Clamping-piece-type microfluidic device and manufacturing method

A device manufacturing method and microfluidic technology, which are applied to low-cost microfluidic devices and their fast, clip-type microfluidic devices and their manufacturing processes, and the fields of batch manufacturing processes, can solve the problem of chip structure size and manufacturing stability. There are no guarantees, the structural design of microfluidic chips is limited, and the chips are difficult to manufacture in batches, etc., to achieve the effects of convenient procurement, improved application stability, and shortened processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

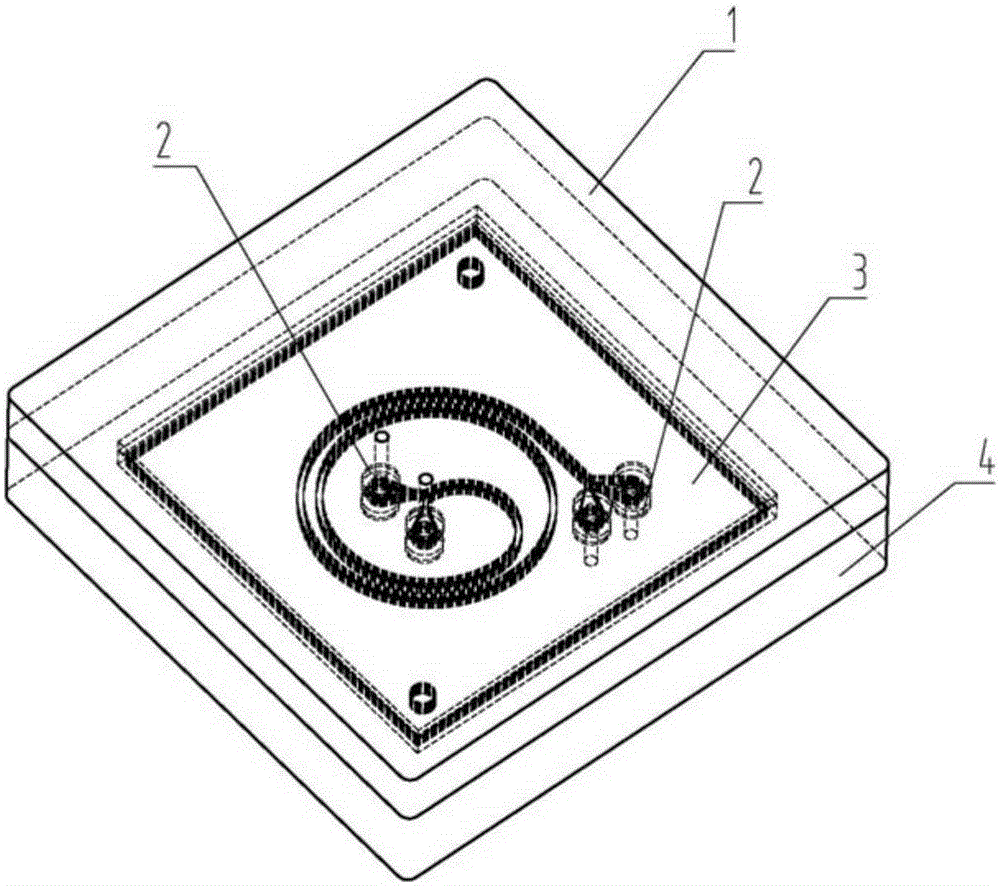

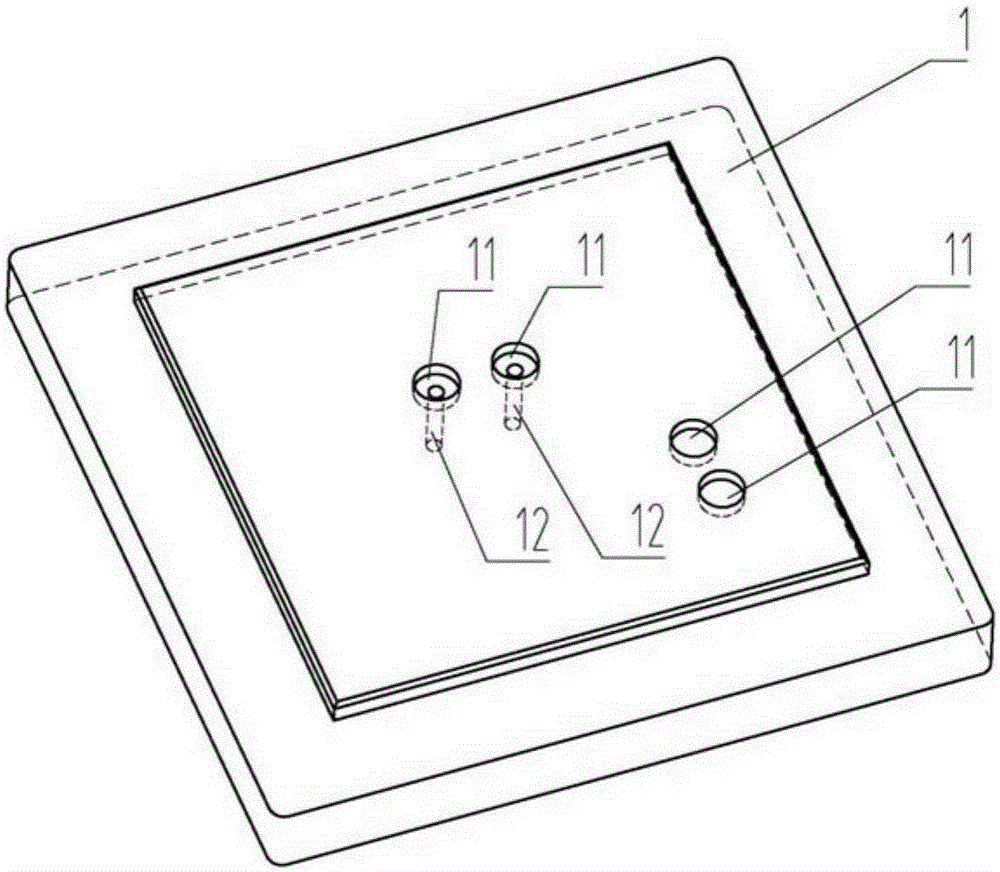

[0047] A clip-type microfluidic device that can be used for high-throughput sorting devices for circulating tumor cells, such as Figure 1-5 As shown: it includes a cover plate 1 , more than one microfluidic chip assembly ( 3 ) and a bottom plate 4 arranged sequentially from top to bottom.

[0048] The cover plate 1 is provided with a sample inlet 12; the cover plate 1 is provided with a cover plate gasket groove 11, and the bottom plate 4 is provided with a bottom plate gasket groove 42; the cover plate gasket groove 11 and the bottom plate The gasket grooves 42 are provided with gaskets 2 .

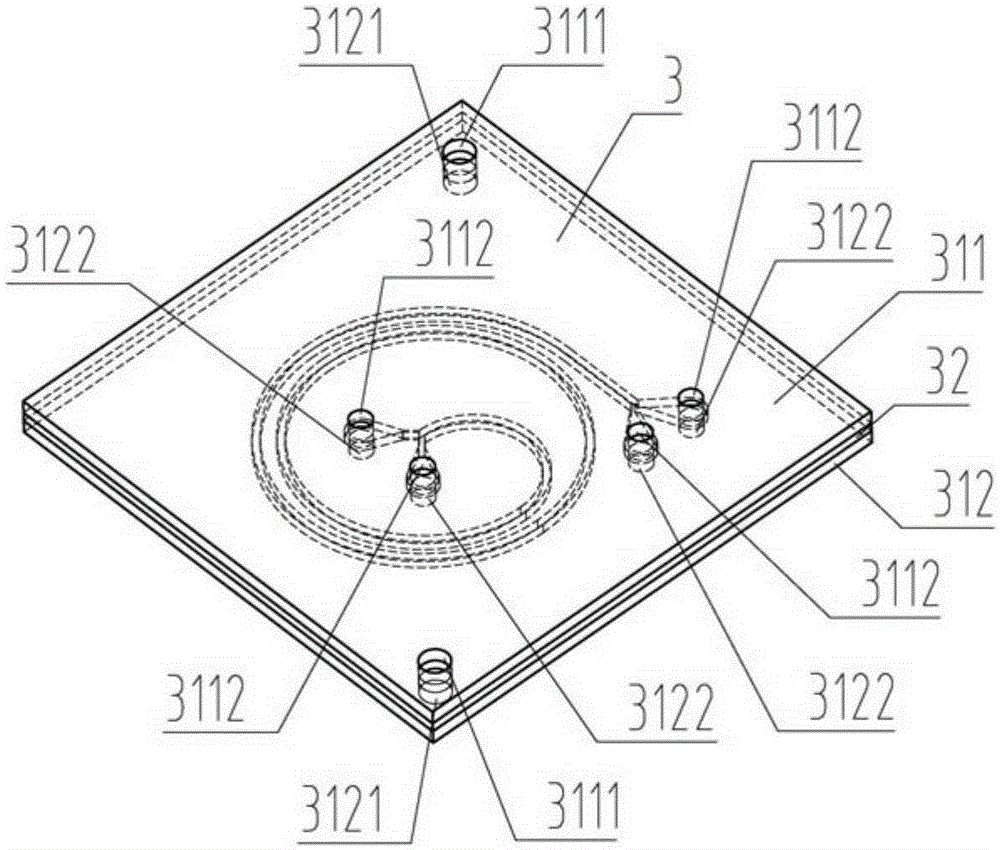

[0049] The microfluidic chip assembly 3 includes a first plastic sealing film 311, a microfluidic chip 32, and a second plastic sealing film 312 arranged in sequence from top to bottom; the microfluidic chip 32 is provided with a microfluidic channel 321 and positioning Holes 322; one end of the micro-channel 321 is provided with a liquid inlet 3211, and the other end is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com