Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

692 results about "Laser direct writing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

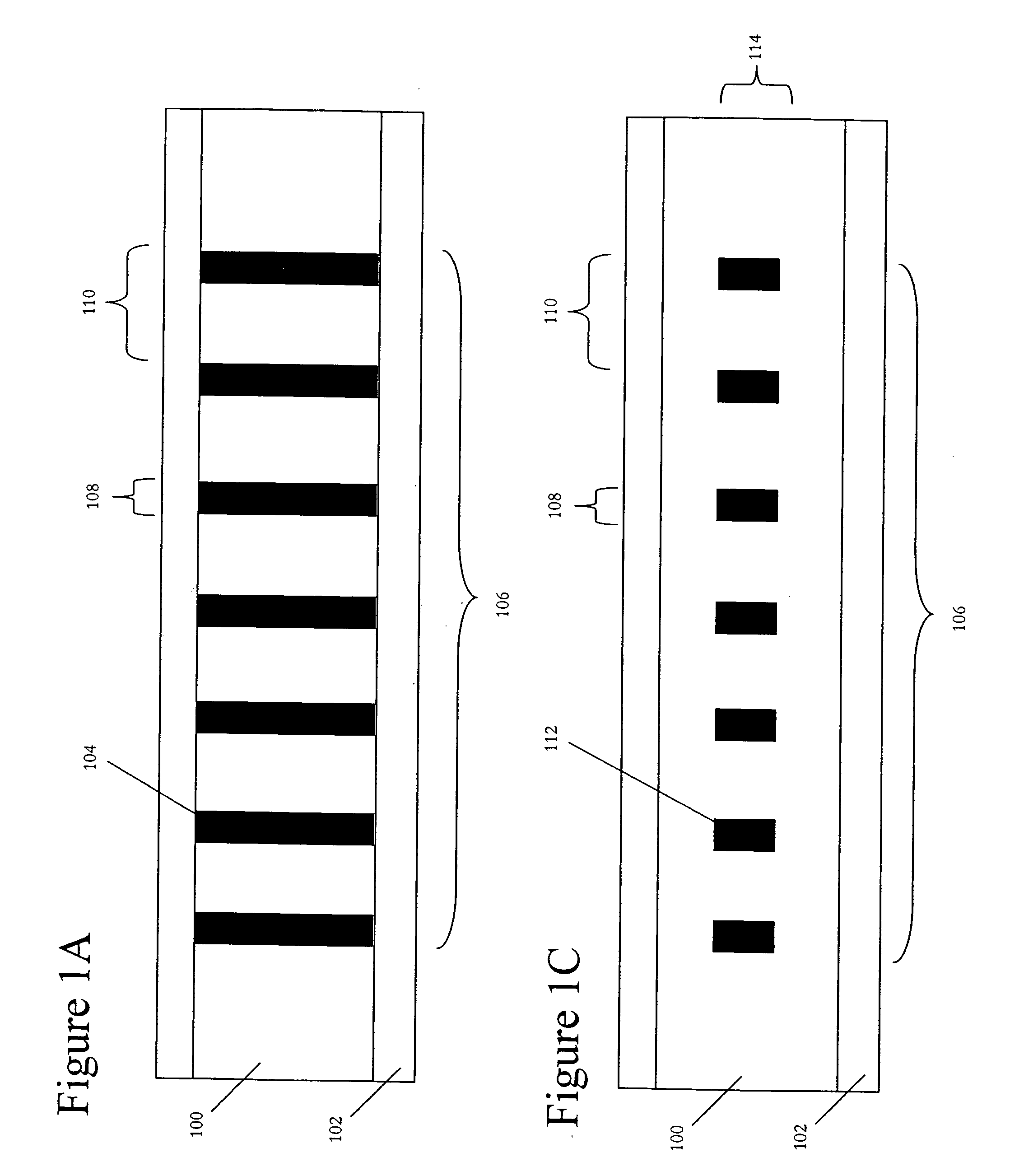

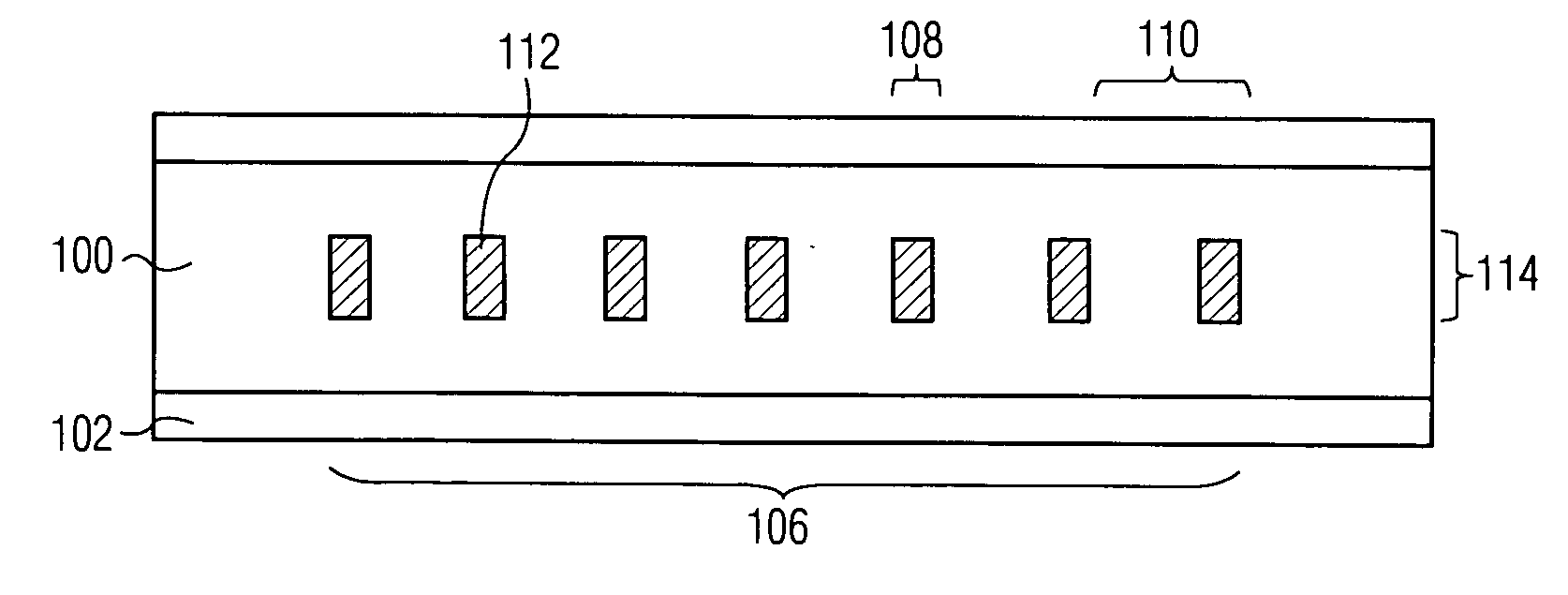

Multimode long period fiber Bragg grating machined by ultrafast laser direct writing

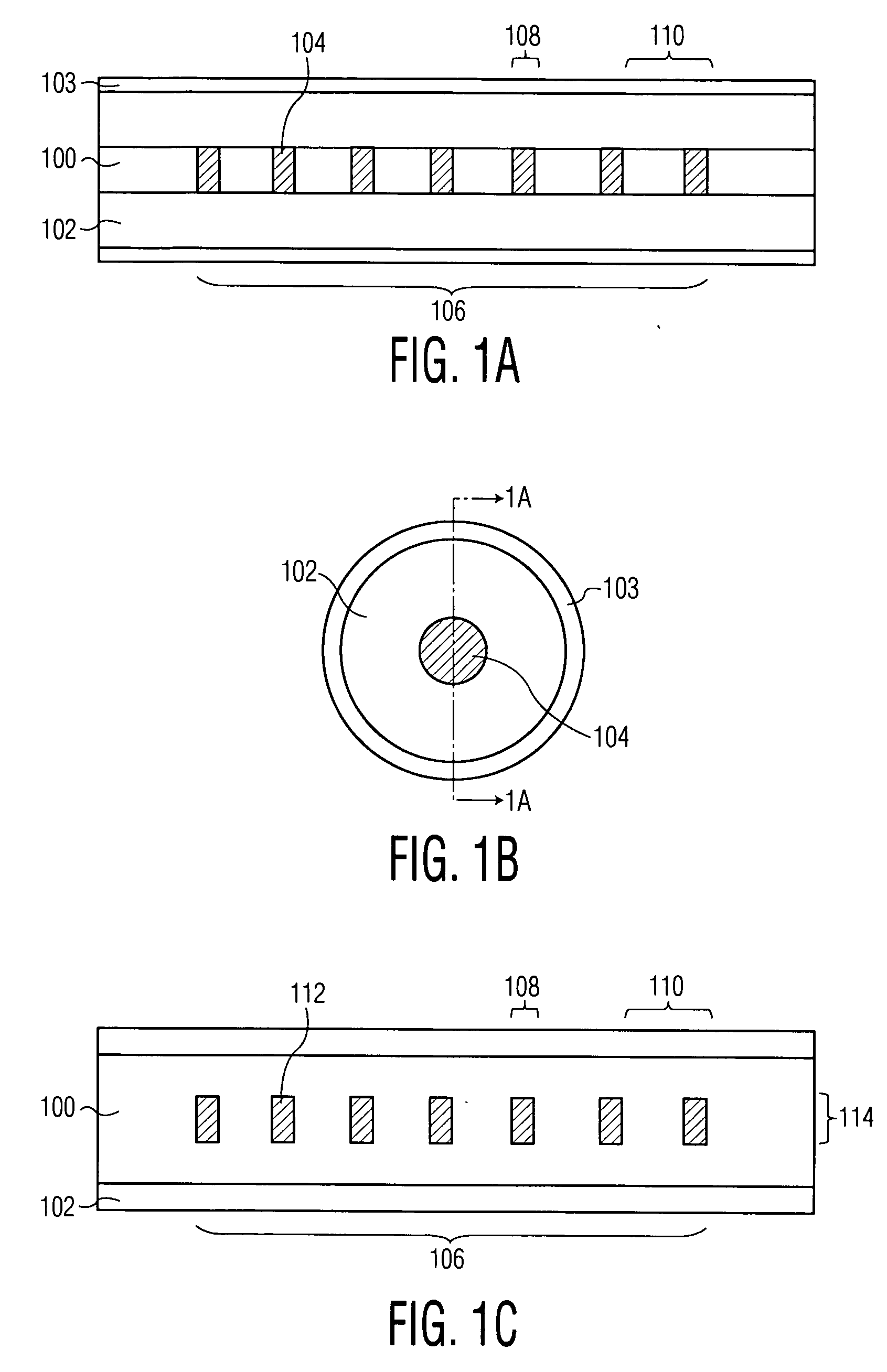

InactiveUS20060093012A1Laser optical resonator constructionOptical resonator shape and constructionGratingFiber Bragg grating

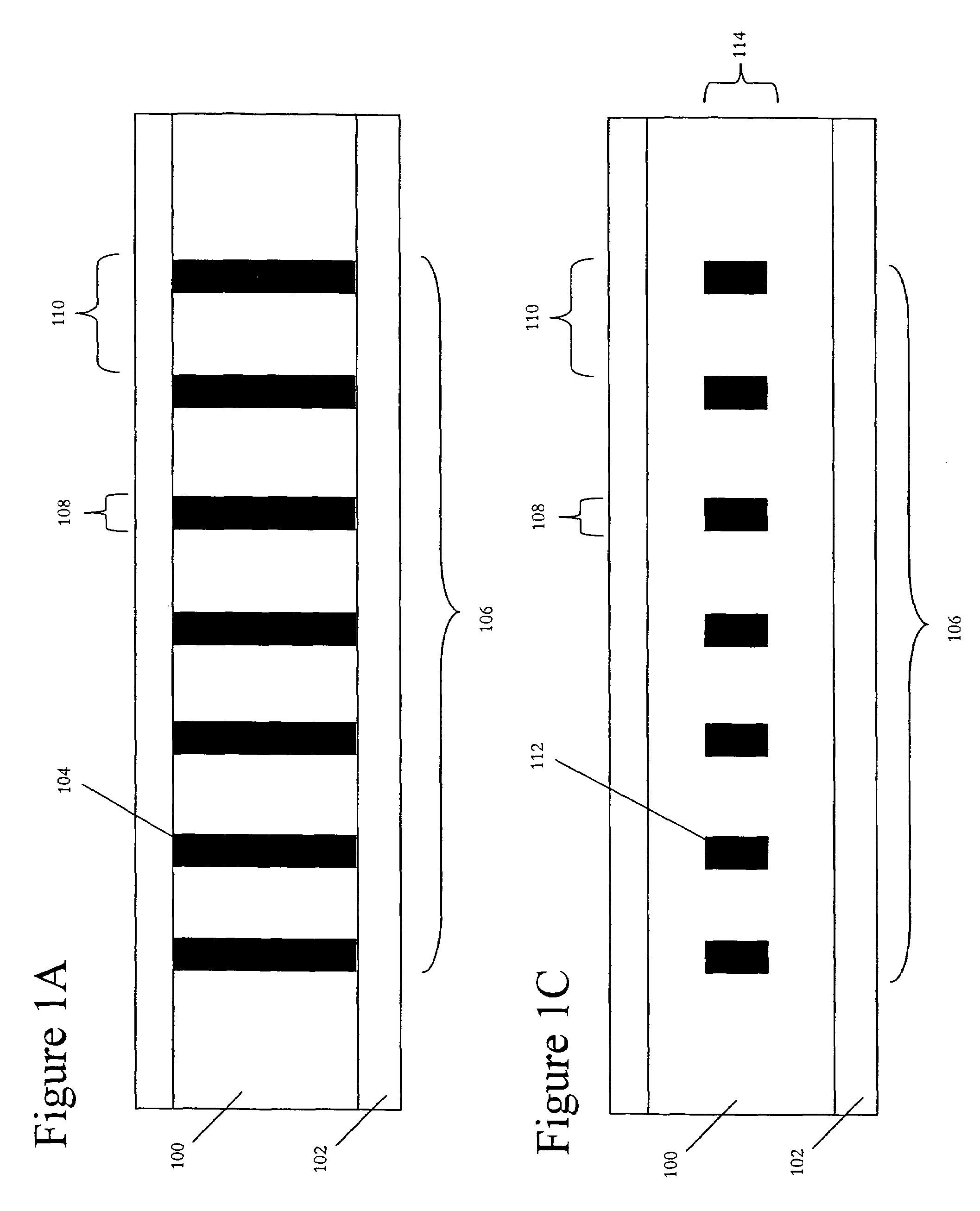

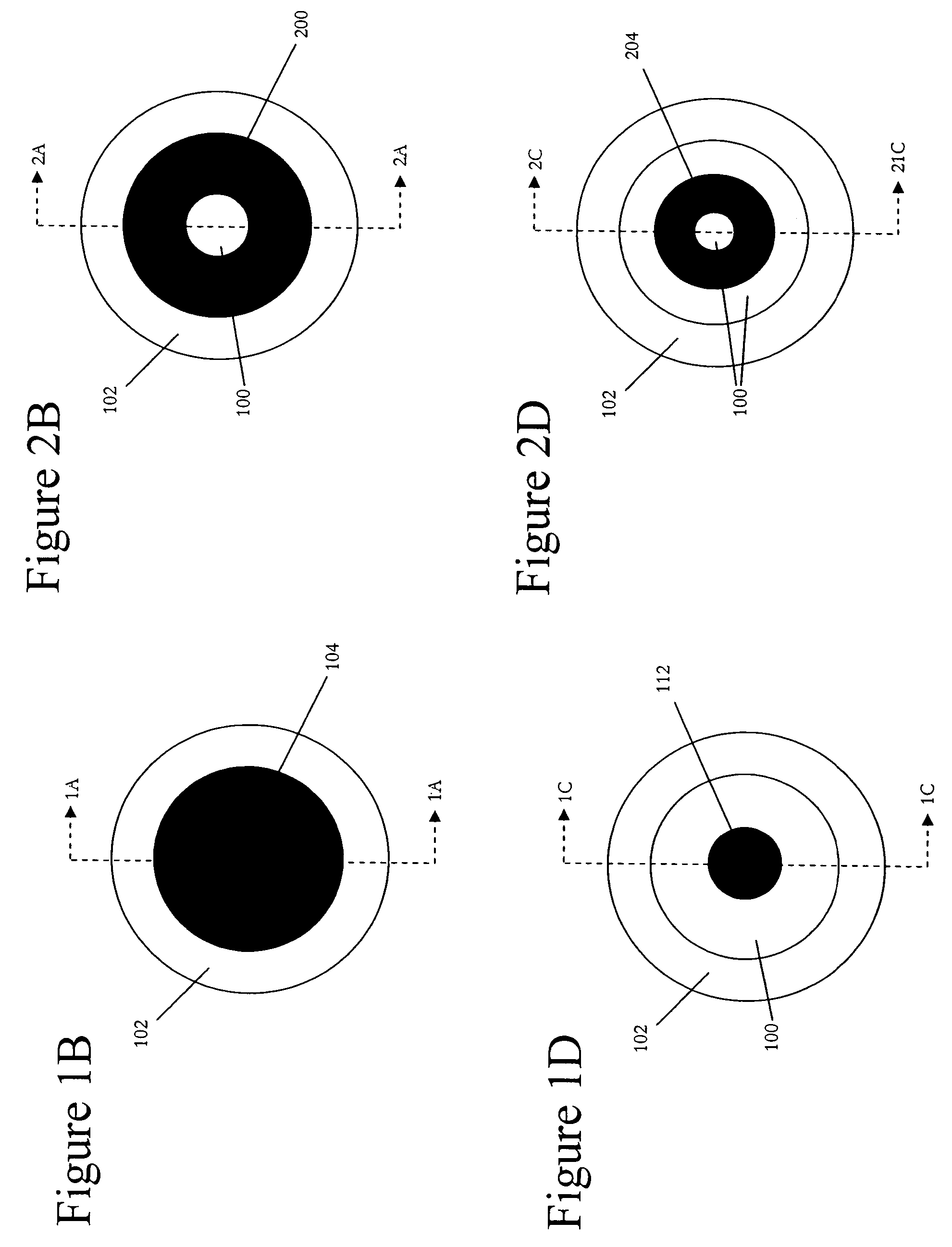

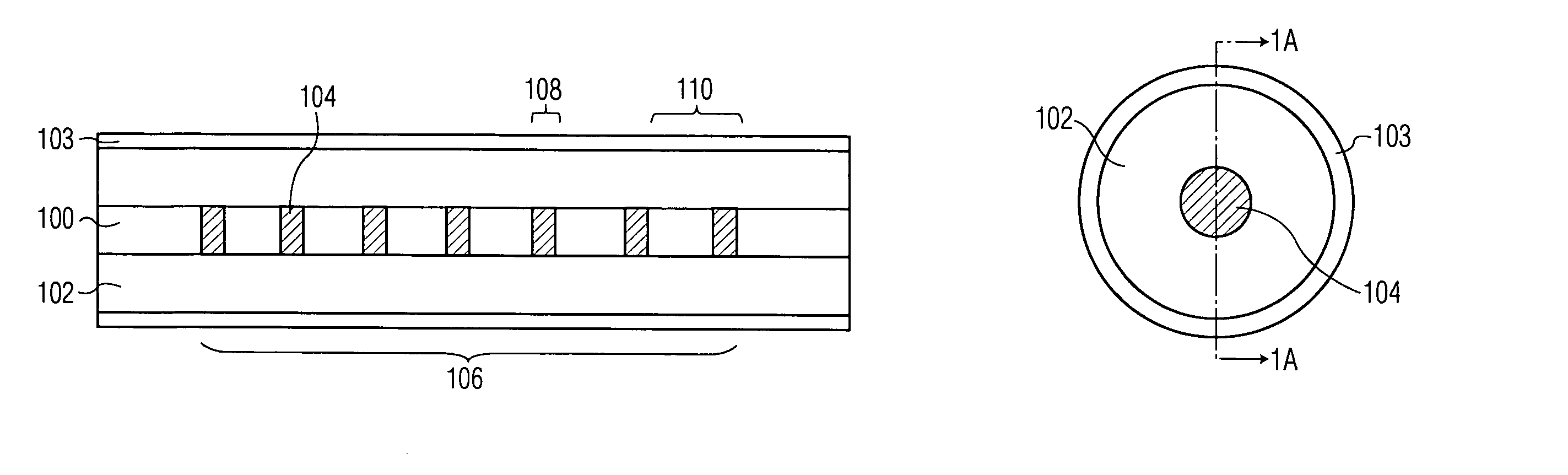

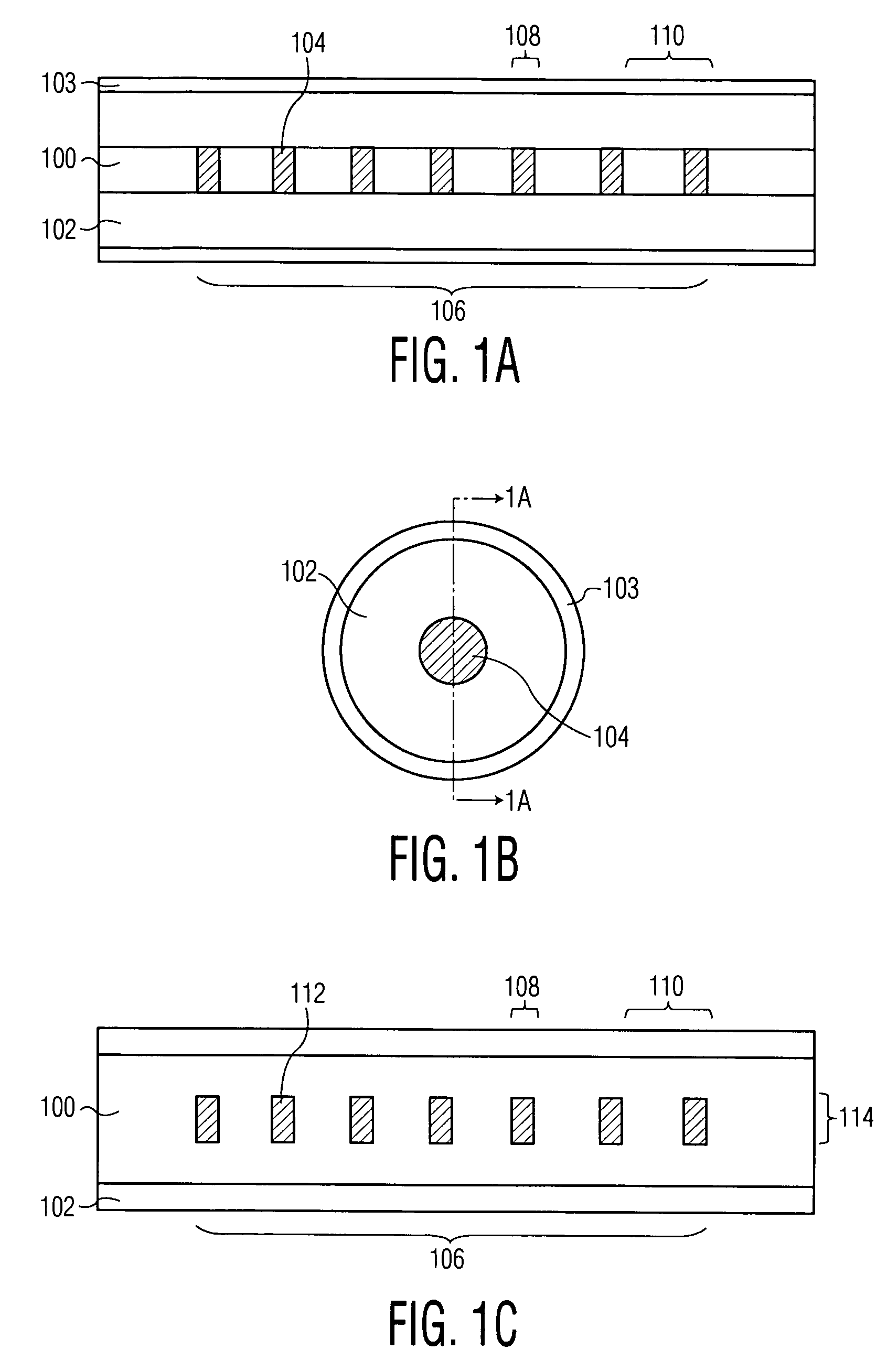

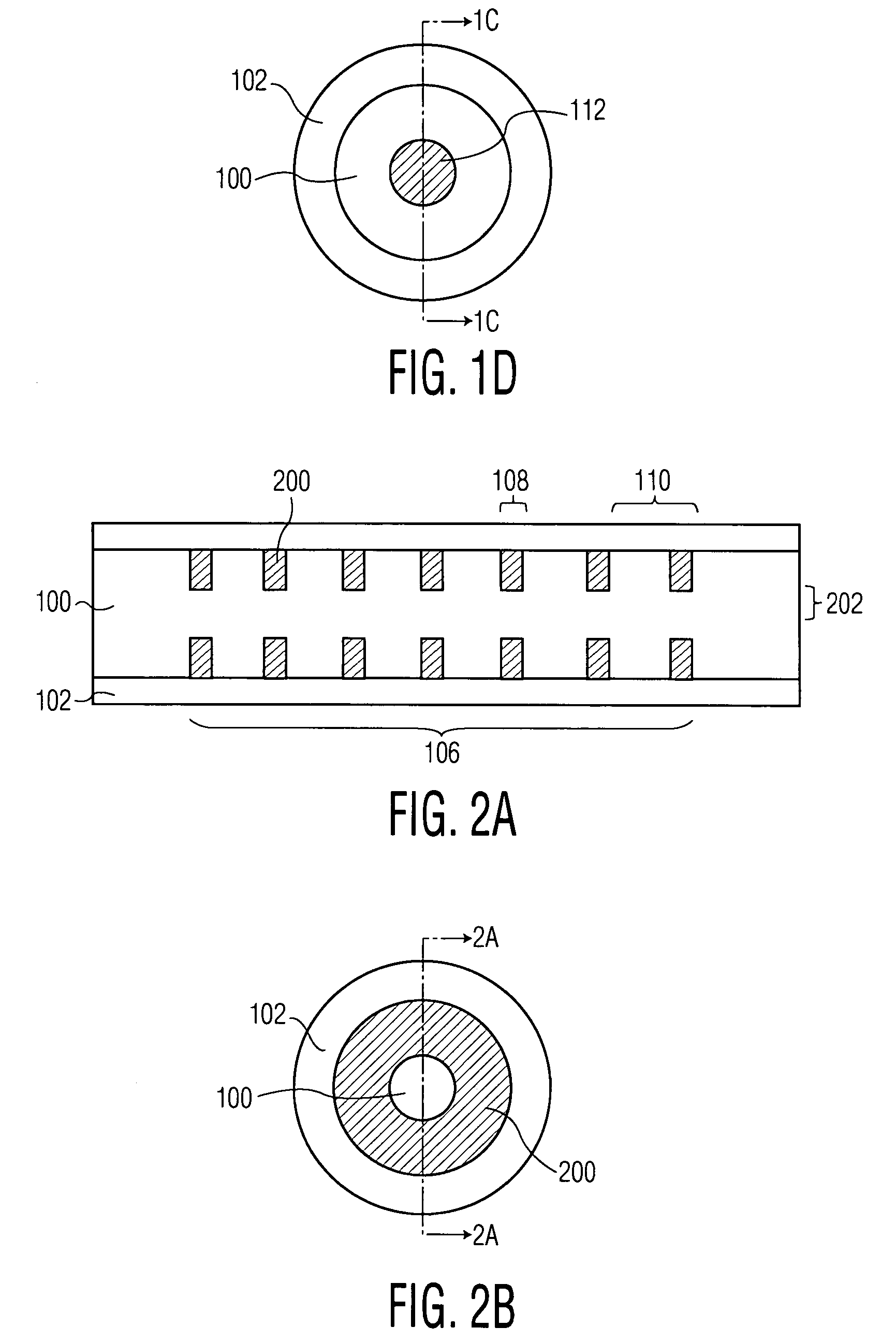

A multimode long period fiber Bragg grating (LPFBG) for a predetermined wavelength band. The LPFBG formed of a non-photosensitive material having an initial index of refraction. The multimode optical fiber core includes a substantially cylindrical surface, a longitudinal core axis, a core radius, and a number of index-altered portions having an altered index of refraction different from the initial cladding index of refraction. Each of the index-altered multimode optical fiber core has a first transmission surface and second transmission surface that is substantially parallel to the first transmission surface. Also, these index-altered portions are arranged within the non-photosensitive material of the multimode optical fiber core such that the first transmission surface of one portion of the plurality of index-altered portions is substantially parallel to the second transmission surface of a neighboring portion to form a long period Bragg grating structure.

Owner:PANASONIC CORP

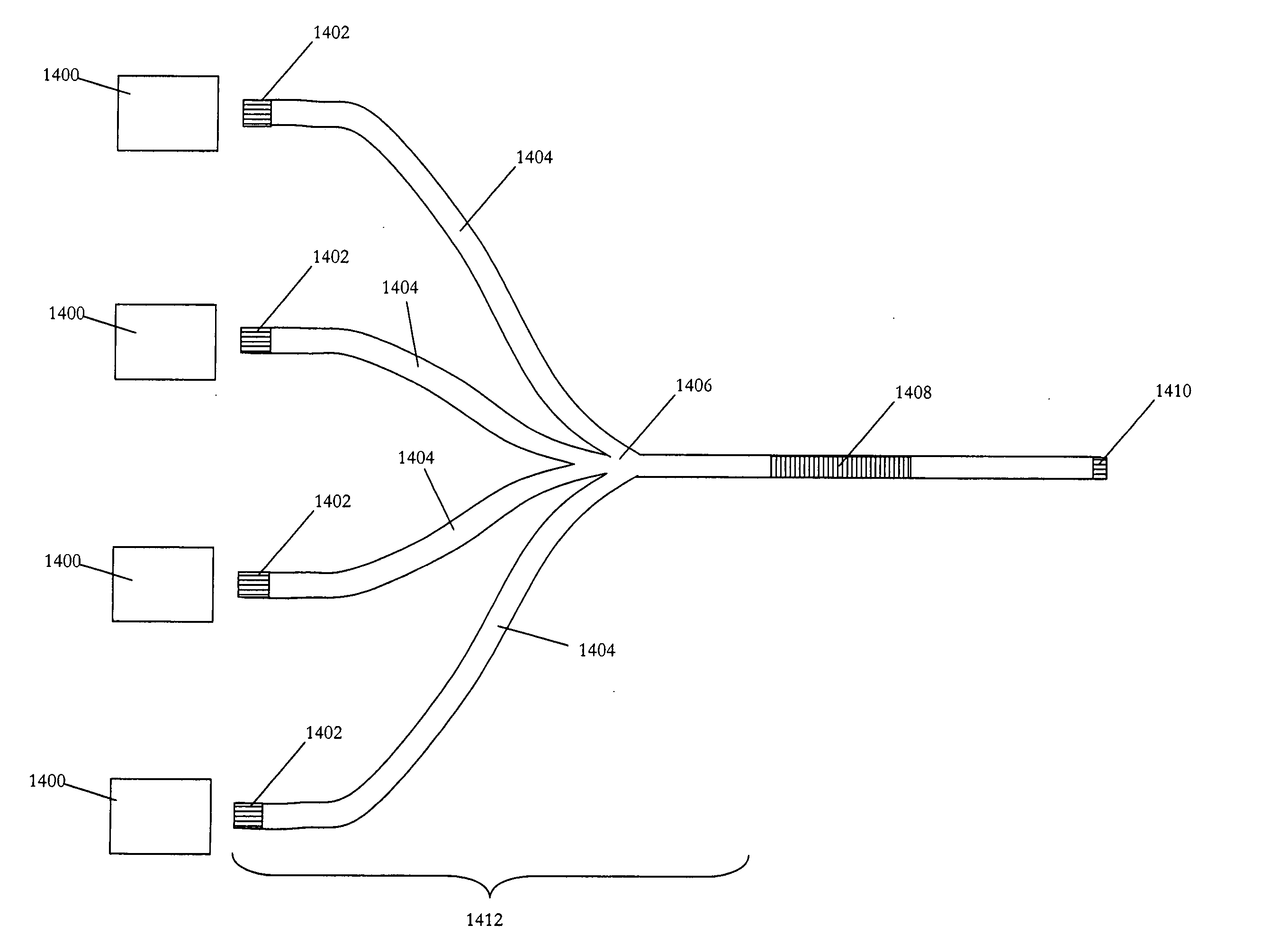

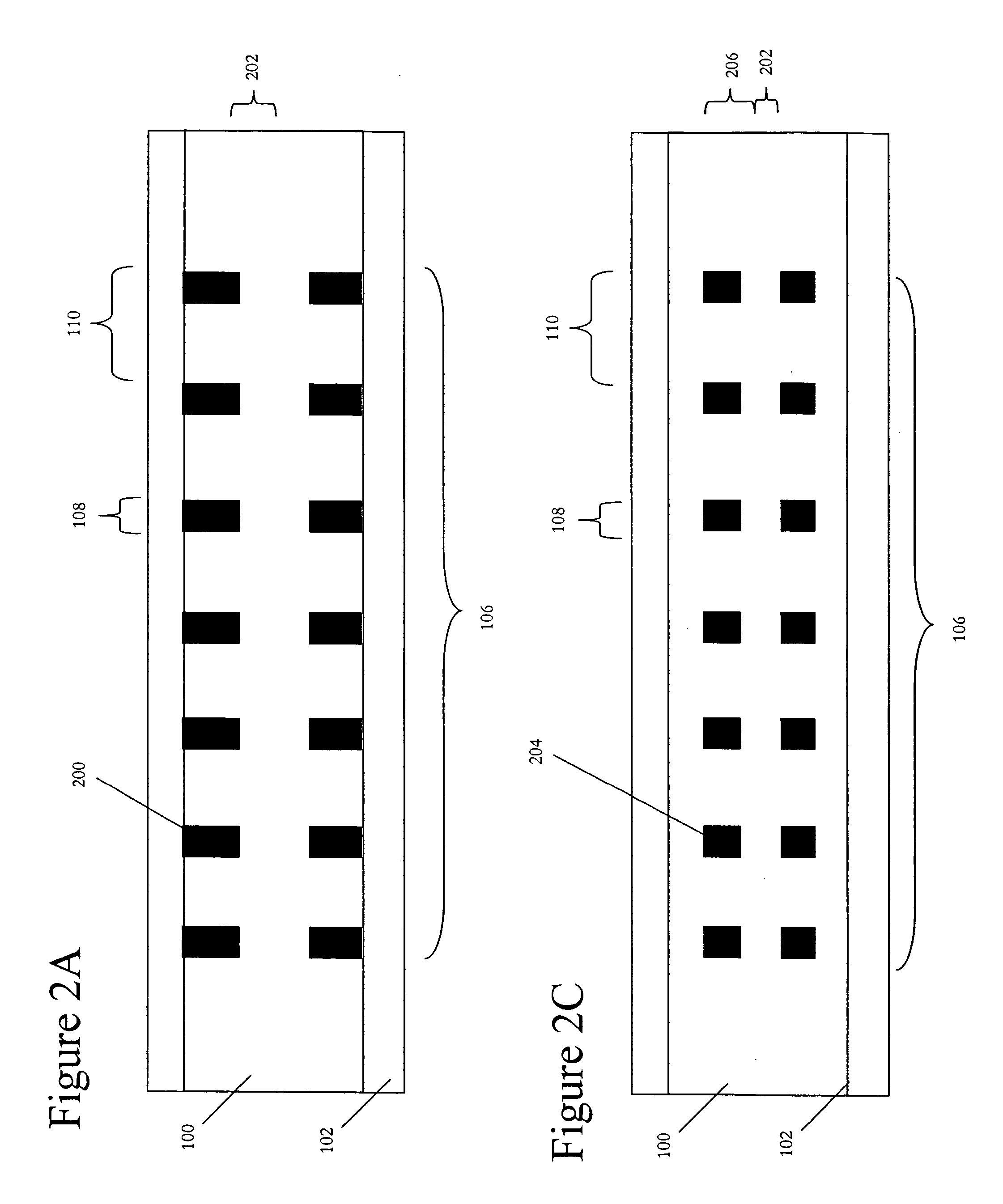

Multicore optical fiber with integral diffractive elements machined by ultrafast laser direct writing

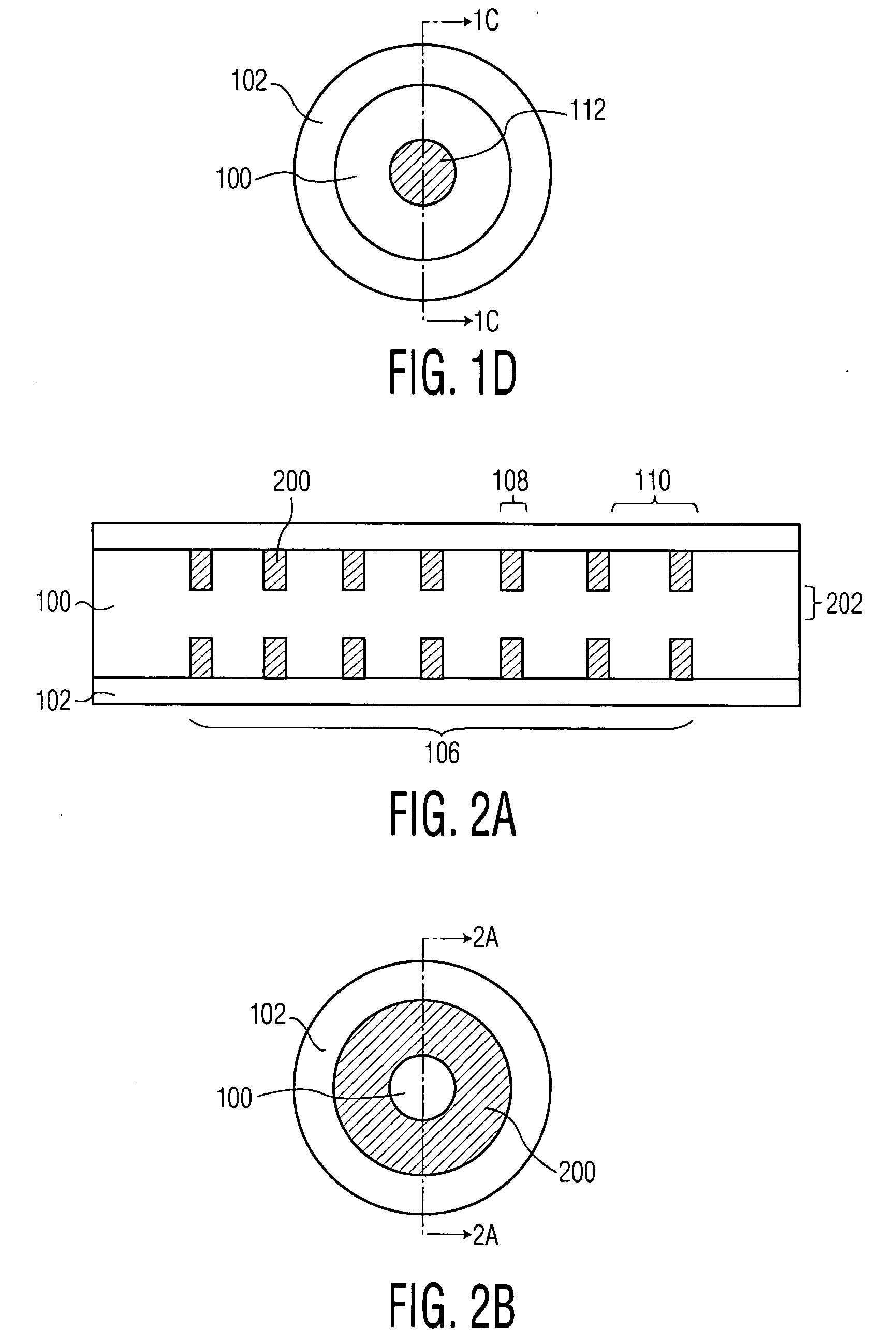

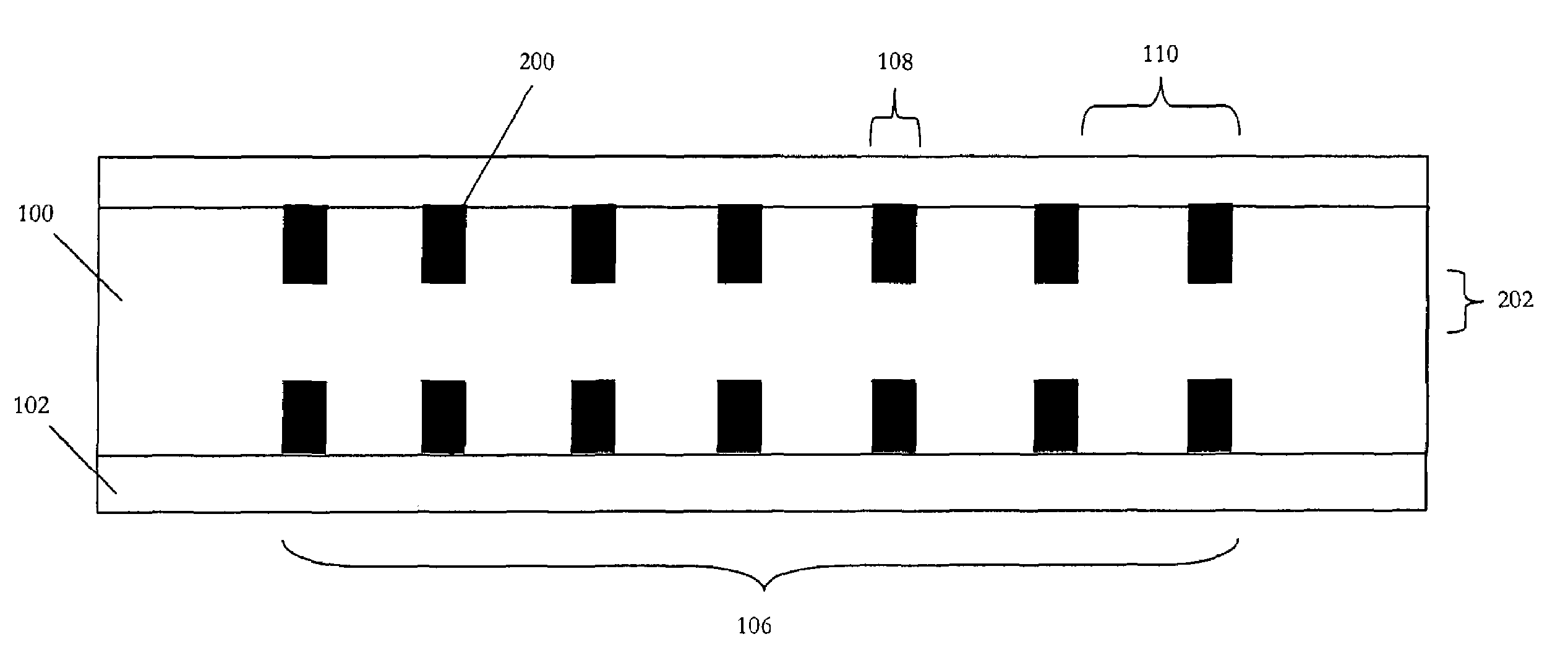

InactiveUS20060215976A1Optical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingRefractive indexMulticore fiber

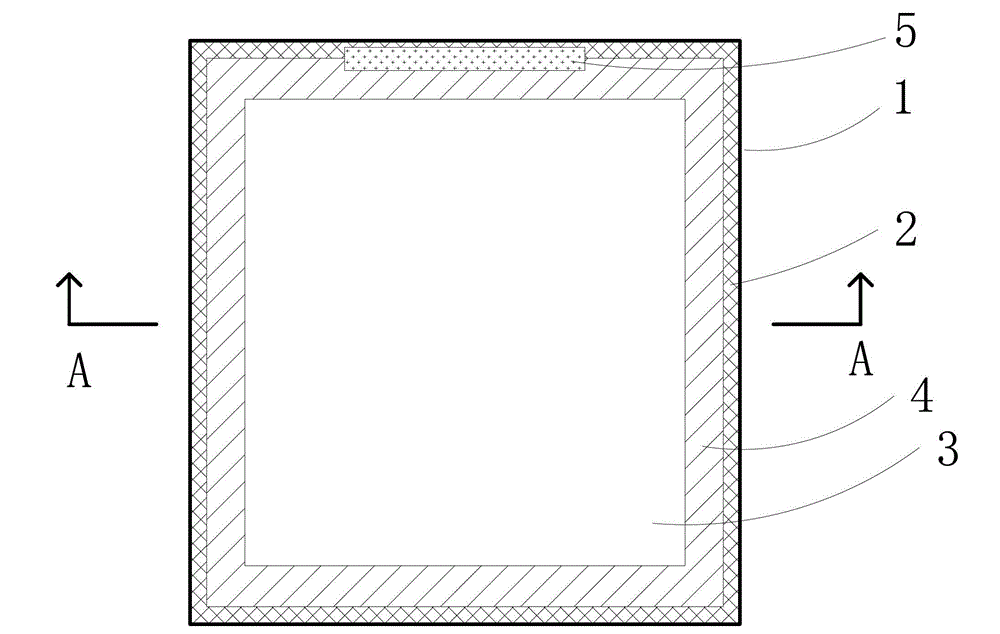

A multicore optical fiber with an integral diffractive element. The multicore optical fiber includes: a first optical fiber core formed of a non-photosensitive material having an initial index of refraction; and a second optical fiber core including a second longitudinal core axis substantially parallel to the first longitudinal axis. The first optical fiber core includes: a first longitudinal core axis; and a number of index-altered portions having an altered index of refraction which is different from the initial index of refraction. The index-altered portions are arranged within the non-photosensitive material of the first optical fiber core to form a diffractive structure of the integral diffractive element.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

System and method for preparing micro-pore array through femtosecond laser direct writing

InactiveCN103071930AEasy to operateTransformation is easy and feasibleLaser beam welding apparatusFrequency spectrumSpatial light modulator

The invention discloses a system and a method for preparing a micro-pore array through femtosecond laser direct writing. The system comprises a femtosecond vector light field generation system, a spatial filtering component, a computer and a three-dimensional mobile platform, wherein a 1 / 2 wave plate, a Glan-laser polarizer, a beam expander and the femtosecond vector light field generation system are arranged on an output straight light path of a femtosecond laser device in sequence; a 4f system is arranged on a light path behind a reflective pure phase spatial light modulator after a holographic phase plate is loaded; a spatial filter is arranged on a frequency spectrum surface; and positive and negative levels of diffraction light which pass through the spatial filter pass through a 1 / 4 wave plate respectively and are combined into a beam of laser through a Rochi grating. A material is adjusted to a focal position through the spatial filtering component, an electronic diaphragm, a focusing lens and the three-dimensional mobile platform; and the spatial light modulator, the electronic diaphragm and the three-dimensional mobile platform are connected with a computer through data lines. The device has the advantages of simple structure, convenience in operation and capabilities of preparing the micro-pore array with various patterns and improving the machining efficiency.

Owner:NANKAI UNIV

Multimode long period fiber bragg grating machined by ultrafast laser direct writing

A multimode long period fiber Bragg grating (LPFBG) for a predetermined wavelength band. The LPFBG formed of a non-photosensitive material having an initial index of refraction. The multimode optical fiber core includes a substantially cylindrical surface, a longitudinal core axis, a core radius, and a number of index-altered portions having an altered index of refraction different from the initial cladding index of refraction. Each of the index-altered multimode optical fiber core has a first transmission surface and second transmission surface that is substantially parallel to the first transmission surface. Also, these index-altered portions are arranged within the non-photosensitive material of the multimode optical fiber core such that the first transmission surface of one portion of the plurality of index-altered portions is substantially parallel to the second transmission surface of a neighboring portion to form a long period Bragg grating structure.

Owner:PANASONIC CORP

Multicore optical fiber with integral diffractive elements machined by ultrafast laser direct writing

InactiveUS7587110B2Optical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingRefractive indexPlastic optical fiber

A multicore optical fiber with an integral diffractive element. The multicore optical fiber includes: a first optical fiber core formed of a non-photosensitive material having an initial index of refraction; and a second optical fiber core including a second longitudinal core axis substantially parallel to the first longitudinal axis. The first optical fiber core includes: a first longitudinal core axis; and a number of index-altered portions having an altered index of refraction which is different from the initial index of refraction. The index-altered portions are arranged within the non-photosensitive material of the first optical fiber core to form a diffractive structure of the integral diffractive element.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

Monolithic capacitive touch screen and preparation method thereof

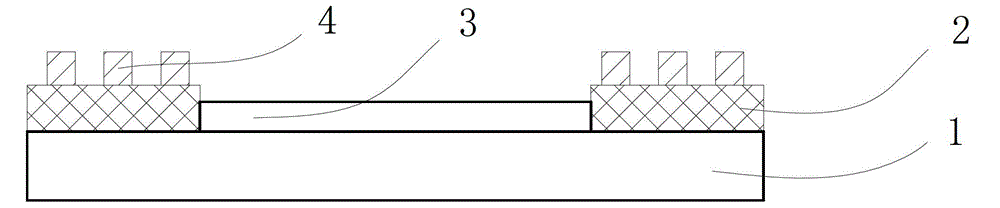

ActiveCN102880369AHigh light transmittanceImprove uniformityInput/output processes for data processingTransmittancePrinting ink

The invention relates to a monolithic capacitive touch screen and a preparation method thereof. The monolithic capacitive touch screen comprises a monolithic substrate (1), a non-window printing ink area (2), a window touch area (3) and a lead area (4), wherein the non-window printing ink area (2) is arranged around on the monolithic substrate (1), and encloses the window touch area (3); the lead area (4) is arranged on the non-window printing ink area (2); and an electrode material of the window touch area (3) is a graphene transparent conductive thin film. According to the preparation method for the touch screen, tampered glass can be favorably manufactured, the strength maintenance capability and stability of the tempered glass are improved, and in addition, the light transmittance and impedance uniformity of a sensing electrode of the touch area can be remarkably improved; and a yellow light preparation process is eliminated, and only laser direct writing etching or a metal mask and reactive ion etching are adopted, so that a manufacturing process is convenient, quick and high in efficiency.

Owner:WUXI GRAPHENE FILM +1

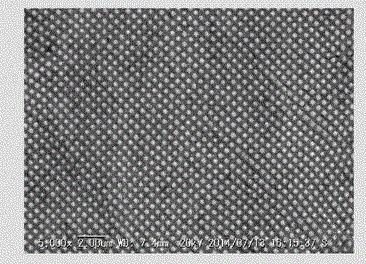

Surface plasma resonance image-forming nanostructure array chip preparation method

ActiveCN101339128AClear edgesImprove uniformityPhase-affecting property measurementsScattering properties measurementsPeriodic nanostructuresEvaporation

The invention relates to a preparation method of nanostructured array chip with surface plasma for resonance imaging. The preparation method is characterized by comprising the following steps: (1) selecting and cleaning a substrate; (2) using a vacuum evaporated coating to coat a first metal film on the substrate; (3) self-assembling a layer of polystyrene nanoparticles on the metal film; (4) coating a second metal film in a way of evaporation on the self-assembled layer so as to fill the gas between balls; (5) eliminating the nanoparticles with the Lift off technology; (6) using laser direct writing machine to manufacture a lattice mask plate of the level of micron; (7) adopting the photolithography to transmit the mask figure to the substrate; (8) acquiring the lattice figure through developing and stripping of photoresist; (9) using a chemical method to eliminate the excessive metal and photoresist; thus the metal lattice chip of the cyclical nanostructure can be formed. The method adopts the polystyrene nanoparticles for self-assembly so as to prepare the cyclical nanostructure, and thus is suitable for massive production of the nanostructure.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

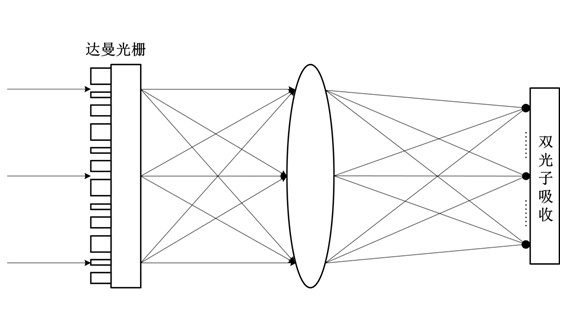

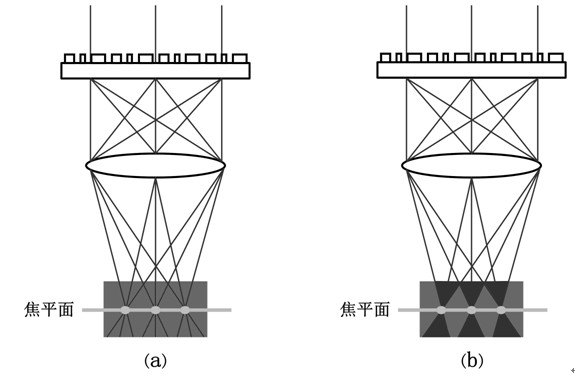

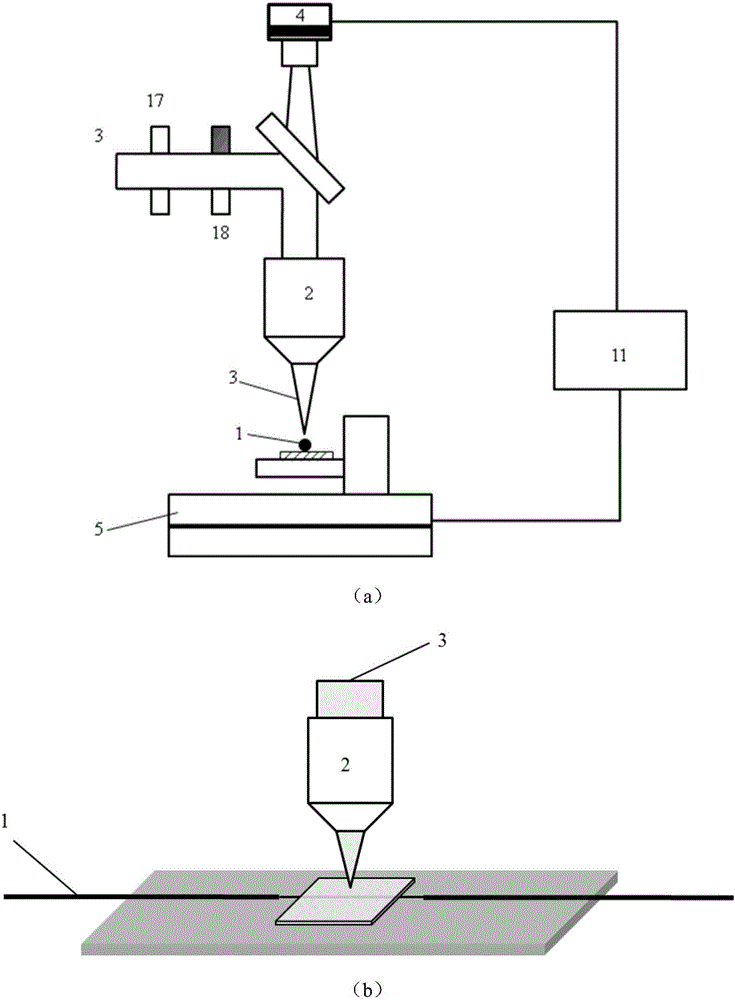

Multi-beam parallel laser direct writing device and method

InactiveCN102621823AAccurate exposure and writingHigh resolutionDiffraction gratingsPhotomechanical exposure apparatusGratingNano structuring

The invention discloses a multi-beam parallel laser direct writing device and a multi-beam parallel laser direct writing method. A Dammann grating beam-splitting device is combined with two-photon absorption, so that the device has the characteristics of high stability and high resolution ratio, a periodic micro-nano structure is easily manufactured, and the processing efficiency can be improved by hundreds of times. The multi-beam parallel laser direct writing device and the multi-beam parallel laser direct writing method are suitable for processing and industrial production of large-area periodic micro-nano optical structures.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

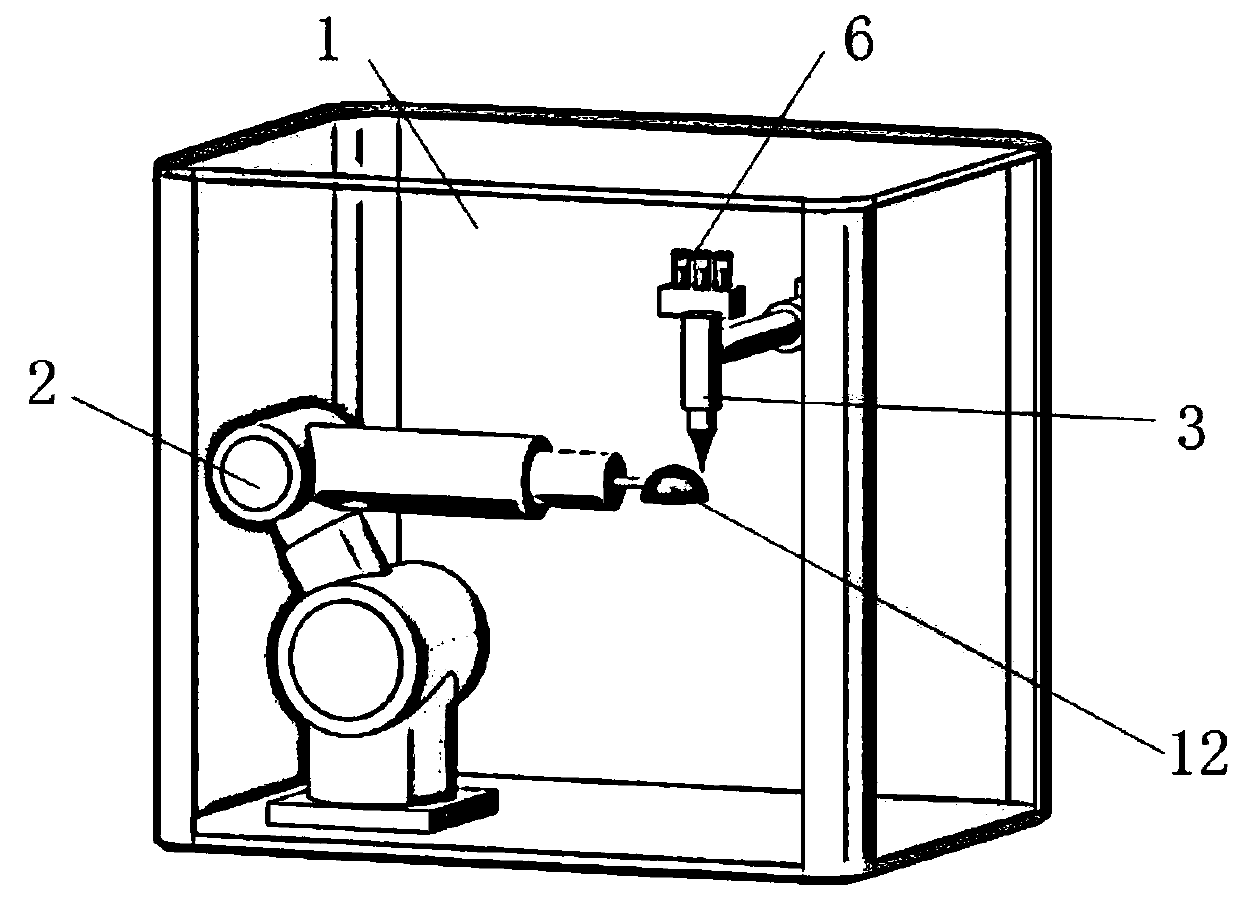

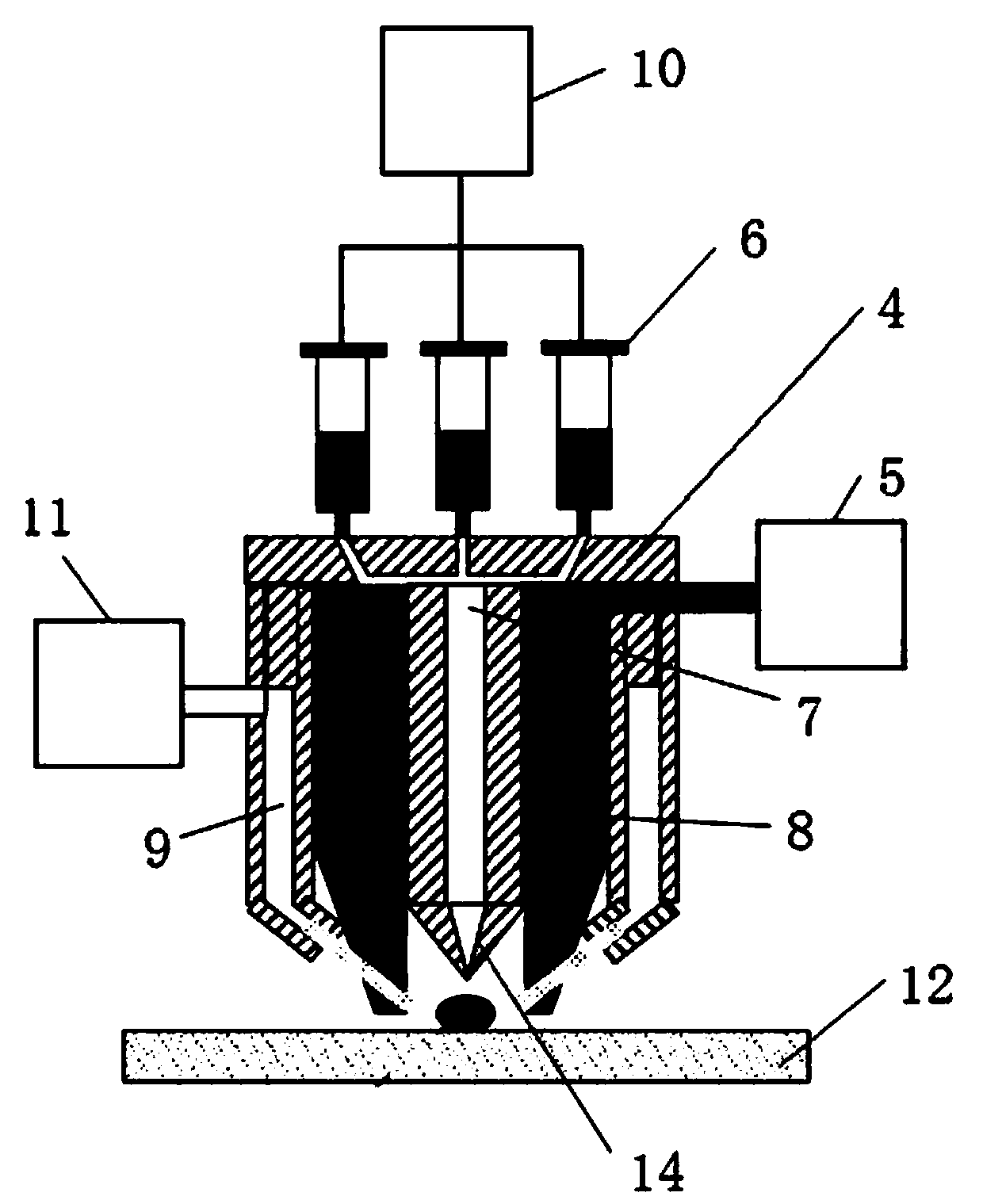

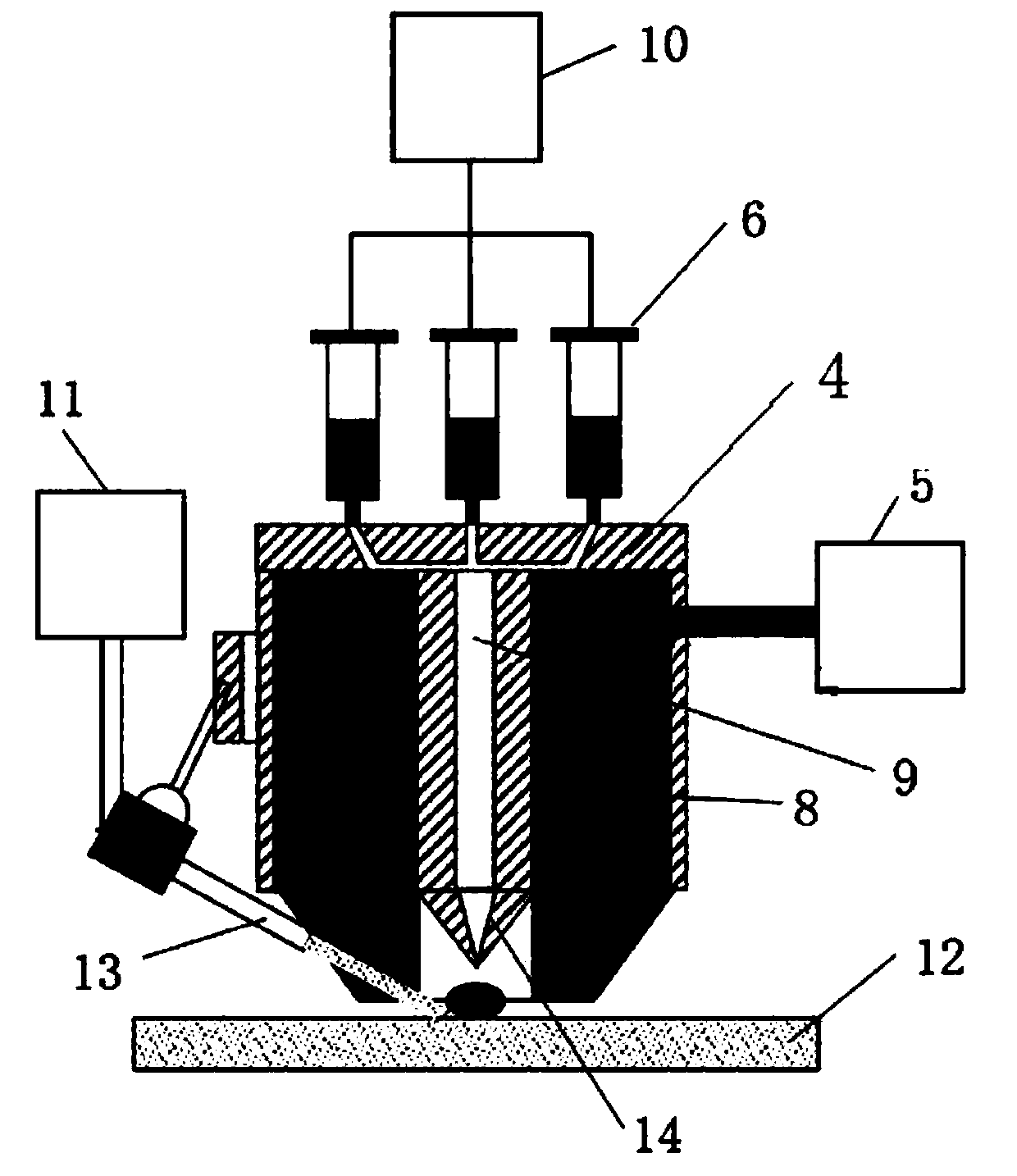

Multi-material laser direct writing conformal system and method

InactiveCN104260360ALarge adjustment rangeHigh repeat positioning accuracyMulti materialControl system

The invention discloses a multi-material laser direct writing conformal system and a method. The system comprises a vacuum seal case, a multi-joint mechanical arm, a multi-material laser direct writing head and a control system for controlling the constituent parts, wherein the mechanical arm and the laser direct writing head are arranged in the vacuum seal case; the laser direct writing head comprises a direct writing head body, a laser and at least two groups of material cylinders; a material channel and a laser focusing channel communicated with the laser and the material cylinders respectively are arranged on the direct writing head body; and the at least two groups of material cylinders are arranged on the direct writing head body in parallel. A particular process is as follows: the mechanical arm drives a workpiece to move along a set path; a material controller selects the corresponding material cylinders; a discharge head delivers and allows materials to be attached to the surface of the workpiece; and at the same time, laser light emitted from the laser focusing channel carries out solidifying or sintering forming on the attached materials. According to the invention, a control process is simple, the forming precision is high, continuous production is achieved, and production efficiency is improved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

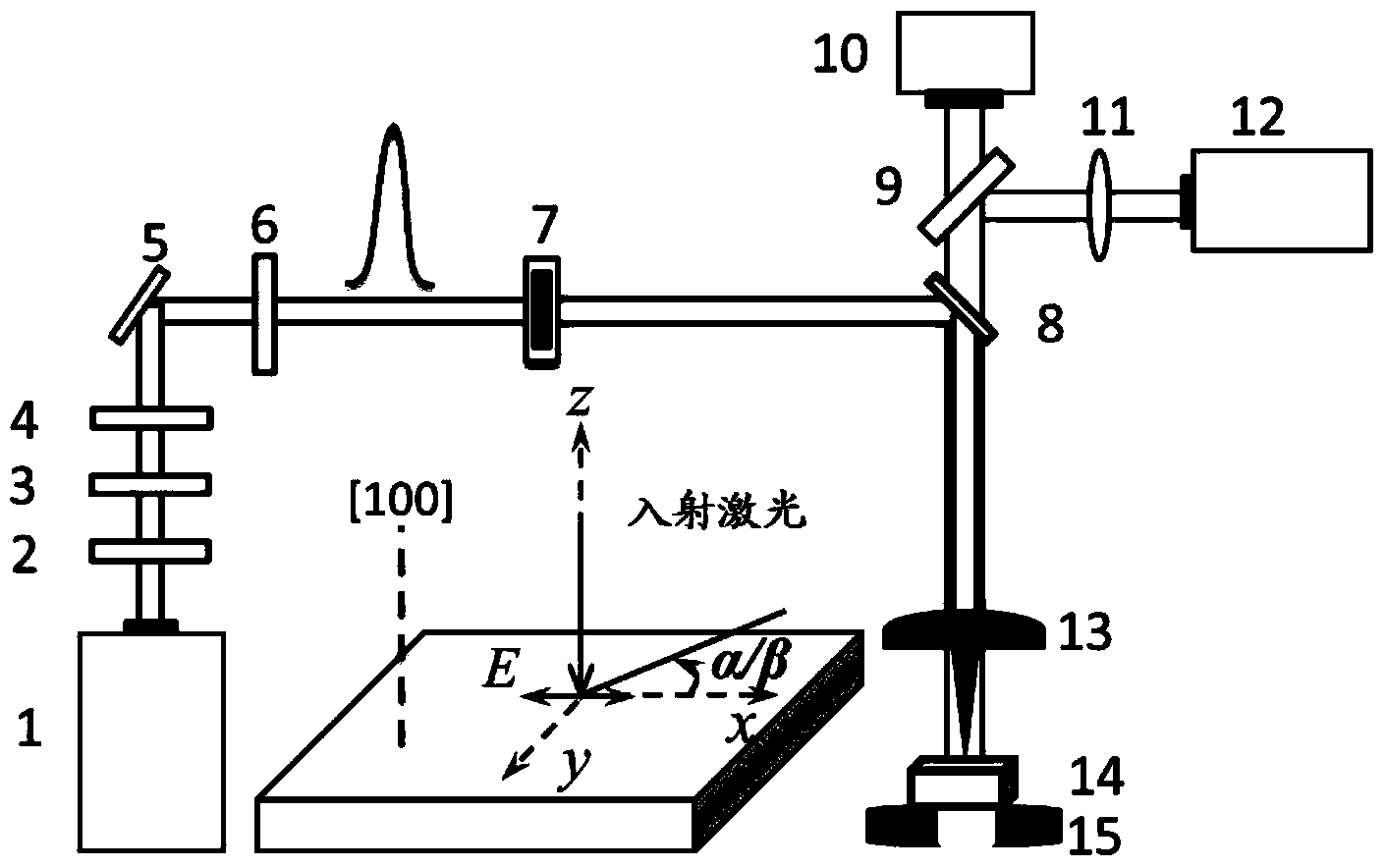

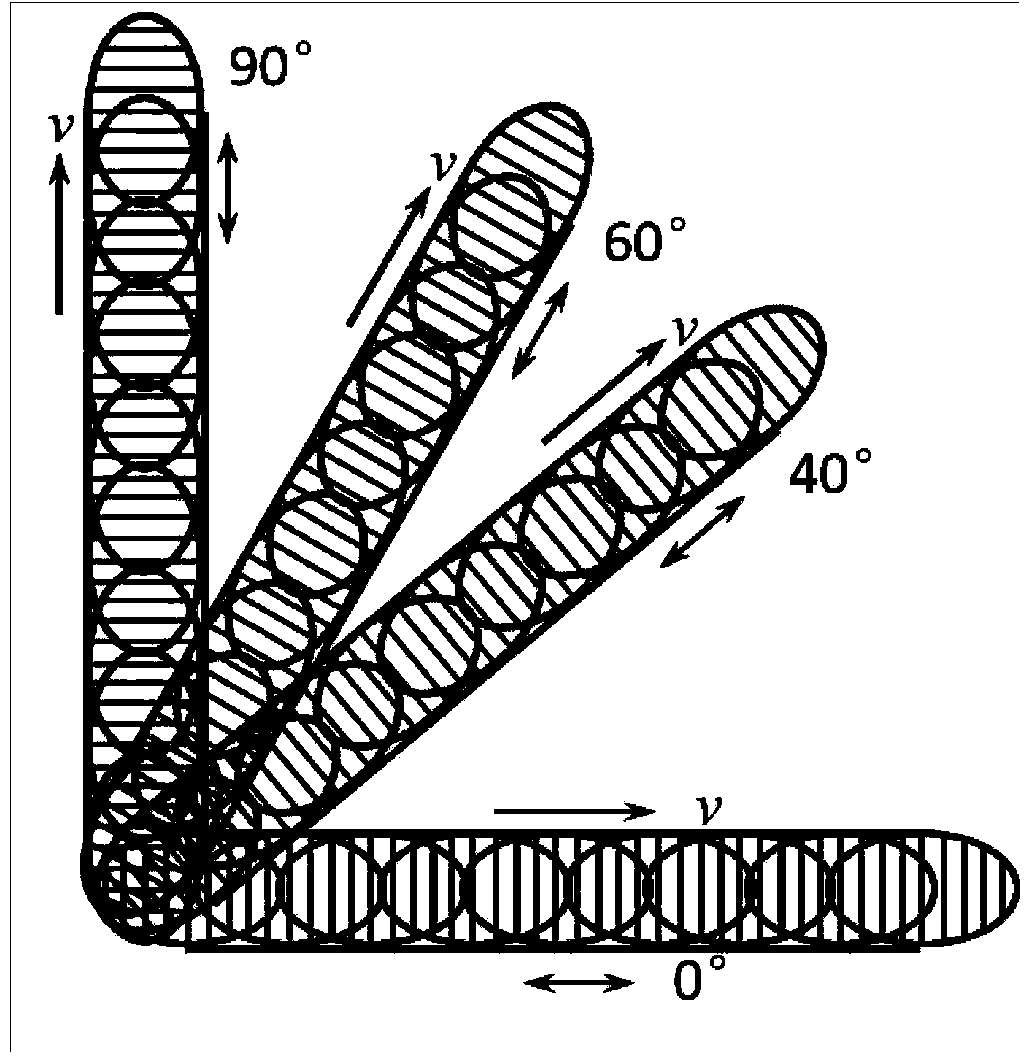

Crystal silicon surface femtosecond laser selective ablation method based on electron dynamic control

ActiveCN103658993AImprove machining accuracyImprove processing efficiencyWelding/soldering/cutting articlesLaser beam welding apparatusMicro nanoNano structuring

The invention relates to a crystal silicon surface femtosecond laser selective ablation method based on electron dynamic control, and belongs to the technical field of femtosecond laser application. The crystal silicon surface femtosecond laser selective ablation method based on the electron dynamic control enables laser polarization parameters and crystal lattice properties of crystal silicon materials to be integrated, through the operation that femtosecond laser rays or the included angel of elliptic polarization and monocrystal silicon is adjusted effectively, the selective induction generation of crystal silicon surface periodical ripple micro nano structures is controlled by regulating and controlling material surface instant electron excitation dynamic states, and the induction generation of the crystal silicon surface periodical ripple micro nano structures can be achieved effectively and accurately according to preliminary design. According to the crystal silicon face femtosecond laser selective ablation method based on the electron dynamic control, selective ablation control is carried out on the silicon surface periodic ripple nano structures with diamond lattice structures from the aspect of static laser irradiation and the aspect of laser direct writing, the processing accuracy and the processing efficiency of the surface processing of the silicon surface periodic ripple nano structures are improved greatly, and the application value of the method on the aspects such as information storage is high.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Clamping-piece-type microfluidic device and manufacturing method

ActiveCN105214747AEasy to purchaseLow costLaboratory glasswaresBiochemical engineeringThermal compression

The invention discloses a clamping-piece-type microfluidic device and a manufacturing method. The clamping-piece-type microfluidic device comprises a cover plate, sealing gaskets, a microfluidic chip assembly and a bottom plate; a sample inlet and a cover plate sealing gasket groove are formed in the cover plate; the microfluidic chip assembly is composed of a laminating film and a microfluidic chip with a microfluidic channel, and a liquid inlet hole, a liquid outlet hole and a positioning hole are formed in the microfluidic chip assembly; the bottom plate is provided with a sample outlet, a bottom plate sealing gasket groove and a positioning column; the sealing gaskets are arranged in the sealing gasket grooves formed in the cover plate and the bottom plate. The manufacturing method comprises an injection molding process method of the cover plate and the bottom plate, a laser direct writing method of the microfluidic chip, a laminating and bonding method of the microfluidic chip assembly and a hot-press assembly method of the microfluidic device. The clamping-piece-type microfluidic device is simple in structure and manufacturing method, low in cost, high in finished product rate and suitable for both one-piece making for laboratory scientific research and commercial mass production.

Owner:SOUTHEAST UNIV

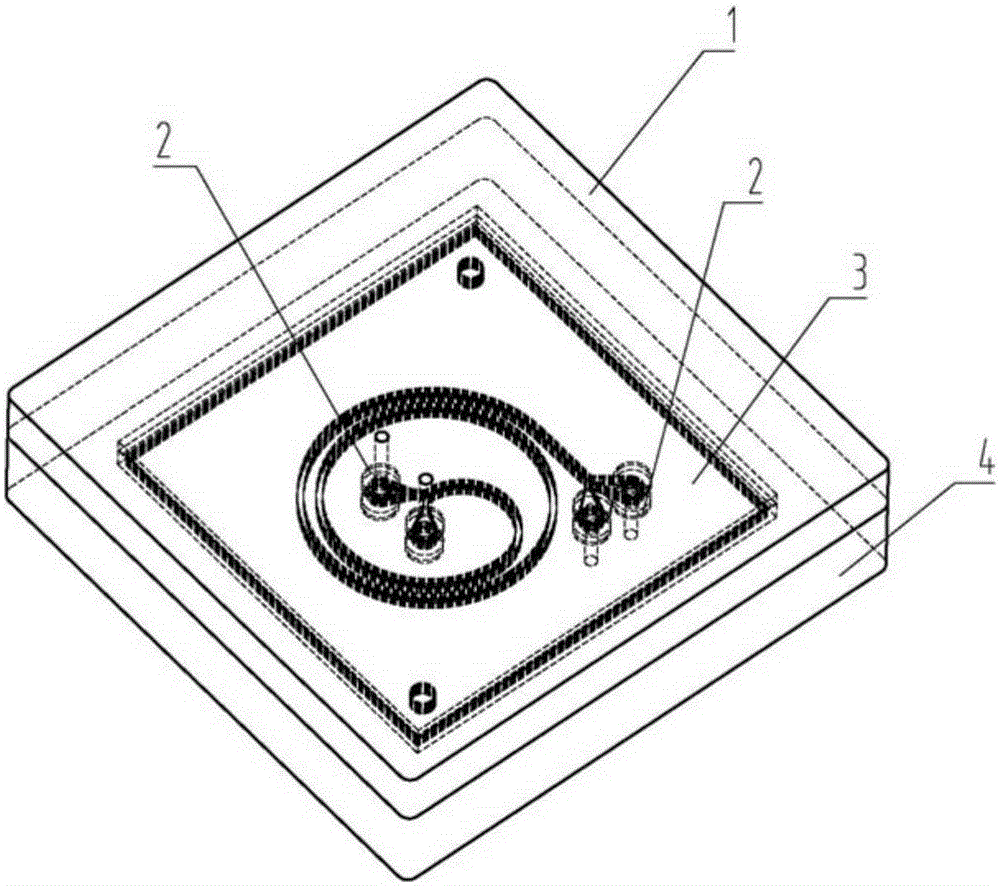

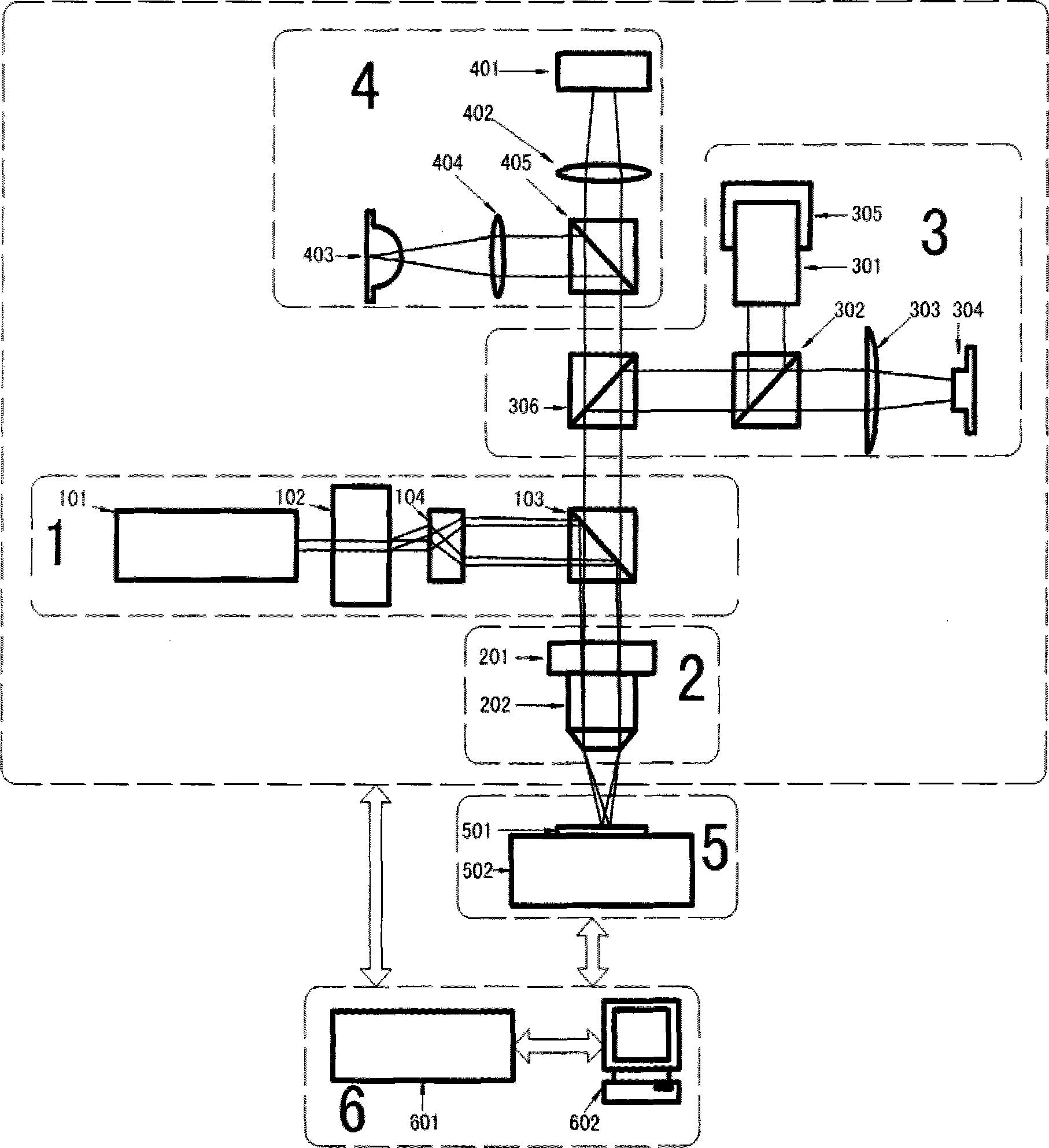

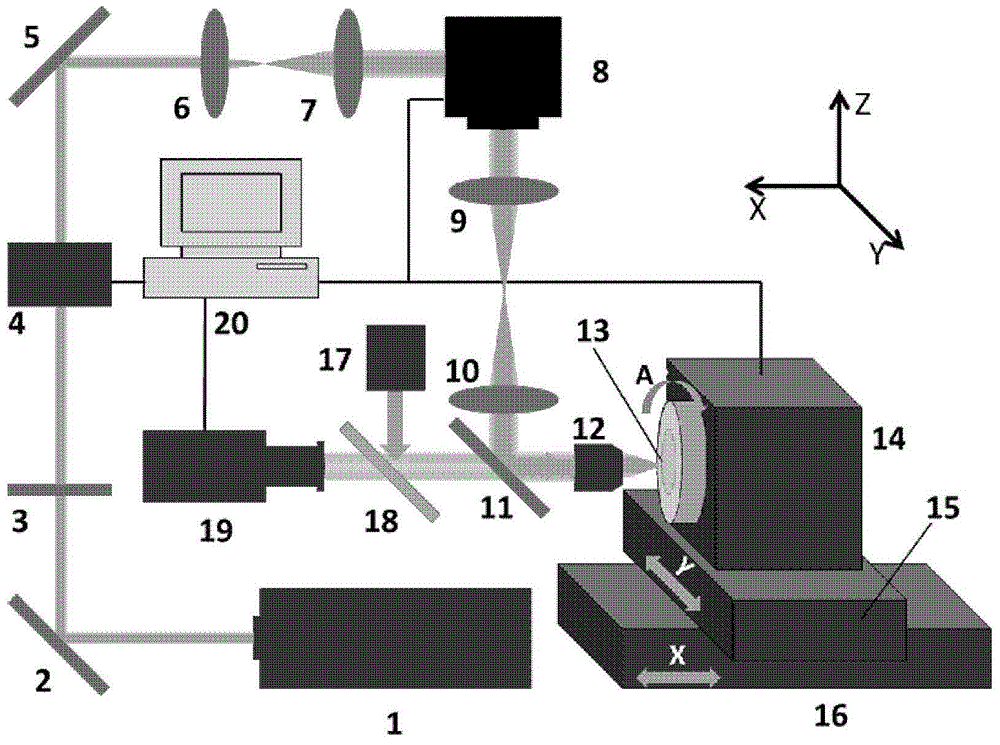

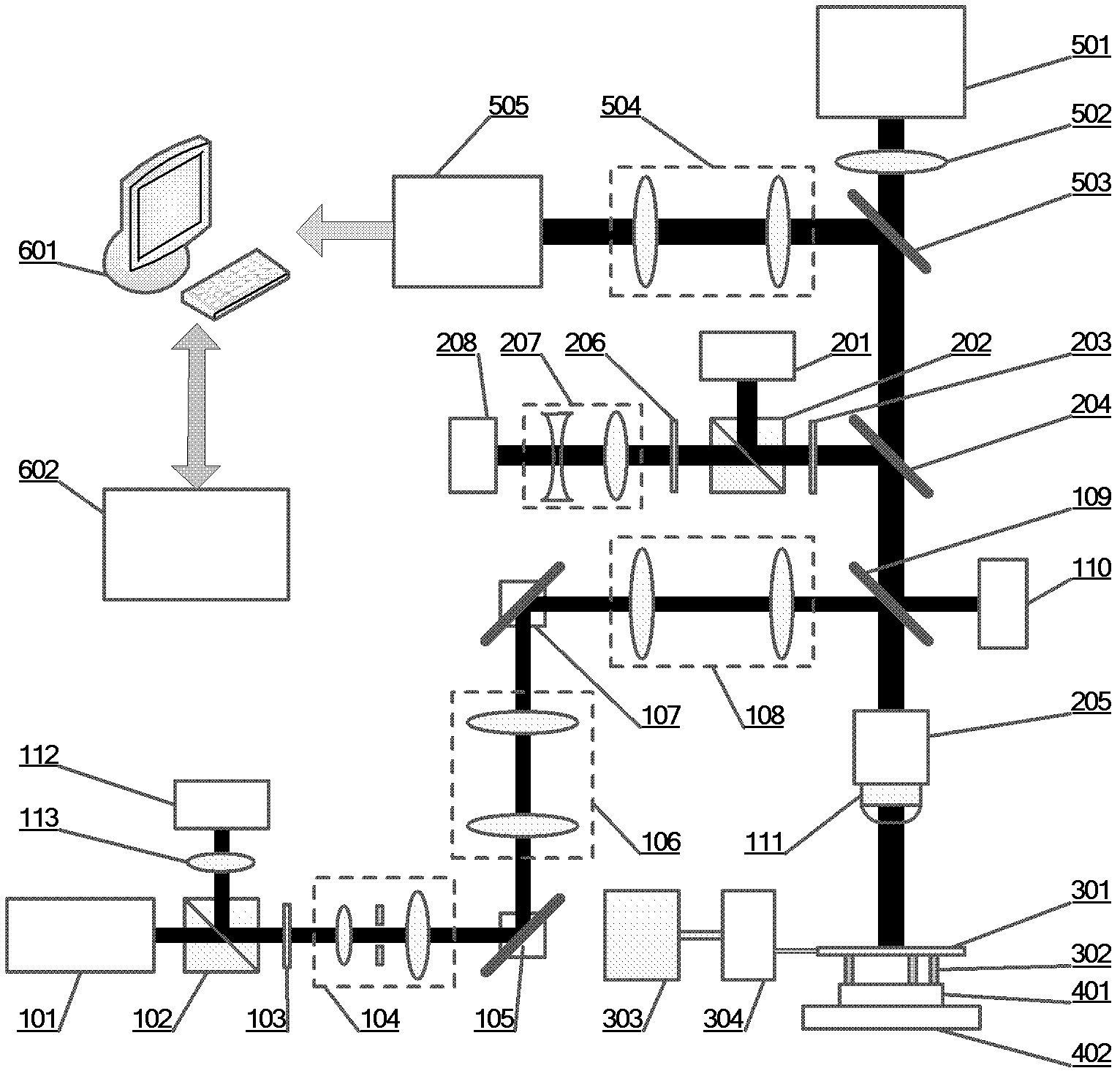

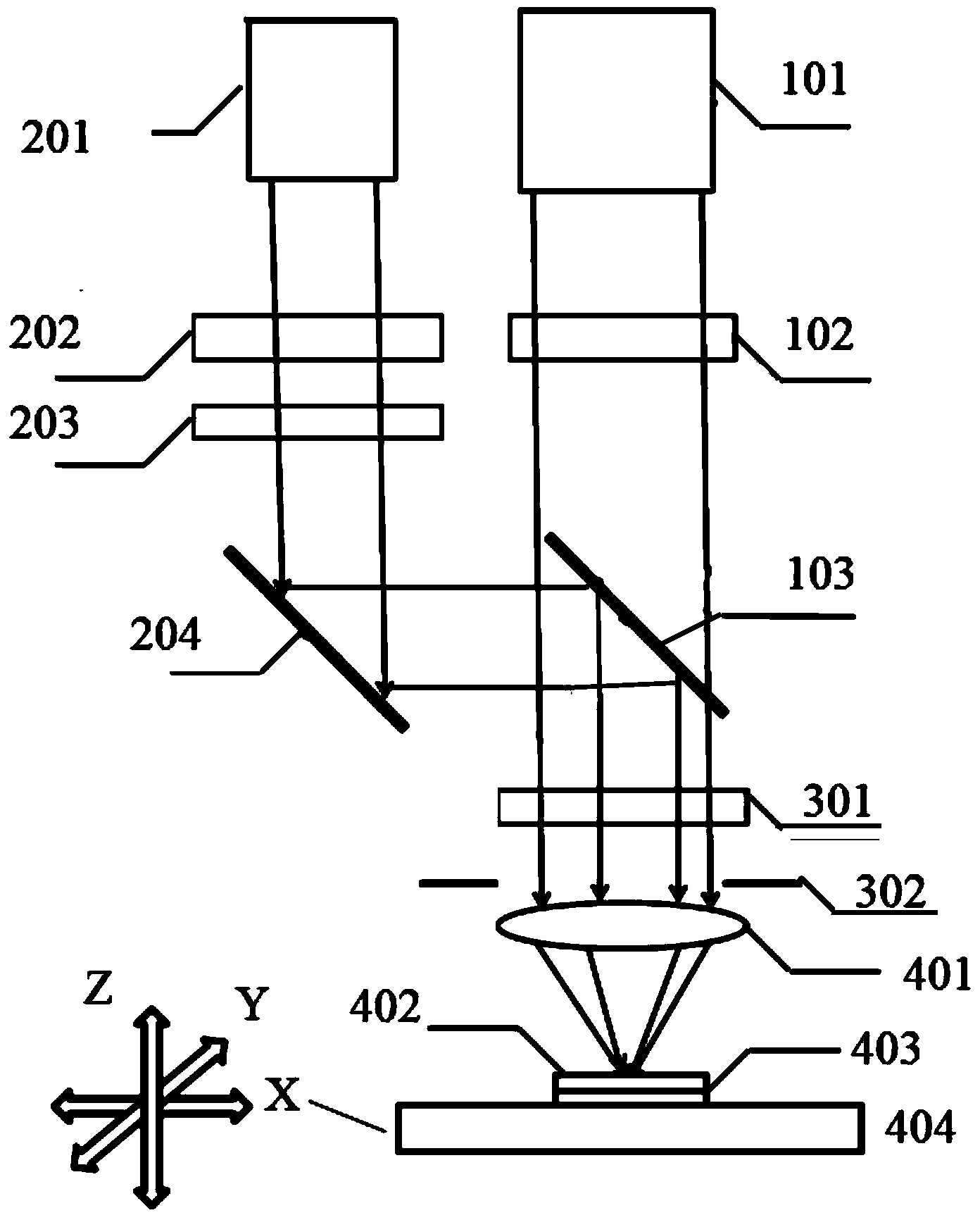

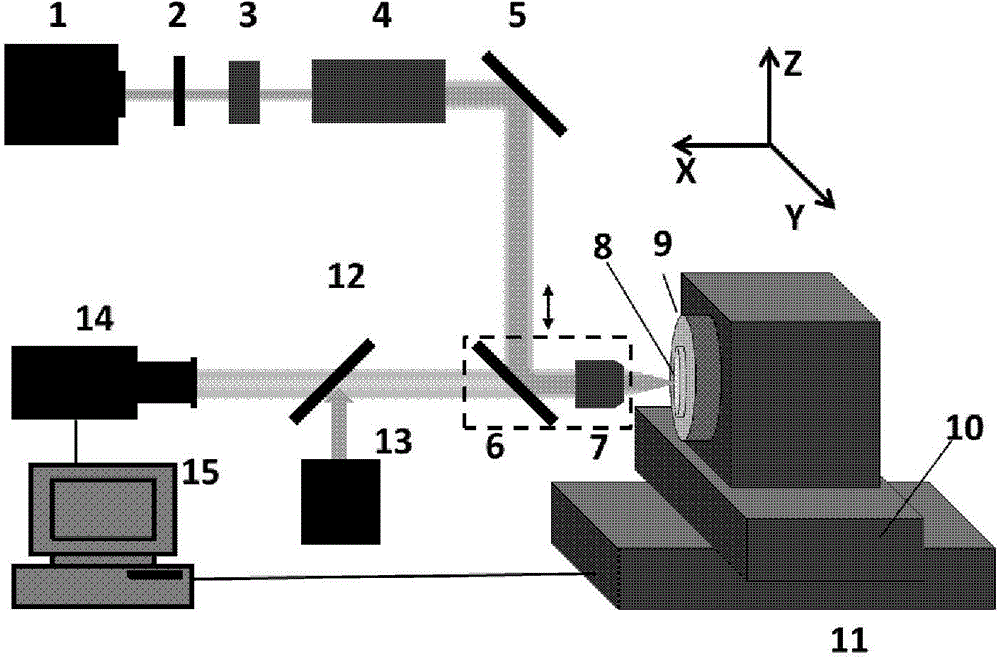

High-speed multi-beam parallel laser direct-writing device

ActiveCN101477306AImprove writing speedThe Impact of Clothing ClipsPhotomechanical exposure apparatusMicrolithography exposure apparatusMicro nanoLight beam

The invention provides a high-speed multi-beam parallel laser direct-writing device applying to micro-nano processing. The device consists of an inscribing light source modulation module, an inscribing optical header, an out-of-focus detection module, an illuminating and monitoring module, a sample displacement table and a master control module. The device greatly improves inscribing speed by multi-beam laser parallel high-speed inscribing. A multi-beam inscribing sub-system can be combined with sample tables with different motion modes to form inscribing devices with different functions according to the requirement of actual application.

Owner:安徽中科春谷激光产业技术研究院有限公司

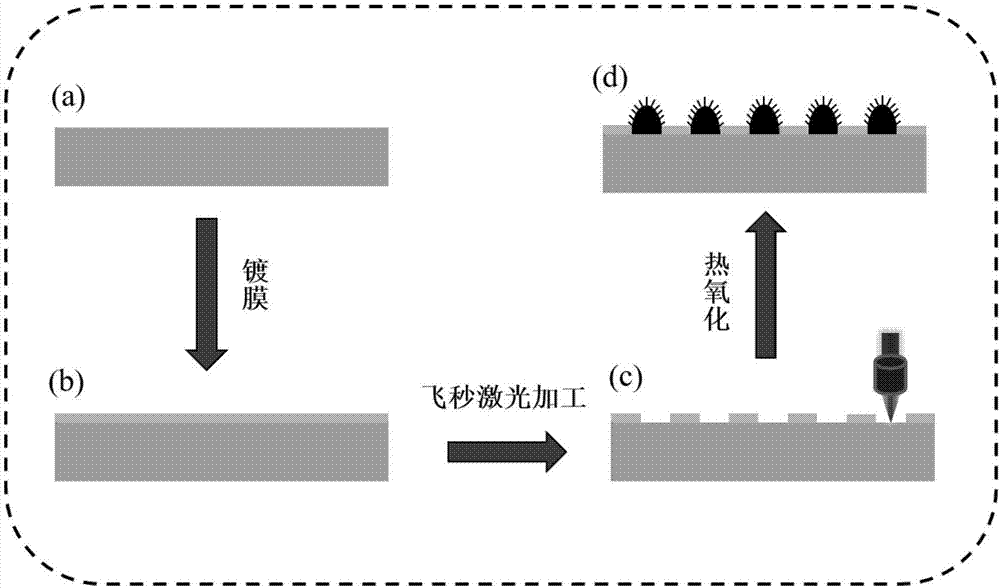

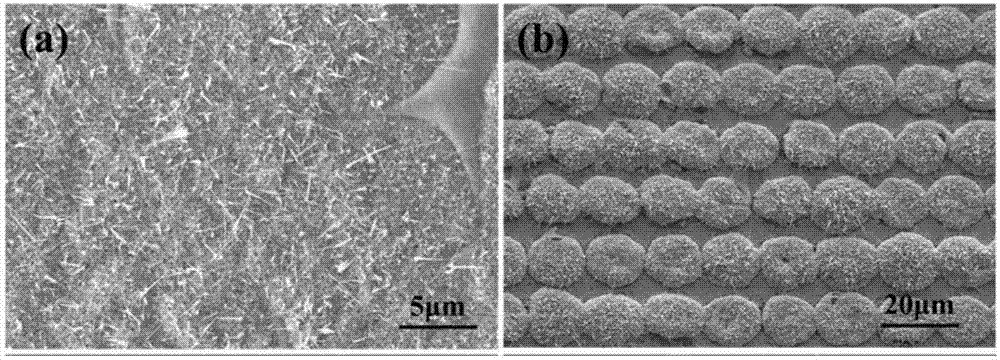

Maskless femtosecond laser manufacturing method for super-hydrophobic and anti-reflective surface

ActiveCN107243697ALow costExcellent superhydrophobicityVacuum evaporation coatingSputtering coatingFemto second laserEvaporation

The invention relates to a maskless femtosecond laser manufacturing method for a super-hydrophobic and anti-reflective surface and belongs to the field of preparation of super-hydrophobic and anti-reflective materials. The maskless femtosecond laser manufacturing method for the super-hydrophobic and anti-reflective surface comprises the following steps that (1) a copper substrate is plated with a film of a nanometer thickness through electron beam evaporation or a magnetron sputtering coating method; (2) through a femtosecond laser direct writing method, patterning is conducted on the copper substrate plated with the film of the nanometer thickness, and the shape of patterning can be controlled through a program; (3) a heating device is used for conducting thermal oxidation treatment on the substrate obtained after femtosecond laser patterning, and then a micro-nanometer composite structure is prepared. Compared with the prior art, the maskless femtosecond laser manufacturing method for the super-hydrophobic and anti-reflective surface has the advantages that the manufacturing process does not need a vacuum device or an optical mask, and the manufactured substrate is controllable in shape and has the super-hydrophobic performance, the self-cleaning performance, the anti-reflective performance and other performances.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

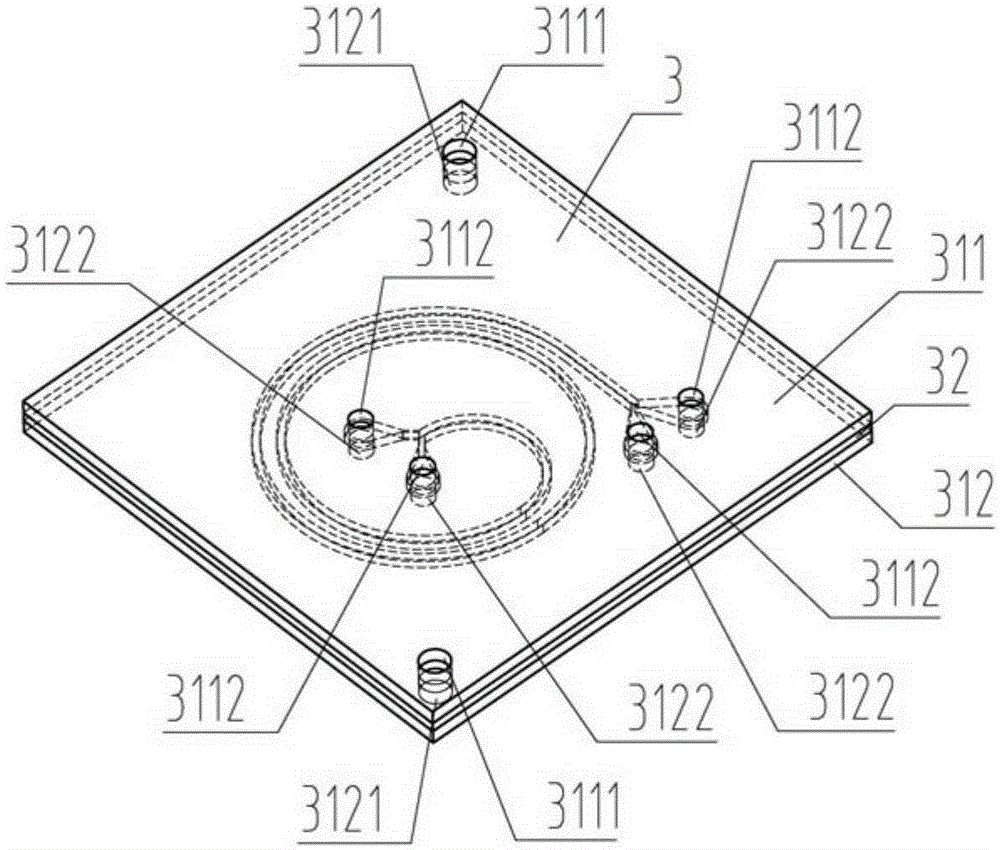

Rotating table type femtosecond laser direct writing method and device

The invention discloses a rotating table type femtosecond laser direct writing device. The rotating table type femtosecond laser direct writing device comprises a femtosecond laser source, a laser path, an X-Y axis two-dimension translation table, a rotating table and a controller, wherein the laser path is provided with a laser modulator, a two-dimension laser scanning galvanometer and a microobjective, after being modulated by the laser modulator, laser beams from the femtosecond laser source pass through the two-dimension laser scanning galvanometer to be projected onto a machined workpiece through the microobjective; the rotating table is arranged on the X-Y axis two-dimension translation table, a rotating shaft of the rotating table is aligned with a direct writing light axis, the table face of the rotating table is perpendicular to the direct writing light axis, and the machined workpiece is fixed onto the table face of the rotating table, and the controller is constructed into a form capable of controlling the laser beams incoming onto the machined workpiece through the laser path and the operation of the X-Y axis two-dimension translation table and the rotating table.

Owner:JILIN UNIV

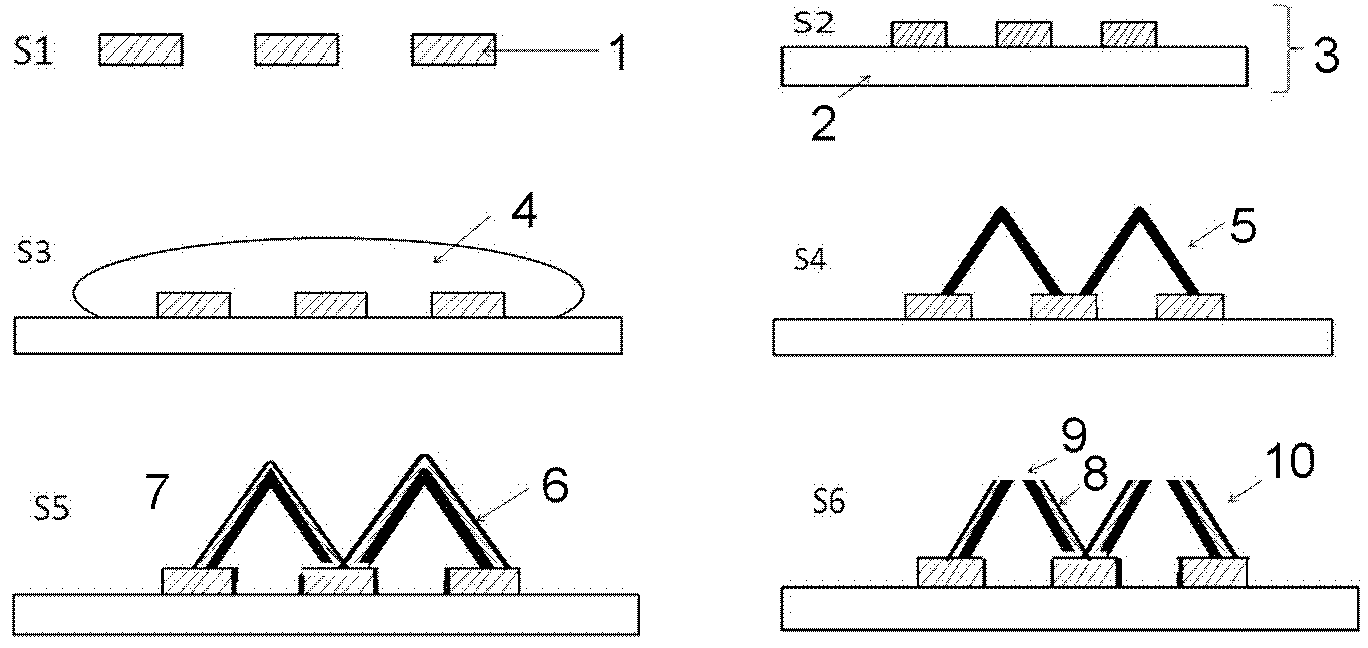

Method for preparing three-dimensional hollow micro nanometer functional structure by utilizing laser direct writing

ActiveCN103011058AEliminate the effects ofReduce processing difficultyDecorative surface effectsPhotomechanical apparatusNanostructureNanometre

Te invention discloses a method for preparing a three-dimensional hollow micro nanometer functional structure by utilizing laser direct writing. The method is used for obtaining a three-dimensional micro nanometer functional structure through surface functionalization. The method comprises the following steps of: selecting and processing a hollow substrate, and placing a hollow substrate on an object carrying support foundation base; titrating a photoresist on the object carrying support foundation base of the hollow substrate, and preparing a laser direct writing photoresist polymeric compound three-dimensional hollow micro nanometer structure; and carrying out surface functionalization of the photoresist polymeric compound three-dimensional hollow micro nanometer structure, carrying out ornament and treatment on the three-dimensional hollow micro nanometer functional structure, thereby obtaining a finished product. The method provided by the invention can be used for preparing photoresist polymeric compound hollow three-dimensional micro nanometer structures with different heights, side lengths and cross-section geometrys on the hollow substrate based on a two-photon polymerization, and then the functionalization of the photoresist polymeric compound hollow three-dimensional micro nanometer structure is realized through growth and ornament treatment of a functionalization material, and the method has the characteristics of complex picture batch, reiteration design and controllable preparation of any complex picture.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

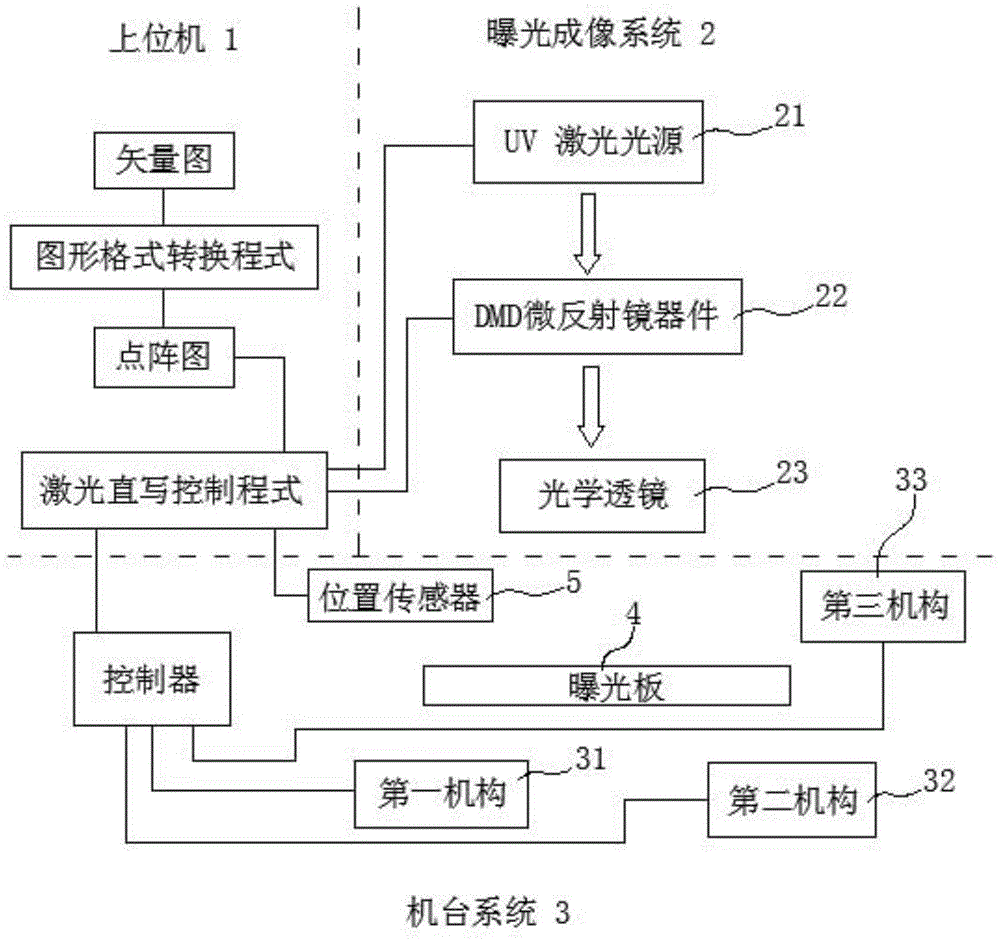

Synchronous pulse exposure method for maskless lithography equipment and digital laser direct-writing system

InactiveCN104865800AExtend effective lifeImprove and increase contrastPhotomechanical exposure apparatusMicrolithography exposure apparatusUv laserDigital micro mirror device

The invention provides a synchronous pulse exposure method for maskless lithography equipment. The maskless lithography equipment adopts an exposure imaging system consisting of a UV (ultraviolet) laser or UV LED light source, a DMD (digital micro-mirror device) and an optical lens; the synchronous pulse exposure method is characterized in that a series of pulse synchronization signals are generated, the DMD and the UV laser or UV LED light source are triggered to synchronously work, and the pulse interval of the pulse synchronization signals depends on the replacement or refreshing cycle of the DMD to graphs; a digital laser direct-writing system comprises an upper computer in charge of outputting digital lattice patterns and the series of pulse synchronization signals to the exposure imaging systems, and one or more exposure imaging systems arranged side by side. According to the method, a synchronous control problem of parts of the lithography equipment is solved, more effective and reasonable exposure and refreshing time is convenient to design, and the shortcomings of low production capacity and poor system adaptability of a conventional exposure machine are overcome.

Owner:ZHONGSHAN AISCENT TECH

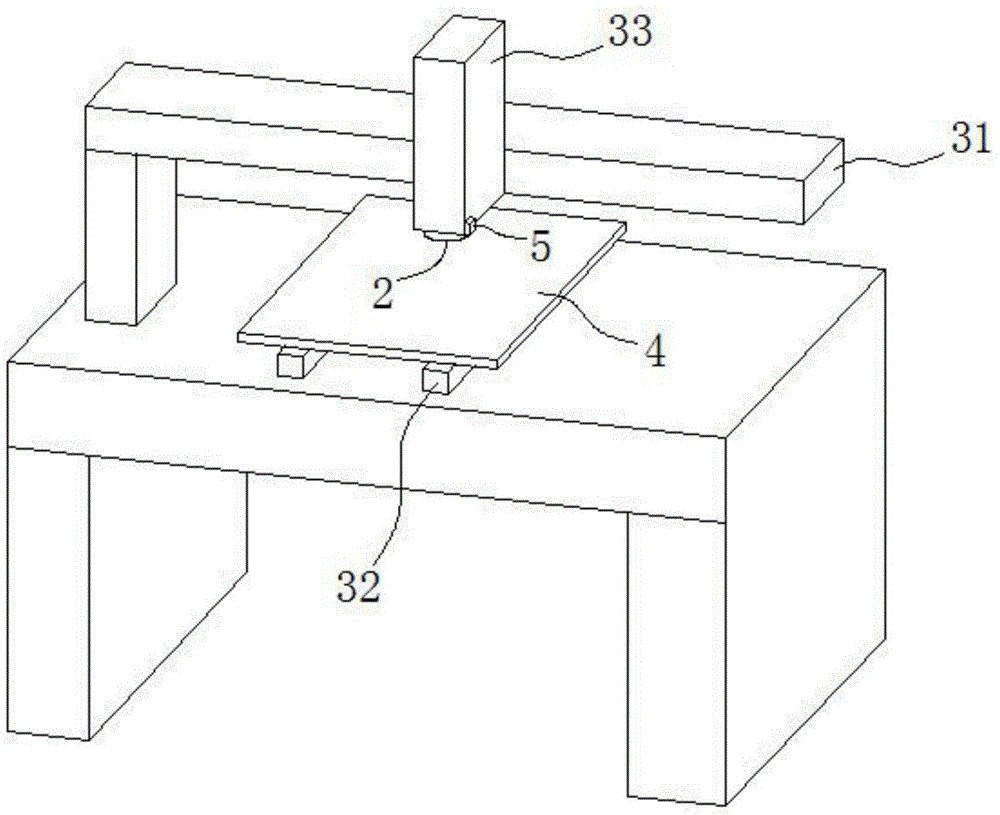

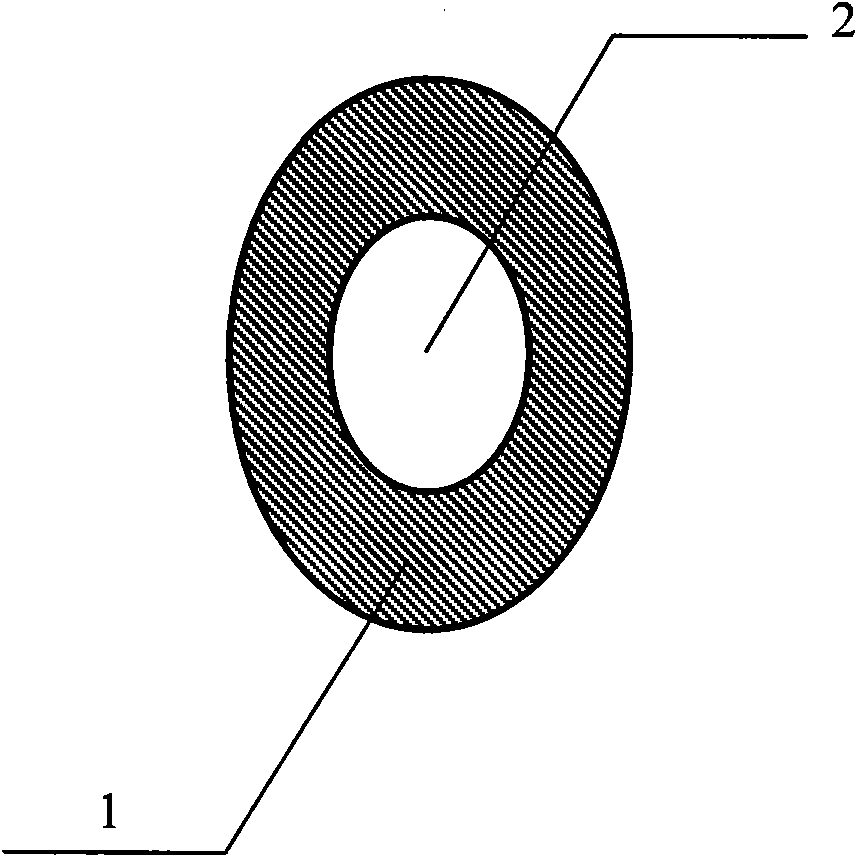

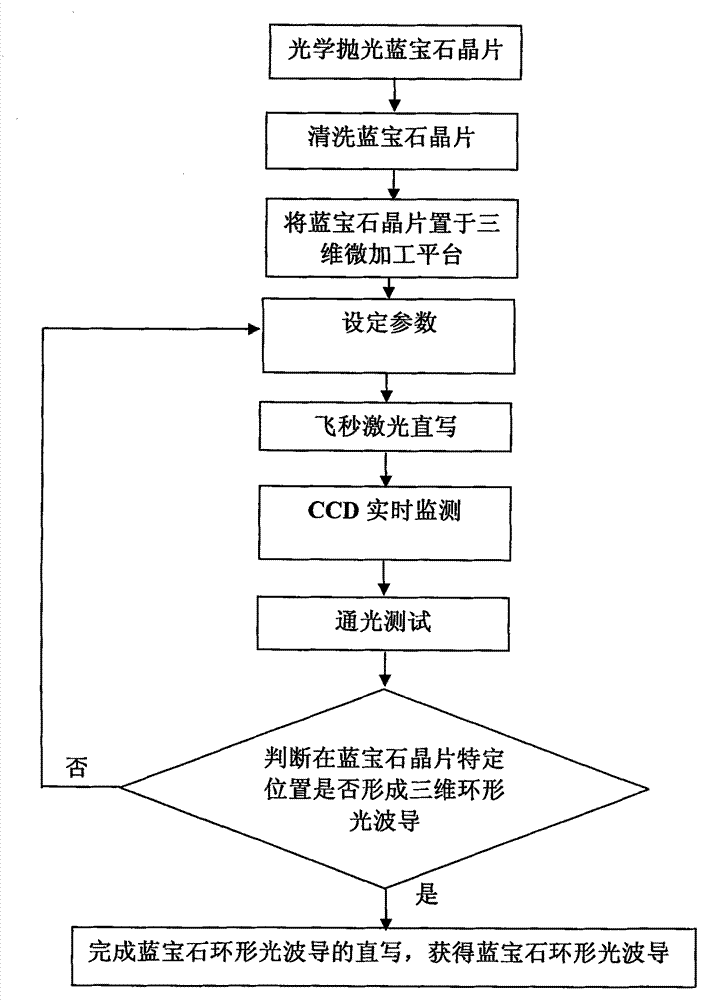

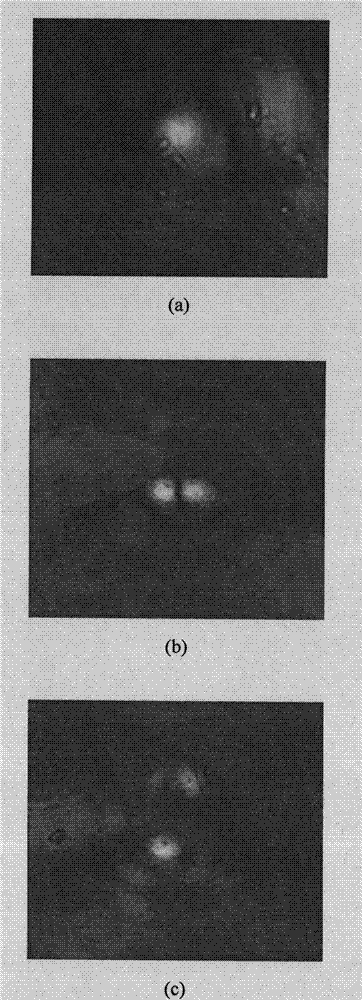

Femtosecond laser direct writing sapphire ring light guide and preparation method thereof

InactiveCN103399377AImprove corrosion resistanceHigh temperature resistantOptical waveguide light guideLaser beam welding apparatusLight guideDirect writing

The invention discloses a femtosecond laser direct writing sapphire ring light guide and a preparation method thereof. A cross section of the prepared femtosecond laser direct writing sapphire ring light guide is elliptic, a light guide part thereof is in a shape of a three-dimensional ring, which is close to a femtosecond laser acting region, and the outer circle of the ring is 200nm from the femtosecond laser acting region. The preparation method comprises the following steps of (1) optically polishing a sapphire wafer; (2) cleaning the sapphire wafer; (3) placing the sapphire wafer on a three-dimensional micromachining platform; (4) setting parameters; (5) carrying out femtosecond laser direct writing; (6) carrying out real-time monitoring through a CCD; (7) carrying out a light pass test; (8) judging whether a three-dimensional ring light guide is formed at a specific position of the sapphire wafer; (9) completing direct writing of the sapphire ring light guide so as to obtain the sapphire ring light guide. The invention is used for transmitting light signals in the environment with ultra-high intensity and ultra-high temperature, and the prepared ring light guide of micron dimension is further used for integration of an optical system.

Owner:XIDIAN UNIV

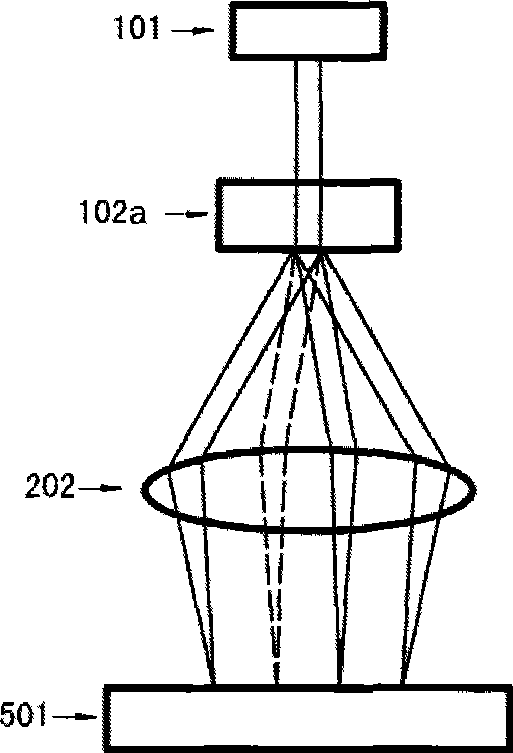

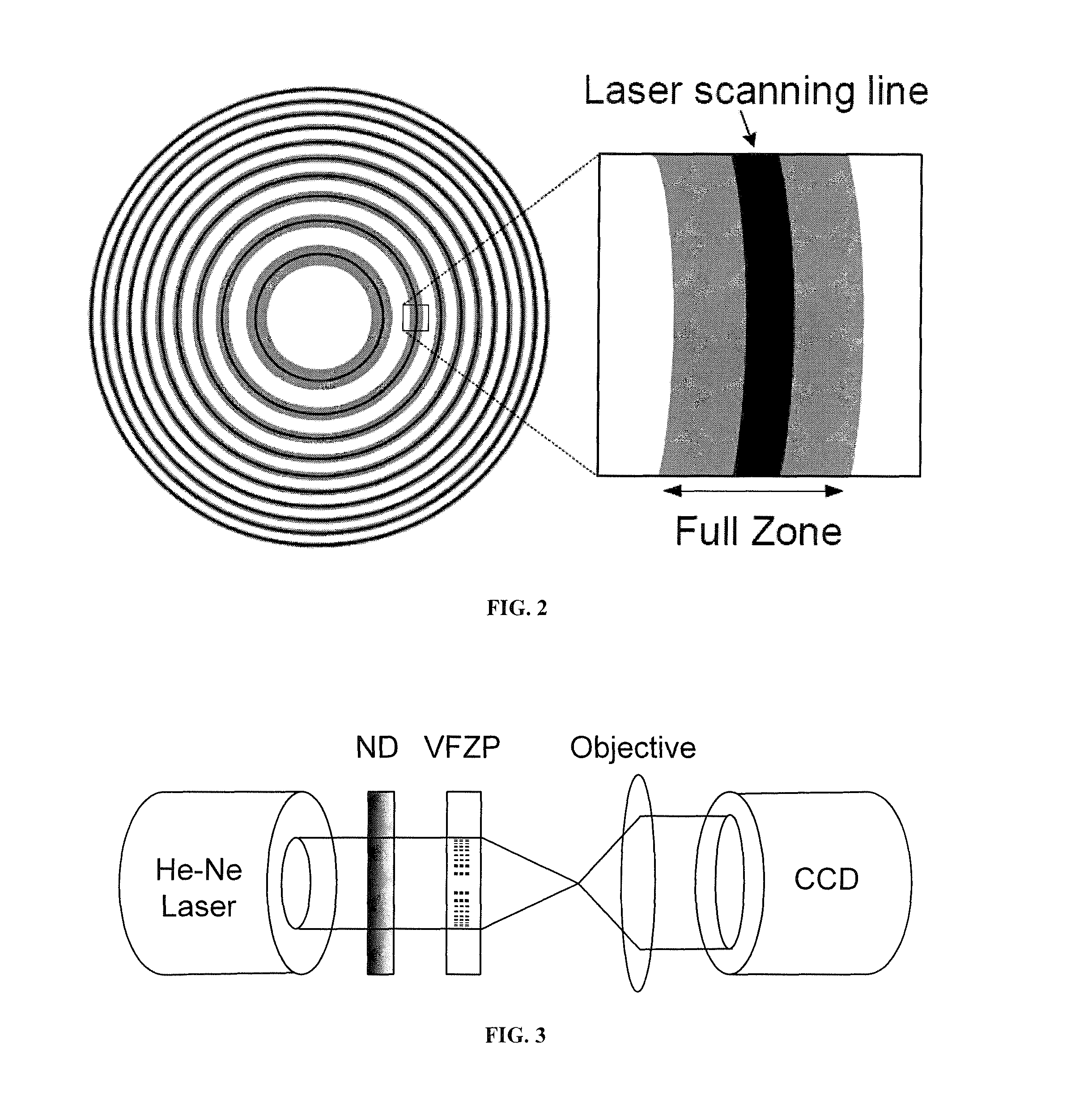

Volume Fresnel zone plates fabricated by laser direct writing

ActiveUS7969654B1High diffraction efficiencyOptical articlesOptical elementsDirect writingNumerical aperture

A volume Fresnel zone plate and a method of producing such a device using a femtosecond laser for direct writing of zone plates. A volume zone plate has a number of Fresnel zone plate layers designed to focus light coherently to a single spot. Embodiments include both low numerical aperture (NA) and high NA zone plates, and provide a significant increase in overall diffraction efficiency over a single Fresnel zone plate.

Owner:PURDUE RES FOUND INC

Laser processing device with linear array optical lens assembly with micro cylindrical lenses in cylindrical distribution

InactiveCN105750729AImprove processing efficiencyLaser beam welding apparatusOptical elementsCamera lensMicro nano

The invention relates to a laser processing device with a linear array optical lens assembly with micro cylindrical lenses in cylindrical distribution, and belongs to the technical field of laser processing. A conventional laser direct writing micro-nano processing method is low in processing efficiency. The laser processing device disclosed by the invention is characterized in that a laser source, a collimating beam expanding mirror, a beam shaping mirror, a biconcave lens, and the linear array optical lens assembly with micro cylindrical lenses in cylindrical distribution are sequentially, optically and coaxially arrayed; the beam shaping mirror is used for shaping laser beams with round light spots and light energy in gaussian distribution into laser beams with square light spots and light energy in uniform distribution; the linear array optical lens assembly with micro cylindrical lenses in cylindrical distribution adopts the structure that a plurality of micro cylindrical lenses are arrayed on a convex cylindrical mirror surface of a plano-convex cylindrical mirror and parallel to a cylindrical generatrix, besides, the diameters of the micro cylindrical lenses are gradually increased from the micro cylindrical lens positioned at the highest point of the convex cylindrical mirror surface to the micro cylindrical lens positioned at the lowest point of the convex cylindrical mirror surface, and symmetrical surfaces of a bar-shaped wedge-shape laser beam emitted from each micro cylindrical lens are mutually parallel; the plane mirror of the plano-convex cylindrical mirror faces towards the biconcave lens.

Owner:CHANGCHUN UNIV OF SCI & TECH

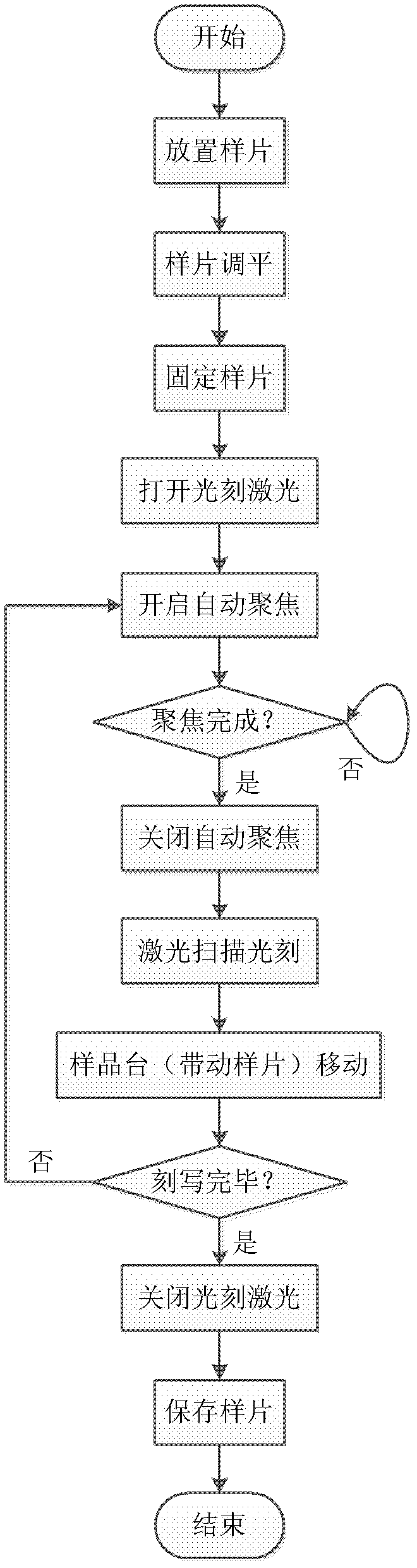

Galvanometer type laser direct writing photoetching machine

ActiveCN102495534AEasy to operateImprove writing speedPhotomechanical exposure apparatusMicrolithography exposure apparatusGalvanometerModular design

A galvanometer type laser direct writing photoetching machine adopts the modular design, and is composed of a laser scanning module, an automatic focusing module, a sample table module, a displacement table module, a sample wafer monitoring module and a control module. By adopting double-galvanometer laser scanning and a wide-range two-dimensional displacement table, the galvanometer type laser direct writing photoetching machine can achieve high-speed wide-range high-precision laser direct writing photolithography, and suitable for rapid and economic manufacture of micronano structures.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

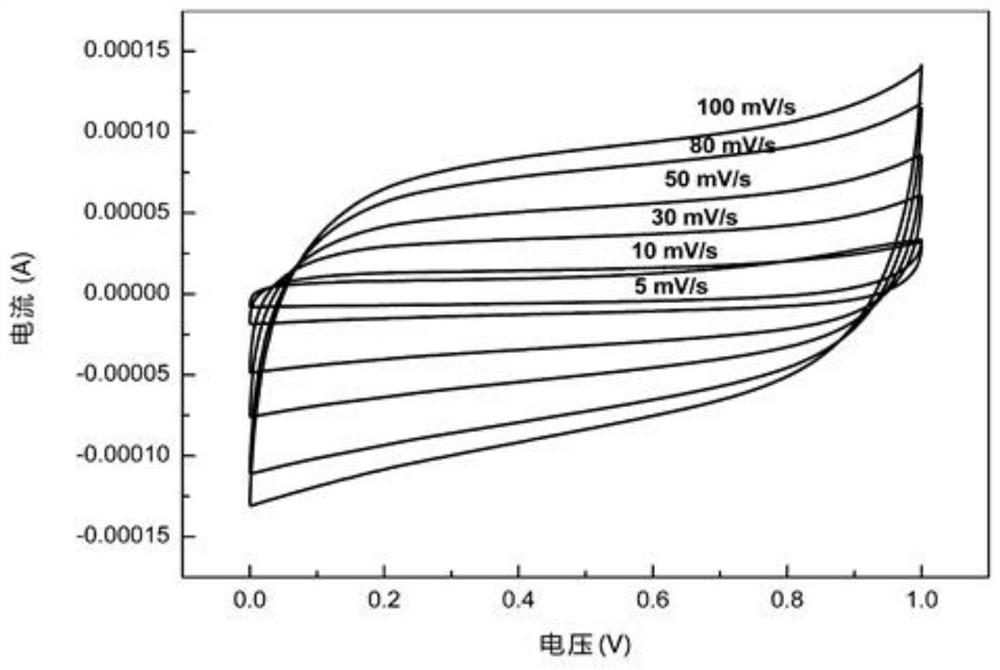

Preparation method of self-powered electronic skin system based on laser reduced graphene/MXene composite material

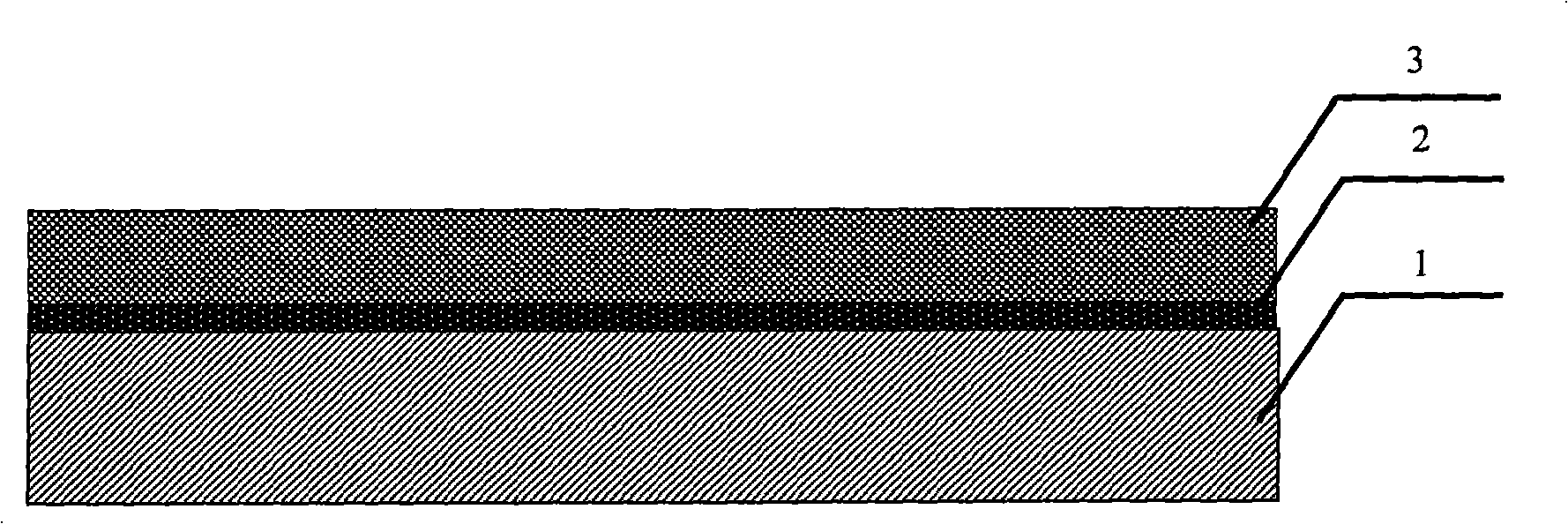

ActiveCN111759315AThe production process is simple and safeHybrid capacitor electrodesDiagnostic recording/measuringComposite filmComposite electrode

The invention discloses a preparation method of a self-powered electronic skin system based on a laser reduced graphene / MXene composite material. The preparation method comprises the following steps:S1, preparing a graphene oxide / MXene mixed solution; S2, uniformly coating a flexible substrate with the graphene oxide / MXene mixed solution prepared in the step S1 to obtain a high-density flexible graphene oxide / MXene composite film; S3, obtaining a patterned laser reduced graphene / MXene composite electrode from the high-density flexible graphene oxide / MXene composite film obtained in the step S2 by a laser direct writing technology. According to the technical scheme, the laser reduced graphene / MXene patterned composite electrode is prepared by the laser direct writing technology after low-cost graphene oxide and an MXene solution are mixed, and the laser reduced graphene / MXene patterned composite electrode is used as a sensing and energy storage material, so that a multifunctional passive self-powered electronic skin system is designed.

Owner:NANJING UNIV OF POSTS & TELECOMM

Method for preparing phase shift optical fiber bragg grating based on femtosecond laser direct writing

ActiveCN106291802AEasy to operatePrecise length controlCladded optical fibreOptical waveguide light guideGratingPhase shifted

The invention provides a method for preparing phase shift optical fiber bragg grating based on femtosecond laser direct writing. The method comprises the following steps: performing fixed point radiation or scanning in a fiber core area of the optical fiber bragg grating of an ordinary structure by using focused femtosecond laser, forming one or more areas with changed refractive indexes in the fiber core area of the optical fiber bragg grating of the ordinary structure, and forming a phase shift structure, thereby obtaining the phase shift optical fiber bragg grating. Compared with the prior art, the method is relatively simple in processing procedure, high in processing speed and applicable to optical fiber of different materials, and precision control of phase shift within 0-2pi can be achieved. The phase shift optical fiber bragg grating prepared by using the method provided by the invention can be applied to fields of sensation, optical fiber laser and the like.

Owner:XI AN JIAOTONG UNIV +1

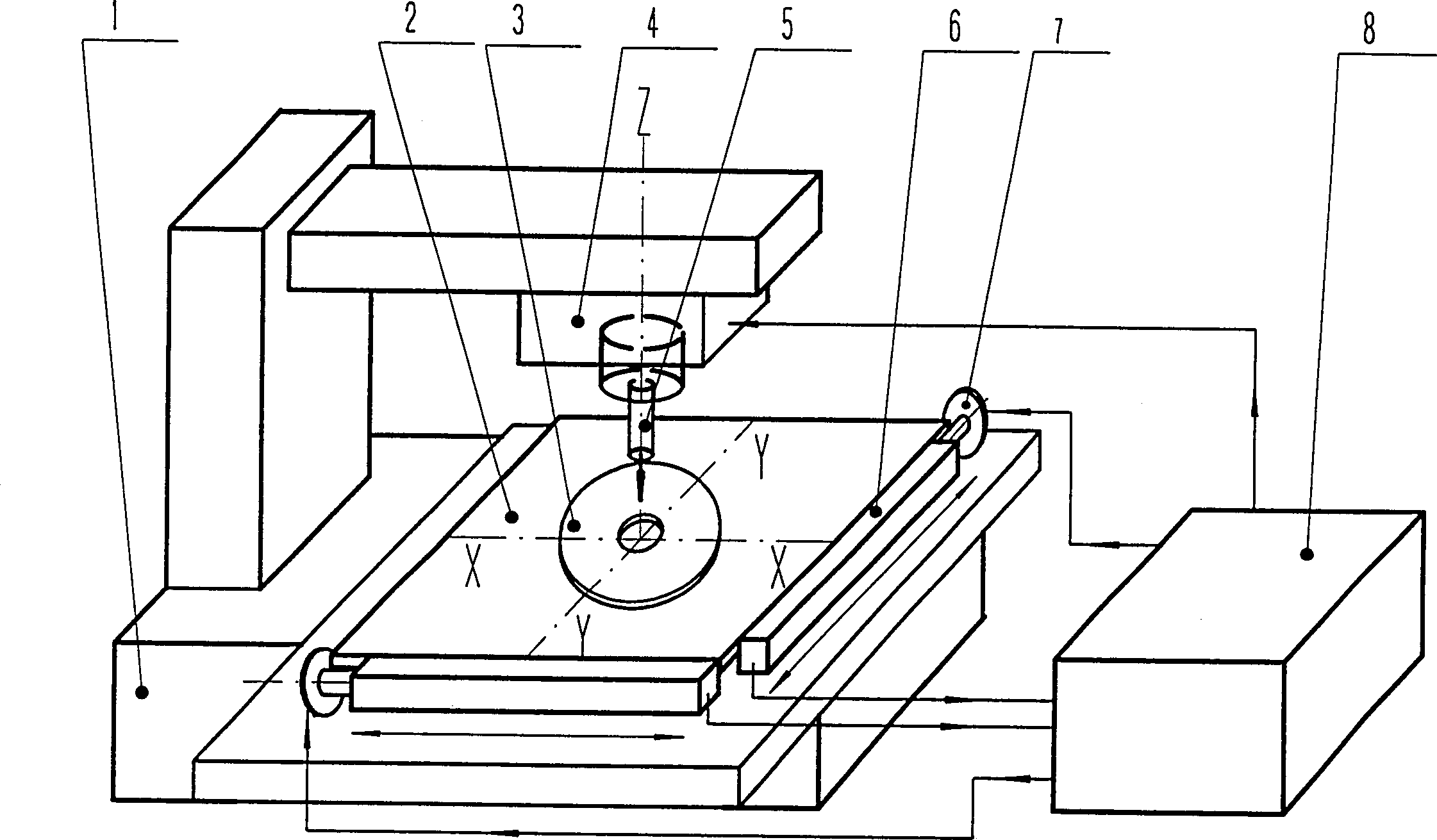

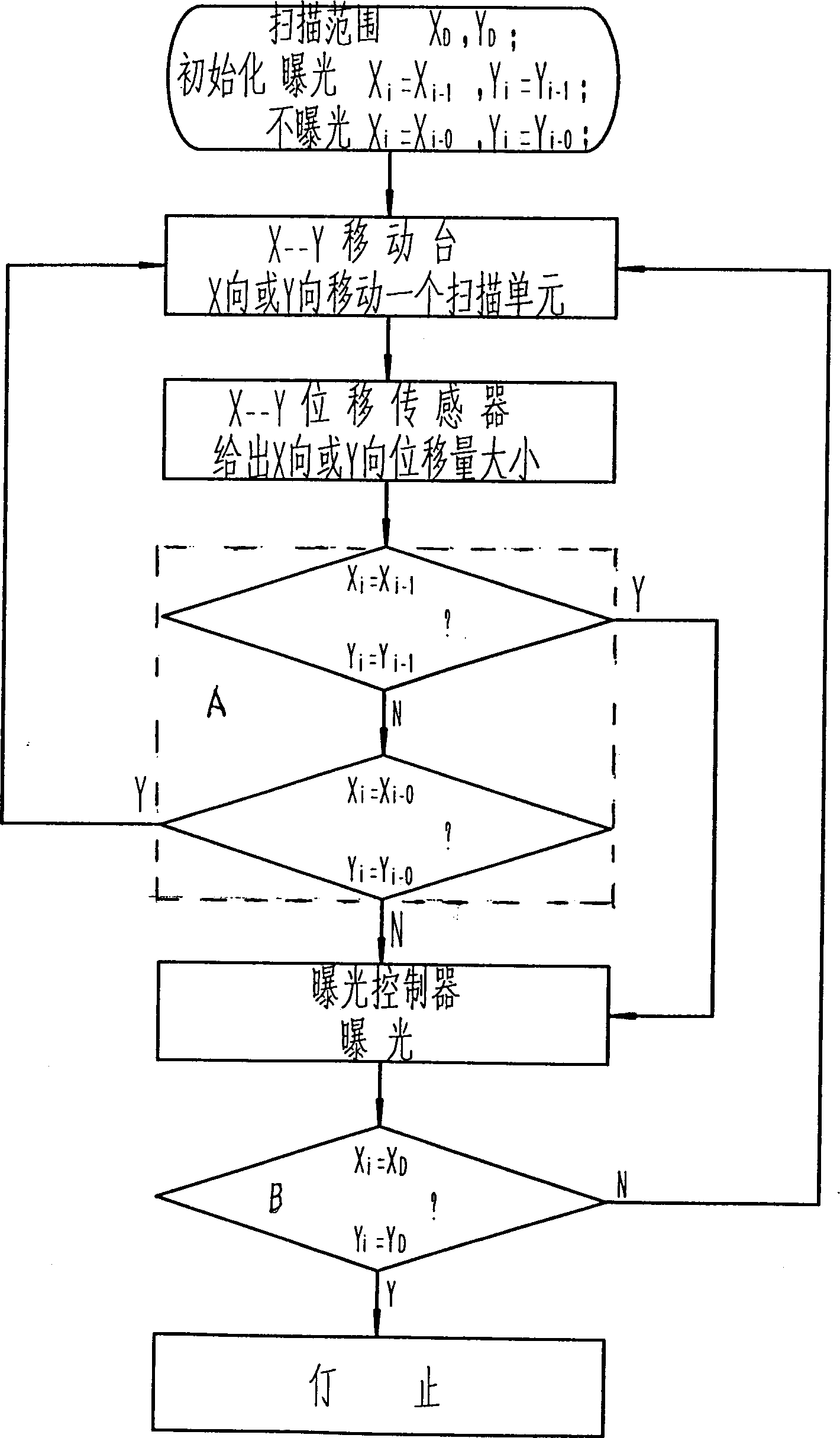

Method for forming gratings by laser direct writing device

InactiveCN1424594AGrid lines with clear edgesThe edge of the grid line is neatProgramme controlComputer controlComputer control systemAutomatic control

The method of making grating using laser direct writing apparatus is mainly used to make and measure long or circular grating. The laser direct writing apparatus is used to expose to light the rough blank of grating coated with photo-sensitive materials, the manufacturing process being controlled automatically by a computer. The operating steps are: The special computer controlling system sends a driving instruction to a displacement driver; the displacement driver drives a making platform to move, a displacement sensor transmits the amount of displacement of the working platform to the computer, comparing the amount with the ruling positions stored in the computer; if "Yes", the computer sends an instruction to an exposure controller to start a light beam scanning head to make an exposure, if "No", it sends an instruction to turn off the scanning head not to make exposure.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Laser direct writing machining system by using liquid crystal light valve reshaping

InactiveCN102837128ARealize processingLaser beam welding apparatusOptical elementsLiquid crystal light valveLaser beam machining

The invention relates to a method and a device of laser direct writing machining and belongs to the technical field of laser machining. The device is a laser machining device which comprises a laser light source, a reflector group, a front reshaping lens group, a liquid crystal light valve, a rear reshaping lens group, a focusing lens, materials to be processed and a reflector or a multi-surface rotating reflector. The laser light source is used to generate laser to be machined, after beams of the laser to be machined are expanded by the front lens group, the laser is reshaped by the liquid crystal light valve, and then the beams of the laser to be machined are expanded by the rear lens group and the laser is converged on the materials to be machined, so that the laser direct writing machining can be achieved. The laser machining device can machine in a high speed direct writing mode, and at the same time, meets requirements of special machining shapes, achieves wide range of laser direct writing machining and has good practical significance.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI +1

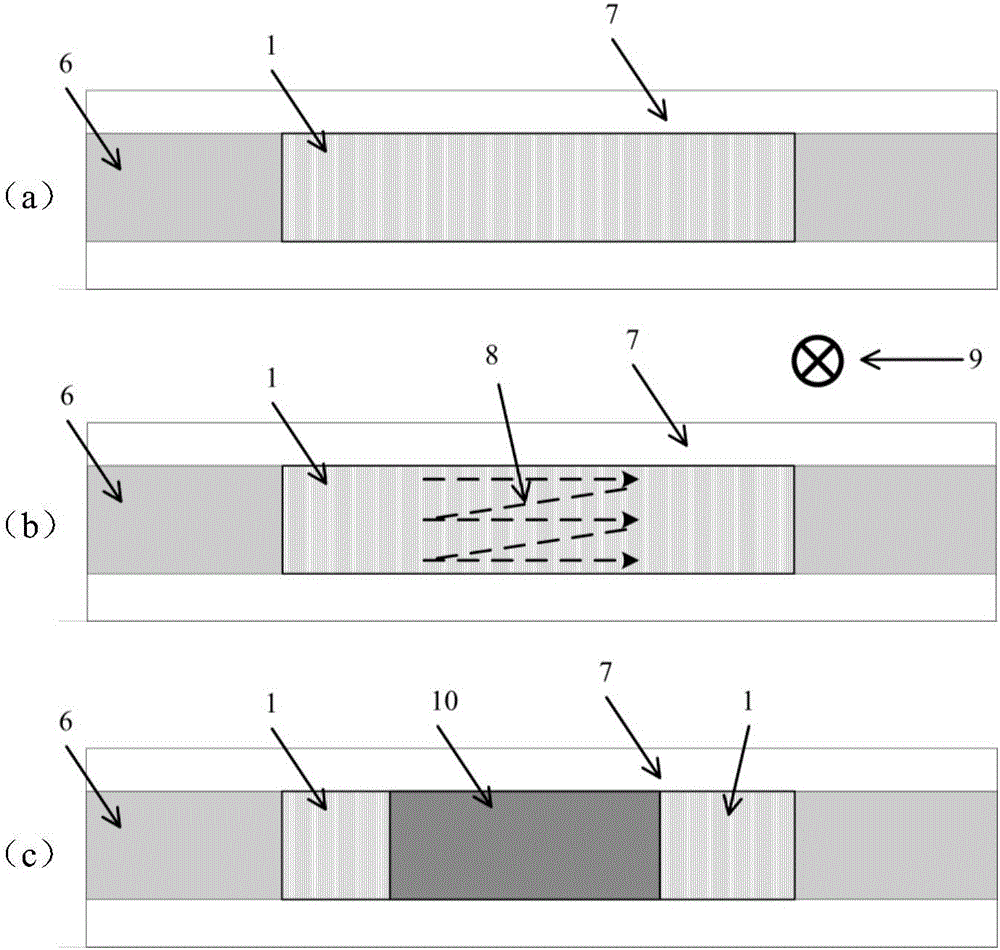

Laser machining method for simultaneously restoring and realizing N doping of graphene oxide microstructure

InactiveCN103626118AOvercome deficienciesOvercome defectsDecorative surface effectsChemical vapor deposition coatingMicro nanoDoped graphene

A laser machining method for simultaneously restoring and realizing N doping of a graphene oxide microstructure belongs to the technological field of micro-nano manufacturing technology, and comprises the following steps: a graphene oxide thin film is prepared on a substrate; a microcavity providing a machining atmosphere is formed on the grapheme oxide thin film; on an NH3 condition, laser direct writing machining is conducted on the graphene oxide thin film through a constructed laser micro-nano machining system to obtain a restored and N-doped graphene oxide microstructure. The invention integrates the characteristics of high precision, arbitrary shaping and the like of laser machining; an N-doped graphene oxide microstructure adopting an arbitrary shape is designed and obtained based on software editing, and arbitrary integration of components is realized; the restoring degree and doping concentration can be adjusted by adjusting the machining atmosphere, laser machining power, exposure time, machining step length, wherein the maximum doping concentration can be up to 10.3%. Types (including graphitized, pyridined and pyrroled nitrogen atoms) and contents of nitrogen atoms can be modulated through the adjustment of laser power.

Owner:JILIN UNIV

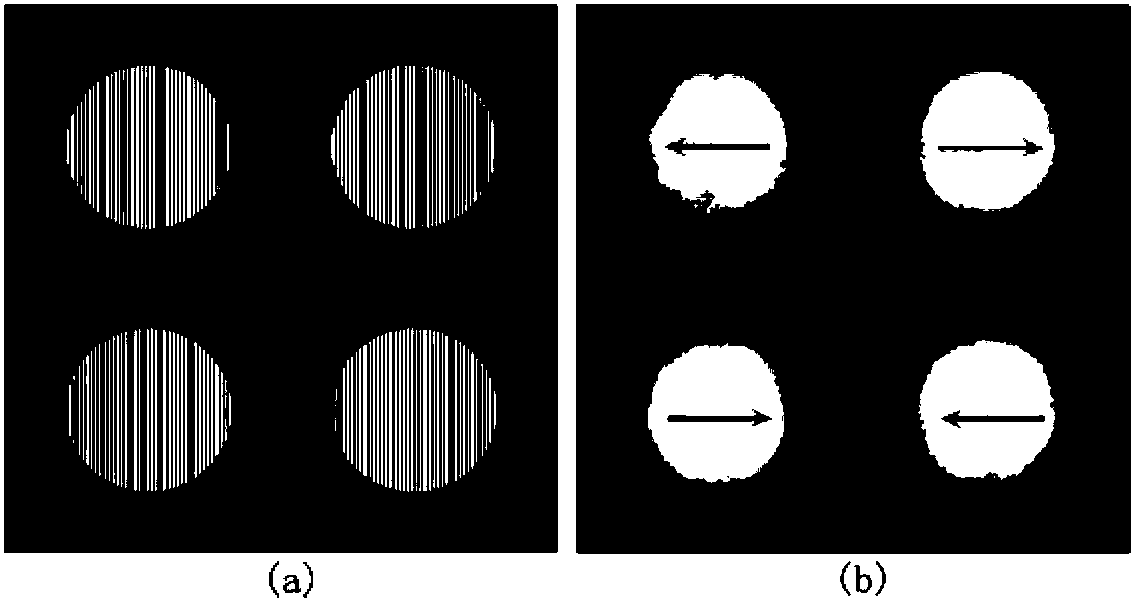

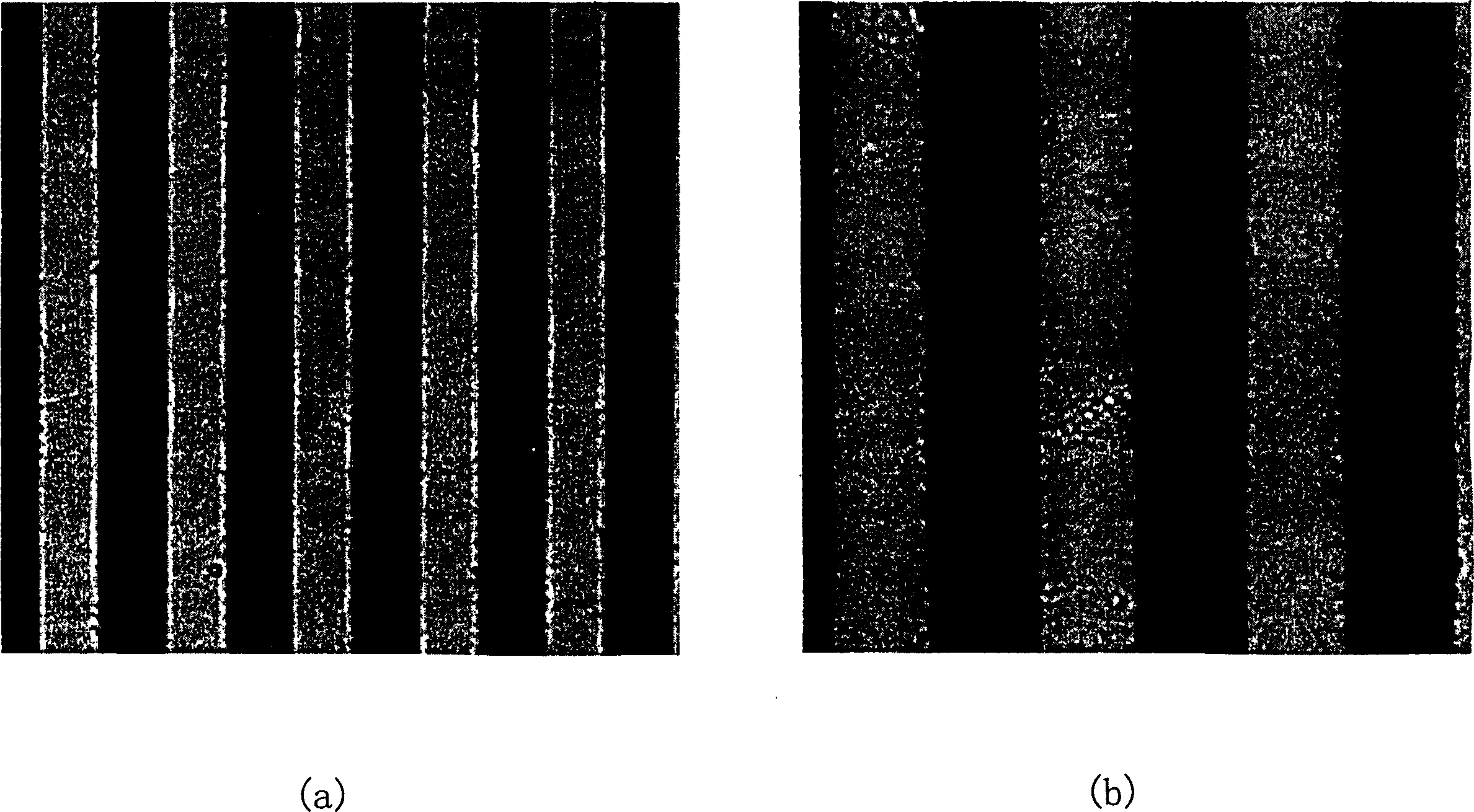

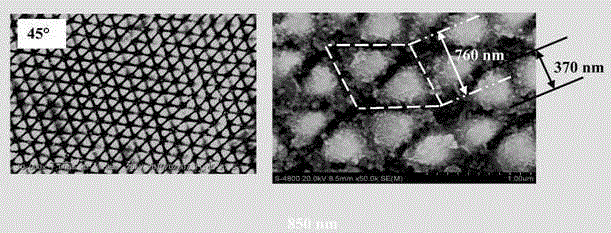

Method for preparing two-dimensional metallic photonic crystal structure in large area through femtosecond laser direct writing

InactiveCN105108342AAvoid complicated proceduresThe technical method is simpleLaser beam welding apparatusBirefringent crystalTime delays

Owner:NANKAI UNIV

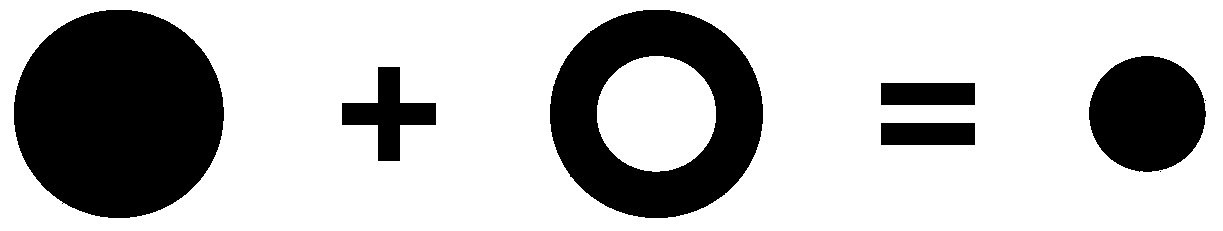

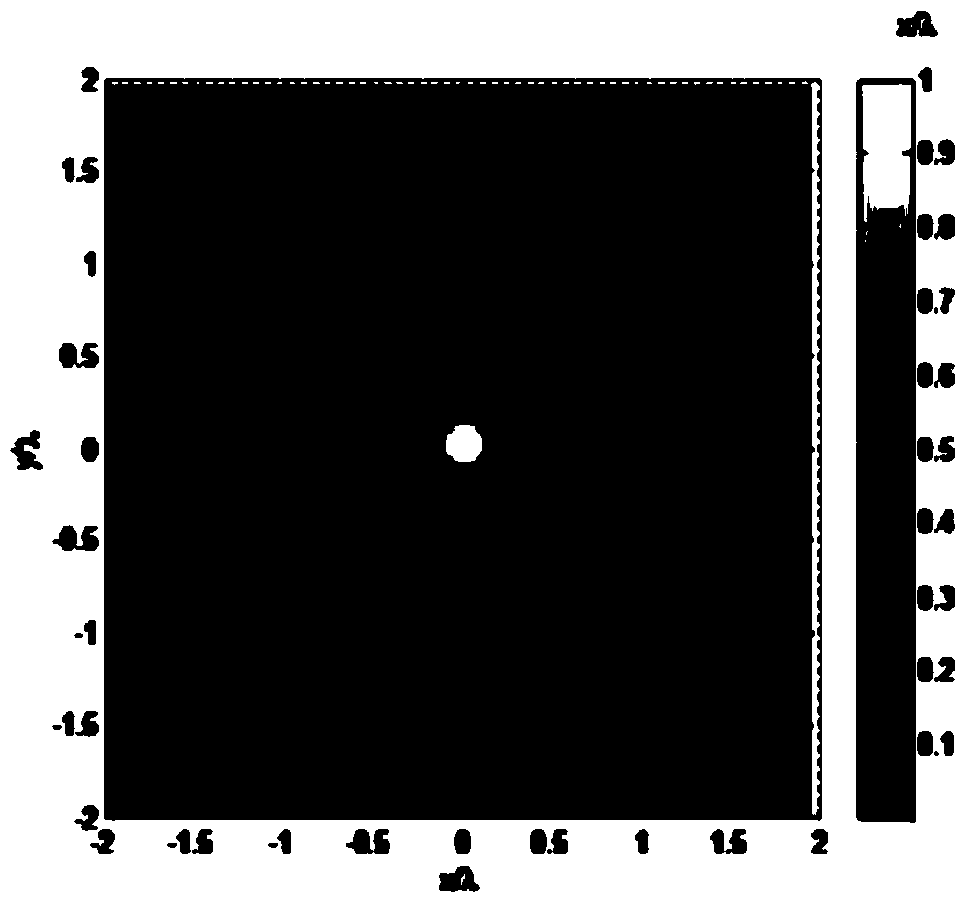

Laser direct writing exposure device based on stimulated light emission loss

ActiveCN103777473AImprove resolutionJiao ShendaPhotomechanical exposure apparatusMicrolithography exposure apparatusSpatial light modulatorHigh numerical aperture

The invention discloses a laser direct writing exposure device based on stimulated light emission loss. The laser direct writing exposure device is characterized by comprising an excitation light source, a de-excitation light source, a first space light modulator, a second space light modulator, a half wave plate group, a dichroscope, a phase position type wave zone plate, an amplitude type wave zone plate, a high numerical value aperture achromatic objective and a three-dimension scanning platform. The laser direct writing exposure device provided by the invention can realize the optical exposure of high resolution and long focus depth.

Owner:BEIJING GUOWANG OPTICAL TECH CO LTD

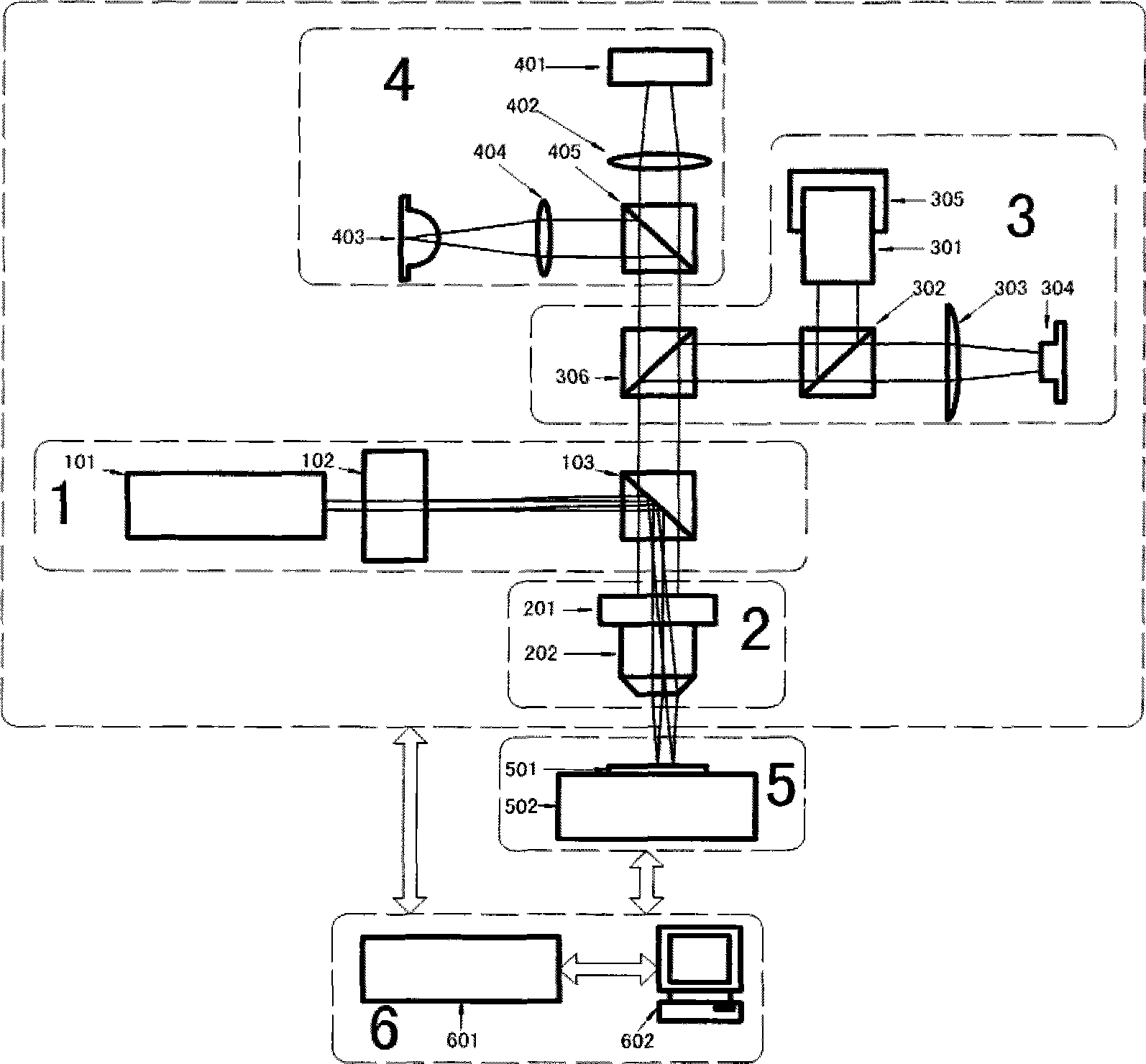

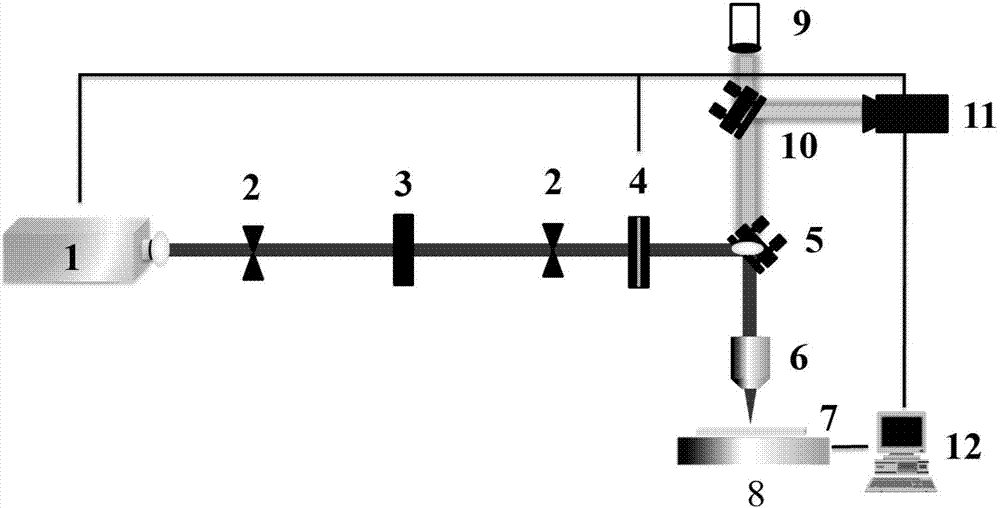

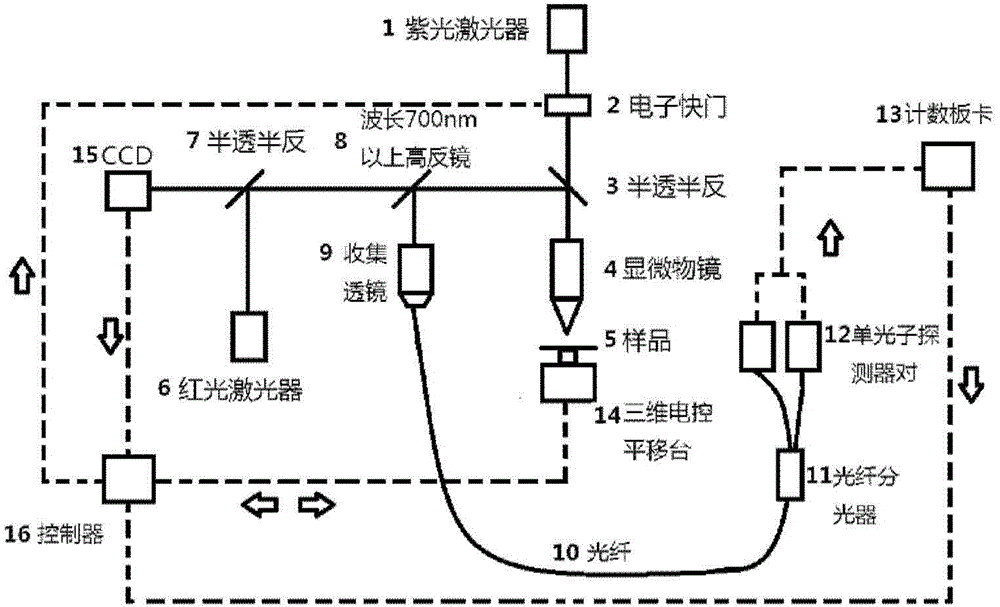

Laser direct writing photolithographic system combined with single quantum dot locating function and method thereof

ActiveCN104678716AGood for small applicationsPhotomechanical exposure apparatusMicrolithography exposure apparatusMicro nanoPhoton detection

The invention discloses a laser direct writing photolithographic system combined with a single quantum dot locating function. The laser direct writing photolithographic system can be directly switched to a direct writing photolithographic function to achieve good connection after locating the position of a single quantum dot in a sample; the laser direct writing photolithographic system combined with the single quantum dot locating function can be used for manufacturing a micro-nano structure directly after locating the quantum dot. The system can use a single photon detection system composed of a single photon detector and a single photon counting board at the detection end and can record the coordinates, thereby achieving the laser direct writing processing function and achieving pumping and detecting operations of the quantum dot, and besides, the laser direct writing processing function and the pumping and detecting function of the quantum dot can be organically combined.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

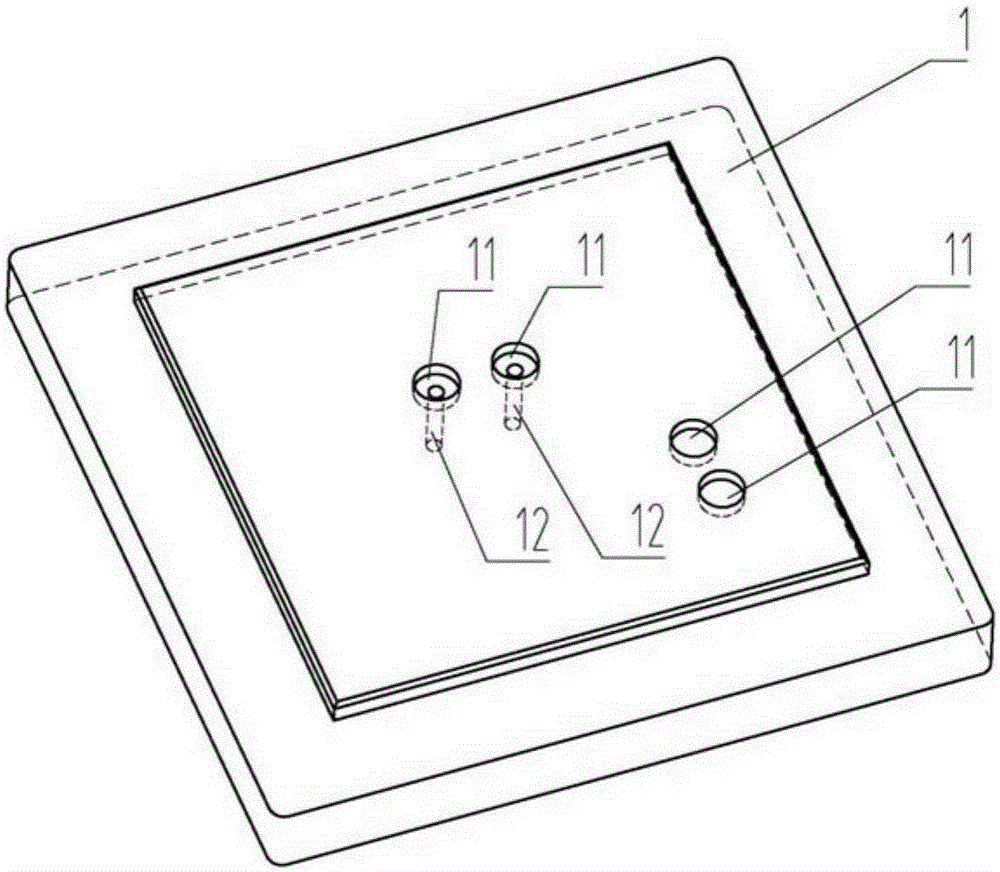

Alignment assembly and method for aligning rotating shaft of rotating table type laser direct writing device to direct writing optical axis

ActiveCN104972232ASimplify Alignment OperationsLaser beam welding apparatusRotary stageDigital imaging

Disclosed is an assembly for aligning a rotating shaft of a rotating table type laser direct writing device to the direct writing optical axis. The direct writing device comprises a laser source, a laser path and a rotating table, wherein a laser modulator, a first reflector, a second reflector and a microscope objective are sequentially arranged on the laser path, laser beams are modulated by the laser modulator and then reflected by the first and second reflectors to be incident onto the microscope objective, and the tabletop of the rotating table is perpendicular to the direct writing optical axis. The alignment assembly comprises a panel piece and a digital imaging system, wherein a metal film is arranged on one side of the panel piece, the panel piece is fixed to the tabletop of the rotating table, the metal film faces the microscope objective, and the digital imaging system comprises a lighting source, a visible light splitter, an image sensor and a displayer. Visible light from the lighting source is reflected by the light splitting piece and then passes through the second reflector to be incident onto the metal film through the microscope objective, visible light reflected by the metal film passes through the microscope objective, the second reflector and the visible light splitter to enter the image sensor, and the displayer displays images from the image sensor.

Owner:JILIN UNIV

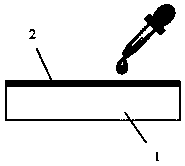

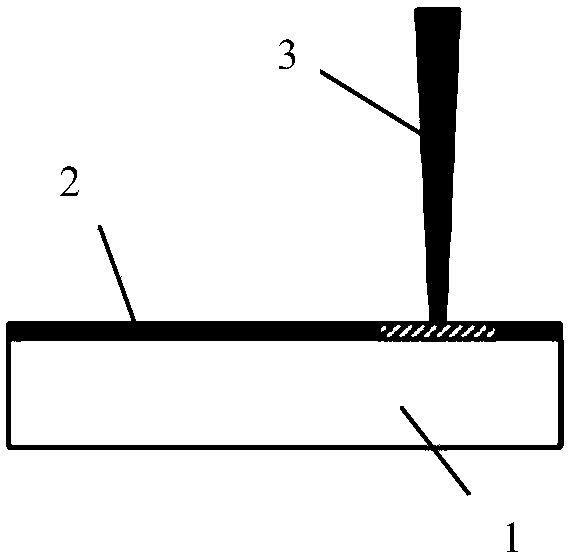

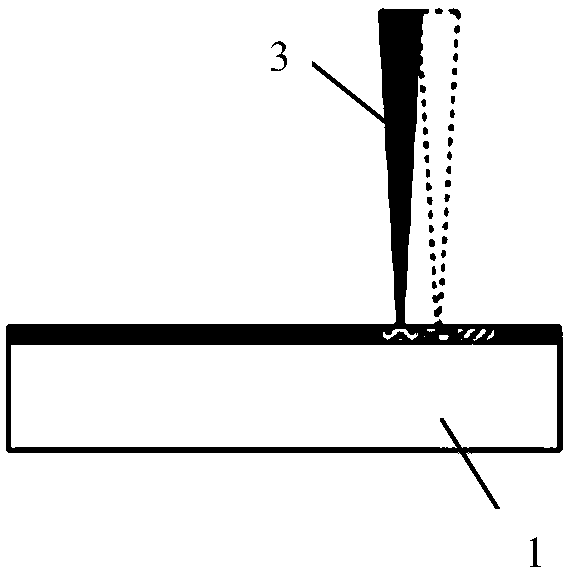

Femtosecond laser direct writing method of copper antioxidant microstructure and copper ion ink

ActiveCN109270798AImprove conductivityMake fastInksPhotomechanical exposure apparatusManufacturing cost reductionCopper wire

The invention provides a femtosecond laser direct writing method of copper antioxidant microstructure and copper ion ink, A method for fabricate a microelectronic device by directly writing a cop microstructure on a copper ion thin film with a femtosecond laser includes that steps of: (a) providing a copper ion ink comprising a copper salt, a polyvinylpyrrolidone, and a long chain alcohol, whereinthe solvent is water; (b) preparing a copper ion film: aft that substrate to be washed by an organic solvent and soaked in deionized wat, the copper ion ink is dripped or spin-coated on the cleaned substrate, and the thickness is 100 DEG C after oven drying; 500 [mu]m copper ion film; (c) directly writing that copper wire using a femtosecond laser direct write device so as to direct write of thedesired electrode circuit on the thin film; (d) removing that area not irradiated by the femtosecond lase: cleaning the substrate with organic solvent and water in turn, and finally obtaining the substrate printed with the electrode circuit. The method of the invention and the copper ion ink can simplify the manufacturing process of the microelectronic device, reduce the manufacturing cost and improve the product performance.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com