Method for building converter bottom

A converter furnace bottom and masonry technology, which is applied in the manufacture of converters, etc., can solve the problems of safety hazards in production, production accidents, and furnace bottom bricks are easy to be corroded, so as to improve the quality of masonry and reduce the amount of bricks to be cut , the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

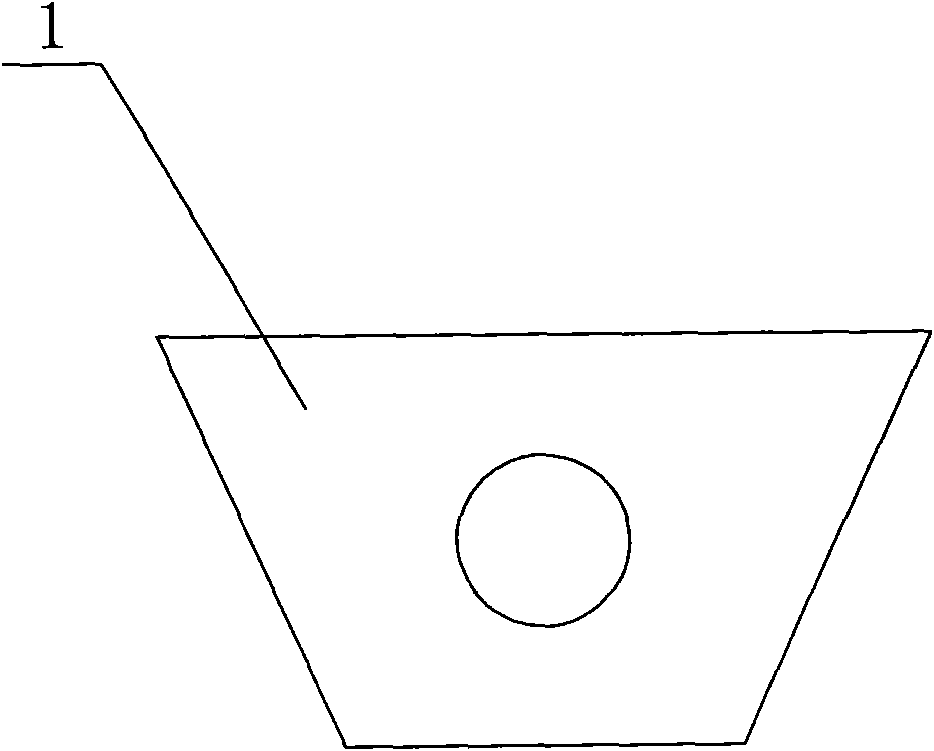

[0016] The original bottom gun brick 1 used to build the furnace bottom has a hole in the middle, such as figure 2 As shown, when building with this kind of brick, it must be ensured that the center hole coincides with the muzzle of the furnace bottom. There is a gap between the bricks 2. At this time, it is necessary to cut the furnace bottom brick 2 to fill the gap. The increase in the amount of brick cutting not only increases the labor intensity, but also the cut furnace bottom brick 2 is easily corroded during smelting, resulting in production accidents. happened.

[0017] The masonry method of the present invention adopts the method of masonry first and then drilling to build the bottom of the converter furnace, and the specific steps are as follows:

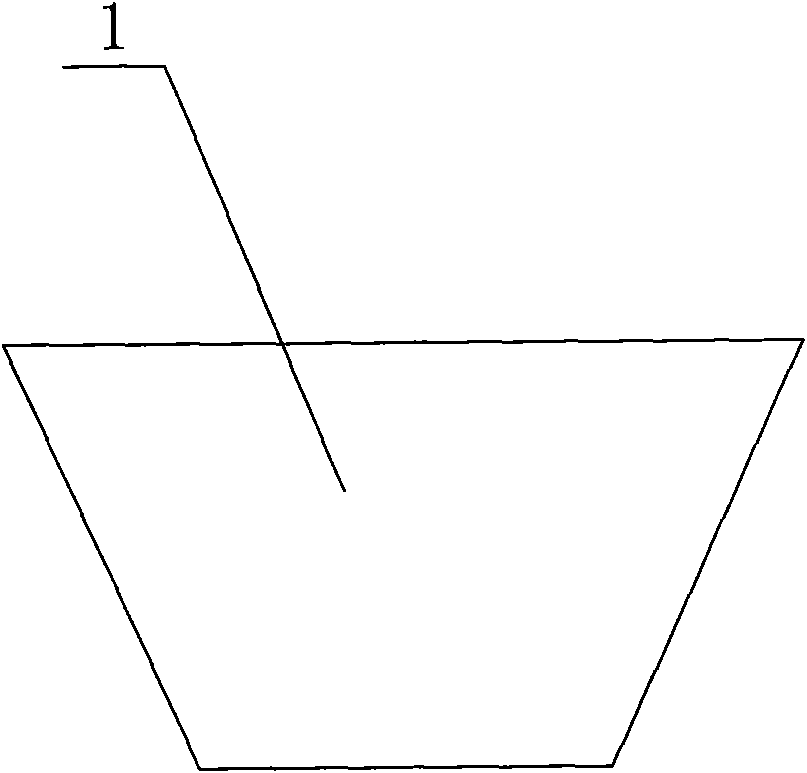

[0018] 1) Take the solid bottom gun brick 1 as a spare, the structure of the solid bottom gun brick 1 is as follows figure 1 shown.

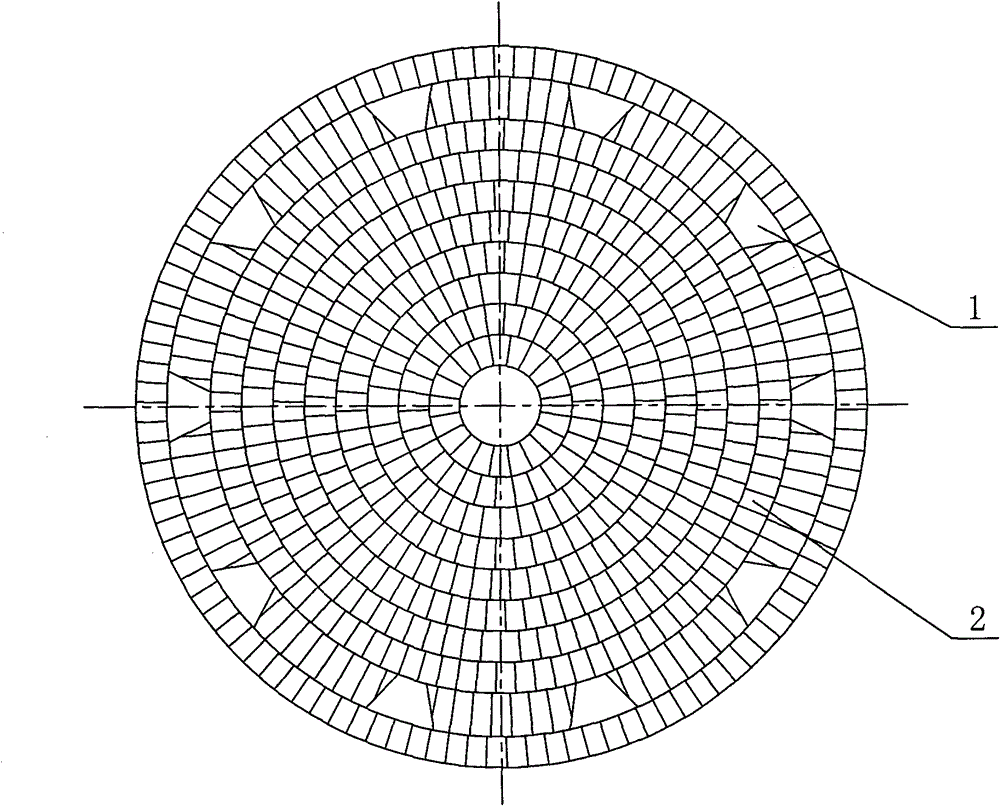

[0019] 2) Bottom bricks 2 are built outward along the center of the furnace bottom. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com