Multilayer roaster building method and hearth replacing method

A technology of a multi-layer roasting furnace and a replacement method is applied to the masonry method of the multi-layer roasting furnace and the field of hearth replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

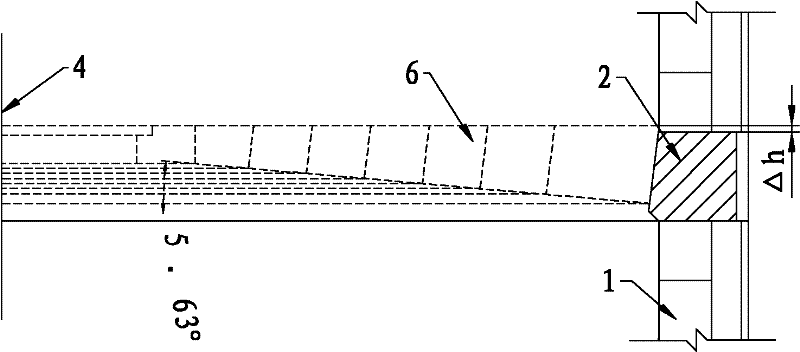

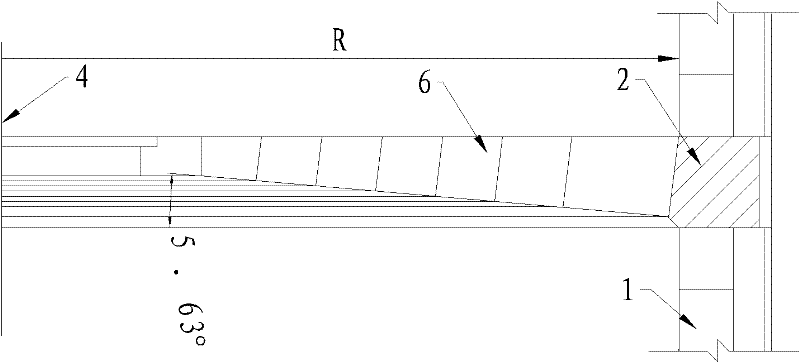

[0039] The overhaul construction of a roaster in a factory. The multi-layer baking furnace has a total of eleven hearths, and each layer of arch angle bricks is 5°38'. The construction process is as follows.

[0040] (1) Pre-laying the hearth

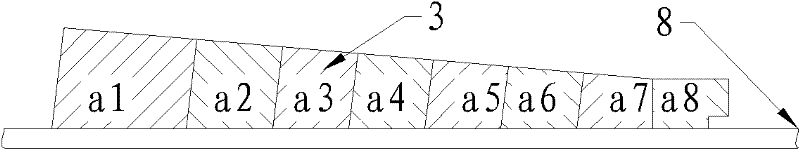

[0041] In order to check the matching of bricks and ensure the quality of masonry, the eleven-layer hearth bricks are processed, polished and pre-built, such as Figure 3a and Figure 3b As shown, the masonry is not allowed to have misalignment or partial unevenness. The "reverse arch method" is used for pre-masonry, that is, the working surface of the hearth brick 3 is placed on a 6.5m×6.5m pre-installed steel platform 8 for brick selection. Masonry to ensure the flatness of the working surface, and then pre-lay it according to the masonry drawing of each layer of the vault. The pre-laying procedure is as follows:

[0042] Select bricks→grind bricks→pre-laying→number→install baskets.

[0043] (2) Determine the ratio of mud between the hearth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com