Monolithic capacitive touch screen and preparation method thereof

A capacitive touch screen, monolithic technology, applied in the direction of electrical digital data processing, instrumentation, data processing input/output process, etc. The effect of improving yield, improving uniformity, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

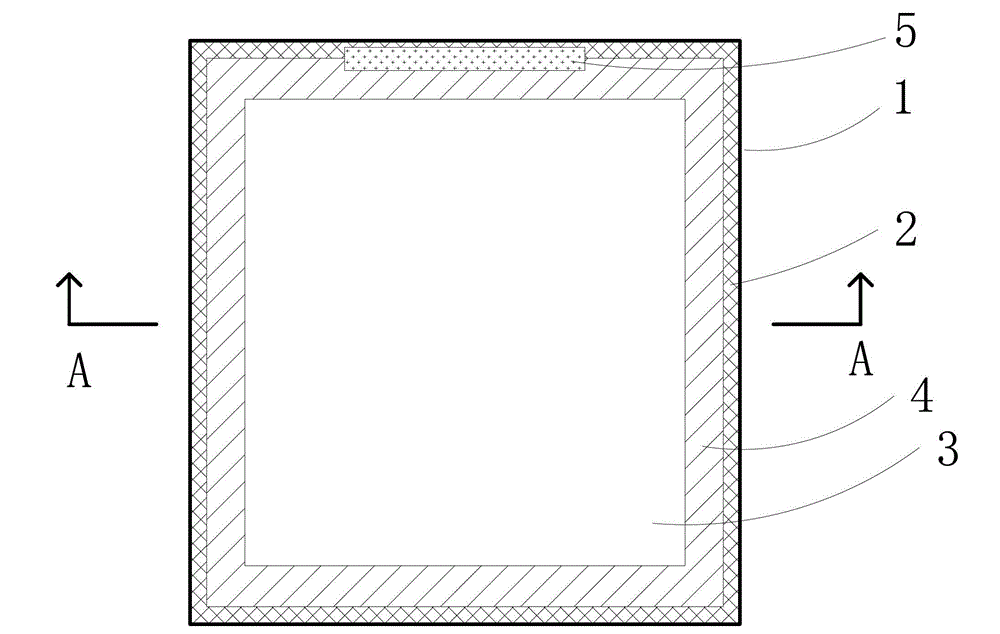

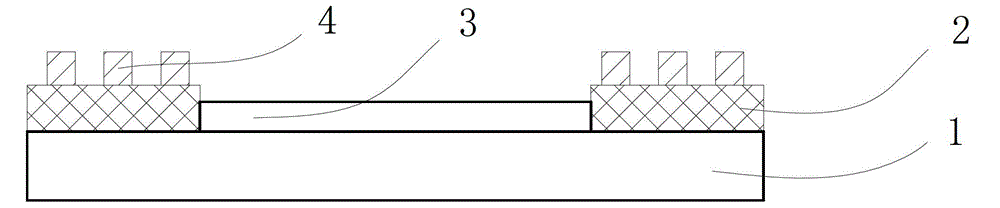

[0078] A capacitive touch screen structure based on a graphene film comprises: a single substrate 1; a non-window ink area 2; a window touch area 3; a lead area 4; a paste controller area 5, wherein the window touch area 3 and the lead area 4 All the electrodes are graphene electrodes, and the electrodes in the lead area 4 are collected into the paste controller area 5, and the external structure is connected through the controller. figure 1 It is a schematic diagram of the appearance of the capacitive touch screen substrate of the present invention. figure 1 The pasting control area 5 only marks the placement position of the controller on the capacitive touch screen.

[0079] The preparation method of the capacitive touch screen based on graphene film comprises the steps:

[0080] (1) Cleaning the transparent monolithic substrate 1;

[0081] (2) A non-window ink area 2 is formed around the transparent monolithic substrate 1, and the middle area surrounded by the non-window ...

Embodiment 2

[0100] A capacitive touch screen structure based on a graphene film comprises: a single substrate 1; a non-window ink area 2; a window touch area 3; a lead area 4, wherein the electrodes in the window touch area 3 are all graphene, and the lead area 4 The electrodes are silver paste electrodes.

[0101] The preparation method of the capacitive touch screen based on graphene film comprises the steps:

[0102] (1) Cleaning the transparent monolithic substrate 1;

[0103] (2) A non-window ink area 2 is formed around the transparent monolithic substrate 1, and the middle area surrounded by the non-window ink area 2 is the area of the window touch area 3;

[0104] (3) Making and patterning the silver paste lead electrodes in the lead area 4;

[0105] (4) transfer the graphene to the transparent monolithic substrate 1, covering the area of the window touch area 3;

[0106] (5) Patterning the graphene covered on the area of the window touch area 3, so that the graphene on th...

Embodiment 3

[0111] A capacitive touch screen structure based on a graphene film comprises: a single substrate 1; a non-window ink area 2; a window touch area 3; a lead area 4, wherein the electrodes of the window touch area 3 and the lead area 4 are graphene electrode.

[0112] The preparation method of the capacitive touch screen based on graphene film comprises the steps:

[0113] (1) Cleaning the transparent monolithic substrate 1;

[0114](2) A non-window ink area 2 is formed around the transparent monolithic substrate 1, and the middle area surrounded by the non-window ink area 2 is the area of the window touch area 3;

[0115] (3) transfer the graphene to the transparent monolithic substrate 1, covering the entire non-window ink area 2 and window touch area 3;

[0116] (4) patterning the graphene covered on the area of the window touch area 3, so that the graphene on the area of the window touch area 3 forms an electrode of the window touch area 3;

[0117] (5) patterning t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com