Method for preparing inorganic hydrous salt phase transition energy-storing material

A phase change energy storage material, inorganic salt technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of supercooling, phase separation, etc., to maintain stability, avoid differences, avoid phase separation and The effect of layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

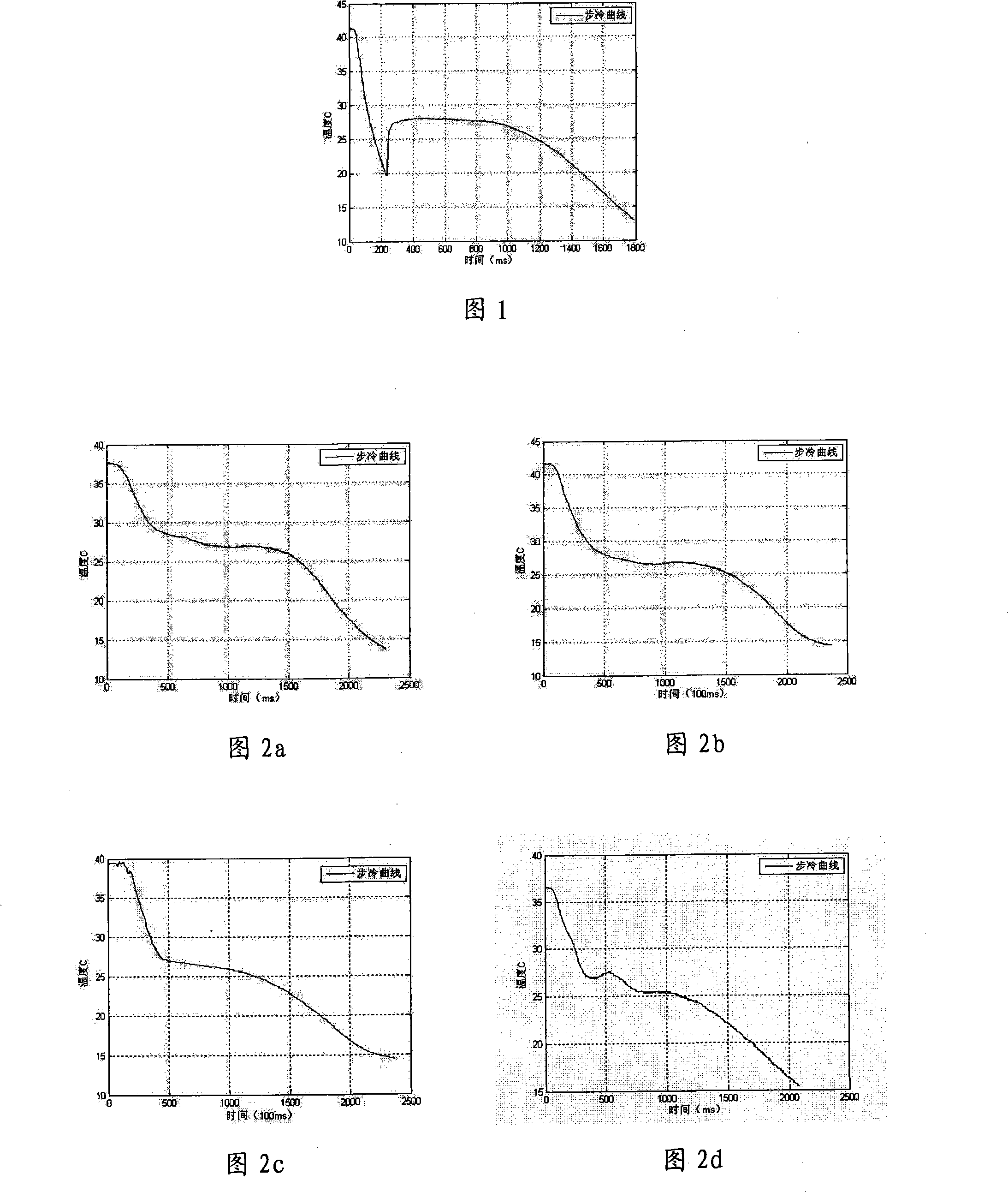

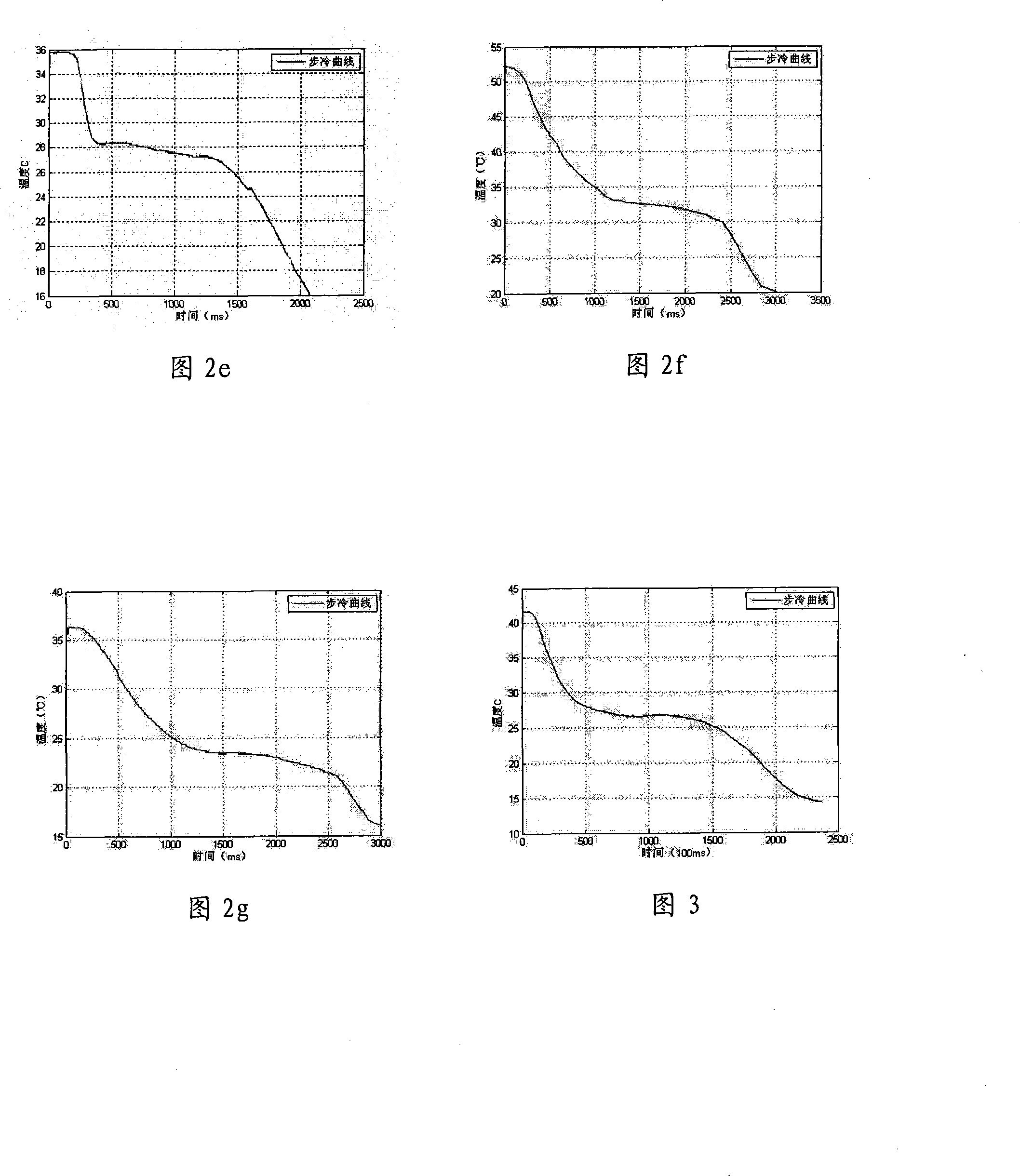

Image

Examples

Embodiment 1

[0021] Carry out the following experimental steps according to each component specified in Table 1:

[0022] Step 1. Take 5 grams of acrylic acid, add 20 grams of water and 0.1 grams of NaHSO 3 , stirred and mixed, heated to 70°C to prepare an acrylic acid solution;

[0023] Step 2, get 10 grams of water, add 0.76 grams (NH 4 ) 2 S 2 o 8 After mixing evenly, add dropwise to the acrylic acid solution prepared in step 1, and keep stirring at 70° C. for 1.5 hours to obtain a sodium polyacrylate solution;

[0024] Step 3, after the viscosity of the sodium polyacrylate solution in step 2 reaches a certain level, add 3 grams of NaOH to the solution, stir and mix, neutralize excess acid, and obtain a viscous sodium polyacrylate solution;

[0025] Step 4, with 70 grams of water, 4 grams of borax (sodium tetraborate) and 40 grams of Na 2 SO 4 Mix and dissolve to make Na 2 SO 4 mixture;

[0026] Step 5, the sodium polyacrylate solution that makes in step 3 is added to the Na t...

Embodiment 2

[0029] Repeat the experimental procedure in Example 1 by each component specified in Table 1, but the consumption of acrylic acid is changed into 7 grams, and the consumption of borax is changed into 3 grams.

[0030] The test results of this embodiment are shown in Figure 2b.

Embodiment 3

[0032] Repeat the experimental procedure in Example 1 by each component specified in Table 1, but the consumption of acrylic acid is changed into 7 grams, and the consumption of borax is changed into 4 grams.

[0033] The test results of this embodiment are shown in Figure 2c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com