2% EW bentonite pregel, 5.4 parts of attapulgite, 8.0 parts of light chrome yellow, 3.7 parts of medium chrome yellow, 3.4 parts of iron oxide yellow, 3.4 parts of pH regulator, film-forming aid 5.64 parts of agent, 0.3 part of substrate wetting agent, 0.3 part of leveling agent, 0.9 part of anti-flash rust agent, 0.86 part of thickener, 4.0 parts of deionized water; the preparation method of the 2% EW bentonite pregel is It is prepared by mixing deionized water and bentonite at a ratio of 98:2 by weight, and dispersing them uniformly through high-speed shearing.

[0031] A kind of waterborne acrylic topcoat in embodiment 1-3 comprises following p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com