Preparation method and application of epoxy-based POSS (polyhedral oligomeric silsesquioxane)/ammonium polyphosphate composite flame retardant

A technology of compound flame retardant and ammonium polyphosphate is applied in the field of cotton spinning and finishing, which can solve the problems of environmental pollution, high cost and insignificant effect, and achieve the effects of high bonding fastness, energy saving and environmental protection, and abundant sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

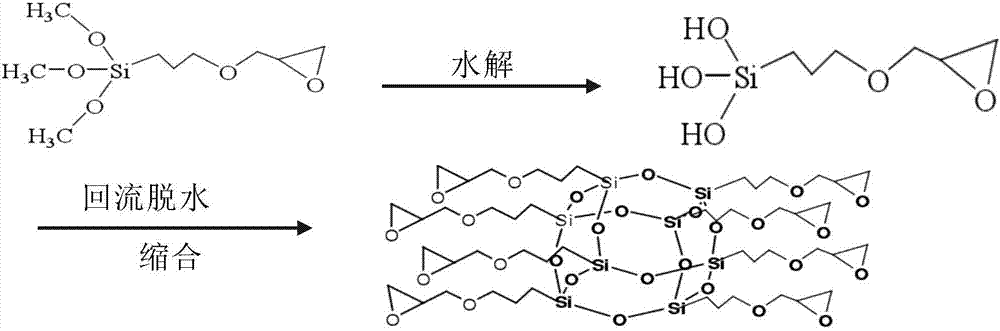

Method used

Image

Examples

Embodiment 1

[0039] Flame Retardant Properties of Cotton Fabrics Without Flame Retardant Treatment

[0040] The test results of the flame retardant properties of pure cotton fabrics show that the limiting oxygen index (LOI) of pure cotton fabrics is 15.11, the vertical burning performance results show that the afterburning time is 30.27s, the smoldering time is 10.34s, and the damage length is 30cm.

Embodiment 2

[0042] Flame retardant properties of cotton fabrics treated with epoxy-based POSS / APP composite flame retardant finishing agent (3:1)

[0043] Preparation of epoxy-based POSS / APP composite flame-retardant finishing agent: After emulsifying an appropriate amount of epoxy-based POSS evenly, add APP according to the mass ratio of epoxy-based POSS and APP to 3:1, heat to dissolve at 90°C and stir evenly to prepare Into a flame retardant finishing agent.

[0044] Flame retardant finishing of cotton fabrics: Cotton fabric → double dipping and double rolling (residue rate 90%) → pre-baking (100°C, 3min) → baking (150°C, 3min).

[0045] The limiting oxygen index of the cotton fabric after finishing is 34.11, the vertical burning performance is 18.54s afterburning time, smoldering time is 0s, and the damage length is 30cm.

Embodiment 3

[0047] Flame-retardant properties of cotton fabrics treated with epoxy-based POSS / APP composite flame-retardant finishing agent (3:2)

[0048] Preparation of epoxy-based POSS / APP composite flame-retardant finishing agent: After emulsifying an appropriate amount of epoxy-based POSS evenly, add APP according to the mass ratio of epoxy-based POSS and APP to 3:2, heat to dissolve at 90°C and stir evenly to prepare Into a flame retardant finishing agent.

[0049] Flame retardant finishing of cotton fabrics: Cotton fabric → double dipping and double rolling (residue rate 90%) → pre-baking (100°C, 3min) → baking (150°C, 3min).

[0050] The limiting oxygen index of the cotton fabric after finishing is 40.56, the vertical burning performance is 0s afterburning time, smoldering burning time is 0s, and the damage length is 5.0cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Smoldering time | aaaaa | aaaaa |

| Damage length | aaaaa | aaaaa |

| Damage length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com