Fluoroplastic-rubber bonding method

A technology of fluoroplastics and rubber, which is applied in the direction of surface pretreatment bonding methods, etc., can solve problems such as the need to improve the bonding strength, affect the performance of rubber, and only apply rubber, and achieve good bonding effect, wide applicability, and high adhesion. combined high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

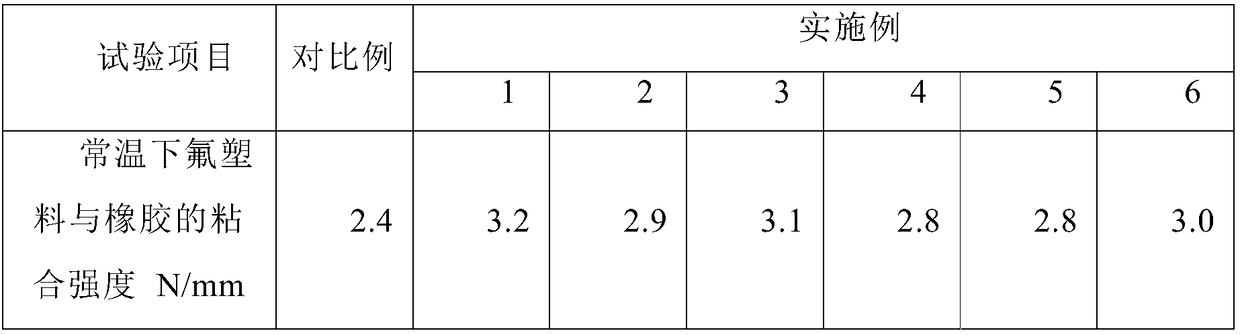

Examples

Embodiment 1

[0029] (1) Mix 2g 1,8-diazabicyclo[5,4,0]undec-7-ene, 2g epichlorohydrin, 1g triallyl isocyanurate and 100g octamethylcyclotetra The siloxane is mixed evenly and prepared as a treatment solution;

[0030] (2) Put the THV fluoroplastic with clean surface in the treatment solution, treat it at 120°C for 5 minutes, then take it out and wash it in ethanol for 5 minutes and then dry it;

[0031] (3) Composite the processed THV fluoroplastics with sheet-shaped nitrile rubber compound, and achieve bonding during the rubber vulcanization process.

Embodiment 2

[0033] (1) Mix 2g 1,8-diazabicyclo[5,4,0]undec-7-ene, 3g epichlorohydrin, 2g allyl glycidyl ether and 100g N,N-dimethylethane The amides are mixed evenly to make a treatment solution;

[0034] ⑵Put the surface-cleaned PVDF fluoroplastic in the treatment solution, treat it at 130°C for 15 minutes, then take it out and wash it in ethanol for 6 minutes and then dry it;

[0035] (3) Composite the treated PVDF fluoroplastic with sheet-shaped nitrile rubber compound, and achieve bonding during the rubber vulcanization process.

Embodiment 3

[0037] (1) Mix 1g 1,5-diazabicyclo[4,3,0]nona-5-ene, 2g epichlorohydrin, 2g triallyl isocyanurate and 100g octamethylcyclotetrasilicon The oxane is mixed evenly and prepared as a treatment liquid;

[0038] (2) Put the THV fluoroplastic with clean surface in the treatment solution, treat it at 110°C for 5 minutes, then take it out and wash it in ethanol for 4 minutes and then dry it;

[0039] ⑶ Composite the treated THV fluoroplastics with sheet-shaped fluorosilicone rubber compound, and achieve bonding during the rubber vulcanization process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com