Wet process for building 3t intermediate frequency electric furnace

An intermediate frequency electric furnace and furnace construction technology, which is applied in the field of 3t intermediate frequency electric furnace wet furnace construction technology, can solve the problems of inability to realize intermediate frequency furnace production and smelting, short service life, and high use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

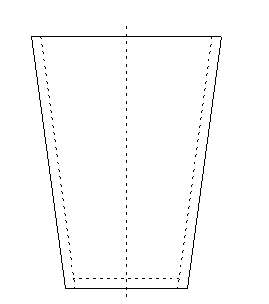

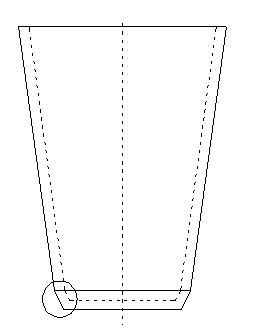

[0009] Embodiment 1: with reference to attached figure 1 . A 3t intermediate frequency electric furnace wet furnace construction process, including a 3t intermediate frequency electric furnace, ⑴ The shape of the steel crucible mold is a truncated hollow cone; ⑵ Laying of insulation layer and heat insulation layer: Two layers of asbestos cloth are used, and the asbestos cloth is both insulating and heat insulating; ⑶ Furnace bottom laying: two layers of asbestos cloth are laid on the bottom of the furnace, and two layers are required to be laid alternately, and each layer is flat and wrinkle-free; ⑷ Furnace wall laying: Lay two layers of asbestos cloth close to the inner wall of the induction coil. When laying, it should be up and down first. The asbestos cloth on the upper plane is pasted on the upper refractory brick plane of the furnace with water glass, and pressed firmly with iron blocks to prevent the asbestos cloth from moving down when building the furnace; ⑸ Furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com