Process method and system for building coke oven by machine

A process method and masonry technology, which are applied in the direction of coke oven bricklaying operations, etc., can solve the problems of limited working space and difficult transportation of machine materials, and achieve the effects of saving construction costs, shortening the masonry cycle, and improving the accuracy of masonry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0027] A kind of technological method of machine masonry coke oven of the present invention, comprises the following steps:

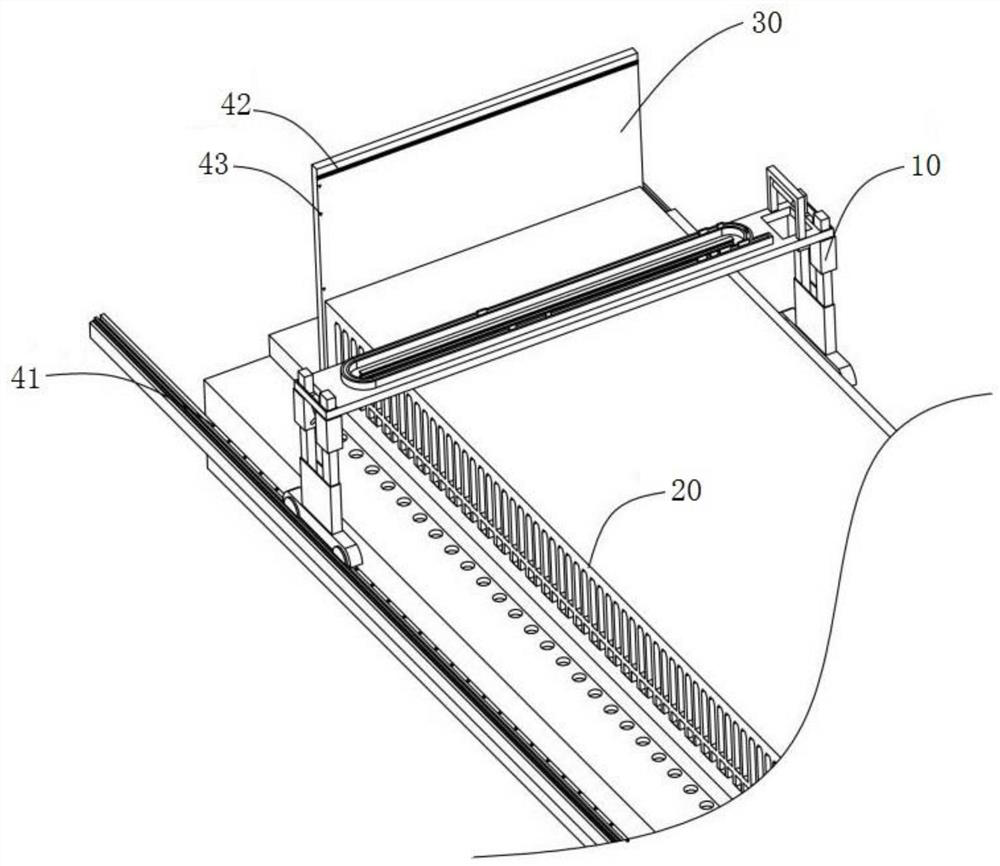

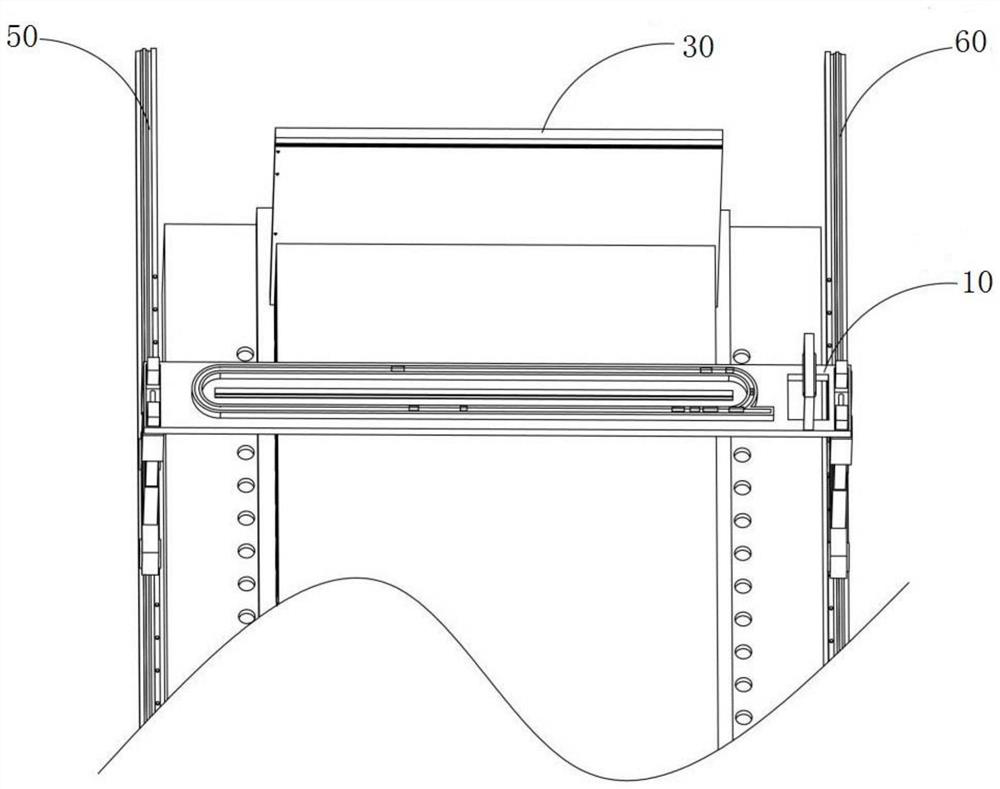

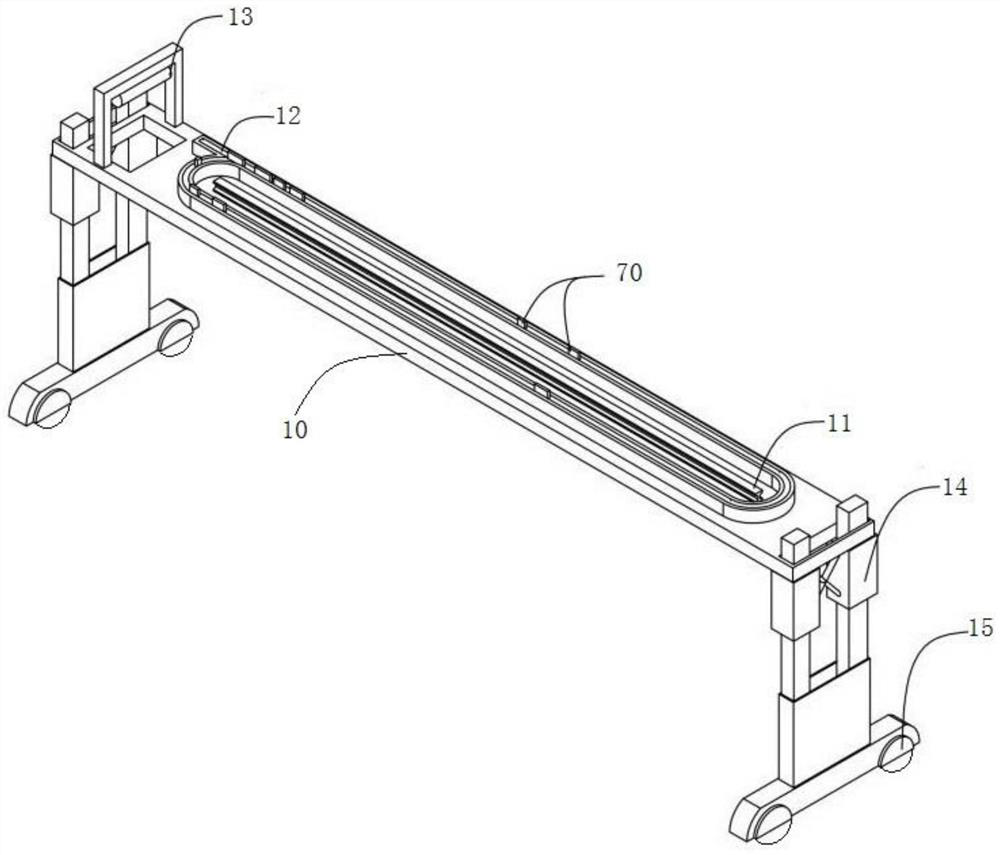

[0028] 1) Preliminary preparation; such as Figure 1-Figure 3 As shown, a masonry platform 10 is built, and the masonry platform 10 is located between the coke quenching car track 5 and the coke pushing car track 6 and can move along the coke quenching car track 50 and the coke pushing car track 60; Beacons are respectively set on the outside of the coke pusher track 60 and the outer surface of the resistance wall 30; the masonry platform 10 can be lifted vertically, and the top of the masonry platform 10 is equipped with a running track 11 and an endless conveyor belt 12, and the masonry machine / masonry robot (not shown in the figure) moving along the running track 11, the endless conveyor belt 12 is used to circulate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com