A self-insulating anti-seismic block and its application method

A self-insulation and block technology, applied in building components, building materials, walls, etc., can solve the problems of low self-strength, low overall strength of masonry walls, and no guarantee of vertical ash joint fullness. The effect of overall strength and seismic performance, improving masonry efficiency and masonry quality, and reducing dependence on worker skill level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

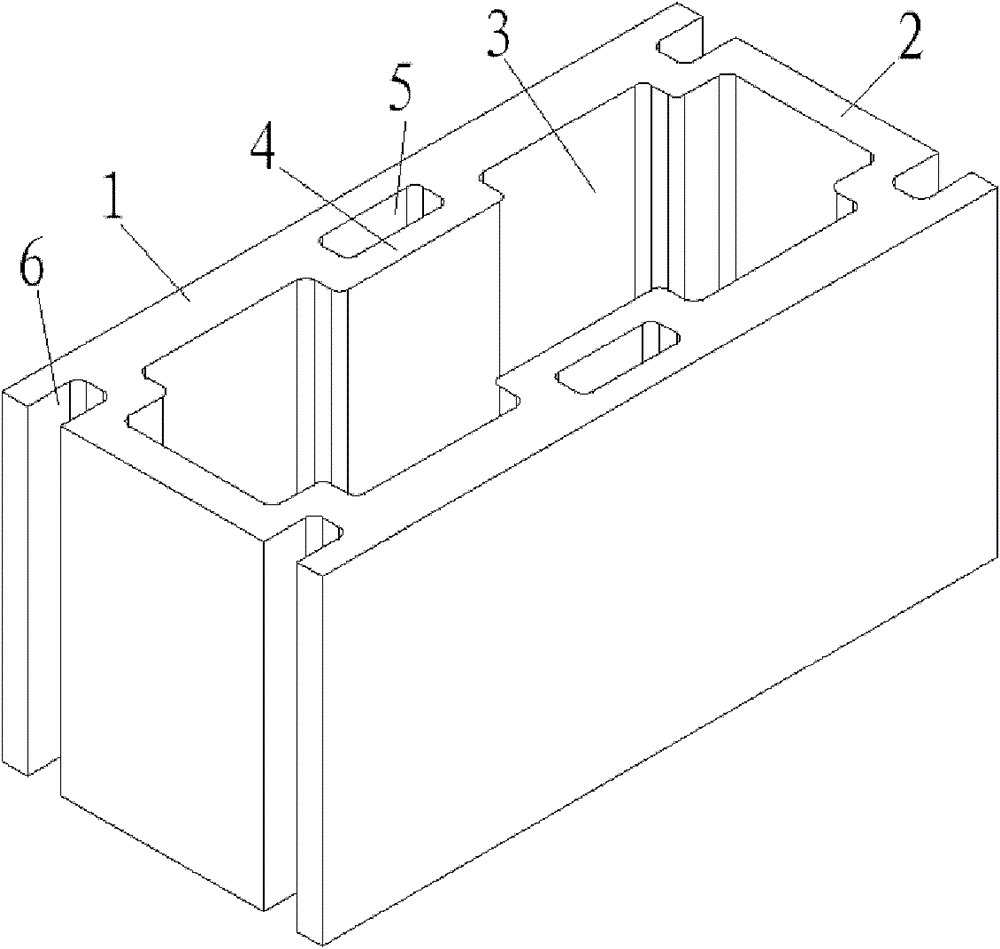

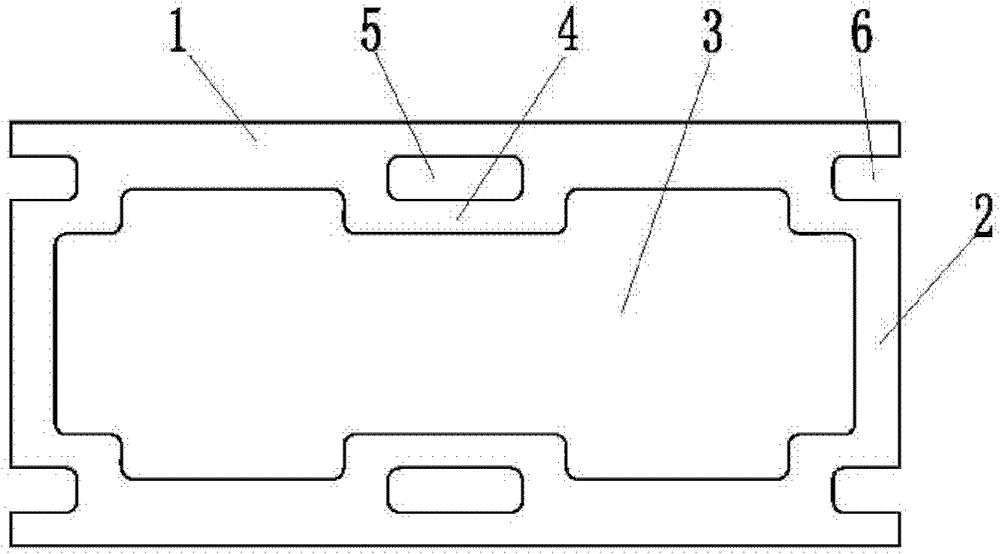

[0048] Such as figure 1 , figure 2 The self-insulating anti-seismic block of the present invention as shown includes a longitudinal outer wall 1 and a transverse outer wall 2, the longitudinal outer wall 1 and the transverse outer wall 2 enclose a hollow insulating cavity 3, and the middle part of the longitudinal outer wall 1 is provided with a reinforcing rib 4 protruding toward the direction of the hollow insulating cavity , the reinforcing ribs 4 and the longitudinal outer wall 1 together form a central grouting channel 5 that runs through vertically. Grouting groove 6 on the end face.

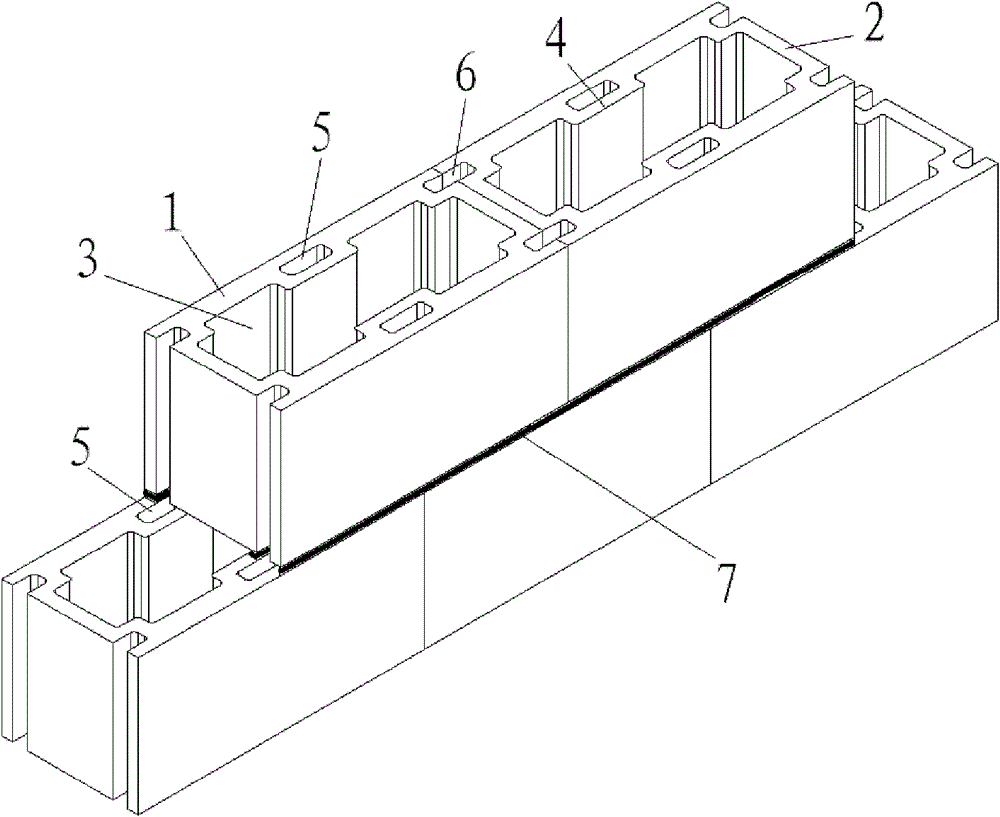

[0049] When applied, such as image 3 As shown, the horizontal end face of the self-insulating anti-seismic block is plastered, and the self-insulating anti-seismic block is used to build the wall layer by layer. During the masonry process, the adjacent self-insulating anti-seismic blocks of the same layer are directly aligned to achieve vertical The self-insulation and anti-seismic bl...

Embodiment 2

[0056] Such as Image 6 The difference between the shown self-insulating anti-seismic block of the present invention and Embodiment 1 is that when the self-insulating anti-seismic block is produced in the factory, the hollow insulating cavity 3 is directly filled with light-weight insulating material 9, and the light-weight insulating material 9 is specifically It is a gypsum foam material, which is made of gypsum mixed with an appropriate amount of fly ash.

[0057] Certainly, there are various types of lightweight heat insulating materials that can be selected, which may be light inorganic foaming materials, light inorganic heat insulating cotton or light organic heat insulating materials. Among them, light inorganic insulation wool includes mineral wool, rock wool or glass wool, etc. Light organic insulation materials include polystyrene insulation materials or polyurethane insulation materials, etc. Light inorganic foam materials include cement foam materials or gypsum foa...

Embodiment 3

[0061] Such as Figure 7 The difference between the shown self-insulating anti-seismic block of the present invention and Embodiment 2 is that in addition to the grouting groove 6 on the end surface and the grouting channel 5 in the middle part of the self-insulating anti-seismic block, the upper and lower end surfaces of the longitudinal outer wall 1 are also provided with horizontal The grouting groove 10 and the horizontal grouting groove 10 are in communication with the end surface grouting groove 6 and the middle grouting channel 5 .

[0062] When applied, such as Figure 8 , Figure 9 with Figure 10 As shown, the wall is built layer by layer with self-insulation and anti-seismic blocks. The horizontal grouting grooves 10 are connected to each other to form a longitudinally continuous mortar core column cavity, and the self-insulating and anti-seismic blocks between the upper and lower layers are overlapped with staggered seams. The end surface grouting grooves 6 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com