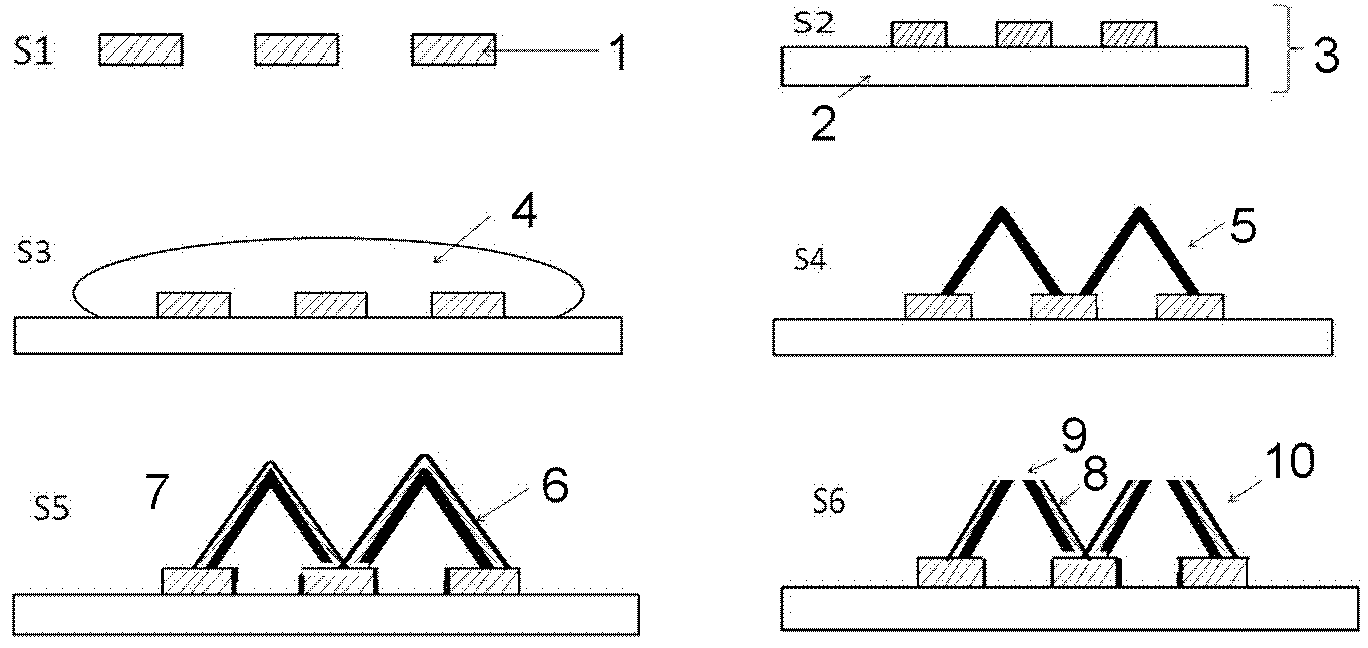

Method for preparing three-dimensional hollow micro nanometer functional structure by utilizing laser direct writing

A micro-nano structure, three-dimensional hollow technology, applied in the manufacture of microstructure devices, microstructure technology, microstructure devices, etc., can solve the problems of complex preparation methods, inability to freely design, inefficiency, etc., to reduce the difficulty of the process and increase the function. , to achieve the effect of functional optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Utilize the preparation method of the present invention, adopt three-dimensional laser direct writing technology to directly prepare the pyramid structure of arbitrary height and side length, and realize the functionalization of photoresist polymer three-dimensional hollow micro-nano structure by electron beam deposition method, specifically Proceed as follows:

[0045] (1) The TEM copper grid 1 with a square grid and the quartz glass 2 were ultrasonically cleaned with acetone, ethanol, and deionized water in sequence, rinsed with isopropanol, and then dried with nitrogen.

[0046] (2) Place the copper grid 1 on the quartz glass 2, drop a drop of negative photoresist IP-L4 in the center of the quartz glass 2 carrying the substrate system 3 with the copper grid 1, and then seal the glass with Fixogum glue. It is fixed on the sample holder of the laser direct writing equipment. Place the sample holder at room temperature for 5 minutes and wait for the glue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com